Scaling Mitigation Strategies for Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scaling Challenges in PHEs

Scaling in plate heat exchangers (PHEs) presents significant challenges that can severely impact their performance and efficiency. The accumulation of mineral deposits on heat transfer surfaces, primarily calcium carbonate and other salts, leads to reduced heat transfer rates and increased pressure drops. This scaling phenomenon is particularly problematic in PHEs due to their compact design and narrow flow channels.

The primary challenge lies in the complex interplay between fluid dynamics, heat transfer, and chemical reactions within the PHE. As fluids flow through the narrow passages, local temperature increases and pressure changes can accelerate scaling processes. The turbulent flow patterns, while beneficial for heat transfer, can also contribute to scale formation by creating localized areas of supersaturation.

Another significant challenge is the variability of scaling rates across different sections of the PHE. Hot spots and areas of low flow velocity are particularly susceptible to scale formation, leading to uneven distribution of deposits. This non-uniform scaling can cause flow maldistribution, further exacerbating the problem and potentially leading to complete blockage of some channels.

The compact nature of PHEs also makes them more sensitive to even small amounts of scaling. Unlike shell-and-tube heat exchangers, which have larger flow areas, PHEs can experience significant performance degradation with relatively minor scale buildup. This sensitivity necessitates more frequent cleaning and maintenance, which can be challenging due to the intricate geometry of the plates.

Material selection for PHEs presents another challenge in scaling mitigation. While certain materials may offer better resistance to scaling, they must also meet other requirements such as corrosion resistance, mechanical strength, and cost-effectiveness. Finding the optimal balance between these factors is crucial for long-term performance and economic viability.

The dynamic nature of scaling processes adds another layer of complexity. Scaling rates can vary significantly based on operating conditions, fluid composition, and even seasonal changes in water quality. This variability makes it difficult to predict and prevent scaling, necessitating adaptive and robust mitigation strategies.

Lastly, the environmental and economic implications of scaling mitigation strategies pose additional challenges. Many traditional anti-scaling treatments involve chemicals that may have environmental impacts. Balancing the need for effective scaling prevention with environmental sustainability and cost considerations is an ongoing challenge in PHE operation and maintenance.

The primary challenge lies in the complex interplay between fluid dynamics, heat transfer, and chemical reactions within the PHE. As fluids flow through the narrow passages, local temperature increases and pressure changes can accelerate scaling processes. The turbulent flow patterns, while beneficial for heat transfer, can also contribute to scale formation by creating localized areas of supersaturation.

Another significant challenge is the variability of scaling rates across different sections of the PHE. Hot spots and areas of low flow velocity are particularly susceptible to scale formation, leading to uneven distribution of deposits. This non-uniform scaling can cause flow maldistribution, further exacerbating the problem and potentially leading to complete blockage of some channels.

The compact nature of PHEs also makes them more sensitive to even small amounts of scaling. Unlike shell-and-tube heat exchangers, which have larger flow areas, PHEs can experience significant performance degradation with relatively minor scale buildup. This sensitivity necessitates more frequent cleaning and maintenance, which can be challenging due to the intricate geometry of the plates.

Material selection for PHEs presents another challenge in scaling mitigation. While certain materials may offer better resistance to scaling, they must also meet other requirements such as corrosion resistance, mechanical strength, and cost-effectiveness. Finding the optimal balance between these factors is crucial for long-term performance and economic viability.

The dynamic nature of scaling processes adds another layer of complexity. Scaling rates can vary significantly based on operating conditions, fluid composition, and even seasonal changes in water quality. This variability makes it difficult to predict and prevent scaling, necessitating adaptive and robust mitigation strategies.

Lastly, the environmental and economic implications of scaling mitigation strategies pose additional challenges. Many traditional anti-scaling treatments involve chemicals that may have environmental impacts. Balancing the need for effective scaling prevention with environmental sustainability and cost considerations is an ongoing challenge in PHE operation and maintenance.

