Predictive Maintenance Technologies for Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Maintenance Evolution

The evolution of maintenance strategies for Plate Heat Exchangers (PHEs) has undergone significant transformations over the years, driven by technological advancements and the increasing demand for operational efficiency. Initially, PHE maintenance relied heavily on reactive approaches, where repairs were conducted only after failures occurred. This method often resulted in unexpected downtime and increased operational costs.

As industrial processes became more complex and the importance of continuous operation grew, preventive maintenance strategies emerged. These approaches involved scheduled inspections and component replacements based on predetermined time intervals or usage metrics. While this method helped reduce unexpected failures, it often led to unnecessary maintenance activities and potential over-servicing of equipment.

The advent of sensor technologies and data analytics in the late 20th century paved the way for condition-based maintenance. This approach utilized real-time monitoring of PHE performance parameters, such as pressure drop, temperature differences, and flow rates, to detect early signs of degradation. By analyzing these indicators, maintenance teams could more accurately predict when interventions were necessary, optimizing resource allocation and minimizing unnecessary downtime.

The latest evolution in PHE maintenance is the shift towards predictive maintenance technologies. This approach leverages advanced analytics, machine learning algorithms, and Internet of Things (IoT) connectivity to forecast potential failures with unprecedented accuracy. By integrating historical performance data, operational conditions, and external factors, predictive maintenance systems can identify subtle patterns and anomalies that may indicate impending issues.

These predictive technologies enable a proactive maintenance strategy, where interventions are planned and executed before failures occur. This approach not only minimizes unplanned downtime but also extends the operational life of PHEs by addressing potential problems at their earliest stages. Furthermore, it allows for more efficient resource allocation, as maintenance activities can be scheduled during planned production lulls or coordinated with other operational activities.

The ongoing development of artificial intelligence and edge computing is further enhancing the capabilities of predictive maintenance systems for PHEs. These advancements are enabling real-time analysis of vast amounts of data, leading to more accurate predictions and faster response times. As these technologies continue to evolve, the future of PHE maintenance is likely to see even more sophisticated, autonomous systems capable of self-diagnosis and potentially self-healing mechanisms.

As industrial processes became more complex and the importance of continuous operation grew, preventive maintenance strategies emerged. These approaches involved scheduled inspections and component replacements based on predetermined time intervals or usage metrics. While this method helped reduce unexpected failures, it often led to unnecessary maintenance activities and potential over-servicing of equipment.

The advent of sensor technologies and data analytics in the late 20th century paved the way for condition-based maintenance. This approach utilized real-time monitoring of PHE performance parameters, such as pressure drop, temperature differences, and flow rates, to detect early signs of degradation. By analyzing these indicators, maintenance teams could more accurately predict when interventions were necessary, optimizing resource allocation and minimizing unnecessary downtime.

The latest evolution in PHE maintenance is the shift towards predictive maintenance technologies. This approach leverages advanced analytics, machine learning algorithms, and Internet of Things (IoT) connectivity to forecast potential failures with unprecedented accuracy. By integrating historical performance data, operational conditions, and external factors, predictive maintenance systems can identify subtle patterns and anomalies that may indicate impending issues.

These predictive technologies enable a proactive maintenance strategy, where interventions are planned and executed before failures occur. This approach not only minimizes unplanned downtime but also extends the operational life of PHEs by addressing potential problems at their earliest stages. Furthermore, it allows for more efficient resource allocation, as maintenance activities can be scheduled during planned production lulls or coordinated with other operational activities.

The ongoing development of artificial intelligence and edge computing is further enhancing the capabilities of predictive maintenance systems for PHEs. These advancements are enabling real-time analysis of vast amounts of data, leading to more accurate predictions and faster response times. As these technologies continue to evolve, the future of PHE maintenance is likely to see even more sophisticated, autonomous systems capable of self-diagnosis and potentially self-healing mechanisms.

Market Demand Analysis

The market demand for predictive maintenance technologies in plate heat exchangers has been steadily increasing due to the growing emphasis on operational efficiency and cost reduction across various industries. As plate heat exchangers are critical components in many industrial processes, their optimal performance and longevity are paramount to maintaining productivity and minimizing downtime.

The global plate heat exchanger market is projected to experience significant growth in the coming years, driven by the expansion of industries such as chemical processing, food and beverage, HVAC, and power generation. This growth directly correlates with the increasing demand for predictive maintenance solutions tailored to these systems.

