Impact of High Temperatures on Plate Heat Exchanger Seals

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Temp PHE Seal Tech Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone of industrial heat transfer applications for decades, offering efficient and compact solutions for various processes. The evolution of PHE technology has been driven by the increasing demand for higher performance in more extreme operating conditions, particularly in high-temperature environments. This technological progression has brought the impact of elevated temperatures on PHE seals to the forefront of research and development efforts.

The historical development of PHE seals has seen a transition from simple gaskets to advanced elastomeric and non-elastomeric materials capable of withstanding harsh conditions. Early PHE designs were limited by the thermal resistance of available sealing materials, restricting their use to moderate temperature ranges. As industries such as petrochemicals, power generation, and food processing pushed for higher efficiency and productivity, the need for PHEs capable of operating at elevated temperatures became increasingly apparent.

The primary objective in addressing the impact of high temperatures on PHE seals is to develop sealing solutions that maintain integrity and performance under extreme thermal stress. This involves enhancing the thermal stability of seal materials, improving their resistance to chemical degradation at high temperatures, and ensuring long-term reliability to minimize maintenance and downtime. Additionally, researchers aim to extend the operational temperature range of PHEs without compromising on their compact design and energy efficiency advantages.

Current technological goals focus on several key areas. First, there is a push to develop novel composite materials that combine the flexibility of elastomers with the heat resistance of advanced polymers or ceramics. Second, researchers are exploring surface modification techniques to enhance the thermal and chemical resistance of existing seal materials. Third, there is ongoing work to optimize seal geometry and compression characteristics to maintain sealing effectiveness under thermal expansion and contraction cycles.

The trajectory of PHE seal technology is closely aligned with broader trends in materials science and manufacturing processes. Advancements in nanotechnology and polymer chemistry are opening new avenues for creating seals with unprecedented heat resistance and durability. Concurrently, the integration of smart materials and sensors into seal designs is being explored to enable real-time monitoring of seal performance and predictive maintenance strategies.

As industries continue to demand more from their heat exchange systems, the development of high-temperature PHE seals remains a critical area of innovation. The successful resolution of challenges in this domain will not only enhance the capabilities of existing PHE applications but also potentially unlock new use cases in extreme environments, further solidifying the position of plate heat exchangers as a versatile and indispensable technology in thermal management across various sectors.

The historical development of PHE seals has seen a transition from simple gaskets to advanced elastomeric and non-elastomeric materials capable of withstanding harsh conditions. Early PHE designs were limited by the thermal resistance of available sealing materials, restricting their use to moderate temperature ranges. As industries such as petrochemicals, power generation, and food processing pushed for higher efficiency and productivity, the need for PHEs capable of operating at elevated temperatures became increasingly apparent.

The primary objective in addressing the impact of high temperatures on PHE seals is to develop sealing solutions that maintain integrity and performance under extreme thermal stress. This involves enhancing the thermal stability of seal materials, improving their resistance to chemical degradation at high temperatures, and ensuring long-term reliability to minimize maintenance and downtime. Additionally, researchers aim to extend the operational temperature range of PHEs without compromising on their compact design and energy efficiency advantages.

Current technological goals focus on several key areas. First, there is a push to develop novel composite materials that combine the flexibility of elastomers with the heat resistance of advanced polymers or ceramics. Second, researchers are exploring surface modification techniques to enhance the thermal and chemical resistance of existing seal materials. Third, there is ongoing work to optimize seal geometry and compression characteristics to maintain sealing effectiveness under thermal expansion and contraction cycles.

The trajectory of PHE seal technology is closely aligned with broader trends in materials science and manufacturing processes. Advancements in nanotechnology and polymer chemistry are opening new avenues for creating seals with unprecedented heat resistance and durability. Concurrently, the integration of smart materials and sensors into seal designs is being explored to enable real-time monitoring of seal performance and predictive maintenance strategies.