Market Demand Analysis

The market demand for scaling mitigation strategies in plate heat exchangers has been steadily increasing due to the growing awareness of the detrimental effects of scaling on heat transfer efficiency and equipment longevity. Industries such as chemical processing, food and beverage, HVAC, and power generation are particularly affected by this issue, driving the need for innovative solutions.

The global plate heat exchanger market is projected to experience significant growth in the coming years, with a compound annual growth rate (CAGR) of around 6% from 2021 to 2026. This growth is largely attributed to the increasing demand for energy-efficient heat transfer solutions across various industries. As scaling is a major concern in these applications, the market for scaling mitigation strategies is expected to grow in tandem with the overall plate heat exchanger market.

In the industrial sector, there is a strong emphasis on reducing operational costs and improving energy efficiency. Scaling in plate heat exchangers can lead to decreased heat transfer rates, increased pressure drops, and higher energy consumption. Consequently, there is a growing demand for scaling mitigation strategies that can maintain optimal heat exchanger performance over extended periods, reducing maintenance requirements and operational downtime.

The food and beverage industry, in particular, has shown a significant interest in scaling mitigation technologies. With stringent hygiene regulations and the need for frequent cleaning cycles, this sector requires solutions that not only prevent scaling but also comply with food safety standards. This has led to an increased demand for environmentally friendly and food-grade scaling inhibitors and advanced cleaning technologies.

In the HVAC sector, the push for more energy-efficient buildings and sustainable practices has driven the adoption of plate heat exchangers in heating and cooling systems. However, the prevalence of hard water in many regions has made scaling a persistent issue, creating a substantial market for scaling mitigation strategies in this field.

The power generation industry, especially in regions relying on geothermal energy or dealing with high mineral content water sources, has also shown a strong demand for scaling mitigation solutions. As these plants strive to maximize energy output and minimize maintenance costs, effective scaling prevention and removal techniques have become crucial for their operations.

Furthermore, the growing focus on water conservation and the increasing use of recycled water in industrial processes have exacerbated scaling issues in many applications. This trend has created additional demand for scaling mitigation strategies that can handle water with higher mineral content and varying quality.

As environmental regulations become more stringent, there is also an increasing market demand for eco-friendly scaling mitigation solutions. This includes non-chemical treatments, such as physical water treatment systems and advanced materials with anti-scaling properties, which are gaining traction across various industries.

The global plate heat exchanger market is projected to experience significant growth in the coming years, with a compound annual growth rate (CAGR) of around 6% from 2021 to 2026. This growth is largely attributed to the increasing demand for energy-efficient heat transfer solutions across various industries. As scaling is a major concern in these applications, the market for scaling mitigation strategies is expected to grow in tandem with the overall plate heat exchanger market.

In the industrial sector, there is a strong emphasis on reducing operational costs and improving energy efficiency. Scaling in plate heat exchangers can lead to decreased heat transfer rates, increased pressure drops, and higher energy consumption. Consequently, there is a growing demand for scaling mitigation strategies that can maintain optimal heat exchanger performance over extended periods, reducing maintenance requirements and operational downtime.

The food and beverage industry, in particular, has shown a significant interest in scaling mitigation technologies. With stringent hygiene regulations and the need for frequent cleaning cycles, this sector requires solutions that not only prevent scaling but also comply with food safety standards. This has led to an increased demand for environmentally friendly and food-grade scaling inhibitors and advanced cleaning technologies.

In the HVAC sector, the push for more energy-efficient buildings and sustainable practices has driven the adoption of plate heat exchangers in heating and cooling systems. However, the prevalence of hard water in many regions has made scaling a persistent issue, creating a substantial market for scaling mitigation strategies in this field.

The power generation industry, especially in regions relying on geothermal energy or dealing with high mineral content water sources, has also shown a strong demand for scaling mitigation solutions. As these plants strive to maximize energy output and minimize maintenance costs, effective scaling prevention and removal techniques have become crucial for their operations.

Furthermore, the growing focus on water conservation and the increasing use of recycled water in industrial processes have exacerbated scaling issues in many applications. This trend has created additional demand for scaling mitigation strategies that can handle water with higher mineral content and varying quality.

