Thermal Stress Impacts on Plate Heat Exchanger Longevity

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stress Challenges

Thermal stress poses significant challenges to the longevity and performance of plate heat exchangers (PHEs). These stresses arise from temperature differentials within the exchanger, causing materials to expand or contract at varying rates. This phenomenon can lead to warping, cracking, and eventual failure of critical components.

One of the primary challenges is the cyclic nature of thermal stress. PHEs often operate in environments with fluctuating temperatures, subjecting them to repeated heating and cooling cycles. This thermal cycling can result in fatigue, weakening the material structure over time and reducing the overall lifespan of the exchanger.

The design of PHEs further complicates the thermal stress issue. The thin plates used to maximize heat transfer efficiency are particularly susceptible to deformation under thermal load. The intricate corrugated patterns on these plates, while beneficial for heat transfer, create stress concentration points that are vulnerable to crack initiation and propagation.

Material selection plays a crucial role in mitigating thermal stress impacts. Different materials exhibit varying coefficients of thermal expansion, which can lead to differential expansion between components. This mismatch can cause severe stress at joints and interfaces, potentially compromising the integrity of gaskets and seals.

Corrosion is another factor that exacerbates thermal stress challenges. High temperatures can accelerate corrosion processes, weakening the material and making it more susceptible to stress-induced damage. The combination of thermal stress and corrosion can significantly reduce the operational life of PHEs, particularly in aggressive chemical environments.

The distribution of thermal stress across the exchanger is often non-uniform, leading to localized areas of high stress. These hotspots can become initiation points for failure, even when the overall stress levels appear manageable. Identifying and addressing these critical areas presents a significant challenge in PHE design and maintenance.

Thermal shock, caused by rapid temperature changes, is a particularly severe form of thermal stress. It can lead to immediate and catastrophic failure of PHE components. Preventing and managing thermal shock events requires careful control of operating conditions and robust design considerations.

As PHEs are scaled up for industrial applications, the challenges associated with thermal stress become more pronounced. Larger plate sizes and higher operating pressures amplify the effects of thermal expansion and contraction, necessitating more complex stress management strategies.

One of the primary challenges is the cyclic nature of thermal stress. PHEs often operate in environments with fluctuating temperatures, subjecting them to repeated heating and cooling cycles. This thermal cycling can result in fatigue, weakening the material structure over time and reducing the overall lifespan of the exchanger.

The design of PHEs further complicates the thermal stress issue. The thin plates used to maximize heat transfer efficiency are particularly susceptible to deformation under thermal load. The intricate corrugated patterns on these plates, while beneficial for heat transfer, create stress concentration points that are vulnerable to crack initiation and propagation.

Material selection plays a crucial role in mitigating thermal stress impacts. Different materials exhibit varying coefficients of thermal expansion, which can lead to differential expansion between components. This mismatch can cause severe stress at joints and interfaces, potentially compromising the integrity of gaskets and seals.

Corrosion is another factor that exacerbates thermal stress challenges. High temperatures can accelerate corrosion processes, weakening the material and making it more susceptible to stress-induced damage. The combination of thermal stress and corrosion can significantly reduce the operational life of PHEs, particularly in aggressive chemical environments.

The distribution of thermal stress across the exchanger is often non-uniform, leading to localized areas of high stress. These hotspots can become initiation points for failure, even when the overall stress levels appear manageable. Identifying and addressing these critical areas presents a significant challenge in PHE design and maintenance.

Thermal shock, caused by rapid temperature changes, is a particularly severe form of thermal stress. It can lead to immediate and catastrophic failure of PHE components. Preventing and managing thermal shock events requires careful control of operating conditions and robust design considerations.

As PHEs are scaled up for industrial applications, the challenges associated with thermal stress become more pronounced. Larger plate sizes and higher operating pressures amplify the effects of thermal expansion and contraction, necessitating more complex stress management strategies.

