How to Improve Erosion Resistance in Plate Heat Exchangers?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Erosion Challenges in PHEs

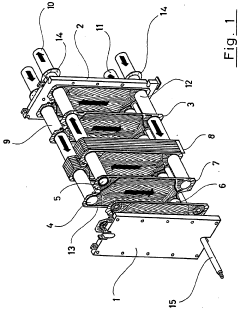

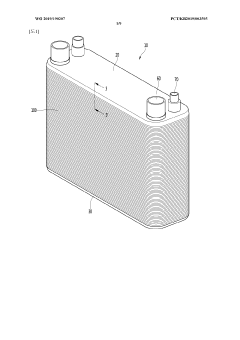

Plate Heat Exchangers (PHEs) are widely used in various industries due to their high efficiency and compact design. However, erosion remains a significant challenge that can severely impact their performance and longevity. Erosion in PHEs occurs when fluid flow containing abrasive particles or high-velocity streams impinges on the plate surfaces, causing material removal and degradation of heat transfer efficiency.

The primary erosion mechanisms in PHEs include particle impingement, cavitation, and flow-accelerated corrosion. Particle impingement erosion is particularly problematic in applications involving slurries or fluids with suspended solids. The impact of these particles on the plate surfaces can lead to localized material loss, especially in areas of high turbulence or flow direction changes.

Cavitation erosion occurs when vapor bubbles form and collapse near the plate surfaces due to pressure fluctuations in the fluid flow. This phenomenon is more prevalent in applications with low operating pressures or high fluid velocities. The repeated formation and collapse of these bubbles can cause significant damage to the plate material over time.

Flow-accelerated corrosion is another erosion mechanism that combines the effects of fluid flow and corrosive media. This type of erosion is particularly challenging in PHEs operating with aggressive fluids or in environments prone to chemical attack. The synergistic effect of mechanical wear and chemical degradation can lead to accelerated material loss and premature failure of the heat exchanger plates.

The consequences of erosion in PHEs are multifaceted and can significantly impact system performance and operational costs. Erosion-induced material loss can lead to thinning of the plates, potentially resulting in leaks or even catastrophic failure. Furthermore, the roughening of plate surfaces due to erosion can increase fluid friction, leading to higher pressure drops and reduced heat transfer efficiency.

Addressing erosion challenges in PHEs requires a multidisciplinary approach, combining materials science, fluid dynamics, and process engineering. Strategies for improving erosion resistance may include the selection of more erosion-resistant materials, optimization of plate geometries to minimize high-velocity impact zones, and the implementation of advanced surface treatments or coatings.

Understanding the specific erosion mechanisms at play in a given PHE application is crucial for developing effective mitigation strategies. This requires careful analysis of operating conditions, fluid properties, and material characteristics. Advanced modeling techniques, such as Computational Fluid Dynamics (CFD), can provide valuable insights into flow patterns and potential erosion hotspots within the exchanger.

The primary erosion mechanisms in PHEs include particle impingement, cavitation, and flow-accelerated corrosion. Particle impingement erosion is particularly problematic in applications involving slurries or fluids with suspended solids. The impact of these particles on the plate surfaces can lead to localized material loss, especially in areas of high turbulence or flow direction changes.

Cavitation erosion occurs when vapor bubbles form and collapse near the plate surfaces due to pressure fluctuations in the fluid flow. This phenomenon is more prevalent in applications with low operating pressures or high fluid velocities. The repeated formation and collapse of these bubbles can cause significant damage to the plate material over time.

Flow-accelerated corrosion is another erosion mechanism that combines the effects of fluid flow and corrosive media. This type of erosion is particularly challenging in PHEs operating with aggressive fluids or in environments prone to chemical attack. The synergistic effect of mechanical wear and chemical degradation can lead to accelerated material loss and premature failure of the heat exchanger plates.

The consequences of erosion in PHEs are multifaceted and can significantly impact system performance and operational costs. Erosion-induced material loss can lead to thinning of the plates, potentially resulting in leaks or even catastrophic failure. Furthermore, the roughening of plate surfaces due to erosion can increase fluid friction, leading to higher pressure drops and reduced heat transfer efficiency.

