Smart Materials for Self-Cleaning Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Material Evolution

The evolution of smart materials for self-cleaning plate heat exchangers represents a significant advancement in thermal management technology. This progression can be traced through several key stages, each marked by innovative developments and breakthroughs in material science and engineering.

In the early stages, researchers focused on developing materials with basic hydrophobic properties. These initial attempts aimed to create surfaces that could repel water and prevent the accumulation of contaminants. However, these early materials often lacked durability and efficiency in real-world applications.

The next phase saw the introduction of more advanced hydrophobic and superhydrophobic coatings. These materials exhibited enhanced water-repellent properties and improved self-cleaning capabilities. Scientists began exploring various nanostructured surfaces and hierarchical architectures to mimic natural self-cleaning phenomena, such as the lotus leaf effect.

A significant milestone in smart material evolution came with the development of photocatalytic materials. These substances, typically based on titanium dioxide (TiO2), could break down organic contaminants when exposed to light. This innovation marked a shift from passive to active self-cleaning mechanisms, greatly enhancing the efficiency of heat exchanger surfaces.

Further advancements led to the creation of stimuli-responsive materials. These smart materials could change their properties in response to external stimuli such as temperature, pH, or electric fields. This adaptability allowed for more dynamic and efficient self-cleaning processes, tailored to specific operating conditions.

Recent years have seen the emergence of multifunctional smart materials. These advanced composites combine multiple self-cleaning mechanisms, such as hydrophobicity, photocatalysis, and stimuli-responsiveness, into a single material system. This integration has resulted in more robust and versatile self-cleaning solutions for plate heat exchangers.

The latest frontier in smart material evolution involves the incorporation of nanotechnology and advanced polymer science. Researchers are now developing materials with precisely engineered surface structures at the nanoscale, offering unprecedented control over surface properties and self-cleaning performance.

Looking ahead, the evolution of smart materials for self-cleaning plate heat exchangers is likely to continue towards more sustainable and energy-efficient solutions. This may include the development of bio-inspired materials, self-healing coatings, and smart materials capable of energy harvesting to power their self-cleaning mechanisms.

In the early stages, researchers focused on developing materials with basic hydrophobic properties. These initial attempts aimed to create surfaces that could repel water and prevent the accumulation of contaminants. However, these early materials often lacked durability and efficiency in real-world applications.

The next phase saw the introduction of more advanced hydrophobic and superhydrophobic coatings. These materials exhibited enhanced water-repellent properties and improved self-cleaning capabilities. Scientists began exploring various nanostructured surfaces and hierarchical architectures to mimic natural self-cleaning phenomena, such as the lotus leaf effect.

A significant milestone in smart material evolution came with the development of photocatalytic materials. These substances, typically based on titanium dioxide (TiO2), could break down organic contaminants when exposed to light. This innovation marked a shift from passive to active self-cleaning mechanisms, greatly enhancing the efficiency of heat exchanger surfaces.

Further advancements led to the creation of stimuli-responsive materials. These smart materials could change their properties in response to external stimuli such as temperature, pH, or electric fields. This adaptability allowed for more dynamic and efficient self-cleaning processes, tailored to specific operating conditions.

Recent years have seen the emergence of multifunctional smart materials. These advanced composites combine multiple self-cleaning mechanisms, such as hydrophobicity, photocatalysis, and stimuli-responsiveness, into a single material system. This integration has resulted in more robust and versatile self-cleaning solutions for plate heat exchangers.

The latest frontier in smart material evolution involves the incorporation of nanotechnology and advanced polymer science. Researchers are now developing materials with precisely engineered surface structures at the nanoscale, offering unprecedented control over surface properties and self-cleaning performance.

Looking ahead, the evolution of smart materials for self-cleaning plate heat exchangers is likely to continue towards more sustainable and energy-efficient solutions. This may include the development of bio-inspired materials, self-healing coatings, and smart materials capable of energy harvesting to power their self-cleaning mechanisms.