Market Demand Analysis

The market demand for plate heat exchangers (PHEs) has been steadily growing, driven by their efficiency, compact design, and versatility across various industries. The global plate heat exchanger market was valued at $5.5 billion in 2020 and is projected to reach $8.8 billion by 2027, with a compound annual growth rate (CAGR) of 7.2% during this period. This growth is primarily fueled by increasing industrialization, stringent energy efficiency regulations, and the rising demand for sustainable heating and cooling solutions.

The impact of thermal stress on PHE longevity has become a critical concern for end-users, particularly in industries where continuous operation and minimal downtime are essential. As a result, there is a growing demand for PHEs with enhanced thermal stress resistance and longer operational lifespans. This trend is especially prominent in sectors such as chemical processing, oil and gas, food and beverage, and power generation, where PHEs are subjected to extreme temperature fluctuations and high-pressure environments.

In the chemical processing industry, which accounts for approximately 25% of the global PHE market, there is a significant focus on improving the durability of heat exchangers to withstand corrosive fluids and thermal cycling. The oil and gas sector, representing about 20% of the market, demands PHEs capable of handling high-temperature differentials and frequent thermal shocks. These industries are willing to invest in advanced PHE technologies that offer extended service life and reduced maintenance requirements.

The food and beverage industry, contributing to roughly 15% of the global PHE market, is experiencing a surge in demand for PHEs with improved thermal stress resistance. This is driven by the need for stringent hygiene standards and the desire to minimize production interruptions caused by heat exchanger failures. Similarly, the power generation sector, accounting for approximately 10% of the market, requires PHEs that can withstand the severe thermal stresses associated with steam generation and cooling processes.

Market research indicates that end-users are increasingly prioritizing the total cost of ownership over initial investment costs when selecting PHEs. This shift in purchasing behavior has created a market opportunity for manufacturers to develop and promote PHEs with advanced thermal stress management features. Customers are willing to pay a premium of 15-20% for PHEs that demonstrate superior longevity and reduced maintenance needs.

The Asia-Pacific region is expected to witness the highest growth rate in the PHE market, with a CAGR of 8.5% from 2021 to 2027. This growth is attributed to rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe, while showing slower growth rates, are seeing a trend towards replacing older heat exchangers with more efficient and durable models, particularly in retrofit applications.

The impact of thermal stress on PHE longevity has become a critical concern for end-users, particularly in industries where continuous operation and minimal downtime are essential. As a result, there is a growing demand for PHEs with enhanced thermal stress resistance and longer operational lifespans. This trend is especially prominent in sectors such as chemical processing, oil and gas, food and beverage, and power generation, where PHEs are subjected to extreme temperature fluctuations and high-pressure environments.

In the chemical processing industry, which accounts for approximately 25% of the global PHE market, there is a significant focus on improving the durability of heat exchangers to withstand corrosive fluids and thermal cycling. The oil and gas sector, representing about 20% of the market, demands PHEs capable of handling high-temperature differentials and frequent thermal shocks. These industries are willing to invest in advanced PHE technologies that offer extended service life and reduced maintenance requirements.

The food and beverage industry, contributing to roughly 15% of the global PHE market, is experiencing a surge in demand for PHEs with improved thermal stress resistance. This is driven by the need for stringent hygiene standards and the desire to minimize production interruptions caused by heat exchanger failures. Similarly, the power generation sector, accounting for approximately 10% of the market, requires PHEs that can withstand the severe thermal stresses associated with steam generation and cooling processes.

Market research indicates that end-users are increasingly prioritizing the total cost of ownership over initial investment costs when selecting PHEs. This shift in purchasing behavior has created a market opportunity for manufacturers to develop and promote PHEs with advanced thermal stress management features. Customers are willing to pay a premium of 15-20% for PHEs that demonstrate superior longevity and reduced maintenance needs.

The Asia-Pacific region is expected to witness the highest growth rate in the PHE market, with a CAGR of 8.5% from 2021 to 2027. This growth is attributed to rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe, while showing slower growth rates, are seeing a trend towards replacing older heat exchangers with more efficient and durable models, particularly in retrofit applications.