Addressing erosion challenges in PHEs requires a multidisciplinary approach, combining materials science, fluid dynamics, and process engineering. Strategies for improving erosion resistance may include the selection of more erosion-resistant materials, optimization of plate geometries to minimize high-velocity impact zones, and the implementation of advanced surface treatments or coatings.

Understanding the specific erosion mechanisms at play in a given PHE application is crucial for developing effective mitigation strategies. This requires careful analysis of operating conditions, fluid properties, and material characteristics. Advanced modeling techniques, such as Computational Fluid Dynamics (CFD), can provide valuable insights into flow patterns and potential erosion hotspots within the exchanger.

Market Demand Analysis

The market demand for improved erosion resistance in plate heat exchangers has been steadily increasing due to the growing emphasis on efficiency and longevity in industrial processes. Industries such as chemical processing, oil and gas, power generation, and food and beverage are particularly driving this demand as they seek to optimize their heat transfer operations while minimizing maintenance costs and downtime.

The global plate heat exchanger market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is partly attributed to the increasing need for more durable and erosion-resistant heat exchangers, especially in harsh operating environments. As industries push for higher productivity and extended equipment lifespan, the demand for plate heat exchangers with enhanced erosion resistance is becoming a critical factor in purchasing decisions.

Environmental regulations and sustainability initiatives are also contributing to the market demand for improved erosion resistance. Stricter emissions standards and the need for more efficient energy utilization are prompting industries to invest in high-performance heat exchangers that can withstand corrosive fluids and abrasive particles. This trend is particularly evident in the chemical and petrochemical sectors, where aggressive media and high-temperature operations are common.

The food and beverage industry represents another significant market segment driving demand for erosion-resistant plate heat exchangers. With the increasing focus on food safety and hygiene, manufacturers are seeking heat exchangers that can withstand frequent cleaning cycles and resist erosion from acidic or alkaline cleaning agents. This demand is further amplified by the industry's need for equipment that can maintain its integrity over extended periods, ensuring consistent product quality and reducing the risk of contamination.

In the power generation sector, the shift towards more efficient and flexible power plants is creating a demand for heat exchangers that can handle varying load conditions and diverse fluid compositions. Erosion-resistant plate heat exchangers are becoming essential in these applications, particularly in waste heat recovery systems and combined cycle power plants, where the ability to withstand thermal cycling and erosive conditions is crucial for long-term reliability.

The oil and gas industry, despite fluctuations in global energy markets, continues to be a significant driver for erosion-resistant heat exchangers. Offshore platforms and refineries require heat transfer equipment that can withstand seawater corrosion, high pressures, and the presence of abrasive particles. As exploration and production activities expand into more challenging environments, the demand for robust and erosion-resistant plate heat exchangers is expected to grow further.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing increased demand for advanced heat exchanger technologies. Rapid industrialization and infrastructure development in these regions are creating new opportunities for erosion-resistant plate heat exchangers across various sectors, including manufacturing, chemical processing, and energy production.

The global plate heat exchanger market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is partly attributed to the increasing need for more durable and erosion-resistant heat exchangers, especially in harsh operating environments. As industries push for higher productivity and extended equipment lifespan, the demand for plate heat exchangers with enhanced erosion resistance is becoming a critical factor in purchasing decisions.

Environmental regulations and sustainability initiatives are also contributing to the market demand for improved erosion resistance. Stricter emissions standards and the need for more efficient energy utilization are prompting industries to invest in high-performance heat exchangers that can withstand corrosive fluids and abrasive particles. This trend is particularly evident in the chemical and petrochemical sectors, where aggressive media and high-temperature operations are common.

The food and beverage industry represents another significant market segment driving demand for erosion-resistant plate heat exchangers. With the increasing focus on food safety and hygiene, manufacturers are seeking heat exchangers that can withstand frequent cleaning cycles and resist erosion from acidic or alkaline cleaning agents. This demand is further amplified by the industry's need for equipment that can maintain its integrity over extended periods, ensuring consistent product quality and reducing the risk of contamination.

In the power generation sector, the shift towards more efficient and flexible power plants is creating a demand for heat exchangers that can handle varying load conditions and diverse fluid compositions. Erosion-resistant plate heat exchangers are becoming essential in these applications, particularly in waste heat recovery systems and combined cycle power plants, where the ability to withstand thermal cycling and erosive conditions is crucial for long-term reliability.