Market Demand Analysis

The market demand for smart materials in self-cleaning plate heat exchangers is experiencing significant growth, driven by the increasing need for efficient and low-maintenance heat transfer solutions across various industries. The global plate heat exchanger market, valued at $5.5 billion in 2021, is projected to reach $9.3 billion by 2028, with a compound annual growth rate (CAGR) of 7.8%. This growth is largely attributed to the rising demand for energy-efficient heat transfer systems and the adoption of advanced technologies in industrial processes.

Self-cleaning plate heat exchangers equipped with smart materials address several critical market needs. Firstly, they offer reduced maintenance requirements, which is particularly valuable in industries where downtime is costly, such as chemical processing, food and beverage production, and power generation. The self-cleaning feature minimizes fouling and scaling, leading to extended operational periods between manual cleanings and reduced labor costs.

Energy efficiency is another key driver of market demand. Smart materials in self-cleaning plate heat exchangers can maintain optimal heat transfer rates over extended periods, resulting in improved energy efficiency and reduced operational costs. This aligns with the global push for sustainable and environmentally friendly industrial processes, as more efficient heat exchangers contribute to lower energy consumption and reduced carbon emissions.

The food and beverage industry represents a significant market segment for self-cleaning plate heat exchangers. Stringent hygiene requirements and the need for frequent cleaning in food processing applications make self-cleaning technologies particularly attractive. The dairy sector, for instance, has shown strong interest in these advanced heat exchangers to maintain product quality and reduce production interruptions.

In the pharmaceutical and biotechnology sectors, where product purity is paramount, self-cleaning plate heat exchangers offer a compelling solution. The ability to maintain sterile conditions and prevent contamination during heat transfer processes is driving adoption in these high-value industries.

The chemical processing industry is another major market for self-cleaning plate heat exchangers. The corrosive and fouling nature of many chemical processes makes traditional heat exchangers prone to rapid degradation and frequent maintenance. Smart materials that can withstand harsh environments and self-clean are in high demand to improve process efficiency and reduce operational costs.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in the adoption of smart materials for self-cleaning plate heat exchangers. This is primarily due to rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe continue to be significant markets, driven by the need to upgrade aging industrial infrastructure with more efficient and sustainable technologies.

Self-cleaning plate heat exchangers equipped with smart materials address several critical market needs. Firstly, they offer reduced maintenance requirements, which is particularly valuable in industries where downtime is costly, such as chemical processing, food and beverage production, and power generation. The self-cleaning feature minimizes fouling and scaling, leading to extended operational periods between manual cleanings and reduced labor costs.

Energy efficiency is another key driver of market demand. Smart materials in self-cleaning plate heat exchangers can maintain optimal heat transfer rates over extended periods, resulting in improved energy efficiency and reduced operational costs. This aligns with the global push for sustainable and environmentally friendly industrial processes, as more efficient heat exchangers contribute to lower energy consumption and reduced carbon emissions.

The food and beverage industry represents a significant market segment for self-cleaning plate heat exchangers. Stringent hygiene requirements and the need for frequent cleaning in food processing applications make self-cleaning technologies particularly attractive. The dairy sector, for instance, has shown strong interest in these advanced heat exchangers to maintain product quality and reduce production interruptions.

In the pharmaceutical and biotechnology sectors, where product purity is paramount, self-cleaning plate heat exchangers offer a compelling solution. The ability to maintain sterile conditions and prevent contamination during heat transfer processes is driving adoption in these high-value industries.

The chemical processing industry is another major market for self-cleaning plate heat exchangers. The corrosive and fouling nature of many chemical processes makes traditional heat exchangers prone to rapid degradation and frequent maintenance. Smart materials that can withstand harsh environments and self-clean are in high demand to improve process efficiency and reduce operational costs.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in the adoption of smart materials for self-cleaning plate heat exchangers. This is primarily due to rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe continue to be significant markets, driven by the need to upgrade aging industrial infrastructure with more efficient and sustainable technologies.

