Plate Heat Exchanger Performance in Varying Chemical Conditions

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Technology Evolution and Objectives

Plate heat exchangers (PHEs) have undergone significant technological evolution since their inception in the 1920s. Initially designed for the dairy industry, PHEs have expanded their applications across various sectors due to their compact design, high efficiency, and versatility. The primary objective of PHE technology has been to enhance heat transfer efficiency while minimizing fouling and corrosion in diverse chemical environments.

The evolution of PHE technology has been driven by the need to improve performance in varying chemical conditions. Early designs focused on simple plate patterns and materials suitable for mild operating conditions. As industrial processes became more complex, PHE manufacturers developed advanced plate geometries and materials to withstand aggressive chemicals and extreme temperatures.

A key milestone in PHE development was the introduction of corrugated plates in the 1960s. This innovation significantly increased heat transfer efficiency by promoting turbulent flow and reducing fouling. Subsequent advancements included the development of asymmetric plate patterns and multi-pass configurations, further optimizing heat transfer and fluid distribution.

Material science has played a crucial role in PHE evolution. The introduction of high-performance alloys and composite materials has extended the operational range of PHEs in corrosive environments. Titanium, high-grade stainless steel, and specialized polymers have become standard options for challenging chemical applications.

Recent technological objectives focus on enhancing PHE performance in dynamic chemical conditions. This includes the development of smart PHEs with integrated sensors for real-time monitoring of fouling and corrosion. Additionally, research is being conducted on self-cleaning surfaces and advanced coatings to mitigate the effects of varying chemical compositions on heat transfer efficiency.

The current technological landscape aims to address several key objectives: improving heat transfer coefficients in multi-component fluid systems, extending equipment lifespan in corrosive environments, and developing predictive maintenance strategies based on real-time performance data. These goals are driving innovation in plate design, material selection, and process control integration.

As industries continue to demand more efficient and flexible heat exchange solutions, the evolution of PHE technology is expected to accelerate. Future objectives include the development of modular PHE systems that can adapt to changing chemical conditions, as well as the integration of artificial intelligence for optimized performance across a wide range of operating parameters.

The evolution of PHE technology has been driven by the need to improve performance in varying chemical conditions. Early designs focused on simple plate patterns and materials suitable for mild operating conditions. As industrial processes became more complex, PHE manufacturers developed advanced plate geometries and materials to withstand aggressive chemicals and extreme temperatures.

A key milestone in PHE development was the introduction of corrugated plates in the 1960s. This innovation significantly increased heat transfer efficiency by promoting turbulent flow and reducing fouling. Subsequent advancements included the development of asymmetric plate patterns and multi-pass configurations, further optimizing heat transfer and fluid distribution.

Material science has played a crucial role in PHE evolution. The introduction of high-performance alloys and composite materials has extended the operational range of PHEs in corrosive environments. Titanium, high-grade stainless steel, and specialized polymers have become standard options for challenging chemical applications.

Recent technological objectives focus on enhancing PHE performance in dynamic chemical conditions. This includes the development of smart PHEs with integrated sensors for real-time monitoring of fouling and corrosion. Additionally, research is being conducted on self-cleaning surfaces and advanced coatings to mitigate the effects of varying chemical compositions on heat transfer efficiency.

The current technological landscape aims to address several key objectives: improving heat transfer coefficients in multi-component fluid systems, extending equipment lifespan in corrosive environments, and developing predictive maintenance strategies based on real-time performance data. These goals are driving innovation in plate design, material selection, and process control integration.

As industries continue to demand more efficient and flexible heat exchange solutions, the evolution of PHE technology is expected to accelerate. Future objectives include the development of modular PHE systems that can adapt to changing chemical conditions, as well as the integration of artificial intelligence for optimized performance across a wide range of operating parameters.