One of the primary factors fueling the market demand is the potential for substantial cost savings. Predictive maintenance technologies can significantly reduce unplanned downtime, which is estimated to cost industrial manufacturers billions of dollars annually. By implementing these technologies, companies can optimize their maintenance schedules, extend equipment lifespan, and improve overall operational efficiency.

The rising adoption of Industry 4.0 and IoT technologies has also contributed to the growing demand for predictive maintenance solutions in plate heat exchangers. These technologies enable real-time monitoring, data collection, and analysis, providing valuable insights into equipment performance and potential issues before they escalate into costly failures.

Environmental regulations and sustainability initiatives have further boosted the market demand for predictive maintenance technologies. By optimizing the performance of plate heat exchangers, companies can reduce energy consumption and minimize their carbon footprint, aligning with global efforts to combat climate change.

The COVID-19 pandemic has accelerated the adoption of remote monitoring and predictive maintenance solutions, as companies seek to reduce on-site personnel and maintain operations with minimal human intervention. This trend is expected to continue, driving further growth in the market for predictive maintenance technologies.

As industries increasingly recognize the value of data-driven decision-making, the demand for advanced analytics and machine learning capabilities in predictive maintenance solutions is on the rise. These technologies offer more accurate predictions, better fault detection, and improved maintenance planning for plate heat exchangers.

The market demand is also influenced by the growing complexity of industrial processes and the need for more sophisticated maintenance approaches. Traditional reactive or scheduled maintenance strategies are becoming less effective in meeting the demands of modern industrial operations, pushing companies to adopt predictive maintenance technologies for their plate heat exchangers.

The global plate heat exchanger market is projected to experience significant growth in the coming years, driven by the expansion of industries such as chemical processing, food and beverage, HVAC, and power generation. This growth directly correlates with the increasing demand for predictive maintenance solutions tailored to these systems.

One of the primary factors fueling the market demand is the potential for substantial cost savings. Predictive maintenance technologies can significantly reduce unplanned downtime, which is estimated to cost industrial manufacturers billions of dollars annually. By implementing these technologies, companies can optimize their maintenance schedules, extend equipment lifespan, and improve overall operational efficiency.

The rising adoption of Industry 4.0 and IoT technologies has also contributed to the growing demand for predictive maintenance solutions in plate heat exchangers. These technologies enable real-time monitoring, data collection, and analysis, providing valuable insights into equipment performance and potential issues before they escalate into costly failures.

Environmental regulations and sustainability initiatives have further boosted the market demand for predictive maintenance technologies. By optimizing the performance of plate heat exchangers, companies can reduce energy consumption and minimize their carbon footprint, aligning with global efforts to combat climate change.

The COVID-19 pandemic has accelerated the adoption of remote monitoring and predictive maintenance solutions, as companies seek to reduce on-site personnel and maintain operations with minimal human intervention. This trend is expected to continue, driving further growth in the market for predictive maintenance technologies.

As industries increasingly recognize the value of data-driven decision-making, the demand for advanced analytics and machine learning capabilities in predictive maintenance solutions is on the rise. These technologies offer more accurate predictions, better fault detection, and improved maintenance planning for plate heat exchangers.

The market demand is also influenced by the growing complexity of industrial processes and the need for more sophisticated maintenance approaches. Traditional reactive or scheduled maintenance strategies are becoming less effective in meeting the demands of modern industrial operations, pushing companies to adopt predictive maintenance technologies for their plate heat exchangers.

Current Tech Challenges

Predictive maintenance technologies for plate heat exchangers face several significant challenges in their current state of development and implementation. One of the primary obstacles is the complexity of data acquisition and interpretation. Plate heat exchangers operate in diverse industrial environments, each with unique conditions that affect their performance and degradation patterns. This variability makes it difficult to establish standardized data collection protocols and develop universally applicable predictive models.

The integration of sensors and monitoring systems into existing plate heat exchanger installations presents another hurdle. Many older systems lack the necessary infrastructure to support advanced monitoring technologies, requiring costly retrofits or replacements. Additionally, the harsh operating conditions in some industries, such as chemical processing or oil refineries, can compromise the reliability and longevity of sensitive monitoring equipment.

Data quality and consistency remain persistent issues in the field. The accuracy of predictive maintenance models heavily relies on the quality and quantity of historical data available. However, many organizations struggle with incomplete or inconsistent maintenance records, making it challenging to train robust predictive algorithms. Furthermore, the dynamic nature of industrial processes often leads to changes in operating conditions, which can render historical data less relevant over time.

