Challenges and Solutions in Plate Heat Exchanger Upkeep

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Maintenance Background and Objectives

Plate heat exchangers (PHEs) have become an integral part of various industrial processes due to their high efficiency and compact design. As these systems play a crucial role in heat transfer applications, their maintenance and upkeep have become increasingly important. The evolution of PHE technology has been driven by the need for improved performance, energy efficiency, and reliability in diverse operating conditions.

The primary objective of this technical research report is to comprehensively examine the challenges faced in plate heat exchanger maintenance and explore innovative solutions to address these issues. By understanding the historical development and current trends in PHE technology, we aim to identify key areas for improvement and potential breakthroughs in maintenance strategies.

Over the years, PHEs have undergone significant advancements in design, materials, and manufacturing processes. Early models were limited in their application due to material constraints and sealing issues. However, continuous research and development efforts have led to the creation of more robust and versatile PHEs capable of handling a wide range of fluids and operating conditions.

The technological progression in PHE maintenance has been marked by several milestones. These include the development of non-destructive testing methods for plate integrity assessment, the introduction of advanced cleaning techniques, and the implementation of predictive maintenance strategies using sensor technologies and data analytics.

Current trends in PHE maintenance focus on enhancing operational efficiency, reducing downtime, and extending equipment lifespan. Key areas of interest include the development of fouling-resistant plate designs, the use of advanced materials for improved corrosion resistance, and the integration of smart monitoring systems for real-time performance optimization.

As we look towards the future, the goals of PHE maintenance technology are centered around achieving greater sustainability, reducing environmental impact, and improving overall system reliability. This involves exploring novel cleaning methods that minimize chemical usage, developing self-cleaning surfaces, and implementing artificial intelligence-driven maintenance scheduling.

By examining the historical context and setting clear objectives for future developments, this report aims to provide a comprehensive understanding of the challenges and potential solutions in plate heat exchanger maintenance. This analysis will serve as a foundation for identifying innovative approaches and guiding future research and development efforts in this critical area of industrial technology.

The primary objective of this technical research report is to comprehensively examine the challenges faced in plate heat exchanger maintenance and explore innovative solutions to address these issues. By understanding the historical development and current trends in PHE technology, we aim to identify key areas for improvement and potential breakthroughs in maintenance strategies.

Over the years, PHEs have undergone significant advancements in design, materials, and manufacturing processes. Early models were limited in their application due to material constraints and sealing issues. However, continuous research and development efforts have led to the creation of more robust and versatile PHEs capable of handling a wide range of fluids and operating conditions.

The technological progression in PHE maintenance has been marked by several milestones. These include the development of non-destructive testing methods for plate integrity assessment, the introduction of advanced cleaning techniques, and the implementation of predictive maintenance strategies using sensor technologies and data analytics.

Current trends in PHE maintenance focus on enhancing operational efficiency, reducing downtime, and extending equipment lifespan. Key areas of interest include the development of fouling-resistant plate designs, the use of advanced materials for improved corrosion resistance, and the integration of smart monitoring systems for real-time performance optimization.

As we look towards the future, the goals of PHE maintenance technology are centered around achieving greater sustainability, reducing environmental impact, and improving overall system reliability. This involves exploring novel cleaning methods that minimize chemical usage, developing self-cleaning surfaces, and implementing artificial intelligence-driven maintenance scheduling.

By examining the historical context and setting clear objectives for future developments, this report aims to provide a comprehensive understanding of the challenges and potential solutions in plate heat exchanger maintenance. This analysis will serve as a foundation for identifying innovative approaches and guiding future research and development efforts in this critical area of industrial technology.

Market Demand Analysis for PHE Maintenance

The market demand for plate heat exchanger (PHE) maintenance has been steadily increasing due to the widespread use of these devices across various industries. PHEs are critical components in many processes, including food and beverage production, chemical processing, HVAC systems, and power generation. As the global industrial sector continues to expand, the need for efficient heat transfer solutions has grown, driving the demand for PHEs and, consequently, their maintenance services.

The PHE maintenance market is primarily driven by the need to ensure optimal performance, extend equipment lifespan, and comply with stringent regulatory standards. Regular maintenance is essential to prevent fouling, scaling, and corrosion, which can significantly reduce heat transfer efficiency and increase operational costs. Industries are increasingly recognizing the importance of preventive maintenance to avoid costly downtime and production losses.

