Plate Heat Exchanger's Role in Hydrogen Production Efficiency

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2 Production & PHE Tech Evolution

The evolution of hydrogen production technologies and plate heat exchangers (PHEs) has been closely intertwined, with advancements in both fields contributing to increased efficiency and sustainability in hydrogen production processes. The journey began in the early 20th century with the development of basic steam reforming techniques for hydrogen production, which relied on rudimentary heat exchange systems.

As the demand for hydrogen grew in various industries, including petroleum refining and ammonia production, the need for more efficient heat transfer solutions became apparent. This led to the introduction of the first plate heat exchangers in the 1920s, initially designed for the dairy industry. However, their potential for application in chemical processes, including hydrogen production, was quickly recognized.

The 1950s and 1960s saw significant improvements in PHE design, with the introduction of corrugated plates and gasket materials capable of withstanding higher temperatures and pressures. These advancements allowed PHEs to be increasingly utilized in hydrogen production processes, particularly in steam methane reforming (SMR) applications, where efficient heat recovery is crucial.

The 1970s marked a turning point in both hydrogen production and PHE technology. The oil crisis sparked renewed interest in alternative energy sources, including hydrogen. Simultaneously, PHE manufacturers began developing more specialized designs for chemical processing, incorporating materials like titanium and high-grade stainless steel to withstand corrosive environments.

The 1980s and 1990s saw the emergence of computer-aided design and computational fluid dynamics, revolutionizing PHE optimization. This led to more efficient plate geometries and flow distributions, directly benefiting hydrogen production processes by improving heat transfer rates and reducing energy consumption.

In the early 2000s, environmental concerns and the push for cleaner energy sources accelerated research into more sustainable hydrogen production methods. This period saw the development of advanced PHE designs specifically tailored for emerging technologies like high-temperature electrolysis and thermochemical water splitting. Concurrently, improvements in manufacturing techniques allowed for the production of compact PHEs with enhanced performance characteristics.

The past decade has witnessed a surge in green hydrogen initiatives, driving innovation in both production methods and heat exchange technologies. Modern PHEs now incorporate advanced materials and designs that can withstand the extreme conditions associated with cutting-edge hydrogen production processes, such as high-temperature steam electrolysis and solar thermochemical cycles.

Looking ahead, the synergy between hydrogen production and PHE technology continues to evolve. Current research focuses on developing novel plate materials and geometries to further improve heat transfer efficiency and durability in hydrogen production applications. Additionally, the integration of smart sensors and real-time monitoring systems in PHEs promises to optimize performance and reduce maintenance costs in hydrogen production facilities.

As the demand for hydrogen grew in various industries, including petroleum refining and ammonia production, the need for more efficient heat transfer solutions became apparent. This led to the introduction of the first plate heat exchangers in the 1920s, initially designed for the dairy industry. However, their potential for application in chemical processes, including hydrogen production, was quickly recognized.

The 1950s and 1960s saw significant improvements in PHE design, with the introduction of corrugated plates and gasket materials capable of withstanding higher temperatures and pressures. These advancements allowed PHEs to be increasingly utilized in hydrogen production processes, particularly in steam methane reforming (SMR) applications, where efficient heat recovery is crucial.

The 1970s marked a turning point in both hydrogen production and PHE technology. The oil crisis sparked renewed interest in alternative energy sources, including hydrogen. Simultaneously, PHE manufacturers began developing more specialized designs for chemical processing, incorporating materials like titanium and high-grade stainless steel to withstand corrosive environments.

The 1980s and 1990s saw the emergence of computer-aided design and computational fluid dynamics, revolutionizing PHE optimization. This led to more efficient plate geometries and flow distributions, directly benefiting hydrogen production processes by improving heat transfer rates and reducing energy consumption.

In the early 2000s, environmental concerns and the push for cleaner energy sources accelerated research into more sustainable hydrogen production methods. This period saw the development of advanced PHE designs specifically tailored for emerging technologies like high-temperature electrolysis and thermochemical water splitting. Concurrently, improvements in manufacturing techniques allowed for the production of compact PHEs with enhanced performance characteristics.