Current Limitations

Plate heat exchangers (PHEs) have become increasingly popular in various industries due to their high efficiency and compact design. However, their longevity is significantly impacted by thermal stress, which presents several current limitations in their application and performance.

One of the primary limitations is the susceptibility of PHEs to thermal fatigue. The repeated cycles of heating and cooling cause expansion and contraction of the plates, leading to stress accumulation over time. This cyclic thermal stress can result in the formation of microcracks, which may propagate and ultimately lead to plate failure. The frequency and magnitude of temperature fluctuations directly correlate with the rate of thermal fatigue, limiting the operational lifespan of PHEs in environments with frequent temperature changes.

Material selection poses another significant challenge in mitigating thermal stress impacts. While materials with high thermal conductivity are desirable for efficient heat transfer, they often have different thermal expansion coefficients compared to the gaskets and frame materials. This mismatch in thermal expansion can lead to warping, distortion, and potential leakage at the plate-gasket interface. Consequently, the choice of materials is often a compromise between thermal efficiency and stress resistance, limiting the overall performance and durability of PHEs.

The design of plate geometry and flow distribution also faces limitations in managing thermal stress. Current plate designs struggle to achieve uniform temperature distribution across the entire plate surface, resulting in localized hot spots and cold regions. These temperature gradients induce thermal stress concentrations, which can accelerate material degradation and reduce the exchanger's lifespan. Additionally, flow maldistribution can exacerbate these thermal gradients, further complicating the management of thermal stress.

Operational constraints present another set of limitations. PHEs are often subject to rapid temperature changes during start-up, shutdown, or process fluctuations. These thermal shocks can cause sudden and severe stress on the plates and gaskets, potentially leading to immediate damage or accelerated wear. As a result, operators must carefully manage temperature ramp rates and process conditions, which can limit operational flexibility and efficiency.

Monitoring and predicting thermal stress impacts also pose significant challenges. Current non-destructive testing methods have limitations in detecting early-stage thermal fatigue and stress accumulation in PHEs. This makes it difficult to accurately assess the remaining lifespan of the exchanger and optimize maintenance schedules. Furthermore, predictive models for thermal stress behavior in complex PHE geometries are still evolving, limiting the ability to design and operate these systems for maximum longevity under varying thermal conditions.

One of the primary limitations is the susceptibility of PHEs to thermal fatigue. The repeated cycles of heating and cooling cause expansion and contraction of the plates, leading to stress accumulation over time. This cyclic thermal stress can result in the formation of microcracks, which may propagate and ultimately lead to plate failure. The frequency and magnitude of temperature fluctuations directly correlate with the rate of thermal fatigue, limiting the operational lifespan of PHEs in environments with frequent temperature changes.

Material selection poses another significant challenge in mitigating thermal stress impacts. While materials with high thermal conductivity are desirable for efficient heat transfer, they often have different thermal expansion coefficients compared to the gaskets and frame materials. This mismatch in thermal expansion can lead to warping, distortion, and potential leakage at the plate-gasket interface. Consequently, the choice of materials is often a compromise between thermal efficiency and stress resistance, limiting the overall performance and durability of PHEs.

The design of plate geometry and flow distribution also faces limitations in managing thermal stress. Current plate designs struggle to achieve uniform temperature distribution across the entire plate surface, resulting in localized hot spots and cold regions. These temperature gradients induce thermal stress concentrations, which can accelerate material degradation and reduce the exchanger's lifespan. Additionally, flow maldistribution can exacerbate these thermal gradients, further complicating the management of thermal stress.

Operational constraints present another set of limitations. PHEs are often subject to rapid temperature changes during start-up, shutdown, or process fluctuations. These thermal shocks can cause sudden and severe stress on the plates and gaskets, potentially leading to immediate damage or accelerated wear. As a result, operators must carefully manage temperature ramp rates and process conditions, which can limit operational flexibility and efficiency.

