Plate Heat Exchanger in Flexible Manufacturing Systems

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Technology Background and Objectives

Plate heat exchangers (PHEs) have emerged as a crucial component in flexible manufacturing systems, revolutionizing thermal management across various industries. The technology behind PHEs has evolved significantly since its inception in the 1920s, with continuous improvements in design, materials, and efficiency. Initially developed for the dairy industry, PHEs have found widespread applications in chemical processing, HVAC systems, and power generation.

The primary objective of PHE technology in flexible manufacturing systems is to achieve optimal heat transfer while maintaining adaptability to changing production requirements. This goal aligns with the broader trend towards Industry 4.0, where manufacturing processes are becoming increasingly agile and responsive to market demands. PHEs contribute to this flexibility by offering modular designs that can be easily scaled or reconfigured to accommodate different heat transfer needs.

Over the years, PHE technology has witnessed several key advancements. The introduction of corrugated plates in the 1950s significantly enhanced heat transfer efficiency by promoting turbulent flow. Subsequent developments focused on improving plate geometries, sealing technologies, and materials to handle a wider range of temperatures and pressures. Recent innovations have explored the use of advanced materials such as titanium and high-performance polymers to extend the application range of PHEs in corrosive environments.

The current technological trajectory of PHEs in flexible manufacturing systems is driven by the need for enhanced energy efficiency, reduced footprint, and improved process control. Researchers and manufacturers are exploring novel plate designs, such as asymmetric patterns and mixed corrugation angles, to optimize heat transfer while minimizing pressure drop. Additionally, there is a growing interest in integrating smart sensors and control systems into PHEs to enable real-time monitoring and adaptive operation.

Looking ahead, the future of PHE technology in flexible manufacturing systems is likely to focus on several key areas. These include the development of compact, high-performance designs to meet the space constraints of modern production facilities, as well as the integration of advanced materials and surface treatments to enhance fouling resistance and extend operational lifetimes. Furthermore, there is a push towards incorporating PHEs into broader energy management strategies, such as waste heat recovery systems and thermal energy storage solutions.

As manufacturing processes become increasingly complex and energy-intensive, the role of PHEs in maintaining thermal equilibrium and process efficiency becomes ever more critical. The ongoing research and development in this field aim to address these challenges, paving the way for more sustainable and adaptable manufacturing systems. The continuous evolution of PHE technology underscores its importance in supporting the transition towards more flexible, efficient, and environmentally friendly production processes.

The primary objective of PHE technology in flexible manufacturing systems is to achieve optimal heat transfer while maintaining adaptability to changing production requirements. This goal aligns with the broader trend towards Industry 4.0, where manufacturing processes are becoming increasingly agile and responsive to market demands. PHEs contribute to this flexibility by offering modular designs that can be easily scaled or reconfigured to accommodate different heat transfer needs.

Over the years, PHE technology has witnessed several key advancements. The introduction of corrugated plates in the 1950s significantly enhanced heat transfer efficiency by promoting turbulent flow. Subsequent developments focused on improving plate geometries, sealing technologies, and materials to handle a wider range of temperatures and pressures. Recent innovations have explored the use of advanced materials such as titanium and high-performance polymers to extend the application range of PHEs in corrosive environments.

The current technological trajectory of PHEs in flexible manufacturing systems is driven by the need for enhanced energy efficiency, reduced footprint, and improved process control. Researchers and manufacturers are exploring novel plate designs, such as asymmetric patterns and mixed corrugation angles, to optimize heat transfer while minimizing pressure drop. Additionally, there is a growing interest in integrating smart sensors and control systems into PHEs to enable real-time monitoring and adaptive operation.

Looking ahead, the future of PHE technology in flexible manufacturing systems is likely to focus on several key areas. These include the development of compact, high-performance designs to meet the space constraints of modern production facilities, as well as the integration of advanced materials and surface treatments to enhance fouling resistance and extend operational lifetimes. Furthermore, there is a push towards incorporating PHEs into broader energy management strategies, such as waste heat recovery systems and thermal energy storage solutions.