The past decade has witnessed a surge in green hydrogen initiatives, driving innovation in both production methods and heat exchange technologies. Modern PHEs now incorporate advanced materials and designs that can withstand the extreme conditions associated with cutting-edge hydrogen production processes, such as high-temperature steam electrolysis and solar thermochemical cycles.

Looking ahead, the synergy between hydrogen production and PHE technology continues to evolve. Current research focuses on developing novel plate materials and geometries to further improve heat transfer efficiency and durability in hydrogen production applications. Additionally, the integration of smart sensors and real-time monitoring systems in PHEs promises to optimize performance and reduce maintenance costs in hydrogen production facilities.

H2 Market Demand Analysis

The global hydrogen market is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards decarbonization. As a key component in various industrial processes and emerging applications, hydrogen's market potential is substantial and continues to expand.

In the energy sector, hydrogen is gaining traction as a versatile energy carrier, capable of supporting the transition to renewable energy systems. Its ability to store and transport energy efficiently makes it an attractive option for balancing intermittent renewable sources like solar and wind. This has led to a surge in interest from utility companies and energy providers looking to integrate hydrogen into their portfolios.

The transportation industry represents another major driver of hydrogen demand. Fuel cell electric vehicles (FCEVs) are emerging as a viable alternative to battery electric vehicles, particularly for long-haul transportation and heavy-duty applications. Major automotive manufacturers are investing heavily in hydrogen technology, with several commercial FCEV models already available in select markets.

Industrial applications continue to be a significant source of hydrogen demand. Traditional uses in petroleum refining and ammonia production remain strong, while new applications in steel manufacturing and other industrial processes are emerging as companies seek to reduce their carbon footprint.

The market for green hydrogen, produced through electrolysis powered by renewable energy, is experiencing particularly rapid growth. This environmentally friendly production method aligns with global sustainability goals and is attracting substantial investment from both public and private sectors.

Geographically, Asia-Pacific leads in hydrogen demand, with China, Japan, and South Korea at the forefront. Europe follows closely, driven by ambitious climate targets and supportive policies. North America is also seeing increased interest, particularly in California and other states with strong clean energy initiatives.

Market forecasts for hydrogen are optimistic, with projections indicating substantial growth over the next decade. This growth is expected to be fueled by declining production costs, improving infrastructure, and supportive government policies worldwide.

However, challenges remain in scaling up hydrogen production to meet this growing demand. Efficiency improvements in production processes, including those involving plate heat exchangers, are crucial to reducing costs and making hydrogen more competitive with traditional energy sources.

In conclusion, the market demand for hydrogen is robust and diversifying, with significant growth potential across multiple sectors. As production technologies advance and costs decrease, hydrogen is poised to play an increasingly important role in the global energy landscape, driving innovation and investment in related technologies and infrastructure.

In the energy sector, hydrogen is gaining traction as a versatile energy carrier, capable of supporting the transition to renewable energy systems. Its ability to store and transport energy efficiently makes it an attractive option for balancing intermittent renewable sources like solar and wind. This has led to a surge in interest from utility companies and energy providers looking to integrate hydrogen into their portfolios.

The transportation industry represents another major driver of hydrogen demand. Fuel cell electric vehicles (FCEVs) are emerging as a viable alternative to battery electric vehicles, particularly for long-haul transportation and heavy-duty applications. Major automotive manufacturers are investing heavily in hydrogen technology, with several commercial FCEV models already available in select markets.

Industrial applications continue to be a significant source of hydrogen demand. Traditional uses in petroleum refining and ammonia production remain strong, while new applications in steel manufacturing and other industrial processes are emerging as companies seek to reduce their carbon footprint.

The market for green hydrogen, produced through electrolysis powered by renewable energy, is experiencing particularly rapid growth. This environmentally friendly production method aligns with global sustainability goals and is attracting substantial investment from both public and private sectors.

Geographically, Asia-Pacific leads in hydrogen demand, with China, Japan, and South Korea at the forefront. Europe follows closely, driven by ambitious climate targets and supportive policies. North America is also seeing increased interest, particularly in California and other states with strong clean energy initiatives.

Market forecasts for hydrogen are optimistic, with projections indicating substantial growth over the next decade. This growth is expected to be fueled by declining production costs, improving infrastructure, and supportive government policies worldwide.