Environmental regulations and energy efficiency requirements are also contributing to the growth of the PHE maintenance market. As companies strive to reduce their carbon footprint and energy consumption, well-maintained PHEs play a crucial role in achieving these goals. This has led to a rise in demand for advanced maintenance techniques and services that can improve the overall efficiency of heat exchange systems.

The food and beverage industry represents a significant portion of the PHE maintenance market. Strict hygiene standards and the need for frequent cleaning and inspection of heat exchangers in food processing plants drive the demand for specialized maintenance services. Similarly, the pharmaceutical industry requires regular maintenance of PHEs to ensure product quality and compliance with Good Manufacturing Practices (GMP).

In the chemical and petrochemical sectors, the corrosive nature of many processes necessitates frequent maintenance of PHEs to prevent leaks and ensure safe operations. The power generation industry, particularly in thermal and nuclear power plants, relies heavily on efficient heat exchangers, creating a substantial market for PHE maintenance services.

The market is also seeing a shift towards predictive maintenance strategies, leveraging IoT sensors and data analytics to optimize maintenance schedules and reduce unexpected failures. This trend is expected to further boost the demand for advanced PHE maintenance services and technologies.

Geographically, the Asia-Pacific region is experiencing the fastest growth in the PHE maintenance market, driven by rapid industrialization and increasing adoption of PHEs in emerging economies. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and implementing more efficient heat exchange systems.

The PHE maintenance market is primarily driven by the need to ensure optimal performance, extend equipment lifespan, and comply with stringent regulatory standards. Regular maintenance is essential to prevent fouling, scaling, and corrosion, which can significantly reduce heat transfer efficiency and increase operational costs. Industries are increasingly recognizing the importance of preventive maintenance to avoid costly downtime and production losses.

Environmental regulations and energy efficiency requirements are also contributing to the growth of the PHE maintenance market. As companies strive to reduce their carbon footprint and energy consumption, well-maintained PHEs play a crucial role in achieving these goals. This has led to a rise in demand for advanced maintenance techniques and services that can improve the overall efficiency of heat exchange systems.

The food and beverage industry represents a significant portion of the PHE maintenance market. Strict hygiene standards and the need for frequent cleaning and inspection of heat exchangers in food processing plants drive the demand for specialized maintenance services. Similarly, the pharmaceutical industry requires regular maintenance of PHEs to ensure product quality and compliance with Good Manufacturing Practices (GMP).

In the chemical and petrochemical sectors, the corrosive nature of many processes necessitates frequent maintenance of PHEs to prevent leaks and ensure safe operations. The power generation industry, particularly in thermal and nuclear power plants, relies heavily on efficient heat exchangers, creating a substantial market for PHE maintenance services.

The market is also seeing a shift towards predictive maintenance strategies, leveraging IoT sensors and data analytics to optimize maintenance schedules and reduce unexpected failures. This trend is expected to further boost the demand for advanced PHE maintenance services and technologies.

Geographically, the Asia-Pacific region is experiencing the fastest growth in the PHE maintenance market, driven by rapid industrialization and increasing adoption of PHEs in emerging economies. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and implementing more efficient heat exchange systems.

Current Challenges in PHE Upkeep

Plate Heat Exchangers (PHEs) are critical components in various industrial processes, yet they face numerous challenges in maintenance and upkeep. One of the primary issues is fouling, which occurs when unwanted materials accumulate on heat transfer surfaces. This buildup reduces thermal efficiency and increases pressure drop, leading to decreased performance and higher energy consumption. Fouling can be particularly problematic in applications involving high-temperature fluids or those with suspended particles.

Corrosion presents another significant challenge in PHE maintenance. The thin plates used in these exchangers are susceptible to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. These issues can compromise the integrity of the plates, leading to leaks and potential cross-contamination between fluid streams. The selection of appropriate materials and coatings is crucial but often complicated by the diverse range of fluids and operating conditions encountered in different industries.

Gasket degradation is a persistent problem in gasketed PHEs. Over time, gaskets can deteriorate due to chemical attack, temperature cycling, and mechanical stress. This degradation can result in leaks, which not only reduce efficiency but also pose safety and environmental risks. The frequent need for gasket replacement increases maintenance costs and downtime, impacting overall operational efficiency.

Cleaning and maintenance procedures themselves present challenges. The compact design of PHEs, while advantageous for heat transfer, can make thorough cleaning difficult. Traditional cleaning methods may not effectively reach all surfaces, leaving residual fouling that can accelerate future buildup. Additionally, improper cleaning techniques or harsh chemicals can damage the plates or gaskets, exacerbating maintenance issues.