As manufacturing processes become increasingly complex and energy-intensive, the role of PHEs in maintaining thermal equilibrium and process efficiency becomes ever more critical. The ongoing research and development in this field aim to address these challenges, paving the way for more sustainable and adaptable manufacturing systems. The continuous evolution of PHE technology underscores its importance in supporting the transition towards more flexible, efficient, and environmentally friendly production processes.

Market Demand Analysis for FMS PHEs

The market demand for Plate Heat Exchangers (PHEs) in Flexible Manufacturing Systems (FMS) has been experiencing significant growth due to the increasing adoption of advanced manufacturing technologies and the need for efficient thermal management solutions. FMS, characterized by their ability to adapt quickly to changing production requirements, have become integral to modern manufacturing processes across various industries.

The primary drivers of market demand for PHEs in FMS include the growing emphasis on energy efficiency, stringent environmental regulations, and the need for compact and high-performance heat transfer solutions. As manufacturers strive to optimize their production processes, the integration of PHEs in FMS offers substantial benefits in terms of improved thermal control, reduced energy consumption, and enhanced overall system performance.

In the automotive sector, the demand for PHEs in FMS has been particularly strong. The industry's shift towards electric and hybrid vehicles has created new thermal management challenges, requiring more sophisticated and flexible cooling solutions. PHEs have proven to be effective in managing the heat generated by batteries, power electronics, and electric motors, contributing to the increased adoption of these components in automotive manufacturing systems.

The food and beverage industry represents another significant market for PHEs in FMS. The need for precise temperature control during various stages of food processing, coupled with stringent hygiene requirements, has led to a growing demand for efficient and easily cleanable heat exchange solutions. PHEs, with their ability to maintain consistent temperatures and their ease of maintenance, have become increasingly popular in this sector.

The chemical and pharmaceutical industries have also shown a rising interest in PHEs for their FMS applications. These industries require precise temperature control for reactions and processes, and the flexibility offered by PHEs in handling different fluids and operating conditions makes them an attractive choice. The compact design of PHEs also allows for better space utilization in complex manufacturing setups.

Market analysts project a compound annual growth rate (CAGR) for PHEs in FMS applications to exceed the overall industrial heat exchanger market growth rate over the next five years. This growth is attributed to the increasing implementation of Industry 4.0 technologies, which demand more flexible and efficient manufacturing processes.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for PHEs in FMS, driven by rapid industrialization and the expansion of manufacturing capabilities in countries like China and India. North America and Europe are also significant markets, with a focus on upgrading existing manufacturing facilities to improve energy efficiency and reduce environmental impact.

The primary drivers of market demand for PHEs in FMS include the growing emphasis on energy efficiency, stringent environmental regulations, and the need for compact and high-performance heat transfer solutions. As manufacturers strive to optimize their production processes, the integration of PHEs in FMS offers substantial benefits in terms of improved thermal control, reduced energy consumption, and enhanced overall system performance.

In the automotive sector, the demand for PHEs in FMS has been particularly strong. The industry's shift towards electric and hybrid vehicles has created new thermal management challenges, requiring more sophisticated and flexible cooling solutions. PHEs have proven to be effective in managing the heat generated by batteries, power electronics, and electric motors, contributing to the increased adoption of these components in automotive manufacturing systems.

The food and beverage industry represents another significant market for PHEs in FMS. The need for precise temperature control during various stages of food processing, coupled with stringent hygiene requirements, has led to a growing demand for efficient and easily cleanable heat exchange solutions. PHEs, with their ability to maintain consistent temperatures and their ease of maintenance, have become increasingly popular in this sector.

The chemical and pharmaceutical industries have also shown a rising interest in PHEs for their FMS applications. These industries require precise temperature control for reactions and processes, and the flexibility offered by PHEs in handling different fluids and operating conditions makes them an attractive choice. The compact design of PHEs also allows for better space utilization in complex manufacturing setups.