As industries continue to demand more from their heat exchange systems, the development of high-temperature PHE seals remains a critical area of innovation. The successful resolution of challenges in this domain will not only enhance the capabilities of existing PHE applications but also potentially unlock new use cases in extreme environments, further solidifying the position of plate heat exchangers as a versatile and indispensable technology in thermal management across various sectors.

Market Analysis for High-Temp PHE Applications

The market for high-temperature plate heat exchanger (PHE) applications has been experiencing significant growth in recent years, driven by increasing demand across various industries. The global PHE market is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period. This growth is primarily attributed to the rising need for energy-efficient heat transfer solutions in industries such as chemical processing, oil and gas, power generation, and food and beverage.

In the chemical processing sector, high-temperature PHEs are increasingly utilized for processes involving corrosive fluids and extreme operating conditions. The oil and gas industry, particularly in refining and petrochemical applications, represents a major market segment for high-temperature PHEs due to their ability to handle high-pressure and high-temperature fluids efficiently. The power generation sector, including both conventional and renewable energy sources, is another key driver for the market growth, as PHEs are essential components in various power plant systems.

The food and beverage industry is also contributing to the market expansion, with high-temperature PHEs being employed in pasteurization, sterilization, and other thermal processing applications. This sector's demand is fueled by stringent food safety regulations and the need for energy-efficient processing equipment.

Geographically, Asia-Pacific is expected to dominate the high-temperature PHE market, owing to rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and the replacement of aging heat exchange systems with more efficient solutions.

The market is characterized by intense competition among key players, who are focusing on product innovation and technological advancements to gain a competitive edge. Manufacturers are investing in research and development to improve the performance and durability of PHE seals at high temperatures, addressing the challenges posed by extreme operating conditions.

Customer demand is increasingly shifting towards customized solutions that can withstand higher temperatures and pressures while maintaining optimal heat transfer efficiency. This trend is prompting manufacturers to develop advanced materials and designs for PHE seals that can withstand temperatures exceeding 200°C without compromising on performance or lifespan.

The growing emphasis on sustainability and energy efficiency is also shaping the market landscape. End-users are seeking PHE solutions that not only withstand high temperatures but also contribute to overall system efficiency and reduced energy consumption. This trend is driving innovation in seal materials and designs that can maintain their integrity under extreme conditions while minimizing heat loss and maximizing heat transfer effectiveness.

In the chemical processing sector, high-temperature PHEs are increasingly utilized for processes involving corrosive fluids and extreme operating conditions. The oil and gas industry, particularly in refining and petrochemical applications, represents a major market segment for high-temperature PHEs due to their ability to handle high-pressure and high-temperature fluids efficiently. The power generation sector, including both conventional and renewable energy sources, is another key driver for the market growth, as PHEs are essential components in various power plant systems.

The food and beverage industry is also contributing to the market expansion, with high-temperature PHEs being employed in pasteurization, sterilization, and other thermal processing applications. This sector's demand is fueled by stringent food safety regulations and the need for energy-efficient processing equipment.

Geographically, Asia-Pacific is expected to dominate the high-temperature PHE market, owing to rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and the replacement of aging heat exchange systems with more efficient solutions.

The market is characterized by intense competition among key players, who are focusing on product innovation and technological advancements to gain a competitive edge. Manufacturers are investing in research and development to improve the performance and durability of PHE seals at high temperatures, addressing the challenges posed by extreme operating conditions.

Customer demand is increasingly shifting towards customized solutions that can withstand higher temperatures and pressures while maintaining optimal heat transfer efficiency. This trend is prompting manufacturers to develop advanced materials and designs for PHE seals that can withstand temperatures exceeding 200°C without compromising on performance or lifespan.

The growing emphasis on sustainability and energy efficiency is also shaping the market landscape. End-users are seeking PHE solutions that not only withstand high temperatures but also contribute to overall system efficiency and reduced energy consumption. This trend is driving innovation in seal materials and designs that can maintain their integrity under extreme conditions while minimizing heat loss and maximizing heat transfer effectiveness.