Current Challenges

The development of smart materials for self-cleaning plate heat exchangers faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the complexity of designing materials that can effectively remove fouling without compromising the heat transfer efficiency of the exchanger. The self-cleaning mechanism must be robust enough to handle various types of fouling, including mineral scaling, biological growth, and particulate deposition, while maintaining the structural integrity of the heat exchanger plates.

Another critical challenge lies in the durability and longevity of smart materials under harsh operating conditions. Plate heat exchangers often operate in environments with extreme temperatures, high pressures, and corrosive fluids. Smart materials must withstand these conditions while consistently performing their self-cleaning function over extended periods. The degradation of these materials over time can lead to reduced effectiveness and increased maintenance requirements, negating the benefits of the self-cleaning feature.

The integration of smart materials into existing heat exchanger designs presents a significant engineering challenge. Retrofitting current systems with self-cleaning capabilities requires careful consideration of the material's compatibility with the exchanger's structure and the fluids being processed. Additionally, the incorporation of smart materials must not significantly alter the flow dynamics within the exchanger, as this could negatively impact heat transfer efficiency.

Cost-effectiveness remains a substantial hurdle in the widespread adoption of smart materials for self-cleaning plate heat exchangers. The development and production of these advanced materials often involve complex processes and expensive raw materials, leading to higher initial costs compared to conventional heat exchangers. Manufacturers and end-users must carefully weigh the long-term benefits of reduced maintenance and improved efficiency against the higher upfront investment.

The scalability of smart material solutions for various sizes and types of plate heat exchangers poses another challenge. What works effectively for small-scale applications may not necessarily translate to larger industrial systems. Researchers and engineers must develop scalable solutions that can be adapted to a wide range of heat exchanger configurations and capacities without losing their self-cleaning efficacy.

Regulatory compliance and safety considerations also present challenges in the development and implementation of smart materials. New materials must meet stringent safety standards, especially in industries such as food processing and pharmaceuticals, where contamination risks are of paramount concern. Obtaining necessary certifications and approvals for novel smart materials can be a time-consuming and costly process, potentially slowing down their market introduction.

Another critical challenge lies in the durability and longevity of smart materials under harsh operating conditions. Plate heat exchangers often operate in environments with extreme temperatures, high pressures, and corrosive fluids. Smart materials must withstand these conditions while consistently performing their self-cleaning function over extended periods. The degradation of these materials over time can lead to reduced effectiveness and increased maintenance requirements, negating the benefits of the self-cleaning feature.

The integration of smart materials into existing heat exchanger designs presents a significant engineering challenge. Retrofitting current systems with self-cleaning capabilities requires careful consideration of the material's compatibility with the exchanger's structure and the fluids being processed. Additionally, the incorporation of smart materials must not significantly alter the flow dynamics within the exchanger, as this could negatively impact heat transfer efficiency.

Cost-effectiveness remains a substantial hurdle in the widespread adoption of smart materials for self-cleaning plate heat exchangers. The development and production of these advanced materials often involve complex processes and expensive raw materials, leading to higher initial costs compared to conventional heat exchangers. Manufacturers and end-users must carefully weigh the long-term benefits of reduced maintenance and improved efficiency against the higher upfront investment.

The scalability of smart material solutions for various sizes and types of plate heat exchangers poses another challenge. What works effectively for small-scale applications may not necessarily translate to larger industrial systems. Researchers and engineers must develop scalable solutions that can be adapted to a wide range of heat exchanger configurations and capacities without losing their self-cleaning efficacy.

Regulatory compliance and safety considerations also present challenges in the development and implementation of smart materials. New materials must meet stringent safety standards, especially in industries such as food processing and pharmaceuticals, where contamination risks are of paramount concern. Obtaining necessary certifications and approvals for novel smart materials can be a time-consuming and costly process, potentially slowing down their market introduction.