Chemical Industry Demand Analysis

The chemical industry's demand for efficient heat transfer solutions has been steadily increasing, driven by the need for improved process efficiency, energy conservation, and cost reduction. Plate heat exchangers (PHEs) have emerged as a crucial technology in this sector, offering superior heat transfer capabilities and compact design compared to traditional shell-and-tube heat exchangers. The market for PHEs in the chemical industry is expected to grow significantly in the coming years, with a particular focus on their performance in varying chemical conditions.

The demand for PHEs in the chemical industry is primarily fueled by their ability to handle corrosive and high-temperature fluids, which are common in many chemical processes. Industries such as petrochemicals, fine chemicals, and specialty chemicals are increasingly adopting PHEs due to their versatility and efficiency. The market is also seeing a rise in demand for customized PHEs that can withstand specific chemical environments, highlighting the need for ongoing research and development in materials and design.

Environmental regulations and sustainability goals are further driving the adoption of PHEs in the chemical industry. As companies strive to reduce their carbon footprint and improve energy efficiency, PHEs offer a solution that can significantly decrease energy consumption in heat transfer processes. This aligns with the industry's broader trend towards green chemistry and sustainable manufacturing practices.

The pharmaceutical sector, a subset of the chemical industry, is another key driver of PHE demand. The stringent requirements for temperature control and cleanliness in drug manufacturing make PHEs an ideal choice. Their ability to maintain precise temperature profiles and ease of cleaning are particularly valuable in this highly regulated environment.

Market analysis indicates that the Asia-Pacific region is expected to see the highest growth in PHE adoption within the chemical industry. This is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in chemical manufacturing facilities. North America and Europe, while more mature markets, continue to show steady demand, particularly for advanced PHE technologies that can handle complex chemical processes.

The trend towards process intensification in the chemical industry is also boosting the demand for PHEs. As companies seek to maximize productivity while minimizing plant footprint, the compact nature of PHEs makes them an attractive option. This is particularly relevant in retrofit projects where space is at a premium.

In conclusion, the chemical industry's demand for PHEs, especially those capable of performing in varying chemical conditions, is robust and growing. The market is driven by the need for efficiency, sustainability, and adaptability to diverse chemical environments. As the industry continues to evolve, the development of PHEs that can meet these challenges will be crucial in shaping the future of chemical processing technologies.

The demand for PHEs in the chemical industry is primarily fueled by their ability to handle corrosive and high-temperature fluids, which are common in many chemical processes. Industries such as petrochemicals, fine chemicals, and specialty chemicals are increasingly adopting PHEs due to their versatility and efficiency. The market is also seeing a rise in demand for customized PHEs that can withstand specific chemical environments, highlighting the need for ongoing research and development in materials and design.

Environmental regulations and sustainability goals are further driving the adoption of PHEs in the chemical industry. As companies strive to reduce their carbon footprint and improve energy efficiency, PHEs offer a solution that can significantly decrease energy consumption in heat transfer processes. This aligns with the industry's broader trend towards green chemistry and sustainable manufacturing practices.

The pharmaceutical sector, a subset of the chemical industry, is another key driver of PHE demand. The stringent requirements for temperature control and cleanliness in drug manufacturing make PHEs an ideal choice. Their ability to maintain precise temperature profiles and ease of cleaning are particularly valuable in this highly regulated environment.

Market analysis indicates that the Asia-Pacific region is expected to see the highest growth in PHE adoption within the chemical industry. This is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in chemical manufacturing facilities. North America and Europe, while more mature markets, continue to show steady demand, particularly for advanced PHE technologies that can handle complex chemical processes.

The trend towards process intensification in the chemical industry is also boosting the demand for PHEs. As companies seek to maximize productivity while minimizing plant footprint, the compact nature of PHEs makes them an attractive option. This is particularly relevant in retrofit projects where space is at a premium.

In conclusion, the chemical industry's demand for PHEs, especially those capable of performing in varying chemical conditions, is robust and growing. The market is driven by the need for efficiency, sustainability, and adaptability to diverse chemical environments. As the industry continues to evolve, the development of PHEs that can meet these challenges will be crucial in shaping the future of chemical processing technologies.