As environmental regulations become more stringent, there is also an increasing market demand for eco-friendly scaling mitigation solutions. This includes non-chemical treatments, such as physical water treatment systems and advanced materials with anti-scaling properties, which are gaining traction across various industries.

Current Scaling Issues

Scaling in plate heat exchangers (PHEs) remains a significant challenge in various industries, particularly in processes involving hard water or mineral-rich fluids. The accumulation of scale on heat transfer surfaces leads to reduced thermal efficiency, increased pressure drop, and higher operational costs. Current scaling issues in PHEs are multifaceted and require a comprehensive understanding of the underlying mechanisms and their impacts.

One of the primary concerns is the formation of calcium carbonate scale, which is prevalent in applications using hard water. As water temperatures increase, calcium carbonate solubility decreases, leading to precipitation and deposition on heat transfer surfaces. This type of scaling is particularly problematic in PHEs due to their compact design and narrow flow channels, which can quickly become obstructed by scale buildup.

Another critical scaling issue is the formation of silica scale, common in geothermal and industrial processes. Silica scaling is challenging to mitigate due to its complex formation mechanisms and high resistance to conventional chemical treatments. The presence of silica scale not only reduces heat transfer efficiency but also creates a tenacious layer that is difficult to remove without damaging the heat exchanger plates.

Fouling by biological growth, such as biofilms, presents an additional scaling challenge in PHEs. These organic deposits can occur in various applications, from food processing to cooling systems. Biofilms not only reduce heat transfer but also create an environment conducive to further scaling and corrosion, compounding the overall scaling problem.

The geometry of PHEs, while advantageous for heat transfer, exacerbates scaling issues. The narrow flow channels and complex flow patterns can create areas of low velocity or stagnation, promoting scale formation. Additionally, the corrugated plate design, which enhances turbulence and heat transfer, can also increase the surface area available for scale deposition.

Current mitigation strategies for scaling in PHEs include chemical treatments, mechanical cleaning, and operational adjustments. However, these methods often have limitations. Chemical treatments may be environmentally problematic or incompatible with certain processes. Mechanical cleaning can be time-consuming and may damage the delicate plate surfaces. Operational adjustments, such as increasing flow rates or limiting temperature differentials, can reduce scaling but often at the cost of reduced thermal performance or increased pumping energy.

The economic impact of scaling in PHEs is substantial, encompassing increased energy consumption, maintenance costs, and production downtime. Industries are increasingly seeking more effective and sustainable solutions to address these scaling challenges, driving research into novel mitigation strategies and advanced materials for PHE construction.

One of the primary concerns is the formation of calcium carbonate scale, which is prevalent in applications using hard water. As water temperatures increase, calcium carbonate solubility decreases, leading to precipitation and deposition on heat transfer surfaces. This type of scaling is particularly problematic in PHEs due to their compact design and narrow flow channels, which can quickly become obstructed by scale buildup.

Another critical scaling issue is the formation of silica scale, common in geothermal and industrial processes. Silica scaling is challenging to mitigate due to its complex formation mechanisms and high resistance to conventional chemical treatments. The presence of silica scale not only reduces heat transfer efficiency but also creates a tenacious layer that is difficult to remove without damaging the heat exchanger plates.

Fouling by biological growth, such as biofilms, presents an additional scaling challenge in PHEs. These organic deposits can occur in various applications, from food processing to cooling systems. Biofilms not only reduce heat transfer but also create an environment conducive to further scaling and corrosion, compounding the overall scaling problem.

The geometry of PHEs, while advantageous for heat transfer, exacerbates scaling issues. The narrow flow channels and complex flow patterns can create areas of low velocity or stagnation, promoting scale formation. Additionally, the corrugated plate design, which enhances turbulence and heat transfer, can also increase the surface area available for scale deposition.

Current mitigation strategies for scaling in PHEs include chemical treatments, mechanical cleaning, and operational adjustments. However, these methods often have limitations. Chemical treatments may be environmentally problematic or incompatible with certain processes. Mechanical cleaning can be time-consuming and may damage the delicate plate surfaces. Operational adjustments, such as increasing flow rates or limiting temperature differentials, can reduce scaling but often at the cost of reduced thermal performance or increased pumping energy.

