The Synergy of Plate Heat Exchanger with Renewable Energies

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE-Renewable Energy Synergy Background

The synergy between plate heat exchangers (PHEs) and renewable energy sources has emerged as a critical area of focus in the pursuit of sustainable and efficient energy systems. This convergence represents a significant shift in the approach to thermal management and energy utilization across various industries. Historically, PHEs have been widely used in traditional energy systems due to their compact design, high efficiency, and versatility. However, the growing emphasis on renewable energy sources has opened new avenues for the application and optimization of PHEs.

The evolution of this synergy can be traced back to the early 2000s when the renewable energy sector began to gain significant traction. As solar, geothermal, and wind energy technologies advanced, the need for efficient heat transfer solutions became increasingly apparent. PHEs, with their ability to handle diverse fluids and temperature ranges, naturally aligned with the requirements of these emerging renewable energy systems.

In the context of solar thermal energy, PHEs have played a crucial role in enhancing the efficiency of heat collection and distribution. They have been instrumental in improving the performance of concentrated solar power plants and solar water heating systems. Similarly, in geothermal applications, PHEs have facilitated the effective extraction and utilization of heat from underground reservoirs, contributing to the viability of geothermal power generation and district heating systems.

The integration of PHEs with wind energy, while less direct, has been significant in optimizing the cooling systems of wind turbines and in energy storage applications. As the renewable energy sector continues to grow, the demand for more efficient and adaptable heat exchange solutions has intensified, driving innovation in PHE design and materials.

This technological convergence has not only enhanced the efficiency of renewable energy systems but has also contributed to their economic viability. By improving heat transfer processes, PHEs have helped reduce operational costs and increase the overall energy output of renewable installations. This synergy has been particularly impactful in regions with limited resources, where maximizing energy efficiency is paramount.

Looking ahead, the integration of PHEs with renewable energy sources is expected to play a crucial role in addressing global energy challenges. As the world transitions towards more sustainable energy solutions, the optimization of heat transfer processes will remain a key focus area. The ongoing research and development in this field aim to further enhance the performance of PHEs in renewable energy applications, exploring new materials, designs, and control strategies to meet the evolving demands of the sector.

The evolution of this synergy can be traced back to the early 2000s when the renewable energy sector began to gain significant traction. As solar, geothermal, and wind energy technologies advanced, the need for efficient heat transfer solutions became increasingly apparent. PHEs, with their ability to handle diverse fluids and temperature ranges, naturally aligned with the requirements of these emerging renewable energy systems.

In the context of solar thermal energy, PHEs have played a crucial role in enhancing the efficiency of heat collection and distribution. They have been instrumental in improving the performance of concentrated solar power plants and solar water heating systems. Similarly, in geothermal applications, PHEs have facilitated the effective extraction and utilization of heat from underground reservoirs, contributing to the viability of geothermal power generation and district heating systems.

The integration of PHEs with wind energy, while less direct, has been significant in optimizing the cooling systems of wind turbines and in energy storage applications. As the renewable energy sector continues to grow, the demand for more efficient and adaptable heat exchange solutions has intensified, driving innovation in PHE design and materials.

This technological convergence has not only enhanced the efficiency of renewable energy systems but has also contributed to their economic viability. By improving heat transfer processes, PHEs have helped reduce operational costs and increase the overall energy output of renewable installations. This synergy has been particularly impactful in regions with limited resources, where maximizing energy efficiency is paramount.

Looking ahead, the integration of PHEs with renewable energy sources is expected to play a crucial role in addressing global energy challenges. As the world transitions towards more sustainable energy solutions, the optimization of heat transfer processes will remain a key focus area. The ongoing research and development in this field aim to further enhance the performance of PHEs in renewable energy applications, exploring new materials, designs, and control strategies to meet the evolving demands of the sector.