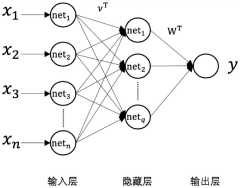

The interpretation of complex sensor data and the development of accurate predictive models pose significant technical challenges. Advanced machine learning and artificial intelligence techniques are required to process and analyze the vast amounts of data generated by modern monitoring systems. However, there is a shortage of skilled professionals who can effectively develop and implement these sophisticated algorithms in industrial settings.

Scalability and interoperability are also major concerns in the adoption of predictive maintenance technologies for plate heat exchangers. Many industrial facilities operate diverse equipment from various manufacturers, each with its own proprietary systems and data formats. Developing solutions that can seamlessly integrate with this heterogeneous landscape while maintaining performance and reliability across different scales of operation remains a significant technical challenge.

Lastly, the cost-benefit analysis of implementing predictive maintenance technologies presents a barrier to widespread adoption. While the long-term benefits of reduced downtime and optimized maintenance schedules are clear, the initial investment in hardware, software, and training can be substantial. Organizations often struggle to justify these upfront costs, particularly in industries with tight profit margins or those facing economic uncertainties.

The integration of sensors and monitoring systems into existing plate heat exchanger installations presents another hurdle. Many older systems lack the necessary infrastructure to support advanced monitoring technologies, requiring costly retrofits or replacements. Additionally, the harsh operating conditions in some industries, such as chemical processing or oil refineries, can compromise the reliability and longevity of sensitive monitoring equipment.

Data quality and consistency remain persistent issues in the field. The accuracy of predictive maintenance models heavily relies on the quality and quantity of historical data available. However, many organizations struggle with incomplete or inconsistent maintenance records, making it challenging to train robust predictive algorithms. Furthermore, the dynamic nature of industrial processes often leads to changes in operating conditions, which can render historical data less relevant over time.

The interpretation of complex sensor data and the development of accurate predictive models pose significant technical challenges. Advanced machine learning and artificial intelligence techniques are required to process and analyze the vast amounts of data generated by modern monitoring systems. However, there is a shortage of skilled professionals who can effectively develop and implement these sophisticated algorithms in industrial settings.

Scalability and interoperability are also major concerns in the adoption of predictive maintenance technologies for plate heat exchangers. Many industrial facilities operate diverse equipment from various manufacturers, each with its own proprietary systems and data formats. Developing solutions that can seamlessly integrate with this heterogeneous landscape while maintaining performance and reliability across different scales of operation remains a significant technical challenge.

Lastly, the cost-benefit analysis of implementing predictive maintenance technologies presents a barrier to widespread adoption. While the long-term benefits of reduced downtime and optimized maintenance schedules are clear, the initial investment in hardware, software, and training can be substantial. Organizations often struggle to justify these upfront costs, particularly in industries with tight profit margins or those facing economic uncertainties.

Existing PM Solutions

01 Cleaning and descaling techniques

Regular cleaning and descaling of plate heat exchangers are essential for maintaining their efficiency. This involves using chemical solutions or mechanical methods to remove deposits, scale, and fouling from the plates. Proper cleaning techniques help restore heat transfer efficiency and prevent corrosion.- Cleaning and descaling techniques: Regular cleaning and descaling of plate heat exchangers are essential for maintaining their efficiency. This involves using chemical solutions or mechanical methods to remove fouling, scale, and other deposits that can accumulate on the plates over time. Proper cleaning techniques help restore heat transfer efficiency and prevent corrosion.

- Plate inspection and replacement: Periodic inspection of heat exchanger plates is crucial for identifying damage, wear, or deformation. Damaged or worn plates should be replaced to maintain the exchanger's performance and prevent leaks. This process may involve disassembling the unit, inspecting individual plates, and replacing them as necessary.

- Gasket maintenance and replacement: Gaskets play a critical role in sealing plate heat exchangers. Regular inspection and replacement of gaskets are necessary to prevent leaks and ensure proper sealing between plates. This maintenance task involves checking for signs of wear, degradation, or damage, and replacing gaskets when needed.

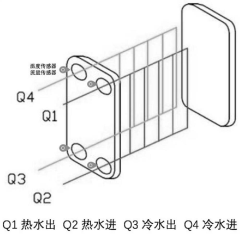

- Monitoring and optimization of operating conditions: Maintaining optimal operating conditions is crucial for the longevity and efficiency of plate heat exchangers. This includes monitoring pressure drops, flow rates, and temperature differentials. Regular adjustments and optimizations based on these parameters can help prevent fouling, improve heat transfer, and extend the equipment's lifespan.