Monitoring and predicting thermal stress impacts also pose significant challenges. Current non-destructive testing methods have limitations in detecting early-stage thermal fatigue and stress accumulation in PHEs. This makes it difficult to accurately assess the remaining lifespan of the exchanger and optimize maintenance schedules. Furthermore, predictive models for thermal stress behavior in complex PHE geometries are still evolving, limiting the ability to design and operate these systems for maximum longevity under varying thermal conditions.

Existing Solutions

01 Corrosion-resistant materials and coatings

Using corrosion-resistant materials or applying protective coatings to plate heat exchanger components can significantly extend their lifespan. This approach helps prevent degradation caused by aggressive fluids or harsh operating conditions, maintaining the exchanger's efficiency and structural integrity over time.- Corrosion-resistant materials and coatings: Using corrosion-resistant materials or applying protective coatings to plate heat exchanger components can significantly extend their lifespan. This approach helps prevent degradation caused by aggressive fluids or environments, maintaining the exchanger's efficiency and structural integrity over time.

- Optimized plate design and configuration: Improving the design and configuration of heat exchanger plates can enhance longevity. This includes optimizing plate geometry, flow distribution, and thermal performance to reduce stress on components and minimize fouling, thereby extending the operational life of the exchanger.

- Advanced sealing and gasket technologies: Implementing advanced sealing and gasket technologies can prevent leaks and improve the overall durability of plate heat exchangers. This includes using high-performance materials and innovative designs that can withstand thermal cycling and chemical exposure, ensuring a longer-lasting seal between plates.

- Intelligent monitoring and maintenance systems: Incorporating intelligent monitoring and maintenance systems can help detect and address issues before they lead to significant damage. These systems may include sensors, predictive algorithms, and automated cleaning mechanisms that optimize performance and extend the operational life of plate heat exchangers.

- Enhanced fouling mitigation techniques: Developing and implementing advanced fouling mitigation techniques can significantly improve the longevity of plate heat exchangers. This may involve surface modifications, novel cleaning methods, or the use of anti-fouling additives to reduce deposit formation and maintain heat transfer efficiency over extended periods.

02 Optimized plate design and configuration

Improving the design and configuration of heat exchanger plates can enhance longevity. This includes optimizing plate geometry, flow patterns, and distribution to reduce wear, fouling, and thermal stress. Such designs can improve heat transfer efficiency while minimizing areas prone to degradation.Expand Specific Solutions03 Advanced sealing and gasket technologies

Implementing advanced sealing and gasket technologies can prevent leaks and extend the operational life of plate heat exchangers. This includes using high-performance materials and innovative designs that can withstand temperature fluctuations, pressure changes, and chemical exposure more effectively.Expand Specific Solutions04 Intelligent monitoring and maintenance systems

Incorporating intelligent monitoring and maintenance systems can help detect potential issues early and optimize maintenance schedules. These systems can track performance parameters, predict failures, and suggest preventive measures, thereby extending the overall lifespan of the heat exchanger.Expand Specific Solutions05 Enhanced cleaning and fouling mitigation techniques

Developing and implementing enhanced cleaning methods and fouling mitigation techniques can significantly improve the longevity of plate heat exchangers. This includes innovative cleaning-in-place (CIP) systems, anti-fouling surface treatments, and optimized flow designs that reduce deposit accumulation and maintain heat transfer efficiency over time.Expand Specific Solutions