Existing Solutions

01 Self-cleaning coatings with nanoparticles

Smart materials for self-cleaning applications often incorporate nanoparticles into coatings. These nanoparticles, such as titanium dioxide or silica, create a superhydrophobic surface that repels water and contaminants. The nanostructured surface allows water droplets to easily roll off, carrying dirt and debris with them, thus maintaining a clean surface.- Hydrophobic coatings for self-cleaning surfaces: Smart materials with hydrophobic coatings can repel water and contaminants, creating self-cleaning surfaces. These coatings often mimic natural structures like lotus leaves, allowing water droplets to roll off easily, carrying dirt and debris with them. This technology can be applied to various surfaces, including textiles, glass, and building materials.

- Photocatalytic materials for self-cleaning: Photocatalytic materials, such as titanium dioxide, can be incorporated into smart materials to create self-cleaning surfaces. When exposed to light, these materials generate reactive oxygen species that break down organic contaminants. This technology is particularly useful for outdoor applications and can be integrated into paints, coatings, and construction materials.

- Shape memory polymers for self-cleaning mechanisms: Smart materials utilizing shape memory polymers can change their surface structure in response to external stimuli, such as temperature or light. This dynamic surface alteration can dislodge contaminants and facilitate self-cleaning. These materials can be used in various applications, including textiles and adaptive surfaces.

- Superhydrophilic coatings for self-cleaning: In contrast to hydrophobic coatings, superhydrophilic smart materials can create a thin water film on surfaces when exposed to water or humidity. This film helps to wash away dirt and contaminants, making the surface self-cleaning. These materials are particularly useful in applications where constant wetness is not an issue, such as outdoor glass or solar panels.

- Nanostructured surfaces for enhanced self-cleaning: Smart materials with nanostructured surfaces can exhibit enhanced self-cleaning properties. These nanostructures can be designed to repel water, trap air pockets, or create specific surface tensions that prevent contaminant adhesion. This technology can be applied to various materials, including metals, polymers, and ceramics, for use in electronics, aerospace, and consumer products.

02 Photocatalytic self-cleaning materials

Some smart materials utilize photocatalytic properties for self-cleaning. When exposed to light, typically UV radiation, these materials trigger chemical reactions that break down organic contaminants on the surface. This process effectively decomposes dirt, bacteria, and other pollutants, keeping the surface clean without manual intervention.Expand Specific Solutions03 Shape memory polymers for self-cleaning

Shape memory polymers are being developed as smart materials for self-cleaning applications. These materials can change their shape or surface structure in response to external stimuli like temperature or light. This shape-changing ability allows the material to shed contaminants or create a self-cleaning effect by altering its surface properties.Expand Specific Solutions04 Electroactive polymers for dynamic cleaning

Smart materials incorporating electroactive polymers can achieve self-cleaning through dynamic surface changes. When an electric field is applied, these polymers can deform or vibrate, effectively dislodging contaminants from the surface. This approach allows for on-demand cleaning without the need for manual intervention or additional cleaning agents.Expand Specific Solutions05 Bio-inspired self-cleaning surfaces

Researchers are developing smart materials that mimic natural self-cleaning surfaces found in nature, such as lotus leaves or butterfly wings. These bio-inspired materials often feature micro- or nano-structured surfaces that repel water and contaminants. By replicating these natural designs, scientists create synthetic self-cleaning surfaces with enhanced durability and efficiency.Expand Specific Solutions

Key Industry Players

The research on smart materials for self-cleaning plate heat exchangers is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of established players and emerging innovators. Companies like Alfa Laval, Haier Smart Home, and Rolls-Royce are leveraging their expertise in heat exchange technology to explore smart material applications. The market size is expected to grow significantly as industries seek more efficient and low-maintenance heat exchange solutions. Technological maturity varies, with some companies like Korea Institute of Energy Research and University of Shanghai for Science & Technology focusing on fundamental research, while others like Carrier Corp. and Vahterus Oy are working on practical applications. The field is highly collaborative, with partnerships between academic institutions and industry leaders driving innovation.

Haier Smart Home Co., Ltd.