- Preventive maintenance scheduling: Implementing a preventive maintenance schedule is essential for ensuring the long-term reliability of plate heat exchangers. This involves planning regular inspections, cleanings, and performance checks at predetermined intervals. A well-designed maintenance schedule can help identify potential issues before they become critical and minimize downtime.

02 Plate design and materials

Innovations in plate design and materials can improve maintenance efficiency. This includes developing plates with special coatings or surface treatments that resist fouling and corrosion, as well as designs that facilitate easier disassembly and cleaning of the heat exchanger.Expand Specific Solutions03 Monitoring and predictive maintenance

Implementing monitoring systems and predictive maintenance strategies can optimize the maintenance schedule for plate heat exchangers. This involves using sensors, data analysis, and machine learning to detect early signs of performance degradation and schedule maintenance before significant issues arise.Expand Specific Solutions04 Gasket replacement and sealing

Proper maintenance of gaskets and seals is crucial for preventing leaks in plate heat exchangers. This includes regular inspection, timely replacement of worn gaskets, and ensuring proper sealing during reassembly. Innovations in gasket materials and designs can extend the service life and improve sealing performance.Expand Specific Solutions05 Corrosion prevention and treatment

Preventing and treating corrosion is essential for extending the lifespan of plate heat exchangers. This involves selecting appropriate materials for the operating environment, using corrosion inhibitors, and implementing proper water treatment strategies. Regular inspection and early intervention can prevent severe corrosion-related damage.Expand Specific Solutions

Key Industry Players

The predictive maintenance technologies for plate heat exchangers market is in a growth phase, driven by increasing demand for efficient industrial processes and energy conservation. The market size is expanding, with estimates suggesting a compound annual growth rate of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Alfa Laval, SPX FLOW, and Mitsubishi Electric leading innovation. These firms are developing sophisticated sensors, data analytics, and AI-driven solutions to enhance predictive maintenance capabilities. However, the technology's maturity varies across different applications and industries, indicating potential for further development and market penetration.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a predictive maintenance system for plate heat exchangers that leverages their e-F@ctory concept, which integrates factory automation and IT systems. Their approach utilizes edge computing devices to collect and process data from sensors installed on PHEs[2]. The system employs advanced analytics and machine learning algorithms to detect patterns and anomalies in the performance data. Mitsubishi's solution also incorporates their proprietary AI technology, Maisart (Mitsubishi Electric's AI creates the State-of-the-ART in technology), to enhance predictive capabilities and optimize maintenance schedules[4]. The system can predict issues such as fouling, leakage, and performance degradation, allowing for proactive maintenance interventions. Additionally, Mitsubishi Electric has integrated their predictive maintenance solution with their broader industrial IoT platform, enabling seamless data exchange and analysis across multiple plant systems[6].

Strengths: Integration with broader industrial IoT ecosystem; utilization of proprietary AI technology; edge computing capabilities for real-time processing. Weaknesses: Potential vendor lock-in; may require integration with existing Mitsubishi Electric systems for optimal performance.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed an advanced predictive maintenance system for plate heat exchangers (PHEs) that combines real-time monitoring, machine learning algorithms, and digital twin technology. Their solution utilizes sensors to continuously collect data on key parameters such as temperature, pressure, and flow rates. This data is then processed using sophisticated algorithms to detect anomalies and predict potential failures before they occur[1]. The system employs a digital twin model of each PHE, which is updated in real-time based on operational data, allowing for accurate simulations and predictive analysis[3]. Additionally, Alfa Laval has integrated their predictive maintenance technology with cloud-based platforms, enabling remote monitoring and analysis, as well as the ability to provide actionable insights to operators through mobile applications and dashboards[5].

Strengths: Comprehensive solution combining multiple advanced technologies; real-time monitoring and analysis capabilities; integration with cloud platforms for remote access. Weaknesses: May require significant initial investment; potential complexity in implementation and training for operators.

Core PM Innovations

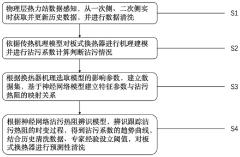

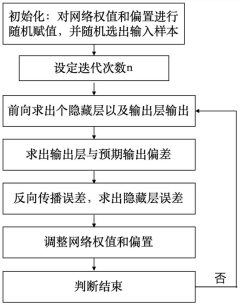

Predictive maintenance method and system for heat exchanger based on machine learning

PatentActiveCN112052564A

Innovation

- Adopt a predictive maintenance method based on machine learning, monitor the operating status through sensors, establish a neural network contamination coefficient identification model, and perform predictive maintenance based on historical data to achieve real-time monitoring and early warning of the contamination of plate heat exchangers and formulate predictions Sexual maintenance program.