Key Industry Players

The thermal stress impact on plate heat exchanger longevity is a critical issue in an evolving industry. The market is in a growth phase, driven by increasing demand for efficient heat transfer solutions across various sectors. The global plate heat exchanger market size is projected to expand significantly, with key players like Alfa Laval, Valeo, and Behr GmbH & Co. KG leading technological advancements. These companies are investing heavily in R&D to improve thermal stress resistance and extend exchanger lifespan. The technology is maturing, with innovations focusing on materials, design optimization, and predictive maintenance. Emerging players like LHE Co., Ltd. and Hanon Systems are also contributing to the competitive landscape, pushing for more durable and efficient solutions.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchanger designs to mitigate thermal stress impacts. Their AlfaNova fusion-bonded plate heat exchangers use a patented fusion bonding technology that creates a homogeneous joint between plates, reducing thermal stress concentrations[1]. They have also implemented computational fluid dynamics (CFD) simulations to optimize flow distribution and minimize temperature gradients across plates[2]. Additionally, Alfa Laval's DynaStab technology actively compensates for thermal expansion, maintaining optimal plate alignment and sealing under varying temperature conditions[3].

Strengths: Superior thermal stress resistance, innovative bonding technology, and active thermal compensation. Weaknesses: Higher initial cost and potential complexity in maintenance compared to traditional designs.

Packinox SA

Technical Solution: Packinox, now part of Alfa Laval, specializes in large-scale plate heat exchangers for high-temperature applications. Their approach to thermal stress management involves using proprietary plate corrugation patterns that promote uniform flow distribution and heat transfer[4]. Packinox employs a multi-pass design that reduces thermal gradients across the exchanger, minimizing localized stress points[5]. They also utilize advanced materials such as high-grade stainless steels and exotic alloys that offer superior thermal fatigue resistance[6].

Strengths: Expertise in high-temperature applications, advanced plate designs for stress reduction. Weaknesses: Limited to large-scale industrial applications, potentially higher material costs.

Core Innovations

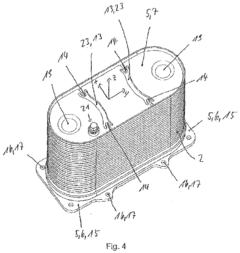

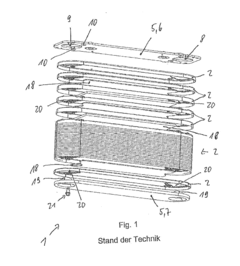

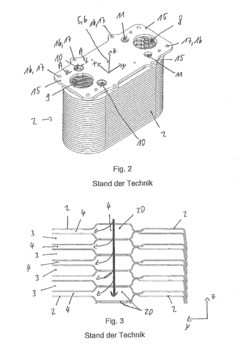

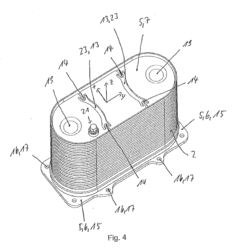

Plate Heat exchanger for high exposure from thermal cycling

PatentInactiveEP2236969A2

Innovation

- The heat exchanger design incorporates end plates with recesses to reduce rigidity and mass, aligning with the disks' geometry, and optionally includes reinforcing disks to minimize the jump in rigidity between end plates and disks, thereby reducing stress and extending service life.

Heat exchanger comprising means for mitigating variations in temperature

PatentInactiveEP3465044A1

Innovation

- Incorporating a heat storage means with phase change materials (PCMs) in the heat exchanger, housed within a conductive casing, to absorb and release heat, thereby damping temperature variations and reducing mechanical stress on the plates.

Material Advancements

Material advancements play a crucial role in mitigating thermal stress impacts on plate heat exchanger longevity. Recent developments in material science have led to significant improvements in the durability and performance of plate heat exchangers under extreme temperature conditions.

One of the most promising advancements is the development of high-performance alloys specifically designed for heat exchanger applications. These alloys, such as advanced stainless steels and nickel-based superalloys, offer superior resistance to thermal fatigue and corrosion. They exhibit enhanced mechanical properties at elevated temperatures, reducing the risk of plate deformation and cracking due to thermal stress.

Composite materials have also emerged as a potential solution to thermal stress-related issues in plate heat exchangers. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are being explored for their excellent thermal stability and low thermal expansion coefficients. These materials can help maintain the structural integrity of heat exchanger plates even under severe temperature fluctuations.