Market Demand Analysis

The market demand for plate heat exchangers in conjunction with renewable energy systems has been experiencing significant growth in recent years. This surge is primarily driven by the global shift towards sustainable energy solutions and the increasing adoption of renewable energy technologies. The synergy between plate heat exchangers and renewable energy sources offers enhanced efficiency and cost-effectiveness, making it an attractive option for various industries and applications.

In the solar thermal energy sector, plate heat exchangers play a crucial role in transferring heat from solar collectors to storage tanks or distribution systems. The market for solar thermal applications is expanding, particularly in regions with high solar irradiation, such as Southern Europe, the Middle East, and parts of Asia and Africa. This growth is fueled by government incentives, rising energy costs, and increasing environmental awareness among consumers.

The geothermal energy industry also presents a substantial market for plate heat exchangers. These devices are essential in extracting heat from underground sources and transferring it to usable forms for heating, cooling, or power generation. Countries with significant geothermal resources, such as Iceland, New Zealand, and the United States, are driving the demand for advanced heat exchange technologies in this sector.

In the rapidly growing heat pump market, plate heat exchangers are integral components for efficient heat transfer between refrigerants and water or air. The increasing adoption of heat pumps for both residential and commercial applications, especially in regions with cold climates, is boosting the demand for high-performance plate heat exchangers.

The waste heat recovery sector is another area where plate heat exchangers are gaining traction. Industries are increasingly recognizing the potential of capturing and reusing waste heat to improve overall energy efficiency and reduce operational costs. This trend is particularly evident in energy-intensive industries such as manufacturing, chemical processing, and power generation.

The market demand is further amplified by stringent environmental regulations and energy efficiency standards imposed by governments worldwide. These policies are encouraging industries to adopt more efficient heat exchange technologies, thereby driving the integration of plate heat exchangers with renewable energy systems.

Emerging markets in developing countries are also contributing to the growing demand. As these nations invest in renewable energy infrastructure and seek to improve their energy efficiency, the market for plate heat exchangers in conjunction with renewable energy systems is expected to expand significantly.

However, the market faces challenges such as high initial investment costs and the need for specialized expertise in system design and integration. Despite these obstacles, the long-term benefits of improved energy efficiency and reduced environmental impact continue to drive market growth. As technology advances and economies of scale are achieved, the synergy between plate heat exchangers and renewable energies is poised to play an increasingly important role in the global energy landscape.

In the solar thermal energy sector, plate heat exchangers play a crucial role in transferring heat from solar collectors to storage tanks or distribution systems. The market for solar thermal applications is expanding, particularly in regions with high solar irradiation, such as Southern Europe, the Middle East, and parts of Asia and Africa. This growth is fueled by government incentives, rising energy costs, and increasing environmental awareness among consumers.

The geothermal energy industry also presents a substantial market for plate heat exchangers. These devices are essential in extracting heat from underground sources and transferring it to usable forms for heating, cooling, or power generation. Countries with significant geothermal resources, such as Iceland, New Zealand, and the United States, are driving the demand for advanced heat exchange technologies in this sector.

In the rapidly growing heat pump market, plate heat exchangers are integral components for efficient heat transfer between refrigerants and water or air. The increasing adoption of heat pumps for both residential and commercial applications, especially in regions with cold climates, is boosting the demand for high-performance plate heat exchangers.

The waste heat recovery sector is another area where plate heat exchangers are gaining traction. Industries are increasingly recognizing the potential of capturing and reusing waste heat to improve overall energy efficiency and reduce operational costs. This trend is particularly evident in energy-intensive industries such as manufacturing, chemical processing, and power generation.

The market demand is further amplified by stringent environmental regulations and energy efficiency standards imposed by governments worldwide. These policies are encouraging industries to adopt more efficient heat exchange technologies, thereby driving the integration of plate heat exchangers with renewable energy systems.

Emerging markets in developing countries are also contributing to the growing demand. As these nations invest in renewable energy infrastructure and seek to improve their energy efficiency, the market for plate heat exchangers in conjunction with renewable energy systems is expected to expand significantly.