Current Challenges in High-Temp PHE Seal Technology

The current challenges in high-temperature plate heat exchanger (PHE) seal technology are multifaceted and complex, reflecting the demanding operational conditions these components must withstand. One of the primary issues is the degradation of seal materials under extreme temperatures. Traditional elastomeric seals, such as those made from EPDM or NBR, often fail prematurely when exposed to temperatures exceeding 150°C, leading to leaks and reduced efficiency.

Material selection for high-temperature seals presents another significant challenge. While advanced materials like fluoroelastomers and perfluoroelastomers offer improved heat resistance, they come with drawbacks such as higher costs and potential brittleness at lower temperatures. This necessitates a careful balance between heat resistance, chemical compatibility, and overall seal performance across a wide temperature range.

Thermal expansion and contraction of seal materials pose additional difficulties. As temperatures fluctuate, seals may experience dimensional changes that can compromise their sealing effectiveness. This is particularly problematic in applications with frequent thermal cycling, where repeated expansion and contraction can lead to fatigue and eventual failure of the seal.

Chemical compatibility is another critical concern, especially in processes involving corrosive or reactive fluids at high temperatures. Seals must not only withstand the heat but also resist chemical attack, which can accelerate degradation and reduce service life. Finding materials that maintain their integrity in both high-temperature and chemically aggressive environments remains a significant challenge.

The design of seal geometries for high-temperature PHEs also presents unique challenges. Engineers must account for the increased thermal stresses and potential deformation of seal profiles under extreme conditions. Innovative designs that can maintain sealing pressure while accommodating thermal expansion are crucial for improving seal performance and longevity.

Furthermore, the long-term reliability of high-temperature seals is a persistent issue. Predicting seal behavior and lifespan under prolonged exposure to high temperatures is complex, often requiring extensive testing and modeling. This uncertainty can lead to conservative maintenance schedules, increasing operational costs and downtime.

Lastly, the development of cost-effective solutions for high-temperature PHE seals remains a significant challenge. While advanced materials and designs can offer improved performance, their higher costs may limit widespread adoption, particularly in industries where cost-sensitivity is a major factor. Balancing performance improvements with economic viability is an ongoing struggle in the advancement of high-temperature seal technology for plate heat exchangers.

Material selection for high-temperature seals presents another significant challenge. While advanced materials like fluoroelastomers and perfluoroelastomers offer improved heat resistance, they come with drawbacks such as higher costs and potential brittleness at lower temperatures. This necessitates a careful balance between heat resistance, chemical compatibility, and overall seal performance across a wide temperature range.

Thermal expansion and contraction of seal materials pose additional difficulties. As temperatures fluctuate, seals may experience dimensional changes that can compromise their sealing effectiveness. This is particularly problematic in applications with frequent thermal cycling, where repeated expansion and contraction can lead to fatigue and eventual failure of the seal.

Chemical compatibility is another critical concern, especially in processes involving corrosive or reactive fluids at high temperatures. Seals must not only withstand the heat but also resist chemical attack, which can accelerate degradation and reduce service life. Finding materials that maintain their integrity in both high-temperature and chemically aggressive environments remains a significant challenge.

The design of seal geometries for high-temperature PHEs also presents unique challenges. Engineers must account for the increased thermal stresses and potential deformation of seal profiles under extreme conditions. Innovative designs that can maintain sealing pressure while accommodating thermal expansion are crucial for improving seal performance and longevity.

Furthermore, the long-term reliability of high-temperature seals is a persistent issue. Predicting seal behavior and lifespan under prolonged exposure to high temperatures is complex, often requiring extensive testing and modeling. This uncertainty can lead to conservative maintenance schedules, increasing operational costs and downtime.

Lastly, the development of cost-effective solutions for high-temperature PHE seals remains a significant challenge. While advanced materials and designs can offer improved performance, their higher costs may limit widespread adoption, particularly in industries where cost-sensitivity is a major factor. Balancing performance improvements with economic viability is an ongoing struggle in the advancement of high-temperature seal technology for plate heat exchangers.