A Performance Monitoring and Prediction Method, System, Storage Medium and Electronic Device for a Plate Heat Exchanger

PatentPendingCN120162638A

Innovation

- A performance monitoring and prediction method of plate heat exchangers is adopted. By collecting real-time operation data, equipment status monitoring and performance evaluation are carried out, performance mechanism model and historical data are used for backwash prediction, and status monitoring results, performance evaluation results and performance parameter prediction results are output.

Cost-Benefit Analysis

Implementing predictive maintenance technologies for plate heat exchangers involves a comprehensive cost-benefit analysis to determine the financial viability and long-term advantages of such systems. The initial investment in predictive maintenance technologies can be substantial, including costs for sensors, data acquisition systems, analytics software, and staff training. However, these upfront expenses are often outweighed by the significant benefits realized over time.

One of the primary advantages of predictive maintenance is the reduction in unplanned downtime. By accurately predicting when maintenance is required, companies can schedule repairs during planned shutdowns, minimizing production losses. This can lead to substantial savings, as unexpected failures in plate heat exchangers can result in costly emergency repairs and extended periods of inactivity.

The implementation of predictive maintenance also contributes to extended equipment lifespan. By addressing issues before they escalate, the overall wear and tear on plate heat exchangers is reduced, potentially extending their operational life by several years. This delay in capital expenditure for replacement equipment represents a significant cost saving for organizations.

Energy efficiency improvements are another key benefit of predictive maintenance technologies. Well-maintained plate heat exchangers operate at optimal efficiency, reducing energy consumption and associated costs. Over time, these energy savings can accumulate to substantial amounts, particularly in energy-intensive industries.

Maintenance costs themselves are often reduced through predictive technologies. By moving away from time-based maintenance schedules to condition-based maintenance, unnecessary interventions are eliminated. This not only saves on labor and parts costs but also reduces the risk of introducing faults through over-maintenance.

The improved reliability and performance of plate heat exchangers under predictive maintenance regimes can lead to enhanced product quality and customer satisfaction. While these benefits may be harder to quantify, they can significantly impact a company's reputation and market position, potentially leading to increased sales and market share.

From a risk management perspective, predictive maintenance technologies can help prevent catastrophic failures that could result in safety incidents, environmental damage, or regulatory non-compliance. The cost avoidance associated with these risks can be substantial, including potential fines, legal fees, and reputational damage.

When conducting a cost-benefit analysis, it's crucial to consider the scalability of predictive maintenance solutions. As these technologies are implemented across multiple assets or facilities, the cost per unit often decreases while the benefits compound, improving the overall return on investment.

One of the primary advantages of predictive maintenance is the reduction in unplanned downtime. By accurately predicting when maintenance is required, companies can schedule repairs during planned shutdowns, minimizing production losses. This can lead to substantial savings, as unexpected failures in plate heat exchangers can result in costly emergency repairs and extended periods of inactivity.

The implementation of predictive maintenance also contributes to extended equipment lifespan. By addressing issues before they escalate, the overall wear and tear on plate heat exchangers is reduced, potentially extending their operational life by several years. This delay in capital expenditure for replacement equipment represents a significant cost saving for organizations.

Energy efficiency improvements are another key benefit of predictive maintenance technologies. Well-maintained plate heat exchangers operate at optimal efficiency, reducing energy consumption and associated costs. Over time, these energy savings can accumulate to substantial amounts, particularly in energy-intensive industries.

Maintenance costs themselves are often reduced through predictive technologies. By moving away from time-based maintenance schedules to condition-based maintenance, unnecessary interventions are eliminated. This not only saves on labor and parts costs but also reduces the risk of introducing faults through over-maintenance.

The improved reliability and performance of plate heat exchangers under predictive maintenance regimes can lead to enhanced product quality and customer satisfaction. While these benefits may be harder to quantify, they can significantly impact a company's reputation and market position, potentially leading to increased sales and market share.

From a risk management perspective, predictive maintenance technologies can help prevent catastrophic failures that could result in safety incidents, environmental damage, or regulatory non-compliance. The cost avoidance associated with these risks can be substantial, including potential fines, legal fees, and reputational damage.