Market analysts project a compound annual growth rate (CAGR) for PHEs in FMS applications to exceed the overall industrial heat exchanger market growth rate over the next five years. This growth is attributed to the increasing implementation of Industry 4.0 technologies, which demand more flexible and efficient manufacturing processes.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for PHEs in FMS, driven by rapid industrialization and the expansion of manufacturing capabilities in countries like China and India. North America and Europe are also significant markets, with a focus on upgrading existing manufacturing facilities to improve energy efficiency and reduce environmental impact.

Current PHE Challenges in FMS

Plate Heat Exchangers (PHEs) in Flexible Manufacturing Systems (FMS) face several significant challenges that hinder their optimal performance and integration. One of the primary issues is the difficulty in maintaining consistent heat transfer efficiency across varying production scenarios. FMS environments often require rapid changes in production parameters, which can lead to fluctuations in heat load and flow rates. These variations can cause thermal imbalances within the PHE, resulting in reduced efficiency and potential thermal stress on the equipment.

Another challenge is the fouling of heat transfer surfaces, which is exacerbated in FMS due to the diverse range of materials and processes involved. The accumulation of deposits on plate surfaces can significantly reduce heat transfer rates and increase pressure drop, leading to decreased overall system performance. This issue is particularly problematic in FMS, where downtime for cleaning and maintenance can disrupt the entire production line.

The compact design of PHEs, while advantageous in many aspects, presents challenges in FMS applications. The limited space between plates can lead to flow distribution problems, especially when dealing with fluids of varying viscosities or those containing particulates. This can result in uneven heat transfer and the creation of "dead zones" within the exchanger, reducing its effectiveness and potentially leading to localized overheating or overcooling.

Corrosion and material compatibility issues also pose significant challenges in FMS environments. The diverse range of fluids and chemicals used in flexible manufacturing processes can accelerate corrosion of PHE components, particularly gaskets and plates. This not only reduces the lifespan of the equipment but also increases the risk of leaks and cross-contamination between fluid streams.

Control and monitoring of PHEs in FMS present additional challenges. The need for rapid response to changing production requirements demands sophisticated control systems capable of adjusting flow rates, temperatures, and pressures in real-time. However, the complexity of these systems can lead to increased costs and potential reliability issues.

Lastly, the integration of PHEs into existing FMS infrastructure can be challenging. Retrofitting older systems to accommodate modern PHE technology often requires significant modifications to piping, pumping, and control systems. This can be both costly and disruptive to ongoing operations, presenting a barrier to the adoption of more efficient heat exchange solutions in FMS environments.

Another challenge is the fouling of heat transfer surfaces, which is exacerbated in FMS due to the diverse range of materials and processes involved. The accumulation of deposits on plate surfaces can significantly reduce heat transfer rates and increase pressure drop, leading to decreased overall system performance. This issue is particularly problematic in FMS, where downtime for cleaning and maintenance can disrupt the entire production line.

The compact design of PHEs, while advantageous in many aspects, presents challenges in FMS applications. The limited space between plates can lead to flow distribution problems, especially when dealing with fluids of varying viscosities or those containing particulates. This can result in uneven heat transfer and the creation of "dead zones" within the exchanger, reducing its effectiveness and potentially leading to localized overheating or overcooling.

Corrosion and material compatibility issues also pose significant challenges in FMS environments. The diverse range of fluids and chemicals used in flexible manufacturing processes can accelerate corrosion of PHE components, particularly gaskets and plates. This not only reduces the lifespan of the equipment but also increases the risk of leaks and cross-contamination between fluid streams.

Control and monitoring of PHEs in FMS present additional challenges. The need for rapid response to changing production requirements demands sophisticated control systems capable of adjusting flow rates, temperatures, and pressures in real-time. However, the complexity of these systems can lead to increased costs and potential reliability issues.

Lastly, the integration of PHEs into existing FMS infrastructure can be challenging. Retrofitting older systems to accommodate modern PHE technology often requires significant modifications to piping, pumping, and control systems. This can be both costly and disruptive to ongoing operations, presenting a barrier to the adoption of more efficient heat exchange solutions in FMS environments.