The oil and gas industry, despite fluctuations in global energy markets, continues to be a significant driver for erosion-resistant heat exchangers. Offshore platforms and refineries require heat transfer equipment that can withstand seawater corrosion, high pressures, and the presence of abrasive particles. As exploration and production activities expand into more challenging environments, the demand for robust and erosion-resistant plate heat exchangers is expected to grow further.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing increased demand for advanced heat exchanger technologies. Rapid industrialization and infrastructure development in these regions are creating new opportunities for erosion-resistant plate heat exchangers across various sectors, including manufacturing, chemical processing, and energy production.

Current Erosion Issues

Plate heat exchangers (PHEs) are widely used in various industries due to their high efficiency and compact design. However, erosion remains a significant challenge that affects their performance and longevity. The current erosion issues in PHEs primarily stem from the high-velocity fluid flow and the presence of abrasive particles in the working fluids.

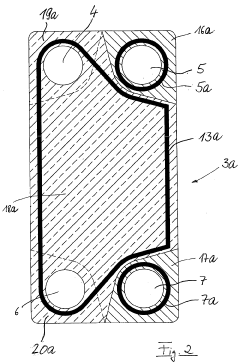

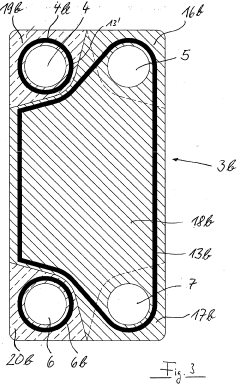

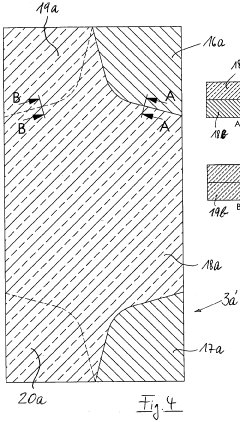

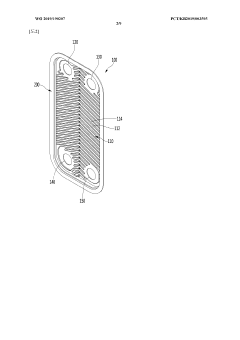

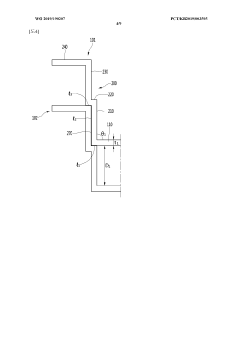

One of the main erosion problems in PHEs is the degradation of plate surfaces. The continuous impingement of fluid and particles on the plate surfaces leads to material removal, resulting in thinning and eventual failure of the plates. This erosion is particularly severe at the inlet and outlet regions of the plates, where flow velocities are highest and flow patterns are most turbulent.

Another critical issue is the erosion of gaskets and seals. These components are essential for maintaining the integrity of the heat exchanger and preventing leaks. However, they are often made of softer materials compared to the plates and are thus more susceptible to erosion damage. Erosion of gaskets can lead to fluid leakage, cross-contamination between fluid streams, and reduced thermal efficiency.

The presence of particulate matter in the working fluids exacerbates erosion problems. Industries such as mining, oil and gas, and chemical processing often deal with fluids containing abrasive particles. These particles can cause accelerated wear on the plate surfaces, especially in areas of high turbulence or where flow is redirected.

Corrosion-erosion synergy is another significant concern in PHEs. Many industrial processes involve corrosive fluids, and the combination of chemical attack and mechanical wear can lead to rapid deterioration of plate materials. This synergistic effect is particularly problematic in applications involving seawater or aggressive chemical solutions.

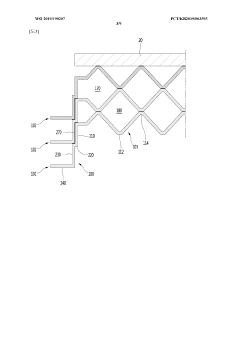

The geometry of PHEs, while beneficial for heat transfer, can contribute to erosion issues. The narrow channels and complex flow paths create areas of high velocity and turbulence, which can accelerate erosion in specific locations. The chevron patterns commonly used in plate designs, while effective for heat transfer, can create localized high-velocity zones prone to erosion.