PHE Challenges in Corrosive Environments

Plate heat exchangers (PHEs) face significant challenges when operating in corrosive environments, which can severely impact their performance and longevity. The primary concern in such conditions is the degradation of materials used in the construction of PHEs, particularly the plates and gaskets. Corrosive chemicals can attack these components, leading to leaks, reduced heat transfer efficiency, and ultimately, equipment failure.

One of the most common issues encountered is the corrosion of metal plates. Stainless steel, a popular material for PHE plates due to its durability and heat transfer properties, can be susceptible to various forms of corrosion in aggressive chemical environments. Pitting corrosion, for instance, can create localized areas of deep penetration, compromising the integrity of the plates. Crevice corrosion is another concern, often occurring in the tight spaces between plates where corrosive media can become trapped.

Gasket materials also face significant challenges in corrosive conditions. Many elastomers used for gaskets can degrade when exposed to certain chemicals, leading to loss of sealing ability and potential leaks. This degradation can occur through swelling, shrinkage, or chemical breakdown of the gasket material, depending on the specific corrosive media present.

The presence of high temperatures in combination with corrosive chemicals can exacerbate these issues. Elevated temperatures often accelerate chemical reactions, potentially increasing the rate of corrosion and material degradation. This synergistic effect between temperature and corrosive media presents a particularly challenging operating environment for PHEs.

Furthermore, the flow dynamics within PHEs can contribute to corrosion-related problems. Areas of high turbulence or stagnation can create localized regions where corrosion is more likely to occur. This can lead to uneven wear and degradation across the heat exchanger, potentially causing unexpected failures in specific areas.

The varying nature of chemical conditions in industrial processes adds another layer of complexity. PHEs may be exposed to fluctuating pH levels, changing concentrations of corrosive species, or intermittent exposure to different chemicals. This variability makes it challenging to predict and mitigate corrosion effects consistently over time.

Addressing these challenges requires a multifaceted approach, including careful material selection, advanced surface treatments, and innovative design modifications. The development of corrosion-resistant alloys and composite materials has opened new possibilities for enhancing PHE performance in harsh environments. However, balancing corrosion resistance with heat transfer efficiency and cost-effectiveness remains an ongoing challenge in the industry.

One of the most common issues encountered is the corrosion of metal plates. Stainless steel, a popular material for PHE plates due to its durability and heat transfer properties, can be susceptible to various forms of corrosion in aggressive chemical environments. Pitting corrosion, for instance, can create localized areas of deep penetration, compromising the integrity of the plates. Crevice corrosion is another concern, often occurring in the tight spaces between plates where corrosive media can become trapped.

Gasket materials also face significant challenges in corrosive conditions. Many elastomers used for gaskets can degrade when exposed to certain chemicals, leading to loss of sealing ability and potential leaks. This degradation can occur through swelling, shrinkage, or chemical breakdown of the gasket material, depending on the specific corrosive media present.

The presence of high temperatures in combination with corrosive chemicals can exacerbate these issues. Elevated temperatures often accelerate chemical reactions, potentially increasing the rate of corrosion and material degradation. This synergistic effect between temperature and corrosive media presents a particularly challenging operating environment for PHEs.

Furthermore, the flow dynamics within PHEs can contribute to corrosion-related problems. Areas of high turbulence or stagnation can create localized regions where corrosion is more likely to occur. This can lead to uneven wear and degradation across the heat exchanger, potentially causing unexpected failures in specific areas.

The varying nature of chemical conditions in industrial processes adds another layer of complexity. PHEs may be exposed to fluctuating pH levels, changing concentrations of corrosive species, or intermittent exposure to different chemicals. This variability makes it challenging to predict and mitigate corrosion effects consistently over time.

Addressing these challenges requires a multifaceted approach, including careful material selection, advanced surface treatments, and innovative design modifications. The development of corrosion-resistant alloys and composite materials has opened new possibilities for enhancing PHE performance in harsh environments. However, balancing corrosion resistance with heat transfer efficiency and cost-effectiveness remains an ongoing challenge in the industry.