When conducting a cost-benefit analysis, it's crucial to consider the scalability of predictive maintenance solutions. As these technologies are implemented across multiple assets or facilities, the cost per unit often decreases while the benefits compound, improving the overall return on investment.

Environmental Impact

The environmental impact of predictive maintenance technologies for plate heat exchangers is a crucial aspect to consider in the broader context of sustainable industrial practices. These technologies contribute significantly to reducing the overall environmental footprint of industrial processes by optimizing the performance and longevity of plate heat exchangers.

One of the primary environmental benefits of predictive maintenance is the reduction in energy consumption. By identifying and addressing potential issues before they escalate, these technologies ensure that plate heat exchangers operate at peak efficiency. This optimization leads to decreased energy requirements, thereby reducing greenhouse gas emissions associated with power generation.

Furthermore, predictive maintenance technologies help extend the lifespan of plate heat exchangers. This extension results in a reduced need for replacement parts and entire units, consequently lowering the demand for raw materials and energy-intensive manufacturing processes. The decreased production of replacement components translates to a reduction in the carbon footprint associated with manufacturing and transportation.

Water conservation is another significant environmental advantage of these technologies. By maintaining optimal performance, plate heat exchangers can operate with improved water efficiency, reducing overall water consumption in industrial processes. This is particularly crucial in water-stressed regions and industries where water usage is a critical environmental concern.

Predictive maintenance also plays a role in minimizing the use of chemical cleaning agents. Traditional maintenance often relies on scheduled chemical cleaning, which can lead to excessive use of potentially harmful substances. Predictive technologies allow for more targeted and less frequent cleaning interventions, reducing the release of chemicals into the environment.

The prevention of sudden failures through predictive maintenance has additional environmental benefits. Unexpected breakdowns can lead to emergency shutdowns, which often result in increased emissions and waste generation during the restart process. By avoiding these incidents, predictive technologies contribute to more stable and environmentally friendly operations.

Moreover, these technologies support the circular economy concept by promoting the reuse and refurbishment of components. Instead of replacing entire units, predictive maintenance allows for the targeted replacement or repair of specific parts, reducing waste and supporting more sustainable resource utilization.

In conclusion, predictive maintenance technologies for plate heat exchangers offer substantial environmental benefits. They contribute to energy efficiency, resource conservation, waste reduction, and overall environmental sustainability in industrial operations. As industries increasingly focus on reducing their environmental impact, these technologies are poised to play a crucial role in achieving sustainability goals while maintaining operational efficiency.

One of the primary environmental benefits of predictive maintenance is the reduction in energy consumption. By identifying and addressing potential issues before they escalate, these technologies ensure that plate heat exchangers operate at peak efficiency. This optimization leads to decreased energy requirements, thereby reducing greenhouse gas emissions associated with power generation.

Furthermore, predictive maintenance technologies help extend the lifespan of plate heat exchangers. This extension results in a reduced need for replacement parts and entire units, consequently lowering the demand for raw materials and energy-intensive manufacturing processes. The decreased production of replacement components translates to a reduction in the carbon footprint associated with manufacturing and transportation.

Water conservation is another significant environmental advantage of these technologies. By maintaining optimal performance, plate heat exchangers can operate with improved water efficiency, reducing overall water consumption in industrial processes. This is particularly crucial in water-stressed regions and industries where water usage is a critical environmental concern.

Predictive maintenance also plays a role in minimizing the use of chemical cleaning agents. Traditional maintenance often relies on scheduled chemical cleaning, which can lead to excessive use of potentially harmful substances. Predictive technologies allow for more targeted and less frequent cleaning interventions, reducing the release of chemicals into the environment.

The prevention of sudden failures through predictive maintenance has additional environmental benefits. Unexpected breakdowns can lead to emergency shutdowns, which often result in increased emissions and waste generation during the restart process. By avoiding these incidents, predictive technologies contribute to more stable and environmentally friendly operations.

Moreover, these technologies support the circular economy concept by promoting the reuse and refurbishment of components. Instead of replacing entire units, predictive maintenance allows for the targeted replacement or repair of specific parts, reducing waste and supporting more sustainable resource utilization.

In conclusion, predictive maintenance technologies for plate heat exchangers offer substantial environmental benefits. They contribute to energy efficiency, resource conservation, waste reduction, and overall environmental sustainability in industrial operations. As industries increasingly focus on reducing their environmental impact, these technologies are poised to play a crucial role in achieving sustainability goals while maintaining operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!