Erosion also impacts the overall performance of PHEs. As surfaces become roughened due to erosion, the flow characteristics within the exchanger change. This can lead to increased pressure drop, reduced heat transfer efficiency, and the potential for fouling as eroded areas become sites for deposit accumulation.

Addressing these erosion issues is crucial for improving the reliability and efficiency of plate heat exchangers. Current research and development efforts are focused on enhancing material properties, optimizing flow designs, and developing protective coatings to mitigate erosion effects. However, the complex interplay of fluid dynamics, material science, and operational conditions makes this a challenging area requiring ongoing innovation and study.

One of the main erosion problems in PHEs is the degradation of plate surfaces. The continuous impingement of fluid and particles on the plate surfaces leads to material removal, resulting in thinning and eventual failure of the plates. This erosion is particularly severe at the inlet and outlet regions of the plates, where flow velocities are highest and flow patterns are most turbulent.

Another critical issue is the erosion of gaskets and seals. These components are essential for maintaining the integrity of the heat exchanger and preventing leaks. However, they are often made of softer materials compared to the plates and are thus more susceptible to erosion damage. Erosion of gaskets can lead to fluid leakage, cross-contamination between fluid streams, and reduced thermal efficiency.

The presence of particulate matter in the working fluids exacerbates erosion problems. Industries such as mining, oil and gas, and chemical processing often deal with fluids containing abrasive particles. These particles can cause accelerated wear on the plate surfaces, especially in areas of high turbulence or where flow is redirected.

Corrosion-erosion synergy is another significant concern in PHEs. Many industrial processes involve corrosive fluids, and the combination of chemical attack and mechanical wear can lead to rapid deterioration of plate materials. This synergistic effect is particularly problematic in applications involving seawater or aggressive chemical solutions.

The geometry of PHEs, while beneficial for heat transfer, can contribute to erosion issues. The narrow channels and complex flow paths create areas of high velocity and turbulence, which can accelerate erosion in specific locations. The chevron patterns commonly used in plate designs, while effective for heat transfer, can create localized high-velocity zones prone to erosion.

Erosion also impacts the overall performance of PHEs. As surfaces become roughened due to erosion, the flow characteristics within the exchanger change. This can lead to increased pressure drop, reduced heat transfer efficiency, and the potential for fouling as eroded areas become sites for deposit accumulation.

Addressing these erosion issues is crucial for improving the reliability and efficiency of plate heat exchangers. Current research and development efforts are focused on enhancing material properties, optimizing flow designs, and developing protective coatings to mitigate erosion effects. However, the complex interplay of fluid dynamics, material science, and operational conditions makes this a challenging area requiring ongoing innovation and study.

Existing Erosion Solutions

01 Coating materials for erosion resistance

Various coating materials can be applied to plate heat exchanger surfaces to enhance erosion resistance. These coatings may include ceramic-based materials, polymers, or metal alloys that provide a protective layer against abrasive particles and corrosive fluids. The coatings are designed to withstand high temperatures and harsh operating conditions while maintaining thermal efficiency.- Corrosion-resistant coatings: Application of specialized coatings on plate heat exchanger surfaces to enhance erosion resistance. These coatings can include ceramic, metallic, or polymer-based materials that provide a protective barrier against erosive forces, extending the lifespan of the heat exchanger components.

- Material selection for plate construction: Choosing appropriate materials for plate construction that inherently possess high erosion resistance properties. This may include the use of high-grade stainless steels, titanium alloys, or other advanced materials that can withstand harsh operating conditions and erosive media.

- Surface treatment techniques: Implementing various surface treatment techniques to enhance the erosion resistance of plate heat exchanger surfaces. These techniques may include shot peening, laser surface hardening, or chemical treatments that modify the surface properties to increase hardness and resistance to erosive wear.

- Design optimization for flow distribution: Optimizing the design of plate heat exchangers to improve flow distribution and reduce localized erosion. This may involve modifying plate geometries, channel configurations, or flow patterns to minimize areas of high turbulence and erosive impact.

- Erosion monitoring and maintenance strategies: Developing and implementing erosion monitoring systems and maintenance strategies to detect and address erosion issues in plate heat exchangers. This may include the use of sensors, regular inspections, and predictive maintenance techniques to identify and mitigate erosion problems before they become severe.