Existing High-Temp Seal Solutions for PHEs

01 High-temperature resistant materials for plate heat exchanger seals

Advanced materials with high temperature resistance are used for manufacturing plate heat exchanger seals. These materials can withstand extreme temperatures while maintaining their sealing properties, ensuring the efficient operation of the heat exchanger in high-temperature environments.- High-temperature resistant materials for plate heat exchanger seals: Advanced materials with high temperature resistance are used for manufacturing plate heat exchanger seals. These materials can withstand extreme temperatures while maintaining their sealing properties, ensuring efficient heat transfer and preventing leakage in high-temperature applications.

- Seal design optimization for temperature resistance: Innovative seal designs are developed to enhance temperature resistance in plate heat exchangers. These designs focus on improving the seal's ability to maintain its shape and function under varying temperature conditions, thereby increasing the overall efficiency and lifespan of the heat exchanger.

- Composite seal materials for improved temperature performance: Composite materials are utilized in the production of plate heat exchanger seals to achieve superior temperature resistance. These materials combine the properties of different components to create seals that can withstand a wide range of temperatures while maintaining their structural integrity and sealing effectiveness.

- Coating technologies for enhancing seal temperature resistance: Advanced coating technologies are applied to plate heat exchanger seals to improve their temperature resistance. These coatings provide an additional layer of protection against high temperatures, helping to extend the seal's lifespan and maintain its performance in extreme operating conditions.

- Testing and validation methods for temperature-resistant seals: Rigorous testing and validation procedures are employed to ensure the temperature resistance of plate heat exchanger seals. These methods involve subjecting the seals to various temperature conditions and stress tests to verify their performance and durability in real-world applications.

02 Seal design optimization for temperature resistance

Innovative seal designs are developed to enhance temperature resistance in plate heat exchangers. These designs focus on improving the seal's ability to maintain its integrity and performance under varying temperature conditions, reducing the risk of leakage and increasing overall efficiency.Expand Specific Solutions03 Composite seal materials for improved temperature resistance

Composite materials are utilized in the production of plate heat exchanger seals to enhance temperature resistance. These materials combine the properties of different components to create seals that can withstand a wide range of temperatures while maintaining flexibility and sealing effectiveness.Expand Specific Solutions04 Coating technologies for enhancing seal temperature resistance

Advanced coating technologies are applied to plate heat exchanger seals to improve their temperature resistance. These coatings provide an additional layer of protection against high temperatures, extending the lifespan of the seals and maintaining their performance in extreme conditions.Expand Specific Solutions05 Testing and validation methods for temperature-resistant seals

Rigorous testing and validation methods are employed to ensure the temperature resistance of plate heat exchanger seals. These methods involve subjecting the seals to extreme temperature conditions and assessing their performance, durability, and sealing capabilities to guarantee their reliability in real-world applications.Expand Specific Solutions

Key Players in PHE and Seal Manufacturing

The impact of high temperatures on plate heat exchanger seals represents a critical challenge in the mature heat exchanger industry. With a global market size exceeding $16 billion, this sector is in a growth phase driven by increasing industrial applications. Companies like Alfa Laval, Danfoss, and API Schmidt-Bretten are at the forefront, developing advanced sealing technologies to withstand extreme temperatures. The technological maturity varies, with established players focusing on incremental improvements while newer entrants like Foshan Kelan and HIFUNDA explore innovative materials and designs to enhance seal performance and longevity under high-temperature conditions.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse Electric has developed specialized sealing solutions for plate heat exchangers used in nuclear power plants, where high temperatures and radiation resistance are critical. Their approach includes the use of metal-to-metal seals and advanced ceramic composites that can withstand temperatures exceeding 1000°C (1832°F)[6]. Westinghouse has also implemented a unique double-barrier sealing system that provides additional protection against leaks in high-temperature, high-pressure environments. The company's plate heat exchanger designs incorporate precision-engineered surface finishes and optimized plate geometries to enhance sealing performance under extreme conditions[7]. Additionally, Westinghouse has developed proprietary coating technologies that improve the corrosion resistance and longevity of sealing surfaces in high-temperature applications.