Technical Solution: Haier has developed a novel self-cleaning technology for plate heat exchangers in their smart home appliances. Their approach utilizes a combination of superhydrophobic coatings and piezoelectric materials[4]. The superhydrophobic coating, inspired by lotus leaf structures, creates a water-repellent surface that prevents contaminant adhesion. The piezoelectric elements, integrated into the heat exchanger plates, generate high-frequency vibrations when electrically stimulated. These vibrations create a thin layer of cavitation bubbles on the plate surface, which implode and generate localized high-pressure jets that dislodge fouling particles[5]. Haier's system also incorporates IoT connectivity, allowing for remote monitoring and optimization of the self-cleaning process based on usage patterns and environmental conditions[6].

Strengths: Effective in removing both organic and inorganic fouling, energy-efficient, and adaptable to various operating conditions. Weaknesses: Complexity of the system may lead to higher initial costs and potential reliability issues in long-term operation.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced self-cleaning plate heat exchangers utilizing smart materials. Their technology incorporates a thin coating of titanium dioxide (TiO2) nanoparticles on the heat exchanger plates[1]. When exposed to UV light, these nanoparticles generate reactive oxygen species that break down organic contaminants. The company has also integrated a UV light system within the exchanger design to activate the photocatalytic process continuously. This self-cleaning mechanism significantly reduces fouling and maintains heat transfer efficiency over extended periods[2]. Additionally, Alfa Laval has implemented a hydrophobic surface treatment that creates a water-repellent layer, further enhancing the self-cleaning properties by allowing contaminants to easily slide off the plates[3].

Strengths: Continuous self-cleaning without process interruption, reduced maintenance costs, and improved energy efficiency. Weaknesses: Potential limitations in environments with limited UV exposure, and possible degradation of coating over time.

Core Innovations

Plate heat exchanger

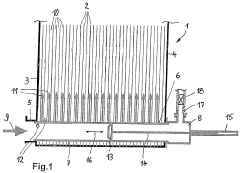

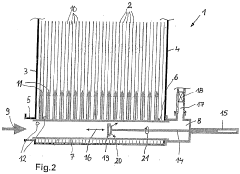

PatentWO2008019659A1

Innovation

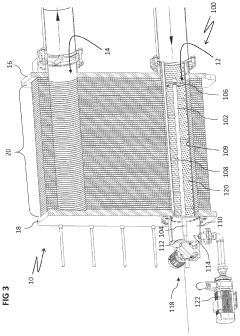

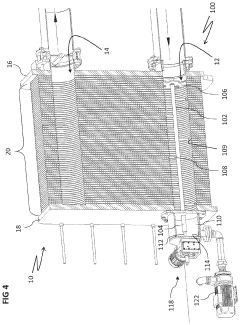

- A self-cleaning plate heat exchanger with a cleaning device that periodically scans the hollow filter's interior, using differential pressure sensors and a rinsing or spray head to remove deposits, allowing continuous operation and maintaining high filter fineness.

Self cleaning filtering apparatus for plate heat exchangers

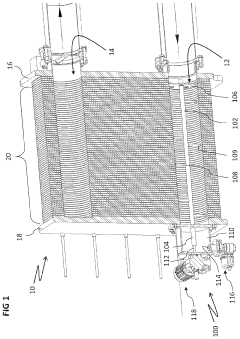

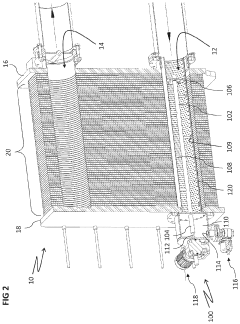

PatentInactiveUS20220268537A1

Innovation

- A self-cleaning filtering apparatus with a suction pipe, nozzles, a low pressure chamber, and a rotation mechanism that performs a backwash process to remove particulates while the heat exchanger operates, using a screen cylinder to filter and an extensible design for versatility.

Environmental Impact

The environmental impact of smart materials for self-cleaning plate heat exchangers is a crucial aspect to consider in their development and implementation. These innovative materials offer significant potential for reducing the ecological footprint of industrial processes and energy systems.