02 Surface treatment techniques

Surface treatment techniques can be employed to improve the erosion resistance of plate heat exchangers. These methods may include chemical etching, shot peening, or laser surface modification. Such treatments can alter the surface properties of the plates, creating a more durable and erosion-resistant surface without significantly affecting heat transfer efficiency.Expand Specific Solutions03 Material selection for plate construction

Careful selection of materials for plate construction can significantly enhance erosion resistance. High-performance alloys, such as stainless steel grades or titanium-based materials, can be chosen based on their inherent resistance to erosion and corrosion. The material selection process considers factors such as fluid composition, operating temperatures, and pressure conditions.Expand Specific Solutions04 Design optimization for flow distribution

Optimizing the design of plate heat exchangers can help minimize erosion by improving flow distribution and reducing localized high-velocity areas. This may involve modifying plate geometries, channel configurations, or inlet/outlet designs to ensure uniform fluid flow and reduce turbulence, thereby minimizing the impact of erosive particles on plate surfaces.Expand Specific Solutions05 Maintenance and cleaning strategies

Implementing effective maintenance and cleaning strategies can help prevent and mitigate erosion in plate heat exchangers. This may include regular inspection, scheduled cleaning procedures, and the use of specialized cleaning agents or techniques to remove deposits and prevent the accumulation of erosive materials. Proper maintenance can extend the lifespan of the heat exchanger and maintain its performance.Expand Specific Solutions

Key PHE Manufacturers

The erosion resistance improvement in plate heat exchangers is a competitive field in an advanced stage of development, with a substantial market size driven by industrial demand. The technology's maturity is high, as evidenced by the involvement of established players like Alfa Laval, Mitsubishi Electric, and Kelvion PHE. These companies, along with others such as API Schmidt-Bretten and Arconic Technologies, are actively pursuing innovations in materials and design to enhance erosion resistance. The market is characterized by a mix of global conglomerates and specialized manufacturers, indicating a diverse competitive landscape with ongoing research and development efforts to address this critical issue in heat exchanger performance and longevity.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced surface modification techniques to improve erosion resistance in plate heat exchangers. Their approach includes the application of specialized coatings and surface treatments to the plates. One of their key innovations is the use of laser surface texturing to create micro-patterns on the plate surface, which can reduce erosion by altering fluid flow characteristics[1]. They have also implemented a proprietary alloy selection process, choosing materials that offer superior erosion resistance for specific applications. Additionally, Alfa Laval has introduced a novel plate design with optimized flow distribution, reducing localized high-velocity areas that are prone to erosion[2]. Their research has shown that these combined strategies can extend the operational life of plate heat exchangers by up to 40% in high-erosion environments[3].

Strengths: Comprehensive approach combining material science, surface engineering, and fluid dynamics. Proven effectiveness in extending equipment lifespan. Weaknesses: Potentially higher initial costs due to advanced materials and processing techniques.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has focused on developing erosion-resistant coatings for plate heat exchangers. Their research has led to the creation of a multi-layer ceramic coating that significantly enhances erosion resistance. This coating is applied using a plasma spray technique, which allows for precise control of coating thickness and composition[4]. The outer layer is designed to be particularly hard and smooth, reducing the impact of abrasive particles in the fluid stream. Mitsubishi has also incorporated nano-particles into the coating to further improve its durability. In addition to coatings, they have developed a computer-aided design process that optimizes plate geometry to minimize areas of high turbulence, which are particularly susceptible to erosion[5]. Their testing has demonstrated a reduction in erosion rates of up to 60% compared to conventional plate designs[6].

Strengths: Advanced coating technology with proven effectiveness. Integration of computational fluid dynamics in design process. Weaknesses: May require specialized equipment for coating application, potentially limiting widespread adoption.

Core Anti-Erosion Innovations

Plate-type heat exchanger, heat exchanger plate and method for producing the same

PatentWO2009112128A1

Innovation

- The heat exchanger plates are made of a standard material like steel or stainless steel, with only specific areas exposed to aggressive media coated with a higher-quality, more corrosion-resistant material such as high-alloy stainless steel, titanium, or tantalum, using methods like soldering or welding, thereby reducing overall material costs.

Plate-type heat exchanger and method for manufacturing same

PatentWO2019190207A1

Innovation

- A plate heat exchanger is designed with stepped flange portions and an adhesive layer made of a glass composition to increase adhesion area and strength, preventing foreign matter accumulation and improving corrosion resistance, using a manufacturing method that involves spraying or dipping an adhesive on the plates and heating to melt it for bonding.