Current PHE Corrosion Resistance Solutions

01 Improved plate design for enhanced heat transfer

Advanced plate designs incorporate features such as corrugations, chevron patterns, or dimples to increase turbulence and surface area. These modifications improve heat transfer efficiency by promoting better fluid mixing and reducing thermal resistance. The optimized plate geometry also helps in minimizing fouling and pressure drop across the exchanger.- Improved plate design for enhanced heat transfer: Advanced plate designs incorporate features such as corrugations, chevron patterns, or dimples to increase turbulence and surface area. These modifications improve heat transfer efficiency and overall performance of plate heat exchangers.

- Optimized flow distribution: Innovative flow distribution systems ensure uniform fluid flow across the plates, reducing dead zones and improving heat transfer. This can include specially designed inlet and outlet ports, as well as internal flow guides.

- Enhanced sealing and gasket technology: Advanced sealing and gasket materials and designs improve leak prevention and allow for higher operating pressures and temperatures. This increases the overall efficiency and reliability of plate heat exchangers.

- Multi-pass configurations: Implementing multi-pass configurations in plate heat exchangers can increase the overall heat transfer coefficient. This design allows for longer fluid paths and increased residence time, resulting in improved thermal performance.

- Material selection for improved performance: Utilizing advanced materials with superior thermal conductivity and corrosion resistance can significantly enhance heat exchanger performance. This includes the use of specialized alloys or composite materials for plate construction.

02 Flow distribution optimization

Enhancing flow distribution within the plate heat exchanger improves overall performance. This is achieved through innovative inlet and outlet port designs, flow guides, and distribution channels. Uniform flow distribution ensures maximum heat transfer across the entire plate surface, reducing dead zones and improving thermal efficiency.Expand Specific Solutions03 Material selection for improved thermal conductivity

Utilizing advanced materials with high thermal conductivity for plate construction enhances heat transfer rates. Materials such as high-grade stainless steel, titanium alloys, or composite materials can significantly improve the overall performance of the plate heat exchanger while also offering benefits like corrosion resistance and durability.Expand Specific Solutions04 Gasket and sealing technology advancements

Improved gasket designs and sealing technologies enhance the performance of plate heat exchangers by preventing leakage and maintaining proper plate alignment. Advanced gasket materials and sealing methods ensure better pressure resistance, longer operational life, and improved overall efficiency of the heat exchanger.Expand Specific Solutions05 Smart monitoring and control systems

Integration of smart monitoring and control systems in plate heat exchangers allows for real-time performance optimization. These systems can adjust flow rates, monitor fouling, and predict maintenance needs. By continuously optimizing operating parameters, the overall efficiency and lifespan of the plate heat exchanger are significantly improved.Expand Specific Solutions

Key PHE Manufacturers and Suppliers

The plate heat exchanger market in varying chemical conditions is in a mature growth stage, with a global market size expected to reach $5.5 billion by 2027. The technology is well-established, with ongoing innovations focusing on improving efficiency and adaptability to diverse chemical environments. Key players like Alfa Laval, Linde, and Mitsubishi Electric are driving advancements in this field. Alfa Laval, a market leader, has a strong focus on developing heat transfer solutions for challenging chemical applications. Emerging companies such as LHE Co. and Jiangsu Weyee Heat Exchanger are also contributing to technological progress, particularly in specialized chemical-resistant designs. The competitive landscape is characterized by a mix of established multinational corporations and innovative smaller firms, all striving to enhance heat exchanger performance across various chemical conditions.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for varying chemical conditions. Their AlfaNova fusion-bonded plate heat exchangers utilize a patented fusion technology that bonds 100% stainless steel plates, making them highly resistant to corrosion and suitable for aggressive media[1]. The company has also introduced the DuroShell plate-and-shell heat exchanger, which combines the thermal efficiency of plate technology with the pressure and temperature resistance of shell-and-tube heat exchangers[2]. This innovation allows for operation in harsh chemical environments with pressures up to 100 bar and temperatures up to 450°C[3]. Alfa Laval's plate heat exchangers incorporate advanced flow distribution systems that ensure uniform fluid distribution across the plates, enhancing heat transfer efficiency and reducing fouling in varying chemical conditions[4].