However, challenges remain in scaling up hydrogen production to meet this growing demand. Efficiency improvements in production processes, including those involving plate heat exchangers, are crucial to reducing costs and making hydrogen more competitive with traditional energy sources.

In conclusion, the market demand for hydrogen is robust and diversifying, with significant growth potential across multiple sectors. As production technologies advance and costs decrease, hydrogen is poised to play an increasingly important role in the global energy landscape, driving innovation and investment in related technologies and infrastructure.

PHE Challenges in H2 Production

Plate heat exchangers (PHEs) play a crucial role in hydrogen production processes, particularly in steam methane reforming (SMR) and water electrolysis. However, their application in these processes presents several challenges that need to be addressed to enhance overall efficiency and reliability.

One of the primary challenges is the high-temperature operation required in hydrogen production. SMR processes typically operate at temperatures ranging from 700°C to 1000°C, which puts significant stress on PHE materials and design. Traditional PHE materials may not withstand these extreme temperatures, leading to reduced lifespan and potential failure. Developing heat-resistant alloys and advanced ceramic materials capable of maintaining structural integrity and thermal efficiency at elevated temperatures is essential.

Corrosion resistance is another critical challenge for PHEs in hydrogen production. The presence of corrosive gases, such as hydrogen sulfide and carbon dioxide, in the feedstock can accelerate material degradation. This issue is particularly pronounced in SMR processes where natural gas is used as a feedstock. Implementing corrosion-resistant materials and protective coatings is necessary to extend the operational life of PHEs and maintain their performance over time.

Fouling and scaling pose significant challenges to PHE efficiency in hydrogen production. The deposition of contaminants and mineral scale on heat transfer surfaces can reduce thermal conductivity and increase pressure drop, leading to decreased overall system efficiency. Developing innovative surface treatments and implementing effective cleaning protocols are essential to mitigate these issues and maintain optimal heat transfer performance.

The high-pressure operation in hydrogen production processes also presents challenges for PHE design and operation. Pressure differentials between process streams can cause deformation of plates and gaskets, potentially leading to leaks and reduced heat transfer efficiency. Enhancing the mechanical strength of PHE components and improving sealing technologies are crucial to ensure reliable operation under high-pressure conditions.

In water electrolysis systems, PHEs face challenges related to managing the heat generated during the electrolysis process. Efficient heat removal is critical to maintain optimal operating temperatures and prevent degradation of electrolyte membranes. Designing PHEs with enhanced heat transfer capabilities and integrating them effectively into electrolysis systems is essential for improving overall process efficiency.

Lastly, the compact nature of PHEs, while advantageous in many applications, can present challenges in hydrogen production processes that involve large volumetric flows. Ensuring adequate flow distribution and minimizing pressure drop across the exchanger becomes increasingly important. Optimizing plate designs and flow channel configurations to accommodate high flow rates while maintaining uniform distribution is a key area for improvement in PHE technology for hydrogen production applications.

One of the primary challenges is the high-temperature operation required in hydrogen production. SMR processes typically operate at temperatures ranging from 700°C to 1000°C, which puts significant stress on PHE materials and design. Traditional PHE materials may not withstand these extreme temperatures, leading to reduced lifespan and potential failure. Developing heat-resistant alloys and advanced ceramic materials capable of maintaining structural integrity and thermal efficiency at elevated temperatures is essential.

Corrosion resistance is another critical challenge for PHEs in hydrogen production. The presence of corrosive gases, such as hydrogen sulfide and carbon dioxide, in the feedstock can accelerate material degradation. This issue is particularly pronounced in SMR processes where natural gas is used as a feedstock. Implementing corrosion-resistant materials and protective coatings is necessary to extend the operational life of PHEs and maintain their performance over time.

Fouling and scaling pose significant challenges to PHE efficiency in hydrogen production. The deposition of contaminants and mineral scale on heat transfer surfaces can reduce thermal conductivity and increase pressure drop, leading to decreased overall system efficiency. Developing innovative surface treatments and implementing effective cleaning protocols are essential to mitigate these issues and maintain optimal heat transfer performance.