Strengths: Exceptional high-temperature and radiation resistance, advanced metal-to-metal and ceramic sealing technologies, and specialized designs for nuclear applications. Weaknesses: High costs associated with specialized materials and manufacturing processes, limited applicability outside of nuclear and other extreme industrial environments.

Danfoss A/S

Technical Solution: Danfoss has focused on developing robust sealing solutions for plate heat exchangers in high-temperature applications. Their approach includes the use of advanced composite materials that combine the flexibility of elastomers with the temperature resistance of ceramics[4]. Danfoss has also introduced a multi-layer sealing system that provides redundancy and improved leak protection at elevated temperatures. The company's semi-welded plate heat exchanger design incorporates laser-welded channels with strategically placed high-temperature gaskets, allowing for operation in environments up to 350°C (662°F)[5]. Danfoss has further enhanced their sealing technology by implementing a proprietary surface treatment process that improves the adhesion between the gasket and plate material at high temperatures.

Strengths: Innovative composite materials, multi-layer sealing system, and semi-welded designs for high-temperature applications. Weaknesses: Limited to moderate high-temperature ranges compared to some competitors, potential for higher maintenance requirements.

Innovative Seal Materials for Extreme Temperatures

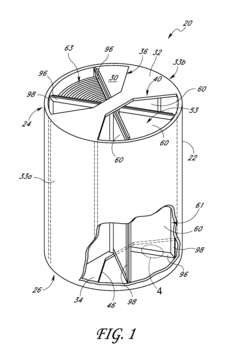

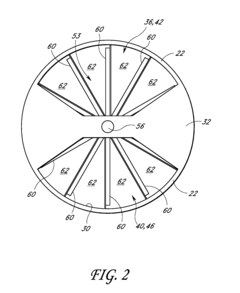

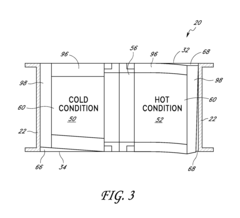

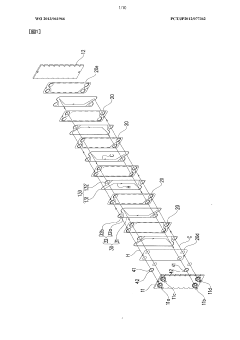

Full contact flexible seal assembly for heat exchanger

PatentActiveUS20110037236A1

Innovation

- A seal assembly with a primary sealing member and an auxiliary member, featuring a flexible contact portion and a cantilevered portion, is designed to maintain consistent contact with sector plates, limiting flexure and enhancing the spring constant to prevent over-flexing and leakage, while a curvilinear support further stabilizes the flexible contact portion.

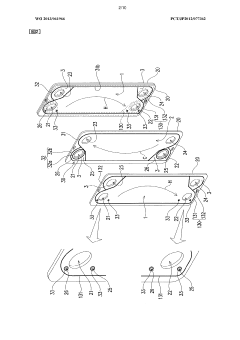

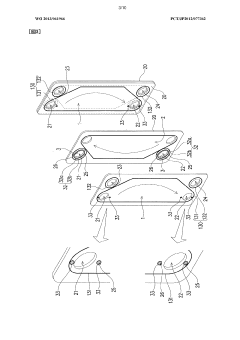

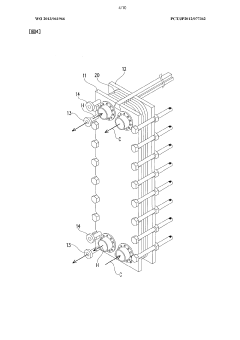

Plate heat exchanger

PatentWO2013061966A1

Innovation

- The implementation of a double-layered gasket configuration, where an inner gasket member surrounds the passage holes and an outer gasket member surrounds the inner gasket, with the inner gasket member being protected from oxygen, and the inclusion of drainage and air supply holes to prevent oxidation deterioration and maintain seal integrity.