The detection and diagnosis of problems within PHEs can be complex. Unlike shell and tube heat exchangers, PHEs are not easily opened for inspection without significant disassembly. This makes it challenging to identify issues early, often leading to reactive rather than proactive maintenance strategies. Advanced monitoring techniques, such as ultrasonic testing or thermal imaging, are being explored but are not yet widely adopted or fully effective for all types of PHEs.

Lastly, the increasing demand for high-performance heat exchangers in various industries is pushing PHEs to operate under more extreme conditions. This trend exacerbates existing maintenance challenges and introduces new ones, such as the need for more frequent inspections and the development of more resilient materials and designs. Balancing these performance requirements with maintainability remains an ongoing challenge for PHE manufacturers and users alike.

Corrosion presents another significant challenge in PHE maintenance. The thin plates used in these exchangers are susceptible to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. These issues can compromise the integrity of the plates, leading to leaks and potential cross-contamination between fluid streams. The selection of appropriate materials and coatings is crucial but often complicated by the diverse range of fluids and operating conditions encountered in different industries.

Gasket degradation is a persistent problem in gasketed PHEs. Over time, gaskets can deteriorate due to chemical attack, temperature cycling, and mechanical stress. This degradation can result in leaks, which not only reduce efficiency but also pose safety and environmental risks. The frequent need for gasket replacement increases maintenance costs and downtime, impacting overall operational efficiency.

Cleaning and maintenance procedures themselves present challenges. The compact design of PHEs, while advantageous for heat transfer, can make thorough cleaning difficult. Traditional cleaning methods may not effectively reach all surfaces, leaving residual fouling that can accelerate future buildup. Additionally, improper cleaning techniques or harsh chemicals can damage the plates or gaskets, exacerbating maintenance issues.

The detection and diagnosis of problems within PHEs can be complex. Unlike shell and tube heat exchangers, PHEs are not easily opened for inspection without significant disassembly. This makes it challenging to identify issues early, often leading to reactive rather than proactive maintenance strategies. Advanced monitoring techniques, such as ultrasonic testing or thermal imaging, are being explored but are not yet widely adopted or fully effective for all types of PHEs.

Lastly, the increasing demand for high-performance heat exchangers in various industries is pushing PHEs to operate under more extreme conditions. This trend exacerbates existing maintenance challenges and introduces new ones, such as the need for more frequent inspections and the development of more resilient materials and designs. Balancing these performance requirements with maintainability remains an ongoing challenge for PHE manufacturers and users alike.

Existing PHE Maintenance Solutions

01 Cleaning and maintenance techniques

Various methods for cleaning and maintaining plate heat exchangers, including chemical cleaning, mechanical cleaning, and preventive maintenance procedures. These techniques help to remove fouling, scale, and other deposits that can reduce heat transfer efficiency and overall performance of the exchanger.- Cleaning and maintenance techniques: Various methods for cleaning and maintaining plate heat exchangers, including chemical cleaning, mechanical cleaning, and preventive maintenance procedures. These techniques help to remove fouling, scale, and other deposits that can reduce heat transfer efficiency and overall performance.

- Monitoring and diagnostic systems: Implementation of advanced monitoring and diagnostic systems to detect issues early and optimize maintenance schedules. These systems may include sensors, data analytics, and predictive maintenance algorithms to assess the condition of plate heat exchangers and prevent unexpected failures.

- Plate design improvements: Innovations in plate design to enhance heat transfer efficiency, reduce fouling, and improve overall performance. These improvements may include changes in plate geometry, surface treatments, or materials to extend the lifespan of plate heat exchangers and reduce maintenance requirements.

- Sealing and gasket maintenance: Techniques for maintaining and replacing gaskets and seals in plate heat exchangers to prevent leaks and ensure optimal performance. This may include innovative gasket designs, installation methods, and materials that improve durability and ease of maintenance.

- Corrosion prevention and treatment: Methods for preventing and treating corrosion in plate heat exchangers, including the use of corrosion-resistant materials, protective coatings, and chemical treatments. These techniques aim to extend the lifespan of the equipment and reduce the frequency of maintenance interventions.