However, the market faces challenges such as high initial investment costs and the need for specialized expertise in system design and integration. Despite these obstacles, the long-term benefits of improved energy efficiency and reduced environmental impact continue to drive market growth. As technology advances and economies of scale are achieved, the synergy between plate heat exchangers and renewable energies is poised to play an increasingly important role in the global energy landscape.

Current Challenges and Limitations

Despite the promising synergy between plate heat exchangers (PHEs) and renewable energy systems, several challenges and limitations currently hinder their widespread adoption and optimal integration. One of the primary obstacles is the intermittent nature of renewable energy sources, particularly solar and wind power. This variability can lead to fluctuations in heat transfer rates and system efficiency, requiring sophisticated control systems and energy storage solutions to maintain stable operation.

The design of PHEs for renewable energy applications also presents challenges. Traditional PHE configurations may not be optimized for the specific temperature ranges and flow rates encountered in renewable energy systems. This necessitates the development of custom designs, which can increase costs and complexity. Additionally, the materials used in conventional PHEs may not always be suitable for the corrosive or high-temperature environments often associated with renewable energy applications, such as geothermal or concentrated solar power systems.

Scaling issues pose another significant limitation. While PHEs are highly efficient in small to medium-scale applications, their performance can degrade when scaled up to the sizes required for large renewable energy installations. This scaling challenge is particularly evident in applications like district heating systems or industrial processes powered by renewable sources, where heat transfer requirements are substantial.

Fouling and contamination remain persistent problems in PHE operation, especially when integrated with renewable energy systems. Biomass-based heating systems, for instance, can introduce particulates and corrosive compounds that accelerate fouling, reducing heat transfer efficiency and increasing maintenance requirements. Similarly, geothermal applications may expose PHEs to mineral-rich fluids that can cause scaling and corrosion.

The economic viability of integrating PHEs with renewable energy systems is another hurdle. While the long-term benefits are clear, the initial capital costs can be high, particularly for custom-designed systems optimized for specific renewable applications. This cost factor can deter adoption, especially in regions where renewable energy incentives are limited.

Lastly, there is a knowledge gap in the industry regarding the optimal integration of PHEs with various renewable energy technologies. This lack of expertise can lead to suboptimal system designs and missed opportunities for efficiency improvements. Overcoming this challenge requires increased research, education, and training programs focused on the synergies between PHEs and renewable energy systems.

The design of PHEs for renewable energy applications also presents challenges. Traditional PHE configurations may not be optimized for the specific temperature ranges and flow rates encountered in renewable energy systems. This necessitates the development of custom designs, which can increase costs and complexity. Additionally, the materials used in conventional PHEs may not always be suitable for the corrosive or high-temperature environments often associated with renewable energy applications, such as geothermal or concentrated solar power systems.

Scaling issues pose another significant limitation. While PHEs are highly efficient in small to medium-scale applications, their performance can degrade when scaled up to the sizes required for large renewable energy installations. This scaling challenge is particularly evident in applications like district heating systems or industrial processes powered by renewable sources, where heat transfer requirements are substantial.

Fouling and contamination remain persistent problems in PHE operation, especially when integrated with renewable energy systems. Biomass-based heating systems, for instance, can introduce particulates and corrosive compounds that accelerate fouling, reducing heat transfer efficiency and increasing maintenance requirements. Similarly, geothermal applications may expose PHEs to mineral-rich fluids that can cause scaling and corrosion.

The economic viability of integrating PHEs with renewable energy systems is another hurdle. While the long-term benefits are clear, the initial capital costs can be high, particularly for custom-designed systems optimized for specific renewable applications. This cost factor can deter adoption, especially in regions where renewable energy incentives are limited.

Lastly, there is a knowledge gap in the industry regarding the optimal integration of PHEs with various renewable energy technologies. This lack of expertise can lead to suboptimal system designs and missed opportunities for efficiency improvements. Overcoming this challenge requires increased research, education, and training programs focused on the synergies between PHEs and renewable energy systems.