The high-pressure operation in hydrogen production processes also presents challenges for PHE design and operation. Pressure differentials between process streams can cause deformation of plates and gaskets, potentially leading to leaks and reduced heat transfer efficiency. Enhancing the mechanical strength of PHE components and improving sealing technologies are crucial to ensure reliable operation under high-pressure conditions.

In water electrolysis systems, PHEs face challenges related to managing the heat generated during the electrolysis process. Efficient heat removal is critical to maintain optimal operating temperatures and prevent degradation of electrolyte membranes. Designing PHEs with enhanced heat transfer capabilities and integrating them effectively into electrolysis systems is essential for improving overall process efficiency.

Lastly, the compact nature of PHEs, while advantageous in many applications, can present challenges in hydrogen production processes that involve large volumetric flows. Ensuring adequate flow distribution and minimizing pressure drop across the exchanger becomes increasingly important. Optimizing plate designs and flow channel configurations to accommodate high flow rates while maintaining uniform distribution is a key area for improvement in PHE technology for hydrogen production applications.

Current PHE Solutions for H2

01 Improved plate design for enhanced heat transfer

Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids. Advanced manufacturing techniques allow for optimized plate geometries that minimize pressure drop while maximizing heat transfer.- Improved plate design for enhanced heat transfer: Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids.

- Optimized flow distribution: Efficient flow distribution within the plate heat exchanger is crucial for maximizing heat transfer. This can be achieved through carefully designed inlet and outlet ports, as well as internal flow channels that ensure uniform fluid distribution across the plates.

- Advanced materials for plate construction: The use of advanced materials with high thermal conductivity and corrosion resistance can significantly improve the efficiency of plate heat exchangers. These materials allow for better heat transfer and longer operational life under various conditions.

- Compact design and modular configuration: Compact and modular designs allow for easy scalability and maintenance of plate heat exchangers. This approach enables efficient heat transfer in a smaller footprint and allows for easy adaptation to changing capacity requirements.

- Enhanced sealing and gasket technology: Improved sealing and gasket technologies prevent fluid leakage and cross-contamination between channels. This ensures optimal performance and maintains the efficiency of the plate heat exchanger over extended periods of operation.

02 Flow distribution optimization

Efficient flow distribution within the plate heat exchanger is crucial for maximizing heat transfer. This can be achieved through carefully designed inlet and outlet ports, as well as internal flow channels. Uniform fluid distribution across the plates ensures that all available surface area is utilized effectively, reducing thermal inefficiencies and improving overall exchanger performance.Expand Specific Solutions03 Material selection for enhanced thermal conductivity

The choice of materials for plate construction plays a significant role in heat exchanger efficiency. High thermal conductivity materials, such as certain alloys or composite materials, can improve heat transfer rates. Additionally, surface treatments or coatings can be applied to plates to enhance their thermal properties or reduce fouling, further improving long-term efficiency.Expand Specific Solutions04 Gasket and sealing technology advancements

Improved gasket designs and sealing technologies contribute to the overall efficiency of plate heat exchangers. High-performance gaskets prevent fluid leakage and maintain proper plate separation, ensuring optimal heat transfer. Advanced sealing methods can also allow for higher operating pressures and temperatures, expanding the range of applications for plate heat exchangers.Expand Specific Solutions05 Smart monitoring and control systems

Integration of smart monitoring and control systems can significantly enhance plate heat exchanger efficiency. These systems can include sensors for real-time performance monitoring, predictive maintenance algorithms, and adaptive control mechanisms. By continuously optimizing operating parameters and detecting potential issues early, these systems ensure that the heat exchanger maintains peak efficiency throughout its operational life.Expand Specific Solutions

Key PHE Manufacturers for H2

The plate heat exchanger market in hydrogen production is in a growth phase, driven by increasing demand for clean energy solutions. The market size is expanding as hydrogen gains traction as a sustainable fuel alternative. Technologically, plate heat exchangers are evolving to meet the specific needs of hydrogen production processes. Companies like Alfa Laval, Haldor Topsøe, and Air Liquide are at the forefront, developing advanced heat exchange solutions tailored for hydrogen applications. These industry leaders are investing in R&D to improve efficiency and scalability, while newer entrants like Clean Power Hydrogen Group are introducing innovative technologies to capture market share in this rapidly developing sector.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed advanced plate heat exchanger technology specifically for hydrogen production processes. Their design incorporates high-efficiency heat transfer surfaces and optimized flow distribution, resulting in improved thermal performance. The company's plate heat exchangers utilize compact, corrugated plates made from corrosion-resistant materials to withstand the harsh conditions in hydrogen production environments. These exchangers are capable of handling high pressures and temperatures, making them suitable for various stages of the hydrogen production process, including steam methane reforming and water-gas shift reactions. Haldor Topsøe's plate heat exchangers have demonstrated up to 30% higher heat transfer coefficients compared to traditional shell-and-tube designs [1], leading to significant improvements in overall process efficiency and reduced energy consumption in hydrogen production plants.