02 Monitoring and diagnostic systems

Implementation of advanced monitoring and diagnostic systems to detect issues early and optimize maintenance schedules. These systems may include sensors, data analysis tools, and predictive maintenance algorithms to assess the condition of the plate heat exchanger and identify potential problems before they escalate.Expand Specific Solutions03 Plate design and materials

Innovations in plate design and materials to enhance durability, reduce fouling, and improve overall performance. This includes the use of corrosion-resistant alloys, specialized coatings, and optimized plate geometries to extend the lifespan of the heat exchanger and minimize maintenance requirements.Expand Specific Solutions04 Sealing and gasket technologies

Advancements in sealing and gasket technologies to prevent leaks and improve the overall reliability of plate heat exchangers. This includes the development of new gasket materials, improved sealing techniques, and innovative designs to enhance the integrity of the exchanger assembly.Expand Specific Solutions05 Modular and easily serviceable designs

Development of modular and easily serviceable plate heat exchanger designs that facilitate quick disassembly, cleaning, and reassembly. These designs aim to reduce downtime during maintenance operations and simplify the overall upkeep process for operators and maintenance personnel.Expand Specific Solutions

Key Players in PHE Maintenance Industry

The plate heat exchanger market is in a mature growth phase, characterized by steady demand and technological refinement. The global market size is estimated to be in the billions of dollars, driven by increasing industrial applications and energy efficiency requirements. Technologically, plate heat exchangers have reached a high level of sophistication, with ongoing innovations focused on improving performance and sustainability. Key players like Alfa Laval, SWEP International, and Danfoss are leading the field with advanced designs and materials. Emerging companies such as Vahterus are introducing novel technologies, while established industrial giants like Mitsubishi Electric and LG Electronics are leveraging their manufacturing expertise to gain market share in this competitive landscape.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced solutions for plate heat exchanger maintenance, including their CIP (Cleaning-in-Place) technology. This system allows for efficient cleaning of heat exchangers without disassembly, significantly reducing downtime and maintenance costs[1]. They have also introduced innovative plate designs, such as their AlfaNova fusion-bonded plate heat exchangers, which offer enhanced durability and resistance to fouling[2]. Alfa Laval's predictive maintenance approach utilizes IoT sensors and data analytics to monitor heat exchanger performance in real-time, enabling proactive maintenance scheduling and preventing unexpected failures[3].

Strengths: Industry-leading CIP technology, innovative plate designs, and advanced predictive maintenance capabilities. Weaknesses: Higher initial investment costs for advanced systems, potential complexity in implementation for smaller operations.

Swep International AB

Technical Solution: Swep International AB has developed a range of compact brazed plate heat exchangers (BPHEs) designed for easier maintenance and longer operational life. Their True Dual function allows for asymmetric plate designs that optimize heat transfer while reducing fouling[4]. Swep's E8AS model, for instance, features an enhanced port design that improves distribution and reduces the risk of clogging[5]. The company has also introduced a self-cleaning technology called DynaStatic, which uses the fluid's own flow to create turbulence and prevent scaling, significantly extending the time between maintenance intervals[6].

Strengths: Compact designs suitable for space-constrained applications, innovative self-cleaning technology. Weaknesses: Limited to smaller capacity applications compared to traditional plate heat exchangers, may not be suitable for all types of fluids or extreme temperature applications.

Innovative PHE Cleaning Technologies

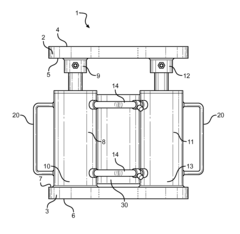

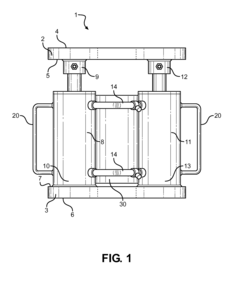

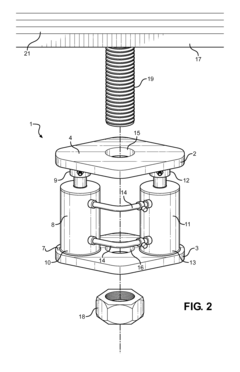

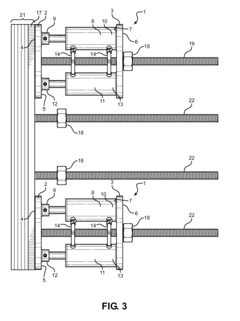

Plate Heat Exchanger Compression Apparatus

PatentInactiveUS20150211811A1

Innovation

- The use of hydraulic linear actuators with a slip-on lock nut having handles for easy rotation without a wrench, along with interchangeable actuators of varying lengths operating at lower pressures, allows for efficient compression and opening/closing of plate heat exchangers, eliminating the need for threaded nut travel and reducing operator risk.