Material Selection Strategies

Material selection plays a crucial role in improving the erosion resistance of plate heat exchangers. The choice of materials directly impacts the longevity and performance of these critical components in various industrial applications. When selecting materials for plate heat exchangers, several factors must be considered to ensure optimal erosion resistance.

Firstly, the material's inherent properties are paramount. Metals with high hardness and toughness, such as stainless steel grades 316 and 304, are commonly used due to their excellent resistance to erosion and corrosion. These alloys contain chromium and nickel, which form a protective oxide layer on the surface, enhancing their durability in harsh environments.

For more demanding applications, advanced materials like titanium and its alloys offer superior erosion resistance. Titanium's exceptional strength-to-weight ratio and its ability to form a stable, protective oxide layer make it an ideal choice for environments with high flow rates and abrasive particles.

Surface treatments and coatings can significantly enhance the erosion resistance of base materials. Techniques such as nitriding, carburizing, or the application of ceramic coatings can create a harder, more wear-resistant surface layer. These treatments can be particularly effective in extending the life of plate heat exchangers in highly erosive environments.

The selection of materials should also consider the specific operating conditions of the heat exchanger. Factors such as fluid composition, temperature, pressure, and flow rates all influence the erosion potential and must be accounted for in the material selection process. For instance, in applications involving high-temperature fluids, nickel-based alloys like Inconel may be more suitable due to their excellent high-temperature strength and erosion resistance.

Composite materials are emerging as innovative solutions for erosion-resistant plate heat exchangers. Fiber-reinforced polymers and metal matrix composites offer unique combinations of properties, including high strength, low weight, and excellent erosion resistance. These materials can be tailored to specific application requirements, potentially outperforming traditional metallic options in certain scenarios.

The economic aspect of material selection cannot be overlooked. While high-performance materials may offer superior erosion resistance, their cost must be balanced against the expected service life and maintenance requirements. Life cycle cost analysis should be conducted to determine the most cost-effective material choice over the long term.

In conclusion, effective material selection strategies for improving erosion resistance in plate heat exchangers involve a comprehensive evaluation of material properties, surface treatments, operating conditions, and economic factors. By carefully considering these aspects, engineers can optimize the performance and longevity of plate heat exchangers in erosive environments.

Firstly, the material's inherent properties are paramount. Metals with high hardness and toughness, such as stainless steel grades 316 and 304, are commonly used due to their excellent resistance to erosion and corrosion. These alloys contain chromium and nickel, which form a protective oxide layer on the surface, enhancing their durability in harsh environments.

For more demanding applications, advanced materials like titanium and its alloys offer superior erosion resistance. Titanium's exceptional strength-to-weight ratio and its ability to form a stable, protective oxide layer make it an ideal choice for environments with high flow rates and abrasive particles.

Surface treatments and coatings can significantly enhance the erosion resistance of base materials. Techniques such as nitriding, carburizing, or the application of ceramic coatings can create a harder, more wear-resistant surface layer. These treatments can be particularly effective in extending the life of plate heat exchangers in highly erosive environments.

The selection of materials should also consider the specific operating conditions of the heat exchanger. Factors such as fluid composition, temperature, pressure, and flow rates all influence the erosion potential and must be accounted for in the material selection process. For instance, in applications involving high-temperature fluids, nickel-based alloys like Inconel may be more suitable due to their excellent high-temperature strength and erosion resistance.

Composite materials are emerging as innovative solutions for erosion-resistant plate heat exchangers. Fiber-reinforced polymers and metal matrix composites offer unique combinations of properties, including high strength, low weight, and excellent erosion resistance. These materials can be tailored to specific application requirements, potentially outperforming traditional metallic options in certain scenarios.

The economic aspect of material selection cannot be overlooked. While high-performance materials may offer superior erosion resistance, their cost must be balanced against the expected service life and maintenance requirements. Life cycle cost analysis should be conducted to determine the most cost-effective material choice over the long term.

In conclusion, effective material selection strategies for improving erosion resistance in plate heat exchangers involve a comprehensive evaluation of material properties, surface treatments, operating conditions, and economic factors. By carefully considering these aspects, engineers can optimize the performance and longevity of plate heat exchangers in erosive environments.