Existing PHE-Renewable Energy Solutions

01 Improved plate design for enhanced heat transfer

Advanced plate designs in heat exchangers aim to increase turbulence and surface area for better heat transfer efficiency. These designs may include corrugated patterns, dimples, or other surface modifications to optimize fluid flow and thermal performance.- Plate design and configuration: Innovations in plate design and configuration for heat exchangers focus on improving heat transfer efficiency and reducing pressure drop. This includes optimizing plate patterns, corrugations, and flow distribution to enhance thermal performance while minimizing fluid resistance.

- Sealing and gasket improvements: Advancements in sealing technology and gasket design for plate heat exchangers aim to prevent leakage, improve durability, and enhance overall system reliability. These innovations include new gasket materials, sealing mechanisms, and plate edge designs to ensure tight seals under various operating conditions.

- Material selection and corrosion resistance: Research into advanced materials for plate heat exchangers focuses on improving corrosion resistance, thermal conductivity, and overall performance. This includes the use of specialized alloys, coatings, and surface treatments to extend equipment lifespan and maintain efficiency in challenging environments.

- Modular and customizable designs: Development of modular and customizable plate heat exchanger designs allows for greater flexibility in application and easier maintenance. These innovations enable quick assembly, disassembly, and reconfiguration of heat exchanger units to meet specific process requirements and facilitate cleaning or replacement of individual components.

- Enhanced flow distribution and turbulence: Innovations in flow distribution and turbulence generation within plate heat exchangers aim to improve heat transfer rates and reduce fouling. This includes the development of novel plate geometries, flow channels, and turbulence promoters to optimize fluid dynamics and enhance overall thermal performance.

02 Sealing and gasket innovations

Novel sealing and gasket technologies are developed to prevent leakage and improve the overall reliability of plate heat exchangers. These innovations may include advanced materials, unique gasket designs, or improved sealing methods to enhance performance under various operating conditions.Expand Specific Solutions03 Modular and customizable configurations

Plate heat exchangers are designed with modular components, allowing for easy customization and scalability. This approach enables the heat exchanger to be tailored to specific applications and capacity requirements, improving flexibility and efficiency in various industrial settings.Expand Specific Solutions04 Integration of advanced materials

The use of advanced materials in plate heat exchangers, such as high-performance alloys or composite materials, aims to improve corrosion resistance, thermal conductivity, and overall durability. These materials can extend the lifespan of the heat exchanger and allow for operation in more demanding environments.Expand Specific Solutions05 Smart monitoring and control systems

Integration of sensors and smart control systems in plate heat exchangers enables real-time monitoring of performance, predictive maintenance, and automatic optimization of operating parameters. These technologies can improve energy efficiency, reduce downtime, and extend the operational life of the heat exchanger.Expand Specific Solutions

Key Industry Players

The synergy between plate heat exchangers and renewable energies is gaining momentum in the evolving energy landscape. This market is in a growth phase, driven by increasing demand for energy-efficient solutions and sustainable practices. The global plate heat exchanger market is expected to reach significant size in the coming years, propelled by applications in renewable energy systems. Technologically, the field is advancing rapidly, with companies like Alfa Laval, Danfoss, and Vahterus leading innovation. These firms are developing more efficient and compact designs, integrating smart controls, and exploring novel materials to enhance heat transfer capabilities and durability in renewable energy applications.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for renewable energy applications. Their technology focuses on maximizing heat transfer efficiency while minimizing fouling and pressure drop. For solar thermal systems, they've introduced the AlfaNova fusion-bonded plate heat exchanger, which can withstand high temperatures and pressures typical in concentrated solar power plants[1]. In geothermal applications, their wide-gap plate heat exchangers are engineered to handle the scaling and corrosive nature of geothermal fluids, improving system longevity and performance[2]. For biomass energy, Alfa Laval's robust plate heat exchangers are designed to manage the high particulate content often found in biomass processes, ensuring efficient heat recovery and system reliability[3].