Current PHE Solutions for FMS

01 Improved plate design for heat exchangers

Advanced plate designs are being developed to enhance the efficiency of heat exchangers. These designs focus on optimizing fluid flow patterns, increasing heat transfer surface area, and reducing pressure drop. Innovations include corrugated patterns, dimpled surfaces, and strategic placement of flow channels to maximize turbulence and heat transfer while minimizing fouling.- Improved plate design for heat exchangers: Advanced plate designs are developed to enhance heat transfer efficiency and reduce pressure drop in plate heat exchangers. These designs may include optimized flow patterns, turbulence promoters, or novel surface geometries that increase heat transfer area while minimizing fluid resistance.

- Sealing and gasket innovations: New sealing technologies and gasket materials are introduced to improve the reliability and longevity of plate heat exchangers. These innovations focus on preventing leaks, enhancing chemical resistance, and allowing for higher operating pressures and temperatures.

- Modular and customizable designs: Plate heat exchangers are designed with modular components, allowing for easy customization, maintenance, and scalability. This approach enables the heat exchanger to be adapted to various applications and capacity requirements without significant redesign.

- Integration of advanced materials: The use of advanced materials, such as high-performance alloys, composites, or coatings, is explored to improve corrosion resistance, thermal conductivity, and overall performance of plate heat exchangers in demanding environments.

- Smart monitoring and control systems: Integration of sensors, IoT technologies, and advanced control systems to enable real-time monitoring, predictive maintenance, and optimization of plate heat exchanger performance. These systems can adjust operating parameters based on changing conditions and detect potential issues before they become critical.

02 Novel materials for plate heat exchangers

Research is ongoing into new materials for plate heat exchanger construction. These materials aim to improve corrosion resistance, thermal conductivity, and overall durability. Composite materials, advanced alloys, and surface treatments are being explored to extend the lifespan of heat exchangers and enhance their performance in various industrial applications.Expand Specific Solutions03 Modular and customizable plate heat exchanger designs

Manufacturers are developing modular plate heat exchanger systems that can be easily customized and scaled for different applications. These designs allow for quick assembly, disassembly, and reconfiguration, making maintenance and capacity adjustments more efficient. The modular approach also enables better optimization for specific heat transfer requirements in various industries.Expand Specific Solutions04 Integration of smart technologies in plate heat exchangers

The incorporation of smart technologies and sensors into plate heat exchangers is becoming more prevalent. These innovations allow for real-time monitoring of performance, predictive maintenance, and automatic adjustments to optimize efficiency. Advanced control systems and data analytics are being used to improve overall system management and energy efficiency.Expand Specific Solutions05 Eco-friendly and energy-efficient plate heat exchanger solutions

There is a growing focus on developing plate heat exchangers that are more environmentally friendly and energy-efficient. This includes designs that minimize material usage, reduce energy consumption during operation, and facilitate the use of renewable energy sources. Innovations in this area also aim to improve heat recovery and reduce the overall carbon footprint of industrial processes.Expand Specific Solutions

Key Players in FMS PHE Industry

The research on plate heat exchangers in flexible manufacturing systems is currently in a growth phase, with increasing market demand driven by the need for energy-efficient solutions. The global market size for plate heat exchangers is expanding, particularly in industries such as HVAC, chemical processing, and food and beverage. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and adaptability. Key players like Alfa Laval, Danfoss, and Vahterus are leading the development of advanced plate heat exchanger technologies, while companies such as LG Electronics and BYD are integrating these systems into their manufacturing processes. The competitive landscape is characterized by a mix of established multinational corporations and specialized heat exchanger manufacturers, with increasing emphasis on customization and smart, connected solutions.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers for flexible manufacturing systems, focusing on optimizing heat transfer efficiency and reducing energy consumption. Their technology incorporates innovative plate designs with enhanced turbulence promoters, which increase heat transfer coefficients by up to 25% compared to conventional designs[1]. The company has also implemented a modular approach, allowing for easy scalability and customization to meet specific process requirements. Their latest models feature a patented distribution system that ensures uniform flow distribution across the entire plate surface, minimizing fouling and improving overall performance[2]. Additionally, Alfa Laval has integrated smart sensors and IoT connectivity into their plate heat exchangers, enabling real-time monitoring and predictive maintenance capabilities[3].