Environmental Impact of High-Temp PHE Operations

The environmental impact of high-temperature plate heat exchanger (PHE) operations is a critical consideration in industrial processes. As temperatures rise, the potential for environmental harm increases, particularly concerning the integrity of PHE seals. These seals play a crucial role in preventing leaks and maintaining system efficiency, but they are vulnerable to degradation under extreme heat conditions.

High-temperature operations in PHEs can lead to increased emissions of volatile organic compounds (VOCs) from seal materials. As seals deteriorate, they may release harmful substances into the atmosphere, contributing to air pollution and potentially violating environmental regulations. This is especially concerning in industries such as chemical processing, where hazardous materials are often involved.

Water pollution is another significant environmental risk associated with high-temperature PHE operations. Seal failure can result in the leakage of process fluids, which may contain toxic chemicals or high-temperature liquids. These leaks can contaminate local water sources, harming aquatic ecosystems and potentially affecting human health if they enter the water supply.

Energy consumption is also a key environmental factor in high-temperature PHE operations. As seals degrade due to heat stress, the overall efficiency of the heat exchanger decreases. This leads to increased energy requirements to maintain the desired heat transfer rates, resulting in higher greenhouse gas emissions from power generation.

The disposal of damaged seals presents additional environmental challenges. High-temperature operations often accelerate seal wear, necessitating more frequent replacements. The materials used in these seals may not be easily recyclable, contributing to industrial waste and potentially releasing harmful substances into landfills.

Noise pollution is an often-overlooked environmental impact of high-temperature PHE operations. As seals deteriorate, they can cause increased vibrations and fluid turbulence, leading to higher noise levels. This can negatively affect both worker health and the surrounding environment, particularly in urban or sensitive ecological areas.

To mitigate these environmental impacts, industries are increasingly focusing on developing more heat-resistant and environmentally friendly seal materials. Advanced polymers and composite materials are being researched to create seals that can withstand higher temperatures while minimizing emissions and extending operational lifespans. Additionally, improved monitoring systems are being implemented to detect seal degradation early, preventing catastrophic failures and reducing environmental risks.

High-temperature operations in PHEs can lead to increased emissions of volatile organic compounds (VOCs) from seal materials. As seals deteriorate, they may release harmful substances into the atmosphere, contributing to air pollution and potentially violating environmental regulations. This is especially concerning in industries such as chemical processing, where hazardous materials are often involved.

Water pollution is another significant environmental risk associated with high-temperature PHE operations. Seal failure can result in the leakage of process fluids, which may contain toxic chemicals or high-temperature liquids. These leaks can contaminate local water sources, harming aquatic ecosystems and potentially affecting human health if they enter the water supply.

Energy consumption is also a key environmental factor in high-temperature PHE operations. As seals degrade due to heat stress, the overall efficiency of the heat exchanger decreases. This leads to increased energy requirements to maintain the desired heat transfer rates, resulting in higher greenhouse gas emissions from power generation.

The disposal of damaged seals presents additional environmental challenges. High-temperature operations often accelerate seal wear, necessitating more frequent replacements. The materials used in these seals may not be easily recyclable, contributing to industrial waste and potentially releasing harmful substances into landfills.

Noise pollution is an often-overlooked environmental impact of high-temperature PHE operations. As seals deteriorate, they can cause increased vibrations and fluid turbulence, leading to higher noise levels. This can negatively affect both worker health and the surrounding environment, particularly in urban or sensitive ecological areas.

To mitigate these environmental impacts, industries are increasingly focusing on developing more heat-resistant and environmentally friendly seal materials. Advanced polymers and composite materials are being researched to create seals that can withstand higher temperatures while minimizing emissions and extending operational lifespans. Additionally, improved monitoring systems are being implemented to detect seal degradation early, preventing catastrophic failures and reducing environmental risks.