Strengths: High efficiency, corrosion resistance, and adaptability to various renewable energy sources. Weaknesses: Higher initial cost compared to traditional shell-and-tube heat exchangers, potential for clogging in certain applications.

Danfoss A/S

Technical Solution: Danfoss has developed innovative plate heat exchanger solutions tailored for renewable energy systems. Their micro plate heat exchangers utilize a unique chevron pattern that increases turbulence, resulting in up to 10% higher efficiency compared to traditional designs[4]. For solar thermal applications, Danfoss offers specially designed heat exchangers that can handle the high temperatures and thermal cycling inherent in solar systems. In the field of geothermal energy, their brazed plate heat exchangers are engineered to withstand the corrosive nature of geothermal fluids while maintaining high thermal efficiency[5]. Danfoss also focuses on compact designs, reducing the physical footprint of renewable energy systems and improving their integration into existing infrastructure.

Strengths: High efficiency, compact design, and durability in harsh conditions. Weaknesses: May require more frequent maintenance in certain high-fouling applications.

Core Innovations in PHE Technology

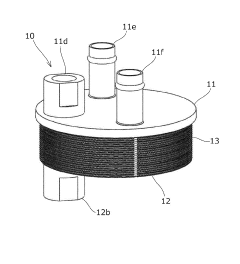

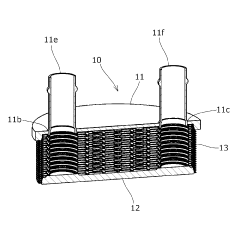

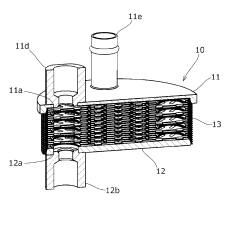

Heat exchanger and cooling system using the same

PatentActiveJP2023059117A

Innovation

- A heat exchanger design featuring alternating male and female plates with angled holes and tubular portions, allowing for uniform fluid flow and enhanced heat exchange efficiency, while maintaining a compact and cost-effective structure.

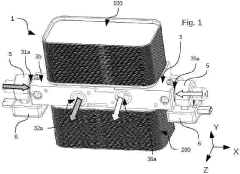

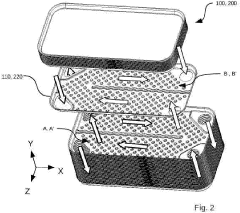

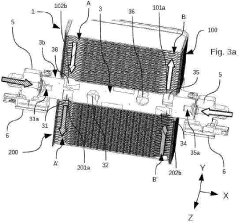

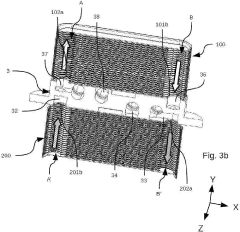

Heat-energy exchange device comprising two plate heat exchangers

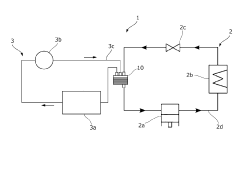

PatentPendingUS20230311612A1

Innovation

- A heat-energy exchange device comprising two plate heat exchangers with a distribution member sandwiched between them, featuring channels connecting inlet and outlet ports and incorporating an expansion device and pressure/temperature sensor for efficient heat transfer fluid management.

Environmental Impact Assessment

The integration of plate heat exchangers with renewable energy systems presents a significant opportunity for enhancing environmental sustainability. This synergy offers substantial potential for reducing greenhouse gas emissions and mitigating the environmental impact of energy production and consumption. By efficiently transferring heat between renewable energy sources and various applications, plate heat exchangers contribute to the overall efficiency of renewable energy systems, thereby reducing the reliance on fossil fuels and associated carbon emissions.

In the context of solar thermal systems, plate heat exchangers play a crucial role in maximizing the utilization of solar energy. They facilitate the transfer of heat from solar collectors to storage tanks or directly to end-use applications, such as domestic hot water or space heating. This efficient heat transfer process minimizes energy losses and optimizes the overall system performance, resulting in reduced energy consumption and lower environmental impact.