The economic impact of scaling in PHEs is substantial, encompassing increased energy consumption, maintenance costs, and production downtime. Industries are increasingly seeking more effective and sustainable solutions to address these scaling challenges, driving research into novel mitigation strategies and advanced materials for PHE construction.

Existing Mitigation Methods

01 Anti-scaling coatings for plate heat exchangers

Specialized coatings can be applied to the surfaces of plate heat exchangers to prevent or reduce scaling. These coatings create a barrier that inhibits the adhesion of scale-forming minerals, thereby maintaining the efficiency of heat transfer and extending the operational life of the exchanger.- Anti-scaling coatings for plate heat exchangers: Specialized coatings can be applied to the surfaces of plate heat exchangers to prevent or reduce scaling. These coatings create a barrier that inhibits the adhesion of scale-forming minerals, thereby maintaining the efficiency of the heat exchanger over time. Various materials and application methods can be used to achieve optimal anti-scaling properties.

- Chemical treatment methods for scale prevention: Chemical treatments can be employed to prevent scaling in plate heat exchangers. These methods often involve the use of scale inhibitors or dispersants that are added to the fluid circulating through the system. The chemicals work by interfering with the crystallization process of scale-forming minerals or by keeping them suspended in the fluid, preventing deposition on heat transfer surfaces.

- Design modifications to reduce scaling: Innovative design features can be incorporated into plate heat exchangers to minimize scaling. These may include optimized flow patterns, turbulence-inducing geometries, or special surface textures that discourage scale formation. By carefully engineering the internal structure of the heat exchanger, the likelihood of scale buildup can be significantly reduced.

- Cleaning and maintenance techniques: Regular cleaning and maintenance procedures are crucial for managing scaling in plate heat exchangers. This can involve mechanical cleaning methods, chemical cleaning processes, or a combination of both. Effective cleaning techniques remove existing scale deposits and help prevent future buildup, ensuring the continued efficiency of the heat exchanger.

- Monitoring and control systems for scale management: Advanced monitoring and control systems can be implemented to detect and manage scaling in plate heat exchangers. These systems may use sensors to monitor key parameters such as pressure drop, temperature differentials, or fluid composition. By providing real-time data and automated responses, these systems allow for proactive scale management and optimization of heat exchanger performance.

02 Chemical treatment methods for scale prevention

Various chemical treatments can be employed to prevent scaling in plate heat exchangers. These may include the use of scale inhibitors, dispersants, or pH adjusters that are added to the fluid circulating through the exchanger. Such treatments can help to keep scale-forming minerals in solution or modify their crystal structure to prevent deposition.Expand Specific Solutions03 Design modifications to reduce scaling

Innovative design features can be incorporated into plate heat exchangers to minimize scaling. These may include optimized flow patterns, turbulence-inducing surface textures, or special geometries that reduce areas prone to scale formation. Such design modifications can help maintain heat transfer efficiency and reduce maintenance requirements.Expand Specific Solutions04 Automated cleaning systems for scale removal

Automated cleaning systems can be integrated into plate heat exchangers to periodically remove scale buildup. These systems may use mechanical methods, chemical cleaning agents, or a combination of both to effectively clean the heat exchanger plates without the need for disassembly, reducing downtime and maintenance costs.Expand Specific Solutions05 Monitoring and predictive maintenance for scaling

Advanced monitoring systems and predictive maintenance techniques can be employed to detect early signs of scaling in plate heat exchangers. These may include sensors for measuring heat transfer efficiency, pressure drop, or fluid composition. By analyzing this data, operators can schedule maintenance or implement preventive measures before scaling significantly impacts performance.Expand Specific Solutions