Strengths: Industry-leading heat transfer efficiency, modular design for flexibility, advanced fouling mitigation, and smart monitoring capabilities. Weaknesses: Higher initial cost compared to traditional heat exchangers, may require specialized maintenance.

Danfoss A/S

Technical Solution: Danfoss has developed micro plate heat exchangers specifically tailored for flexible manufacturing systems, focusing on maximizing efficiency in compact spaces. Their technology utilizes a unique fishbone pattern on the plates, which creates controlled turbulence and improves heat transfer by up to 10% compared to traditional chevron patterns[6]. Danfoss has also implemented an innovative distribution system that ensures even flow across the entire plate surface, reducing dead zones and improving overall efficiency. The company's latest models incorporate a modular design that allows for easy expansion and adaptation to changing process requirements. Additionally, Danfoss has developed advanced brazing techniques that enable the use of thinner plates, further reducing material costs and improving heat transfer rates[7]. Their heat exchangers also feature integrated control systems that optimize performance based on real-time process conditions.

Strengths: Highly compact design, excellent efficiency in small-scale applications, modular and adaptable configuration, integrated control systems. Weaknesses: Limited capacity for very large-scale operations, may have higher per-unit costs for smaller production runs.

Core PHE Innovations for FMS

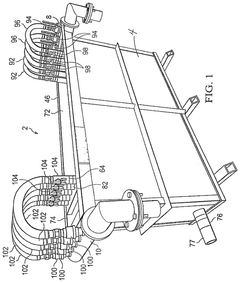

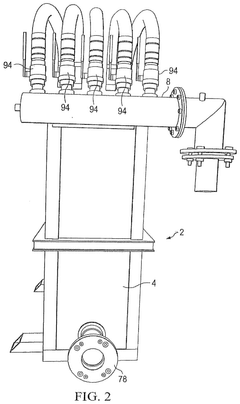

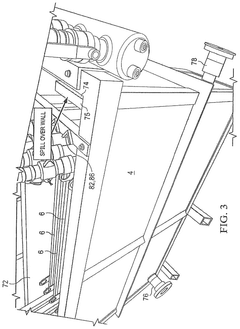

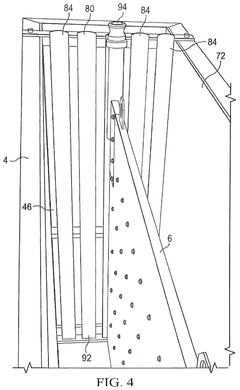

Heat exchanger, plate element therefor, and method of construction

PatentPendingUS20250116468A1

Innovation

- The improved plate heat exchanger system features individually removable heat exchanging plate elements with a modular configuration, providing high resistance to water hammer without welding, and allowing the use of water of any quality, including seawater.

Plate heat exchanger

PatentActiveEP2452149A2

Innovation

- The plate heat exchanger is constructed using plastic plates with connections on the front and end panels, allowing for simple assembly and production by gluing or welding, eliminating the need for seals and enabling the use of disposable units. The plates are designed to be structurally identical and can be produced using a single mold, with flow converters and a collecting space for condensate management, and are made from sterilizable materials for easy sterilization.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the implementation of plate heat exchangers within flexible manufacturing systems. These systems, characterized by their adaptability to changing production requirements, demand optimal energy utilization to maintain cost-effectiveness and sustainability. Plate heat exchangers play a pivotal role in this context, offering superior heat transfer capabilities and compact design that contribute to overall system efficiency.

The energy efficiency of plate heat exchangers in flexible manufacturing systems can be evaluated through several key parameters. Heat transfer coefficient is a primary factor, with plate heat exchangers typically achieving higher values compared to traditional shell-and-tube designs. This enhanced heat transfer capability translates to reduced energy consumption for the same heating or cooling load. Additionally, the lower fluid inventory in plate heat exchangers results in quicker response times to temperature changes, further contributing to energy savings in dynamic manufacturing environments.