Similarly, in geothermal energy applications, plate heat exchangers enable the effective extraction of heat from underground sources. By efficiently transferring geothermal heat to buildings or industrial processes, these systems reduce the need for conventional heating methods, leading to significant reductions in carbon emissions and other pollutants associated with fossil fuel combustion.

The use of plate heat exchangers in waste heat recovery systems also contributes to environmental protection. By capturing and repurposing waste heat from industrial processes or power generation, these systems improve overall energy efficiency and reduce the demand for primary energy sources. This not only lowers greenhouse gas emissions but also minimizes thermal pollution in water bodies and the atmosphere.

In the realm of bioenergy, plate heat exchangers support the efficient conversion of biomass into usable heat or electricity. By optimizing heat transfer in biogas plants or biomass-fired power stations, these systems enhance the overall efficiency of bioenergy production, reducing waste and maximizing the utilization of renewable biomass resources.

The environmental benefits of integrating plate heat exchangers with renewable energy systems extend beyond emissions reduction. These systems often require less space and fewer materials compared to traditional heat exchange methods, resulting in reduced land use and resource consumption. Additionally, the improved efficiency and longevity of renewable energy systems equipped with plate heat exchangers contribute to a decrease in the environmental impact associated with system maintenance and replacement.

However, it is important to consider the full lifecycle environmental impact of plate heat exchangers, including their production, installation, and eventual disposal. While the operational benefits are clear, efforts should be made to ensure sustainable manufacturing practices and proper end-of-life management to maximize the net positive environmental impact of these systems.

In the context of solar thermal systems, plate heat exchangers play a crucial role in maximizing the utilization of solar energy. They facilitate the transfer of heat from solar collectors to storage tanks or directly to end-use applications, such as domestic hot water or space heating. This efficient heat transfer process minimizes energy losses and optimizes the overall system performance, resulting in reduced energy consumption and lower environmental impact.

Similarly, in geothermal energy applications, plate heat exchangers enable the effective extraction of heat from underground sources. By efficiently transferring geothermal heat to buildings or industrial processes, these systems reduce the need for conventional heating methods, leading to significant reductions in carbon emissions and other pollutants associated with fossil fuel combustion.

The use of plate heat exchangers in waste heat recovery systems also contributes to environmental protection. By capturing and repurposing waste heat from industrial processes or power generation, these systems improve overall energy efficiency and reduce the demand for primary energy sources. This not only lowers greenhouse gas emissions but also minimizes thermal pollution in water bodies and the atmosphere.

In the realm of bioenergy, plate heat exchangers support the efficient conversion of biomass into usable heat or electricity. By optimizing heat transfer in biogas plants or biomass-fired power stations, these systems enhance the overall efficiency of bioenergy production, reducing waste and maximizing the utilization of renewable biomass resources.

The environmental benefits of integrating plate heat exchangers with renewable energy systems extend beyond emissions reduction. These systems often require less space and fewer materials compared to traditional heat exchange methods, resulting in reduced land use and resource consumption. Additionally, the improved efficiency and longevity of renewable energy systems equipped with plate heat exchangers contribute to a decrease in the environmental impact associated with system maintenance and replacement.

However, it is important to consider the full lifecycle environmental impact of plate heat exchangers, including their production, installation, and eventual disposal. While the operational benefits are clear, efforts should be made to ensure sustainable manufacturing practices and proper end-of-life management to maximize the net positive environmental impact of these systems.

Regulatory Framework

The regulatory framework surrounding the synergy of plate heat exchangers with renewable energies is complex and evolving, reflecting the growing emphasis on sustainable energy solutions worldwide. At the international level, the Paris Agreement has set ambitious targets for reducing greenhouse gas emissions, driving countries to implement policies that promote renewable energy integration and energy efficiency. This has led to increased support for technologies like plate heat exchangers that can enhance the performance of renewable energy systems.