Strengths: High corrosion resistance, suitable for aggressive media, high pressure and temperature tolerance, efficient heat transfer. Weaknesses: Higher initial cost compared to traditional heat exchangers, may require specialized maintenance.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed innovative plate heat exchanger solutions for varying chemical conditions, particularly in the field of catalysis and chemical processing. Their plate heat exchangers incorporate proprietary catalytic coatings that can withstand harsh chemical environments while promoting desired reactions[1]. The company's CATOX™ technology integrates catalytic oxidation directly into the heat exchanger design, allowing for simultaneous heat recovery and pollutant abatement in chemical processes[2]. Haldor Topsøe's plate heat exchangers feature advanced materials such as high-grade stainless steel and specialized alloys that resist corrosion and fouling in diverse chemical streams[3]. The company has also implemented modular designs that allow for easy maintenance and replacement of individual plates, enhancing the overall lifespan and adaptability of the heat exchangers in changing chemical conditions[4].

Strengths: Integrated catalytic functionality, high chemical resistance, modular design for easy maintenance. Weaknesses: Specialized applications may limit broader market appeal, potentially higher costs due to advanced materials and coatings.

Innovative Materials for PHE Plates

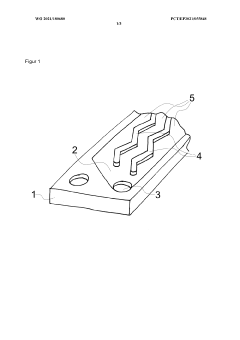

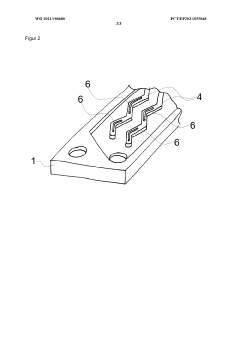

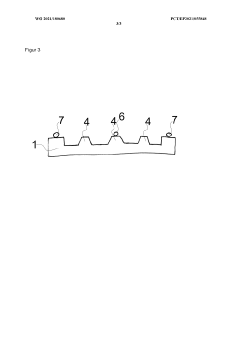

Plate heat exchanger

PatentWO2021180680A1

Innovation

- A plate heat exchanger design featuring two heat exchange plates with a channel system sealed by a support element and a sealing element, where the support element is spaced apart from the sealing element, using fluoropolymer materials for both, and a detachable joint connection to ensure stability and reliability under high pressures.

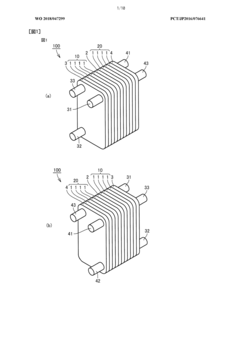

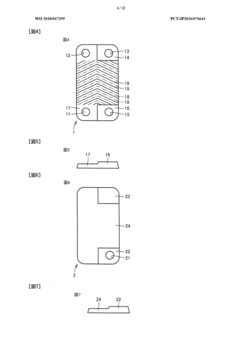

Plate-type heat exchanger and refrigeration cycle device

PatentWO2018047299A1

Innovation

- A plate heat exchanger design with alternating flow paths and a partition plate configuration that minimizes pressure differences by positioning flow paths closer to the partition plate, reducing the stress on the partition plate and enhancing its reliability.

Environmental Impact of PHE Manufacturing

The manufacturing process of plate heat exchangers (PHEs) has significant environmental implications that warrant careful consideration. The production of PHEs involves several stages, each with its own environmental impact. The primary materials used in PHE manufacturing are metals, typically stainless steel or titanium, which require energy-intensive mining and refining processes. These activities contribute to greenhouse gas emissions and can lead to habitat disruption and water pollution if not properly managed.