Regulatory Standards for High-Temp Heat Exchangers

Regulatory standards for high-temperature heat exchangers play a crucial role in ensuring the safety, reliability, and efficiency of these critical components in various industries. These standards are developed and enforced by regulatory bodies such as the American Society of Mechanical Engineers (ASME), the European Pressure Equipment Directive (PED), and the International Organization for Standardization (ISO).

One of the primary focuses of these regulations is the material selection for heat exchanger components, particularly seals, which are subjected to extreme temperatures. The ASME Boiler and Pressure Vessel Code Section VIII, Division 1, provides guidelines for the design and construction of pressure vessels, including heat exchangers. It specifies the acceptable materials and their temperature limits for various applications.

The European Pressure Equipment Directive (PED) 2014/68/EU sets out essential safety requirements for pressure equipment, including heat exchangers operating at high temperatures. It mandates the use of materials that can withstand the specified operating conditions and requires manufacturers to provide material certificates and perform risk assessments.

ISO 15547-1:2005 specifically addresses the design of plate-type heat exchangers for the petroleum, petrochemical, and natural gas industries. This standard provides guidelines for material selection, design considerations, and testing procedures for heat exchangers operating in high-temperature environments.

Regulatory standards also emphasize the importance of proper testing and certification. The ASME PTC 12.5-2000 standard outlines performance test procedures for single-phase heat exchangers, including those operating at high temperatures. These tests ensure that the heat exchangers meet the specified performance criteria and can withstand the intended operating conditions.

Furthermore, regulations often require regular inspection and maintenance of high-temperature heat exchangers. The API 510 Pressure Vessel Inspection Code provides guidelines for in-service inspection, repair, alteration, and rerating of pressure vessels, including heat exchangers. This standard helps ensure the ongoing integrity and safety of these components throughout their operational life.

Compliance with these regulatory standards is essential for manufacturers and operators of high-temperature heat exchangers. It not only ensures the safety and reliability of the equipment but also facilitates international trade and acceptance of products across different markets. As technology advances and new materials are developed, these standards are periodically updated to reflect the latest best practices and safety requirements in the industry.

One of the primary focuses of these regulations is the material selection for heat exchanger components, particularly seals, which are subjected to extreme temperatures. The ASME Boiler and Pressure Vessel Code Section VIII, Division 1, provides guidelines for the design and construction of pressure vessels, including heat exchangers. It specifies the acceptable materials and their temperature limits for various applications.

The European Pressure Equipment Directive (PED) 2014/68/EU sets out essential safety requirements for pressure equipment, including heat exchangers operating at high temperatures. It mandates the use of materials that can withstand the specified operating conditions and requires manufacturers to provide material certificates and perform risk assessments.

ISO 15547-1:2005 specifically addresses the design of plate-type heat exchangers for the petroleum, petrochemical, and natural gas industries. This standard provides guidelines for material selection, design considerations, and testing procedures for heat exchangers operating in high-temperature environments.

Regulatory standards also emphasize the importance of proper testing and certification. The ASME PTC 12.5-2000 standard outlines performance test procedures for single-phase heat exchangers, including those operating at high temperatures. These tests ensure that the heat exchangers meet the specified performance criteria and can withstand the intended operating conditions.

Furthermore, regulations often require regular inspection and maintenance of high-temperature heat exchangers. The API 510 Pressure Vessel Inspection Code provides guidelines for in-service inspection, repair, alteration, and rerating of pressure vessels, including heat exchangers. This standard helps ensure the ongoing integrity and safety of these components throughout their operational life.

Compliance with these regulatory standards is essential for manufacturers and operators of high-temperature heat exchangers. It not only ensures the safety and reliability of the equipment but also facilitates international trade and acceptance of products across different markets. As technology advances and new materials are developed, these standards are periodically updated to reflect the latest best practices and safety requirements in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!