Surface engineering techniques have made significant strides in improving the thermal stress resistance of plate heat exchangers. Advanced coatings, such as thermal barrier coatings (TBCs) and nanostructured coatings, can be applied to the plate surfaces to enhance their thermal insulation properties and reduce the impact of thermal gradients.

Researchers are also investigating the potential of functionally graded materials (FGMs) in plate heat exchanger design. FGMs offer a gradual transition in material properties across the thickness of the plate, allowing for better distribution of thermal stresses and improved overall performance.

Additive manufacturing technologies have opened up new possibilities for creating complex geometries and internal structures in heat exchanger plates. This enables the design of optimized flow channels and heat transfer surfaces that can better accommodate thermal expansion and contraction, reducing the overall thermal stress on the system.

Smart materials, such as shape memory alloys and piezoelectric materials, are being explored for their potential to actively respond to thermal stress. These materials could potentially be integrated into plate heat exchanger designs to provide real-time adjustments and mitigate the effects of thermal cycling.

As material science continues to advance, the development of novel nanomaterials and metamaterials holds promise for further improvements in thermal stress management. These materials could potentially offer unprecedented combinations of thermal conductivity, mechanical strength, and thermal expansion properties, leading to more resilient and efficient plate heat exchangers in the future.

One of the most promising advancements is the development of high-performance alloys specifically designed for heat exchanger applications. These alloys, such as advanced stainless steels and nickel-based superalloys, offer superior resistance to thermal fatigue and corrosion. They exhibit enhanced mechanical properties at elevated temperatures, reducing the risk of plate deformation and cracking due to thermal stress.

Composite materials have also emerged as a potential solution to thermal stress-related issues in plate heat exchangers. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are being explored for their excellent thermal stability and low thermal expansion coefficients. These materials can help maintain the structural integrity of heat exchanger plates even under severe temperature fluctuations.

Surface engineering techniques have made significant strides in improving the thermal stress resistance of plate heat exchangers. Advanced coatings, such as thermal barrier coatings (TBCs) and nanostructured coatings, can be applied to the plate surfaces to enhance their thermal insulation properties and reduce the impact of thermal gradients.

Researchers are also investigating the potential of functionally graded materials (FGMs) in plate heat exchanger design. FGMs offer a gradual transition in material properties across the thickness of the plate, allowing for better distribution of thermal stresses and improved overall performance.

Additive manufacturing technologies have opened up new possibilities for creating complex geometries and internal structures in heat exchanger plates. This enables the design of optimized flow channels and heat transfer surfaces that can better accommodate thermal expansion and contraction, reducing the overall thermal stress on the system.

Smart materials, such as shape memory alloys and piezoelectric materials, are being explored for their potential to actively respond to thermal stress. These materials could potentially be integrated into plate heat exchanger designs to provide real-time adjustments and mitigate the effects of thermal cycling.

As material science continues to advance, the development of novel nanomaterials and metamaterials holds promise for further improvements in thermal stress management. These materials could potentially offer unprecedented combinations of thermal conductivity, mechanical strength, and thermal expansion properties, leading to more resilient and efficient plate heat exchangers in the future.

Simulation Techniques

Simulation techniques play a crucial role in understanding and predicting the thermal stress impacts on plate heat exchanger longevity. These advanced computational methods allow engineers and researchers to model complex thermal and mechanical interactions within the heat exchanger without the need for extensive physical testing.

Finite Element Analysis (FEA) is one of the most widely used simulation techniques in this field. It involves dividing the heat exchanger geometry into small elements and solving equations for each element to determine stress distribution, deformation, and temperature gradients. FEA software packages such as ANSYS, COMSOL, and Abaqus are commonly employed to perform these simulations, offering detailed insights into the thermal stress behavior of plate heat exchangers under various operating conditions.