Strengths: Specialized design for hydrogen production, high thermal efficiency, corrosion resistance, and compact size. Weaknesses: Potentially higher initial cost and more complex maintenance compared to simpler heat exchanger designs.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed a range of plate heat exchangers tailored for hydrogen production applications. Their technology focuses on maximizing heat recovery and minimizing energy consumption throughout the hydrogen production process. Alfa Laval's plate heat exchangers feature a modular design that allows for easy scalability and customization to meet specific process requirements. The company's proprietary plate patterns enhance turbulence and heat transfer while minimizing fouling, which is crucial for maintaining long-term efficiency in hydrogen production. Alfa Laval's exchangers are designed to handle the high temperatures and pressures associated with various hydrogen production methods, including electrolysis and steam methane reforming. Their plate heat exchangers have been reported to achieve up to 25% higher overall heat transfer coefficients compared to conventional technologies [2], contributing to improved energy efficiency and reduced operating costs in hydrogen production facilities.

Strengths: Modular and scalable design, high heat transfer efficiency, and fouling resistance. Weaknesses: May require more frequent maintenance due to the complexity of plate designs and potential for gasket degradation in harsh environments.

PHE Innovations for H2 Efficiency

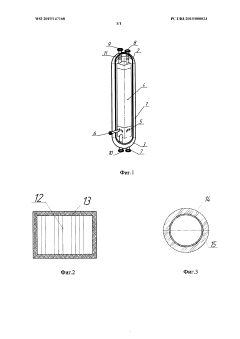

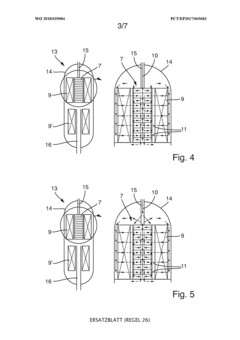

Plate heat exchanger for hydrogenation plants for re-refining oil

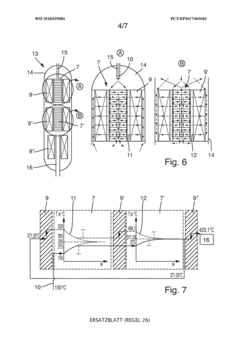

PatentWO2019147168A2

Innovation

- A plate heat exchanger with a vertical cylindrical steel housing and a package of vertically installed metal heat exchange plates, featuring external and internal thermal insulation, particularly using carbon fiber materials, to minimize heat loss and enhance heat recovery.

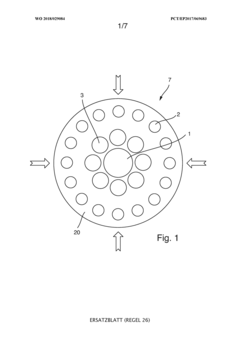

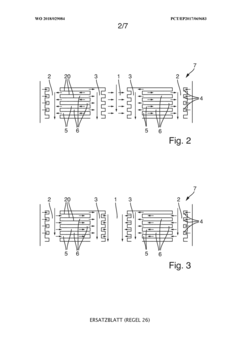

Plate heat exchanger, synthesis device, and method for producing a product

PatentWO2018029084A1

Innovation

- A plate heat exchanger design with alternating fluid channels and lateral inflow openings for a second fluid, allowing direct heat exchange without deflection, reducing pressure loss and space requirements, and enabling a more compact and efficient heat transfer process.

H2 Production Safety Standards

Safety standards play a crucial role in hydrogen production processes, especially when utilizing plate heat exchangers. These standards are designed to mitigate risks associated with the highly flammable and explosive nature of hydrogen gas. The primary focus of H2 production safety standards is to prevent leaks, minimize ignition sources, and ensure proper containment throughout the production process.