Pressure drop across the exchanger is another crucial aspect affecting energy efficiency. While plate heat exchangers generally exhibit higher pressure drops than shell-and-tube counterparts, advanced plate designs and optimized flow distributions can mitigate this issue. Manufacturers are continually developing innovative plate geometries and channel configurations to balance heat transfer performance with minimized pressure losses, thereby reducing pumping power requirements and associated energy consumption.

Fouling resistance is a significant concern in maintaining long-term energy efficiency. Plate heat exchangers, with their turbulent flow characteristics and smooth plate surfaces, typically demonstrate lower fouling tendencies compared to other heat exchanger types. This attribute not only preserves heat transfer efficiency over time but also reduces the frequency of cleaning operations, which often require system downtime and energy-intensive cleaning processes.

The modular nature of plate heat exchangers aligns well with the flexibility demands of modern manufacturing systems. This modularity allows for easy capacity adjustment by adding or removing plates, enabling manufacturers to optimize energy usage based on varying production loads. Furthermore, the ability to implement multi-pass arrangements within a single unit facilitates temperature cross and approach optimization, maximizing thermodynamic efficiency across diverse operating conditions.

In the context of flexible manufacturing, the integration of plate heat exchangers with advanced control systems presents significant opportunities for energy optimization. Real-time monitoring of heat transfer performance, coupled with predictive maintenance algorithms, can ensure that the exchangers operate at peak efficiency throughout their lifecycle. Adaptive control strategies can dynamically adjust flow rates and temperature setpoints in response to changing production demands, further enhancing overall system energy efficiency.

The energy efficiency of plate heat exchangers in flexible manufacturing systems can be evaluated through several key parameters. Heat transfer coefficient is a primary factor, with plate heat exchangers typically achieving higher values compared to traditional shell-and-tube designs. This enhanced heat transfer capability translates to reduced energy consumption for the same heating or cooling load. Additionally, the lower fluid inventory in plate heat exchangers results in quicker response times to temperature changes, further contributing to energy savings in dynamic manufacturing environments.

Pressure drop across the exchanger is another crucial aspect affecting energy efficiency. While plate heat exchangers generally exhibit higher pressure drops than shell-and-tube counterparts, advanced plate designs and optimized flow distributions can mitigate this issue. Manufacturers are continually developing innovative plate geometries and channel configurations to balance heat transfer performance with minimized pressure losses, thereby reducing pumping power requirements and associated energy consumption.

Fouling resistance is a significant concern in maintaining long-term energy efficiency. Plate heat exchangers, with their turbulent flow characteristics and smooth plate surfaces, typically demonstrate lower fouling tendencies compared to other heat exchanger types. This attribute not only preserves heat transfer efficiency over time but also reduces the frequency of cleaning operations, which often require system downtime and energy-intensive cleaning processes.

The modular nature of plate heat exchangers aligns well with the flexibility demands of modern manufacturing systems. This modularity allows for easy capacity adjustment by adding or removing plates, enabling manufacturers to optimize energy usage based on varying production loads. Furthermore, the ability to implement multi-pass arrangements within a single unit facilitates temperature cross and approach optimization, maximizing thermodynamic efficiency across diverse operating conditions.

In the context of flexible manufacturing, the integration of plate heat exchangers with advanced control systems presents significant opportunities for energy optimization. Real-time monitoring of heat transfer performance, coupled with predictive maintenance algorithms, can ensure that the exchangers operate at peak efficiency throughout their lifecycle. Adaptive control strategies can dynamically adjust flow rates and temperature setpoints in response to changing production demands, further enhancing overall system energy efficiency.

PHE Integration with Industry 4.0

The integration of Plate Heat Exchangers (PHEs) with Industry 4.0 technologies represents a significant advancement in flexible manufacturing systems. This convergence enhances the efficiency, adaptability, and performance of PHEs in industrial processes. Industry 4.0, characterized by smart manufacturing, Internet of Things (IoT), and data analytics, offers numerous opportunities to optimize PHE operations.