Key Industry Players

The research on scaling mitigation strategies for plate heat exchangers is in a mature stage, with significant market potential due to the widespread use of these devices across industries. The global market for plate heat exchangers is substantial, driven by increasing demand in sectors such as chemical processing, HVAC, and power generation. Key players like Alfa Laval, Danfoss, and Mitsubishi Electric are at the forefront of innovation, developing advanced technologies to address scaling issues. These companies, along with others such as ExxonMobil and China Petroleum & Chemical Corp., are investing in research and development to improve heat exchanger efficiency and longevity, indicating a competitive and technologically advanced landscape.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced scaling mitigation strategies for plate heat exchangers, focusing on both preventive and reactive measures. Their approach includes innovative surface treatments that reduce scale adhesion, such as their patented AlfaNova fusion-bonded plate technology[1]. This technology creates a highly corrosion-resistant surface that minimizes scaling. Additionally, Alfa Laval has implemented smart cleaning systems that use controlled flow reversal and pulsation techniques to dislodge scale deposits without interrupting operations[2]. They have also developed specialized chemical cleaning solutions tailored to different types of scale, which can be used in conjunction with their CIP (Cleaning-in-Place) systems for efficient descaling[3]. Alfa Laval's research has led to the development of predictive maintenance algorithms that use real-time monitoring of heat transfer efficiency to detect early signs of scaling, allowing for timely intervention[4].

Strengths: Comprehensive approach combining prevention and treatment; Industry-leading surface treatment technology; Efficient cleaning systems integrated with heat exchanger design. Weaknesses: Some solutions may be more expensive than traditional methods; Specialized cleaning chemicals may require careful handling and disposal.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has invested heavily in research on scaling mitigation for plate heat exchangers, particularly in the context of oil and gas operations. Their approach focuses on understanding the fundamental mechanisms of scale formation and developing targeted solutions. ExxonMobil has pioneered the use of advanced computational fluid dynamics (CFD) modeling to predict scale formation patterns in plate heat exchangers[5]. This allows for optimized design of plate geometries and flow patterns to minimize scaling. They have also developed proprietary anti-scaling coatings that incorporate nano-engineered surfaces to disrupt scale nucleation and growth[6]. In addition, ExxonMobil has implemented intelligent dosing systems for scale inhibitors, using machine learning algorithms to optimize chemical usage based on real-time operating conditions[7]. Their research extends to novel physical scale removal techniques, including the use of controlled cavitation and ultrasonic vibrations to break down existing scale deposits[8].

Strengths: Advanced modeling capabilities for scale prediction; Innovative surface engineering solutions; Intelligent chemical management systems. Weaknesses: Solutions may be primarily tailored to oil and gas industry applications; Some technologies may require significant capital investment for implementation.

Innovative Anti-Scaling Tech

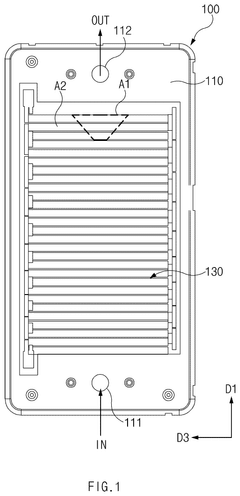

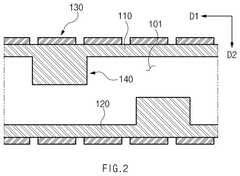

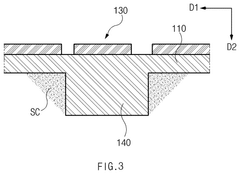

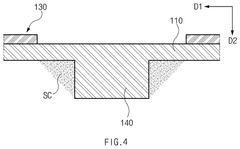

Heat exchanger

PatentPendingUS20250216157A1

Innovation

- A heat exchanger design with specific reference areas on plates where heat emitting parts are strategically positioned to avoid high temperature zones, combined with rib structures for turbulence and a descaling mechanism to manage scale formation.

Environmental Regulations

Environmental regulations play a crucial role in shaping the strategies for scaling mitigation in plate heat exchangers. As industries strive to improve energy efficiency and reduce environmental impact, governments worldwide have implemented stringent regulations to control emissions and promote sustainable practices. These regulations directly influence the design, operation, and maintenance of plate heat exchangers, particularly in addressing scaling issues.