One of the key safety considerations in hydrogen production is the prevention of hydrogen embrittlement. This phenomenon can cause structural degradation in metals, potentially leading to catastrophic failures. Safety standards mandate the use of materials resistant to hydrogen embrittlement in plate heat exchangers and other critical components. Regular inspections and non-destructive testing procedures are also required to detect any signs of material degradation.

Pressure management is another critical aspect addressed by safety standards. Hydrogen production often involves high-pressure systems, and plate heat exchangers must be designed and operated within specified pressure limits. Safety relief valves and pressure monitoring systems are mandatory to prevent over-pressurization and potential ruptures. Additionally, standards dictate the implementation of emergency shutdown systems that can quickly isolate and depressurize the system in case of a detected leak or abnormal operating conditions.

Ventilation and gas detection systems are integral components of hydrogen production safety. Standards require adequate ventilation in production areas to prevent the accumulation of hydrogen gas. Hydrogen sensors must be strategically placed to detect leaks promptly and trigger alarms or automated safety responses. These systems are particularly important in areas where plate heat exchangers are installed, as they are potential points of gas leakage.

Electrical safety is another crucial aspect covered by H2 production safety standards. All electrical equipment, including those associated with plate heat exchangers, must be properly rated for use in potentially explosive atmospheres. This includes the use of explosion-proof enclosures, intrinsically safe circuits, and proper grounding to prevent spark generation.

Training and operational procedures form a significant part of safety standards. Personnel involved in hydrogen production must receive comprehensive training on the hazards associated with hydrogen, emergency response procedures, and the proper operation of equipment, including plate heat exchangers. Standard operating procedures (SOPs) must be developed and strictly followed to ensure consistent and safe operation.

Maintenance and inspection protocols are also outlined in safety standards. Regular maintenance schedules, including the cleaning and inspection of plate heat exchangers, are mandatory to ensure their continued safe operation. Any modifications or repairs must be carried out in compliance with the established safety standards and by qualified personnel.

One of the key safety considerations in hydrogen production is the prevention of hydrogen embrittlement. This phenomenon can cause structural degradation in metals, potentially leading to catastrophic failures. Safety standards mandate the use of materials resistant to hydrogen embrittlement in plate heat exchangers and other critical components. Regular inspections and non-destructive testing procedures are also required to detect any signs of material degradation.

Pressure management is another critical aspect addressed by safety standards. Hydrogen production often involves high-pressure systems, and plate heat exchangers must be designed and operated within specified pressure limits. Safety relief valves and pressure monitoring systems are mandatory to prevent over-pressurization and potential ruptures. Additionally, standards dictate the implementation of emergency shutdown systems that can quickly isolate and depressurize the system in case of a detected leak or abnormal operating conditions.

Ventilation and gas detection systems are integral components of hydrogen production safety. Standards require adequate ventilation in production areas to prevent the accumulation of hydrogen gas. Hydrogen sensors must be strategically placed to detect leaks promptly and trigger alarms or automated safety responses. These systems are particularly important in areas where plate heat exchangers are installed, as they are potential points of gas leakage.

Electrical safety is another crucial aspect covered by H2 production safety standards. All electrical equipment, including those associated with plate heat exchangers, must be properly rated for use in potentially explosive atmospheres. This includes the use of explosion-proof enclosures, intrinsically safe circuits, and proper grounding to prevent spark generation.

Training and operational procedures form a significant part of safety standards. Personnel involved in hydrogen production must receive comprehensive training on the hazards associated with hydrogen, emergency response procedures, and the proper operation of equipment, including plate heat exchangers. Standard operating procedures (SOPs) must be developed and strictly followed to ensure consistent and safe operation.

Maintenance and inspection protocols are also outlined in safety standards. Regular maintenance schedules, including the cleaning and inspection of plate heat exchangers, are mandatory to ensure their continued safe operation. Any modifications or repairs must be carried out in compliance with the established safety standards and by qualified personnel.

PHE Material Advancements

Material advancements in plate heat exchangers (PHEs) have played a crucial role in enhancing their performance and efficiency in hydrogen production processes. The development of new materials has focused on improving corrosion resistance, thermal conductivity, and overall durability of PHE components.