Computational Fluid Dynamics (CFD) is another powerful simulation tool used in conjunction with FEA. CFD simulations help in analyzing fluid flow patterns, heat transfer rates, and pressure distributions within the heat exchanger. By coupling CFD with FEA, researchers can obtain a more comprehensive understanding of how fluid dynamics influence thermal stresses and overall exchanger performance.

Multi-physics simulations have gained prominence in recent years, allowing for the simultaneous analysis of thermal, structural, and fluid dynamics aspects. These simulations provide a holistic view of the heat exchanger's behavior, accounting for complex interactions between different physical phenomena. Software platforms like COMSOL Multiphysics and ANSYS Workbench offer integrated environments for such multi-physics simulations.

Thermal fatigue analysis is a specialized simulation technique focused on predicting the long-term effects of cyclic thermal stresses on plate heat exchangers. These simulations typically involve time-dependent studies that model the accumulation of damage over numerous thermal cycles, helping to estimate the exchanger's lifespan and identify potential failure points.

Machine learning and artificial intelligence are emerging as powerful tools in heat exchanger simulation. These techniques can be used to optimize simulation parameters, predict long-term performance based on short-term data, and even generate surrogate models that can rapidly approximate complex simulations for real-time decision-making.

Virtual reality (VR) and augmented reality (AR) technologies are being integrated with simulation results to provide immersive visualization of thermal stress patterns. This allows engineers to interact with simulation data in three-dimensional space, gaining new insights and facilitating more intuitive design improvements.

As simulation techniques continue to advance, their accuracy and predictive capabilities are improving. However, it remains crucial to validate simulation results against experimental data to ensure reliability. The integration of real-world sensor data with simulation models is an area of ongoing research, aiming to create digital twins that can provide real-time insights into heat exchanger performance and thermal stress impacts.

Finite Element Analysis (FEA) is one of the most widely used simulation techniques in this field. It involves dividing the heat exchanger geometry into small elements and solving equations for each element to determine stress distribution, deformation, and temperature gradients. FEA software packages such as ANSYS, COMSOL, and Abaqus are commonly employed to perform these simulations, offering detailed insights into the thermal stress behavior of plate heat exchangers under various operating conditions.

Computational Fluid Dynamics (CFD) is another powerful simulation tool used in conjunction with FEA. CFD simulations help in analyzing fluid flow patterns, heat transfer rates, and pressure distributions within the heat exchanger. By coupling CFD with FEA, researchers can obtain a more comprehensive understanding of how fluid dynamics influence thermal stresses and overall exchanger performance.

Multi-physics simulations have gained prominence in recent years, allowing for the simultaneous analysis of thermal, structural, and fluid dynamics aspects. These simulations provide a holistic view of the heat exchanger's behavior, accounting for complex interactions between different physical phenomena. Software platforms like COMSOL Multiphysics and ANSYS Workbench offer integrated environments for such multi-physics simulations.

Thermal fatigue analysis is a specialized simulation technique focused on predicting the long-term effects of cyclic thermal stresses on plate heat exchangers. These simulations typically involve time-dependent studies that model the accumulation of damage over numerous thermal cycles, helping to estimate the exchanger's lifespan and identify potential failure points.

Machine learning and artificial intelligence are emerging as powerful tools in heat exchanger simulation. These techniques can be used to optimize simulation parameters, predict long-term performance based on short-term data, and even generate surrogate models that can rapidly approximate complex simulations for real-time decision-making.

Virtual reality (VR) and augmented reality (AR) technologies are being integrated with simulation results to provide immersive visualization of thermal stress patterns. This allows engineers to interact with simulation data in three-dimensional space, gaining new insights and facilitating more intuitive design improvements.

As simulation techniques continue to advance, their accuracy and predictive capabilities are improving. However, it remains crucial to validate simulation results against experimental data to ensure reliability. The integration of real-world sensor data with simulation models is an area of ongoing research, aiming to create digital twins that can provide real-time insights into heat exchanger performance and thermal stress impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!