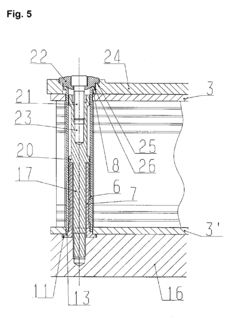

Plate heat exchanger

PatentActiveEP1985955A3

Innovation

- A holding arrangement with a fixing sleeve and screw, along with a separate clamping arrangement, is used to compress the plate stack, allowing for lightweight assembly and high clamping forces during operation, with the clamping arrangement integrated into the holding arrangement to minimize space and prevent deformation.

Environmental Impact of PHE Maintenance

The maintenance of plate heat exchangers (PHEs) has significant environmental implications that extend beyond the immediate operational context. The cleaning processes and chemical treatments used in PHE upkeep can potentially introduce harmful substances into the environment if not managed properly. Traditional cleaning methods often involve harsh chemicals that, when discharged, may contaminate water sources and disrupt local ecosystems.

Moreover, the energy consumption associated with PHE maintenance contributes to the overall carbon footprint of industrial operations. Inefficient cleaning procedures or frequent maintenance cycles due to suboptimal practices can lead to increased energy usage, thereby exacerbating environmental concerns related to greenhouse gas emissions.

The disposal of worn-out gaskets and plates presents another environmental challenge. These components, often made from materials that are not easily biodegradable, can accumulate in landfills if not properly recycled or repurposed. The production of replacement parts also carries an environmental cost in terms of raw material extraction and manufacturing processes.

However, advancements in PHE maintenance technologies are addressing these environmental concerns. The development of eco-friendly cleaning agents and methods, such as ultrasonic cleaning or the use of biodegradable detergents, is reducing the environmental impact of maintenance procedures. These innovations not only minimize chemical waste but also often require less water and energy, thus promoting resource conservation.

Furthermore, the adoption of predictive maintenance strategies, enabled by sensors and data analytics, allows for more targeted and efficient upkeep. By reducing unnecessary maintenance cycles, these approaches help to decrease overall resource consumption and waste generation associated with PHE maintenance.

Recycling and circular economy initiatives are also gaining traction in the PHE industry. Some manufacturers are implementing take-back programs for used plates and gaskets, ensuring proper recycling or refurbishment. This not only reduces waste but also conserves resources by extending the lifecycle of PHE components.

The environmental impact of PHE maintenance is increasingly becoming a focal point for regulatory bodies and industry standards. Stricter regulations on chemical usage, waste disposal, and emissions are driving innovation in maintenance practices. Companies are now incentivized to develop and implement more sustainable maintenance solutions, aligning their operations with broader environmental protection goals.

Moreover, the energy consumption associated with PHE maintenance contributes to the overall carbon footprint of industrial operations. Inefficient cleaning procedures or frequent maintenance cycles due to suboptimal practices can lead to increased energy usage, thereby exacerbating environmental concerns related to greenhouse gas emissions.

The disposal of worn-out gaskets and plates presents another environmental challenge. These components, often made from materials that are not easily biodegradable, can accumulate in landfills if not properly recycled or repurposed. The production of replacement parts also carries an environmental cost in terms of raw material extraction and manufacturing processes.

However, advancements in PHE maintenance technologies are addressing these environmental concerns. The development of eco-friendly cleaning agents and methods, such as ultrasonic cleaning or the use of biodegradable detergents, is reducing the environmental impact of maintenance procedures. These innovations not only minimize chemical waste but also often require less water and energy, thus promoting resource conservation.

Furthermore, the adoption of predictive maintenance strategies, enabled by sensors and data analytics, allows for more targeted and efficient upkeep. By reducing unnecessary maintenance cycles, these approaches help to decrease overall resource consumption and waste generation associated with PHE maintenance.

Recycling and circular economy initiatives are also gaining traction in the PHE industry. Some manufacturers are implementing take-back programs for used plates and gaskets, ensuring proper recycling or refurbishment. This not only reduces waste but also conserves resources by extending the lifecycle of PHE components.