Fluid Dynamics Optimization

Fluid dynamics optimization plays a crucial role in improving erosion resistance in plate heat exchangers. By carefully analyzing and modifying the flow patterns within these devices, engineers can significantly reduce the wear and tear caused by fluid-induced erosion.

One of the primary approaches to fluid dynamics optimization is the redesign of plate geometries. By altering the shape, size, and arrangement of the plates, it is possible to create more favorable flow conditions that minimize turbulence and reduce the impact of fluid particles on the plate surfaces. This can involve the introduction of strategically placed corrugations, dimples, or protrusions that guide the fluid flow in a manner that reduces erosive effects.

Computational Fluid Dynamics (CFD) simulations have become an invaluable tool in this optimization process. These advanced modeling techniques allow engineers to visualize and predict fluid behavior within the heat exchanger under various operating conditions. By utilizing CFD, researchers can identify areas of high velocity or turbulence that are prone to erosion and make informed design modifications to mitigate these issues.

Another key aspect of fluid dynamics optimization is the careful selection of flow rates and pressure drops. By maintaining optimal flow velocities, it is possible to balance heat transfer efficiency with erosion resistance. This often involves finding a sweet spot where the fluid moves fast enough for effective heat exchange but not so rapidly that it causes excessive wear on the plate surfaces.

The use of flow distributors and baffles can also contribute significantly to erosion resistance. These components help to evenly distribute the fluid across the plate surface, preventing localized high-velocity zones that can lead to accelerated erosion. Properly designed distributors can ensure a more uniform flow pattern, reducing the likelihood of erosive hot spots.

Surface treatments and coatings represent another avenue for improving erosion resistance through fluid dynamics optimization. By applying specialized coatings or surface textures, it is possible to alter the interaction between the fluid and the plate surface at a microscopic level. This can lead to reduced friction and improved flow characteristics, ultimately contributing to enhanced erosion resistance.

Lastly, the consideration of multi-phase flows is essential in many industrial applications of plate heat exchangers. Optimizing fluid dynamics for systems involving mixtures of liquids and gases requires a nuanced approach that accounts for the complex interactions between different phases. This may involve the use of advanced modeling techniques and experimental validation to ensure that the chosen design effectively mitigates erosion across all operating conditions.

One of the primary approaches to fluid dynamics optimization is the redesign of plate geometries. By altering the shape, size, and arrangement of the plates, it is possible to create more favorable flow conditions that minimize turbulence and reduce the impact of fluid particles on the plate surfaces. This can involve the introduction of strategically placed corrugations, dimples, or protrusions that guide the fluid flow in a manner that reduces erosive effects.

Computational Fluid Dynamics (CFD) simulations have become an invaluable tool in this optimization process. These advanced modeling techniques allow engineers to visualize and predict fluid behavior within the heat exchanger under various operating conditions. By utilizing CFD, researchers can identify areas of high velocity or turbulence that are prone to erosion and make informed design modifications to mitigate these issues.

Another key aspect of fluid dynamics optimization is the careful selection of flow rates and pressure drops. By maintaining optimal flow velocities, it is possible to balance heat transfer efficiency with erosion resistance. This often involves finding a sweet spot where the fluid moves fast enough for effective heat exchange but not so rapidly that it causes excessive wear on the plate surfaces.

The use of flow distributors and baffles can also contribute significantly to erosion resistance. These components help to evenly distribute the fluid across the plate surface, preventing localized high-velocity zones that can lead to accelerated erosion. Properly designed distributors can ensure a more uniform flow pattern, reducing the likelihood of erosive hot spots.

Surface treatments and coatings represent another avenue for improving erosion resistance through fluid dynamics optimization. By applying specialized coatings or surface textures, it is possible to alter the interaction between the fluid and the plate surface at a microscopic level. This can lead to reduced friction and improved flow characteristics, ultimately contributing to enhanced erosion resistance.

Lastly, the consideration of multi-phase flows is essential in many industrial applications of plate heat exchangers. Optimizing fluid dynamics for systems involving mixtures of liquids and gases requires a nuanced approach that accounts for the complex interactions between different phases. This may involve the use of advanced modeling techniques and experimental validation to ensure that the chosen design effectively mitigates erosion across all operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!