One of the primary environmental benefits of self-cleaning plate heat exchangers is their ability to maintain optimal performance over extended periods without the need for frequent cleaning or maintenance. This results in reduced water consumption and decreased use of chemical cleaning agents, which can be harmful to aquatic ecosystems when discharged. By minimizing the frequency of cleaning cycles, these smart materials contribute to water conservation efforts and reduce the release of potentially toxic substances into the environment.

Energy efficiency is another key environmental advantage of self-cleaning plate heat exchangers. As these systems maintain their cleanliness autonomously, they consistently operate at peak efficiency, reducing energy consumption compared to conventional heat exchangers that experience performance degradation due to fouling. This improved energy efficiency translates to lower greenhouse gas emissions and a reduced carbon footprint for industrial processes utilizing these advanced heat exchangers.

The longevity of self-cleaning plate heat exchangers also contributes to their positive environmental impact. By extending the operational lifespan of these components, the demand for replacement parts and the associated resource consumption for manufacturing new units is significantly reduced. This decrease in material turnover leads to conservation of raw materials and energy resources required for production, transportation, and installation of replacement heat exchangers.

However, it is essential to consider the potential environmental challenges associated with the production and disposal of smart materials used in self-cleaning plate heat exchangers. The manufacturing processes for these advanced materials may involve energy-intensive techniques or the use of rare or toxic elements. As such, a comprehensive life cycle assessment is necessary to ensure that the environmental benefits during operation outweigh any negative impacts during production or end-of-life disposal.

Furthermore, the development of biodegradable or easily recyclable smart materials for self-cleaning plate heat exchangers presents an opportunity for further environmental improvement. By designing these materials with end-of-life considerations in mind, the industry can minimize waste and promote a circular economy approach to heat exchanger technology.

In conclusion, smart materials for self-cleaning plate heat exchangers offer substantial environmental benefits through reduced water and energy consumption, decreased chemical usage, and extended equipment lifespan. However, ongoing research and development efforts should focus on optimizing the entire life cycle of these materials to maximize their positive environmental impact and address any potential challenges associated with their production and disposal.

One of the primary environmental benefits of self-cleaning plate heat exchangers is their ability to maintain optimal performance over extended periods without the need for frequent cleaning or maintenance. This results in reduced water consumption and decreased use of chemical cleaning agents, which can be harmful to aquatic ecosystems when discharged. By minimizing the frequency of cleaning cycles, these smart materials contribute to water conservation efforts and reduce the release of potentially toxic substances into the environment.

Energy efficiency is another key environmental advantage of self-cleaning plate heat exchangers. As these systems maintain their cleanliness autonomously, they consistently operate at peak efficiency, reducing energy consumption compared to conventional heat exchangers that experience performance degradation due to fouling. This improved energy efficiency translates to lower greenhouse gas emissions and a reduced carbon footprint for industrial processes utilizing these advanced heat exchangers.

The longevity of self-cleaning plate heat exchangers also contributes to their positive environmental impact. By extending the operational lifespan of these components, the demand for replacement parts and the associated resource consumption for manufacturing new units is significantly reduced. This decrease in material turnover leads to conservation of raw materials and energy resources required for production, transportation, and installation of replacement heat exchangers.

However, it is essential to consider the potential environmental challenges associated with the production and disposal of smart materials used in self-cleaning plate heat exchangers. The manufacturing processes for these advanced materials may involve energy-intensive techniques or the use of rare or toxic elements. As such, a comprehensive life cycle assessment is necessary to ensure that the environmental benefits during operation outweigh any negative impacts during production or end-of-life disposal.

Furthermore, the development of biodegradable or easily recyclable smart materials for self-cleaning plate heat exchangers presents an opportunity for further environmental improvement. By designing these materials with end-of-life considerations in mind, the industry can minimize waste and promote a circular economy approach to heat exchanger technology.

In conclusion, smart materials for self-cleaning plate heat exchangers offer substantial environmental benefits through reduced water and energy consumption, decreased chemical usage, and extended equipment lifespan. However, ongoing research and development efforts should focus on optimizing the entire life cycle of these materials to maximize their positive environmental impact and address any potential challenges associated with their production and disposal.