In recent years, many countries have introduced or tightened regulations on water usage and discharge, which significantly impact scaling mitigation strategies. For instance, the European Union's Water Framework Directive sets strict limits on the concentration of minerals and chemicals in industrial wastewater. This has led to increased focus on developing scaling mitigation techniques that minimize the use of harsh chemicals and reduce the need for frequent cleaning cycles.

The United States Environmental Protection Agency (EPA) has also implemented regulations that affect scaling mitigation in plate heat exchangers. The Clean Water Act and the Safe Drinking Water Act impose limitations on the discharge of scaling-related byproducts and the use of certain anti-scaling chemicals. These regulations have spurred research into more environmentally friendly scaling mitigation methods, such as the development of green inhibitors and the optimization of physical cleaning techniques.

In Asia, countries like China and India have recently strengthened their environmental policies to address industrial pollution. The Chinese government's Action Plan for Water Pollution Prevention and Control has set targets for reducing water consumption and improving wastewater treatment in industries. This has led to increased adoption of advanced scaling mitigation technologies in plate heat exchangers, particularly in sectors such as power generation and chemical processing.

The global push towards reducing greenhouse gas emissions has indirectly influenced scaling mitigation strategies. As industries seek to improve energy efficiency to meet emission reduction targets, there is a growing emphasis on maintaining the optimal performance of heat exchangers. This has led to increased investment in research and development of scaling mitigation techniques that can help maintain high heat transfer efficiency over extended periods.

Environmental regulations have also driven innovation in monitoring and control systems for plate heat exchangers. Many jurisdictions now require continuous monitoring of water quality and energy efficiency in industrial processes. This has led to the development of advanced sensors and predictive maintenance systems that can detect early signs of scaling and optimize mitigation strategies in real-time.

As environmental regulations continue to evolve, the future of scaling mitigation in plate heat exchangers is likely to focus on sustainable and eco-friendly solutions. This may include the development of bio-based anti-scaling agents, the integration of renewable energy sources in cleaning processes, and the implementation of circular economy principles in managing scaling byproducts. The ongoing regulatory pressure will undoubtedly shape the direction of research and innovation in this field for years to come.

In recent years, many countries have introduced or tightened regulations on water usage and discharge, which significantly impact scaling mitigation strategies. For instance, the European Union's Water Framework Directive sets strict limits on the concentration of minerals and chemicals in industrial wastewater. This has led to increased focus on developing scaling mitigation techniques that minimize the use of harsh chemicals and reduce the need for frequent cleaning cycles.

The United States Environmental Protection Agency (EPA) has also implemented regulations that affect scaling mitigation in plate heat exchangers. The Clean Water Act and the Safe Drinking Water Act impose limitations on the discharge of scaling-related byproducts and the use of certain anti-scaling chemicals. These regulations have spurred research into more environmentally friendly scaling mitigation methods, such as the development of green inhibitors and the optimization of physical cleaning techniques.

In Asia, countries like China and India have recently strengthened their environmental policies to address industrial pollution. The Chinese government's Action Plan for Water Pollution Prevention and Control has set targets for reducing water consumption and improving wastewater treatment in industries. This has led to increased adoption of advanced scaling mitigation technologies in plate heat exchangers, particularly in sectors such as power generation and chemical processing.

The global push towards reducing greenhouse gas emissions has indirectly influenced scaling mitigation strategies. As industries seek to improve energy efficiency to meet emission reduction targets, there is a growing emphasis on maintaining the optimal performance of heat exchangers. This has led to increased investment in research and development of scaling mitigation techniques that can help maintain high heat transfer efficiency over extended periods.

Environmental regulations have also driven innovation in monitoring and control systems for plate heat exchangers. Many jurisdictions now require continuous monitoring of water quality and energy efficiency in industrial processes. This has led to the development of advanced sensors and predictive maintenance systems that can detect early signs of scaling and optimize mitigation strategies in real-time.