One key aspect of this integration is the implementation of smart sensors and IoT devices on PHEs. These sensors continuously monitor critical parameters such as temperature, pressure, flow rates, and fouling levels. The real-time data collected is transmitted to cloud-based platforms or edge computing systems for analysis. This constant monitoring enables predictive maintenance strategies, reducing downtime and extending the operational life of PHEs.

Machine learning algorithms and artificial intelligence play a crucial role in analyzing the vast amounts of data generated by these sensors. These advanced analytics can predict potential issues before they occur, optimize heat transfer efficiency, and suggest adjustments to operating parameters in real-time. This predictive capability allows for proactive maintenance and operational optimization, significantly improving the overall performance of PHEs in flexible manufacturing environments.

Digital twin technology is another Industry 4.0 concept being applied to PHEs. By creating a virtual replica of the physical PHE, engineers can simulate various operating conditions, test different configurations, and optimize designs without the need for physical prototypes. This not only accelerates the development process but also allows for continuous improvement of existing PHE installations.

The integration of PHEs with Industry 4.0 also facilitates enhanced process control and automation. Advanced control systems can automatically adjust PHE parameters based on real-time data and production requirements. This level of automation ensures optimal performance across varying operating conditions, a crucial feature in flexible manufacturing systems where production needs can change rapidly.

Furthermore, the connectivity enabled by Industry 4.0 allows for remote monitoring and control of PHEs. This capability is particularly valuable in large-scale industrial settings or geographically dispersed operations. Engineers can access PHE performance data, conduct diagnostics, and even make adjustments from remote locations, improving operational efficiency and reducing response times to potential issues.

The integration of PHEs with Industry 4.0 technologies also contributes to sustainability efforts in manufacturing. By optimizing heat transfer efficiency and reducing energy consumption, this integration helps in lowering the carbon footprint of industrial processes. Additionally, the improved maintenance and operational strategies extend the lifespan of PHEs, reducing waste and the need for frequent replacements.

One key aspect of this integration is the implementation of smart sensors and IoT devices on PHEs. These sensors continuously monitor critical parameters such as temperature, pressure, flow rates, and fouling levels. The real-time data collected is transmitted to cloud-based platforms or edge computing systems for analysis. This constant monitoring enables predictive maintenance strategies, reducing downtime and extending the operational life of PHEs.

Machine learning algorithms and artificial intelligence play a crucial role in analyzing the vast amounts of data generated by these sensors. These advanced analytics can predict potential issues before they occur, optimize heat transfer efficiency, and suggest adjustments to operating parameters in real-time. This predictive capability allows for proactive maintenance and operational optimization, significantly improving the overall performance of PHEs in flexible manufacturing environments.

Digital twin technology is another Industry 4.0 concept being applied to PHEs. By creating a virtual replica of the physical PHE, engineers can simulate various operating conditions, test different configurations, and optimize designs without the need for physical prototypes. This not only accelerates the development process but also allows for continuous improvement of existing PHE installations.

The integration of PHEs with Industry 4.0 also facilitates enhanced process control and automation. Advanced control systems can automatically adjust PHE parameters based on real-time data and production requirements. This level of automation ensures optimal performance across varying operating conditions, a crucial feature in flexible manufacturing systems where production needs can change rapidly.

Furthermore, the connectivity enabled by Industry 4.0 allows for remote monitoring and control of PHEs. This capability is particularly valuable in large-scale industrial settings or geographically dispersed operations. Engineers can access PHE performance data, conduct diagnostics, and even make adjustments from remote locations, improving operational efficiency and reducing response times to potential issues.

The integration of PHEs with Industry 4.0 technologies also contributes to sustainability efforts in manufacturing. By optimizing heat transfer efficiency and reducing energy consumption, this integration helps in lowering the carbon footprint of industrial processes. Additionally, the improved maintenance and operational strategies extend the lifespan of PHEs, reducing waste and the need for frequent replacements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!