The environmental impact of PHE maintenance is increasingly becoming a focal point for regulatory bodies and industry standards. Stricter regulations on chemical usage, waste disposal, and emissions are driving innovation in maintenance practices. Companies are now incentivized to develop and implement more sustainable maintenance solutions, aligning their operations with broader environmental protection goals.

Cost-Benefit Analysis of PHE Upkeep Strategies

The cost-benefit analysis of plate heat exchanger (PHE) upkeep strategies is crucial for optimizing operational efficiency and minimizing long-term expenses. This analysis involves evaluating various maintenance approaches and their associated costs against the potential benefits and savings they offer.

One primary consideration is the comparison between preventive and reactive maintenance strategies. Preventive maintenance involves regular inspections, cleaning, and parts replacement based on predetermined schedules or usage metrics. While this approach incurs upfront costs, it can significantly reduce the likelihood of unexpected breakdowns and extend the overall lifespan of the PHE. The benefits include minimized production downtime, improved energy efficiency, and reduced risk of catastrophic failures.

Reactive maintenance, on the other hand, addresses issues only when they arise. This strategy may seem cost-effective in the short term due to lower immediate expenses. However, it often leads to higher long-term costs associated with emergency repairs, extended downtime, and potential damage to other system components.

The analysis should also consider the cost implications of different cleaning methods. Chemical cleaning, while effective, involves expenses related to chemicals, disposal, and potential environmental compliance. Mechanical cleaning may require specialized equipment and skilled labor but can be more environmentally friendly and less corrosive to PHE components.

Frequency of maintenance is another critical factor. More frequent maintenance can lead to higher short-term costs but may result in better performance and longevity. Conversely, extending maintenance intervals can reduce immediate expenses but may increase the risk of efficiency loss and unexpected failures.

The cost-benefit analysis should incorporate the impact of PHE upkeep on energy efficiency. Well-maintained heat exchangers typically operate at higher efficiency levels, resulting in lower energy consumption and associated costs. This factor is particularly significant in industries where energy expenses constitute a substantial portion of operational costs.

Additionally, the analysis should consider the costs and benefits of implementing condition monitoring technologies. These systems can provide real-time data on PHE performance, enabling predictive maintenance strategies. While the initial investment may be significant, the long-term benefits of optimized maintenance schedules and reduced unexpected downtime can often justify the expense.

Lastly, the analysis should factor in the potential costs of non-compliance with regulatory standards and the benefits of maintaining optimal performance in terms of product quality and consistency. This holistic approach ensures that all aspects of PHE upkeep are considered, leading to more informed decision-making and optimized maintenance strategies.

One primary consideration is the comparison between preventive and reactive maintenance strategies. Preventive maintenance involves regular inspections, cleaning, and parts replacement based on predetermined schedules or usage metrics. While this approach incurs upfront costs, it can significantly reduce the likelihood of unexpected breakdowns and extend the overall lifespan of the PHE. The benefits include minimized production downtime, improved energy efficiency, and reduced risk of catastrophic failures.

Reactive maintenance, on the other hand, addresses issues only when they arise. This strategy may seem cost-effective in the short term due to lower immediate expenses. However, it often leads to higher long-term costs associated with emergency repairs, extended downtime, and potential damage to other system components.

The analysis should also consider the cost implications of different cleaning methods. Chemical cleaning, while effective, involves expenses related to chemicals, disposal, and potential environmental compliance. Mechanical cleaning may require specialized equipment and skilled labor but can be more environmentally friendly and less corrosive to PHE components.

Frequency of maintenance is another critical factor. More frequent maintenance can lead to higher short-term costs but may result in better performance and longevity. Conversely, extending maintenance intervals can reduce immediate expenses but may increase the risk of efficiency loss and unexpected failures.

The cost-benefit analysis should incorporate the impact of PHE upkeep on energy efficiency. Well-maintained heat exchangers typically operate at higher efficiency levels, resulting in lower energy consumption and associated costs. This factor is particularly significant in industries where energy expenses constitute a substantial portion of operational costs.

Additionally, the analysis should consider the costs and benefits of implementing condition monitoring technologies. These systems can provide real-time data on PHE performance, enabling predictive maintenance strategies. While the initial investment may be significant, the long-term benefits of optimized maintenance schedules and reduced unexpected downtime can often justify the expense.

Lastly, the analysis should factor in the potential costs of non-compliance with regulatory standards and the benefits of maintaining optimal performance in terms of product quality and consistency. This holistic approach ensures that all aspects of PHE upkeep are considered, leading to more informed decision-making and optimized maintenance strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!