In the European Union, the Renewable Energy Directive (RED II) mandates that member states achieve a collective target of 32% renewable energy in their energy mix by 2030. This directive has spurred the development of national policies that incentivize the adoption of renewable heating and cooling solutions, including those incorporating plate heat exchangers. Additionally, the Energy Performance of Buildings Directive (EPBD) requires all new buildings to be nearly zero-energy by 2021, further encouraging the use of efficient heat exchange technologies in conjunction with renewable energy sources.

In the United States, the regulatory landscape varies by state, but federal initiatives like the Investment Tax Credit (ITC) and Production Tax Credit (PTC) have been instrumental in promoting renewable energy projects. These incentives can apply to systems that integrate plate heat exchangers with renewable energy sources, such as solar thermal or geothermal installations. The Department of Energy's Building Technologies Office also supports research and development in energy-efficient building technologies, including advanced heat exchanger designs for renewable energy applications.

China, as a major player in renewable energy deployment, has implemented its Renewable Energy Law, which provides a comprehensive framework for promoting renewable energy utilization. This law, coupled with the country's ambitious targets for renewable energy capacity, has created a favorable environment for technologies that enhance renewable energy efficiency, including plate heat exchangers.

Regulatory bodies such as the International Organization for Standardization (ISO) have developed standards specific to plate heat exchangers, such as ISO 15547, which provides guidelines for their design. These standards ensure safety, reliability, and performance consistency across different applications, including those in renewable energy systems. Similarly, the American Society of Mechanical Engineers (ASME) has established codes and standards for pressure vessels, which often apply to plate heat exchangers used in renewable energy installations.

As the global focus on climate change mitigation intensifies, it is anticipated that regulatory frameworks will continue to evolve, potentially introducing more stringent efficiency requirements and expanded incentives for renewable energy technologies. This ongoing regulatory development is likely to further drive innovation in plate heat exchanger design and its integration with renewable energy systems, fostering a more sustainable and efficient energy landscape.

In the European Union, the Renewable Energy Directive (RED II) mandates that member states achieve a collective target of 32% renewable energy in their energy mix by 2030. This directive has spurred the development of national policies that incentivize the adoption of renewable heating and cooling solutions, including those incorporating plate heat exchangers. Additionally, the Energy Performance of Buildings Directive (EPBD) requires all new buildings to be nearly zero-energy by 2021, further encouraging the use of efficient heat exchange technologies in conjunction with renewable energy sources.

In the United States, the regulatory landscape varies by state, but federal initiatives like the Investment Tax Credit (ITC) and Production Tax Credit (PTC) have been instrumental in promoting renewable energy projects. These incentives can apply to systems that integrate plate heat exchangers with renewable energy sources, such as solar thermal or geothermal installations. The Department of Energy's Building Technologies Office also supports research and development in energy-efficient building technologies, including advanced heat exchanger designs for renewable energy applications.

China, as a major player in renewable energy deployment, has implemented its Renewable Energy Law, which provides a comprehensive framework for promoting renewable energy utilization. This law, coupled with the country's ambitious targets for renewable energy capacity, has created a favorable environment for technologies that enhance renewable energy efficiency, including plate heat exchangers.

Regulatory bodies such as the International Organization for Standardization (ISO) have developed standards specific to plate heat exchangers, such as ISO 15547, which provides guidelines for their design. These standards ensure safety, reliability, and performance consistency across different applications, including those in renewable energy systems. Similarly, the American Society of Mechanical Engineers (ASME) has established codes and standards for pressure vessels, which often apply to plate heat exchangers used in renewable energy installations.

As the global focus on climate change mitigation intensifies, it is anticipated that regulatory frameworks will continue to evolve, potentially introducing more stringent efficiency requirements and expanded incentives for renewable energy technologies. This ongoing regulatory development is likely to further drive innovation in plate heat exchanger design and its integration with renewable energy systems, fostering a more sustainable and efficient energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!