The metal forming and stamping processes used to create the plates consume substantial amounts of energy and may generate metal waste. While much of this waste can be recycled, the recycling process itself requires energy and resources. The use of chemicals for cleaning and surface treatment of the plates can result in hazardous waste that needs proper disposal to prevent environmental contamination.

Gasket production, an essential component of PHEs, often involves synthetic rubber materials derived from petroleum products. The manufacturing of these gaskets contributes to the depletion of non-renewable resources and may release volatile organic compounds (VOCs) during the production process. These emissions can contribute to air pollution and potentially harm human health if not adequately controlled.

The assembly of PHEs requires precision welding or brazing, which consumes energy and may produce fumes containing metal particulates. Proper ventilation and filtration systems are necessary to mitigate the release of these pollutants into the environment. Additionally, the packaging and transportation of finished PHEs contribute to the overall carbon footprint of the manufacturing process.

However, it is important to note that the environmental impact of PHE manufacturing should be considered in the context of the product's lifecycle. PHEs are designed to improve energy efficiency in various industrial processes, potentially offsetting their manufacturing emissions over time through reduced energy consumption in their applications. Furthermore, the long lifespan and recyclability of PHEs contribute to their overall environmental sustainability.

To mitigate the environmental impact of PHE manufacturing, companies are increasingly adopting cleaner production techniques. These include implementing energy-efficient machinery, optimizing material use to reduce waste, and exploring alternative, more sustainable materials for gaskets. Some manufacturers are also investing in renewable energy sources to power their production facilities, further reducing the carbon footprint of PHE manufacturing.

The metal forming and stamping processes used to create the plates consume substantial amounts of energy and may generate metal waste. While much of this waste can be recycled, the recycling process itself requires energy and resources. The use of chemicals for cleaning and surface treatment of the plates can result in hazardous waste that needs proper disposal to prevent environmental contamination.

Gasket production, an essential component of PHEs, often involves synthetic rubber materials derived from petroleum products. The manufacturing of these gaskets contributes to the depletion of non-renewable resources and may release volatile organic compounds (VOCs) during the production process. These emissions can contribute to air pollution and potentially harm human health if not adequately controlled.

The assembly of PHEs requires precision welding or brazing, which consumes energy and may produce fumes containing metal particulates. Proper ventilation and filtration systems are necessary to mitigate the release of these pollutants into the environment. Additionally, the packaging and transportation of finished PHEs contribute to the overall carbon footprint of the manufacturing process.

However, it is important to note that the environmental impact of PHE manufacturing should be considered in the context of the product's lifecycle. PHEs are designed to improve energy efficiency in various industrial processes, potentially offsetting their manufacturing emissions over time through reduced energy consumption in their applications. Furthermore, the long lifespan and recyclability of PHEs contribute to their overall environmental sustainability.

To mitigate the environmental impact of PHE manufacturing, companies are increasingly adopting cleaner production techniques. These include implementing energy-efficient machinery, optimizing material use to reduce waste, and exploring alternative, more sustainable materials for gaskets. Some manufacturers are also investing in renewable energy sources to power their production facilities, further reducing the carbon footprint of PHE manufacturing.

PHE Maintenance and Lifecycle Management

Effective maintenance and lifecycle management are crucial for optimizing the performance and longevity of plate heat exchangers (PHEs) operating in varying chemical conditions. A comprehensive maintenance strategy should encompass regular inspections, cleaning procedures, and proactive replacement of components to ensure optimal heat transfer efficiency and prevent unexpected failures.

Routine inspections are essential for identifying early signs of fouling, corrosion, or mechanical damage. These inspections should be conducted at intervals determined by the specific operating conditions and fluid properties. Visual examinations can reveal surface deposits, while pressure drop measurements and thermal performance monitoring can indicate internal fouling or blockages.

Cleaning procedures must be tailored to the specific chemical environment and fouling characteristics. Chemical cleaning methods, such as circulation cleaning or CIP (Clean-in-Place) systems, are often preferred for their effectiveness in removing various types of deposits. The selection of cleaning agents should consider compatibility with plate materials and gaskets to prevent damage during the cleaning process.