Cost-Benefit Analysis

The implementation of smart materials for self-cleaning plate heat exchangers presents a compelling case for cost-benefit analysis. Initial investment in these advanced materials may be higher than traditional options, but the long-term benefits can significantly outweigh the upfront costs.

One of the primary advantages is the reduction in maintenance expenses. Self-cleaning heat exchangers require less frequent manual cleaning, reducing labor costs and minimizing production downtime. This can lead to substantial savings, especially in industries where continuous operation is critical. The extended operational periods between cleanings also contribute to increased overall efficiency and productivity.

Energy efficiency is another key factor in the cost-benefit equation. Smart materials can maintain optimal heat transfer rates for longer periods, reducing energy consumption and associated costs. This improved performance can result in lower utility bills and a smaller carbon footprint, aligning with sustainability goals and potentially qualifying for energy efficiency incentives.

The longevity of smart materials is a crucial consideration. While the initial investment may be higher, these materials often have a longer lifespan than conventional alternatives. This extended durability translates to reduced replacement frequency and lower lifecycle costs. The resistance to fouling and corrosion also helps preserve the integrity of the heat exchanger, potentially decreasing repair and replacement expenses over time.

From an operational perspective, smart self-cleaning materials can enhance process reliability and product quality. By maintaining consistent heat transfer efficiency, these materials help ensure stable production conditions, potentially reducing waste and improving output quality. This can lead to increased customer satisfaction and potentially higher market share, indirectly contributing to the overall financial benefits.

However, it's important to consider potential drawbacks in the cost-benefit analysis. The higher initial cost may present a barrier for some organizations, particularly those with limited capital budgets. Additionally, the relatively new nature of these smart materials may require specialized training for maintenance personnel, incurring additional short-term costs.

When evaluating the return on investment, companies must consider their specific operational context. Factors such as the scale of operations, frequency of heat exchanger fouling, energy costs, and regulatory environment all play a role in determining the overall cost-benefit ratio. A thorough analysis should include both quantitative metrics, such as payback period and net present value, as well as qualitative factors like improved safety and environmental impact.

One of the primary advantages is the reduction in maintenance expenses. Self-cleaning heat exchangers require less frequent manual cleaning, reducing labor costs and minimizing production downtime. This can lead to substantial savings, especially in industries where continuous operation is critical. The extended operational periods between cleanings also contribute to increased overall efficiency and productivity.

Energy efficiency is another key factor in the cost-benefit equation. Smart materials can maintain optimal heat transfer rates for longer periods, reducing energy consumption and associated costs. This improved performance can result in lower utility bills and a smaller carbon footprint, aligning with sustainability goals and potentially qualifying for energy efficiency incentives.

The longevity of smart materials is a crucial consideration. While the initial investment may be higher, these materials often have a longer lifespan than conventional alternatives. This extended durability translates to reduced replacement frequency and lower lifecycle costs. The resistance to fouling and corrosion also helps preserve the integrity of the heat exchanger, potentially decreasing repair and replacement expenses over time.

From an operational perspective, smart self-cleaning materials can enhance process reliability and product quality. By maintaining consistent heat transfer efficiency, these materials help ensure stable production conditions, potentially reducing waste and improving output quality. This can lead to increased customer satisfaction and potentially higher market share, indirectly contributing to the overall financial benefits.

However, it's important to consider potential drawbacks in the cost-benefit analysis. The higher initial cost may present a barrier for some organizations, particularly those with limited capital budgets. Additionally, the relatively new nature of these smart materials may require specialized training for maintenance personnel, incurring additional short-term costs.

When evaluating the return on investment, companies must consider their specific operational context. Factors such as the scale of operations, frequency of heat exchanger fouling, energy costs, and regulatory environment all play a role in determining the overall cost-benefit ratio. A thorough analysis should include both quantitative metrics, such as payback period and net present value, as well as qualitative factors like improved safety and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!