As environmental regulations continue to evolve, the future of scaling mitigation in plate heat exchangers is likely to focus on sustainable and eco-friendly solutions. This may include the development of bio-based anti-scaling agents, the integration of renewable energy sources in cleaning processes, and the implementation of circular economy principles in managing scaling byproducts. The ongoing regulatory pressure will undoubtedly shape the direction of research and innovation in this field for years to come.

Economic Impact Assessment

The economic impact of scaling mitigation strategies for plate heat exchangers is significant and multifaceted. Scaling, a common issue in heat exchanger operations, can lead to substantial financial losses if left unaddressed. The implementation of effective mitigation strategies not only improves operational efficiency but also yields considerable economic benefits across various industries.

One of the primary economic advantages of scaling mitigation is the reduction in energy consumption. As scale builds up on heat transfer surfaces, it acts as an insulator, reducing heat transfer efficiency. This inefficiency forces systems to work harder, consuming more energy to achieve the desired heat exchange. By implementing effective scaling mitigation strategies, industries can significantly reduce their energy costs, which often represent a substantial portion of operational expenses.

Maintenance costs are another area where scaling mitigation strategies demonstrate their economic value. Regular cleaning and descaling of heat exchangers can be labor-intensive and time-consuming, often requiring production shutdowns. Advanced mitigation techniques can extend the intervals between maintenance cycles, reducing both direct maintenance costs and the indirect costs associated with production downtime. This improved operational continuity translates to increased productivity and revenue generation.

The longevity of equipment is also a crucial factor in the economic assessment of scaling mitigation strategies. Scaling can cause accelerated wear and tear on heat exchanger components, leading to premature equipment failure and the need for costly replacements. By effectively preventing or minimizing scale formation, these strategies can significantly extend the lifespan of heat exchangers, deferring capital expenditures on new equipment and improving the return on investment for existing assets.

In industries where product quality is paramount, such as food and beverage or pharmaceuticals, scaling mitigation strategies play a critical role in maintaining consistent product standards. Scale buildup can affect temperature control and product flow, potentially leading to quality issues. By ensuring optimal heat exchanger performance, these strategies help maintain product quality, reducing the risk of costly product recalls or reputation damage.

Furthermore, the adoption of advanced scaling mitigation technologies can provide a competitive edge in the market. Companies that effectively manage scaling issues can offer more reliable services, potentially commanding premium prices or capturing larger market shares. This competitive advantage can lead to increased revenue and improved profitability in the long term.

One of the primary economic advantages of scaling mitigation is the reduction in energy consumption. As scale builds up on heat transfer surfaces, it acts as an insulator, reducing heat transfer efficiency. This inefficiency forces systems to work harder, consuming more energy to achieve the desired heat exchange. By implementing effective scaling mitigation strategies, industries can significantly reduce their energy costs, which often represent a substantial portion of operational expenses.

Maintenance costs are another area where scaling mitigation strategies demonstrate their economic value. Regular cleaning and descaling of heat exchangers can be labor-intensive and time-consuming, often requiring production shutdowns. Advanced mitigation techniques can extend the intervals between maintenance cycles, reducing both direct maintenance costs and the indirect costs associated with production downtime. This improved operational continuity translates to increased productivity and revenue generation.

The longevity of equipment is also a crucial factor in the economic assessment of scaling mitigation strategies. Scaling can cause accelerated wear and tear on heat exchanger components, leading to premature equipment failure and the need for costly replacements. By effectively preventing or minimizing scale formation, these strategies can significantly extend the lifespan of heat exchangers, deferring capital expenditures on new equipment and improving the return on investment for existing assets.

In industries where product quality is paramount, such as food and beverage or pharmaceuticals, scaling mitigation strategies play a critical role in maintaining consistent product standards. Scale buildup can affect temperature control and product flow, potentially leading to quality issues. By ensuring optimal heat exchanger performance, these strategies help maintain product quality, reducing the risk of costly product recalls or reputation damage.

Furthermore, the adoption of advanced scaling mitigation technologies can provide a competitive edge in the market. Companies that effectively manage scaling issues can offer more reliable services, potentially commanding premium prices or capturing larger market shares. This competitive advantage can lead to increased revenue and improved profitability in the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!