One significant advancement has been the introduction of high-performance stainless steel alloys. These alloys, such as Super Duplex and 254 SMO, offer superior resistance to corrosion and pitting, particularly in high-temperature and high-pressure environments common in hydrogen production. The improved corrosion resistance allows for extended operational lifetimes and reduced maintenance requirements, contributing to increased overall efficiency.

Titanium-based materials have also gained prominence in PHE construction. Titanium's excellent corrosion resistance, coupled with its high strength-to-weight ratio, makes it an ideal choice for applications involving aggressive media or seawater cooling. The use of titanium in PHEs has enabled more compact designs and improved heat transfer efficiency, particularly in processes where contamination must be minimized.

Advancements in polymer-based materials have opened new possibilities for PHE applications in hydrogen production. Fluoropolymers, such as PTFE and PVDF, offer exceptional chemical resistance and can withstand a wide range of temperatures. These materials are particularly useful in applications involving highly corrosive fluids or where metal contamination must be avoided.

Composite materials have emerged as a promising avenue for PHE material development. Carbon fiber reinforced polymers (CFRP) and other advanced composites offer a combination of high strength, low weight, and excellent corrosion resistance. These materials allow for the design of larger, more efficient PHEs that can handle higher pressures and temperatures while maintaining structural integrity.

Nanotechnology has also made significant contributions to PHE material advancements. Nanocoatings and nanocomposites have been developed to enhance the surface properties of PHE plates. These coatings can improve heat transfer efficiency by reducing fouling and scaling, which are common issues in hydrogen production processes.

The development of advanced manufacturing techniques, such as 3D printing and additive manufacturing, has enabled the creation of complex geometries and novel material combinations in PHE construction. These techniques allow for the optimization of flow patterns and heat transfer surfaces, leading to improved overall efficiency in hydrogen production applications.

As research in material science continues, future advancements are expected to focus on developing even more durable and efficient materials for PHEs. This may include the exploration of new alloys, advanced ceramics, and hybrid materials that can withstand extreme conditions while maintaining optimal heat transfer properties.

One significant advancement has been the introduction of high-performance stainless steel alloys. These alloys, such as Super Duplex and 254 SMO, offer superior resistance to corrosion and pitting, particularly in high-temperature and high-pressure environments common in hydrogen production. The improved corrosion resistance allows for extended operational lifetimes and reduced maintenance requirements, contributing to increased overall efficiency.

Titanium-based materials have also gained prominence in PHE construction. Titanium's excellent corrosion resistance, coupled with its high strength-to-weight ratio, makes it an ideal choice for applications involving aggressive media or seawater cooling. The use of titanium in PHEs has enabled more compact designs and improved heat transfer efficiency, particularly in processes where contamination must be minimized.

Advancements in polymer-based materials have opened new possibilities for PHE applications in hydrogen production. Fluoropolymers, such as PTFE and PVDF, offer exceptional chemical resistance and can withstand a wide range of temperatures. These materials are particularly useful in applications involving highly corrosive fluids or where metal contamination must be avoided.

Composite materials have emerged as a promising avenue for PHE material development. Carbon fiber reinforced polymers (CFRP) and other advanced composites offer a combination of high strength, low weight, and excellent corrosion resistance. These materials allow for the design of larger, more efficient PHEs that can handle higher pressures and temperatures while maintaining structural integrity.

Nanotechnology has also made significant contributions to PHE material advancements. Nanocoatings and nanocomposites have been developed to enhance the surface properties of PHE plates. These coatings can improve heat transfer efficiency by reducing fouling and scaling, which are common issues in hydrogen production processes.

The development of advanced manufacturing techniques, such as 3D printing and additive manufacturing, has enabled the creation of complex geometries and novel material combinations in PHE construction. These techniques allow for the optimization of flow patterns and heat transfer surfaces, leading to improved overall efficiency in hydrogen production applications.

As research in material science continues, future advancements are expected to focus on developing even more durable and efficient materials for PHEs. This may include the exploration of new alloys, advanced ceramics, and hybrid materials that can withstand extreme conditions while maintaining optimal heat transfer properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!