Mechanical cleaning techniques, including high-pressure water jetting or brushing, may be necessary for more stubborn deposits. However, care must be taken to avoid damaging the plate surfaces or compromising the integrity of the gaskets. In some cases, a combination of chemical and mechanical cleaning methods may yield the best results.

Predictive maintenance strategies, leveraging data analytics and condition monitoring technologies, can significantly enhance PHE lifecycle management. By analyzing trends in performance data, operators can anticipate maintenance needs and schedule interventions before efficiency degradation becomes critical. This approach minimizes downtime and extends the overall operational life of the exchanger.

Component replacement is an integral part of PHE lifecycle management. Gaskets, in particular, require periodic replacement due to degradation from chemical exposure and thermal cycling. Implementing a systematic approach to gasket replacement, based on material properties and operating conditions, can prevent leaks and maintain system integrity.

Plate replacement may be necessary in cases of severe corrosion or erosion. The frequency of plate replacement can be minimized by selecting appropriate materials for the specific chemical environment and implementing effective fouling mitigation strategies. When replacement is required, it presents an opportunity to upgrade to more corrosion-resistant materials or enhanced plate designs that may offer improved heat transfer efficiency.

Training and documentation play a vital role in ensuring consistent and effective maintenance practices. Operators and maintenance personnel should be well-versed in the specific requirements of PHEs operating in varying chemical conditions. Detailed maintenance logs and performance records are invaluable for tracking the exchanger's history and informing future maintenance decisions.

By implementing a comprehensive maintenance and lifecycle management strategy, organizations can maximize the operational efficiency of their plate heat exchangers, reduce unplanned downtime, and optimize the total cost of ownership over the equipment's lifespan.

Routine inspections are essential for identifying early signs of fouling, corrosion, or mechanical damage. These inspections should be conducted at intervals determined by the specific operating conditions and fluid properties. Visual examinations can reveal surface deposits, while pressure drop measurements and thermal performance monitoring can indicate internal fouling or blockages.

Cleaning procedures must be tailored to the specific chemical environment and fouling characteristics. Chemical cleaning methods, such as circulation cleaning or CIP (Clean-in-Place) systems, are often preferred for their effectiveness in removing various types of deposits. The selection of cleaning agents should consider compatibility with plate materials and gaskets to prevent damage during the cleaning process.

Mechanical cleaning techniques, including high-pressure water jetting or brushing, may be necessary for more stubborn deposits. However, care must be taken to avoid damaging the plate surfaces or compromising the integrity of the gaskets. In some cases, a combination of chemical and mechanical cleaning methods may yield the best results.

Predictive maintenance strategies, leveraging data analytics and condition monitoring technologies, can significantly enhance PHE lifecycle management. By analyzing trends in performance data, operators can anticipate maintenance needs and schedule interventions before efficiency degradation becomes critical. This approach minimizes downtime and extends the overall operational life of the exchanger.

Component replacement is an integral part of PHE lifecycle management. Gaskets, in particular, require periodic replacement due to degradation from chemical exposure and thermal cycling. Implementing a systematic approach to gasket replacement, based on material properties and operating conditions, can prevent leaks and maintain system integrity.

Plate replacement may be necessary in cases of severe corrosion or erosion. The frequency of plate replacement can be minimized by selecting appropriate materials for the specific chemical environment and implementing effective fouling mitigation strategies. When replacement is required, it presents an opportunity to upgrade to more corrosion-resistant materials or enhanced plate designs that may offer improved heat transfer efficiency.

Training and documentation play a vital role in ensuring consistent and effective maintenance practices. Operators and maintenance personnel should be well-versed in the specific requirements of PHEs operating in varying chemical conditions. Detailed maintenance logs and performance records are invaluable for tracking the exchanger's history and informing future maintenance decisions.

By implementing a comprehensive maintenance and lifecycle management strategy, organizations can maximize the operational efficiency of their plate heat exchangers, reduce unplanned downtime, and optimize the total cost of ownership over the equipment's lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!