Plate Heat Exchanger Innovations for Low-Temperature Processes

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Low-Temp Tech Evolution

The evolution of plate heat exchanger (PHE) technology for low-temperature processes has been marked by significant advancements over the past few decades. Initially developed in the 1920s for the dairy industry, PHEs have since found widespread applications in various sectors, particularly in cryogenic and refrigeration systems.

In the 1950s and 1960s, the focus was on improving the basic design and materials of PHEs to enhance their efficiency in low-temperature applications. Stainless steel became the preferred material due to its excellent corrosion resistance and thermal properties at low temperatures. During this period, the chevron plate design was introduced, significantly improving heat transfer performance.

The 1970s and 1980s saw a shift towards optimizing flow distribution and reducing pressure drop in PHEs. Researchers developed new plate corrugation patterns and experimented with asymmetrical designs to achieve better thermal performance while minimizing pressure losses. This era also witnessed the introduction of semi-welded PHEs, which combined the benefits of gasketed and welded designs for improved leak resistance in low-temperature operations.

The 1990s brought about a revolution in PHE manufacturing techniques. Computer-aided design and simulation tools enabled engineers to create more complex and efficient plate geometries. This period also saw the development of compact PHEs with higher heat transfer coefficients, making them increasingly suitable for cryogenic applications.

In the early 2000s, the focus shifted towards enhancing the durability and reliability of PHEs in extreme low-temperature environments. Advanced materials such as titanium and nickel alloys were introduced for specific applications. Additionally, improved gasket materials and sealing technologies were developed to prevent leakage at cryogenic temperatures.

The past decade has seen a surge in research on micro-channel and nano-enhanced PHEs for low-temperature processes. These innovations aim to further increase heat transfer rates while reducing the overall size and weight of the exchangers. Simultaneously, there has been growing interest in using PHEs for energy recovery in liquefied natural gas (LNG) processes and other cryogenic applications.

Recent developments have focused on integrating smart technologies into PHE systems. This includes the use of sensors and IoT devices for real-time monitoring and predictive maintenance, ensuring optimal performance in low-temperature operations. Furthermore, advancements in additive manufacturing techniques are opening up new possibilities for creating complex, highly efficient PHE designs that were previously impossible to manufacture using traditional methods.

In the 1950s and 1960s, the focus was on improving the basic design and materials of PHEs to enhance their efficiency in low-temperature applications. Stainless steel became the preferred material due to its excellent corrosion resistance and thermal properties at low temperatures. During this period, the chevron plate design was introduced, significantly improving heat transfer performance.

The 1970s and 1980s saw a shift towards optimizing flow distribution and reducing pressure drop in PHEs. Researchers developed new plate corrugation patterns and experimented with asymmetrical designs to achieve better thermal performance while minimizing pressure losses. This era also witnessed the introduction of semi-welded PHEs, which combined the benefits of gasketed and welded designs for improved leak resistance in low-temperature operations.

The 1990s brought about a revolution in PHE manufacturing techniques. Computer-aided design and simulation tools enabled engineers to create more complex and efficient plate geometries. This period also saw the development of compact PHEs with higher heat transfer coefficients, making them increasingly suitable for cryogenic applications.

In the early 2000s, the focus shifted towards enhancing the durability and reliability of PHEs in extreme low-temperature environments. Advanced materials such as titanium and nickel alloys were introduced for specific applications. Additionally, improved gasket materials and sealing technologies were developed to prevent leakage at cryogenic temperatures.

The past decade has seen a surge in research on micro-channel and nano-enhanced PHEs for low-temperature processes. These innovations aim to further increase heat transfer rates while reducing the overall size and weight of the exchangers. Simultaneously, there has been growing interest in using PHEs for energy recovery in liquefied natural gas (LNG) processes and other cryogenic applications.

Recent developments have focused on integrating smart technologies into PHE systems. This includes the use of sensors and IoT devices for real-time monitoring and predictive maintenance, ensuring optimal performance in low-temperature operations. Furthermore, advancements in additive manufacturing techniques are opening up new possibilities for creating complex, highly efficient PHE designs that were previously impossible to manufacture using traditional methods.

Market Demand Analysis

The market demand for plate heat exchanger innovations in low-temperature processes has been steadily increasing due to the growing emphasis on energy efficiency and sustainability across various industries. This trend is particularly evident in sectors such as food and beverage processing, pharmaceuticals, chemical manufacturing, and HVAC systems, where low-temperature operations are critical.

In the food and beverage industry, there is a rising need for efficient cooling and pasteurization processes. Plate heat exchangers are increasingly preferred for their ability to maintain precise temperature control and minimize product degradation. The dairy sector, in particular, has shown significant demand growth, driven by the need for rapid cooling of milk and the production of various dairy products at low temperatures.

The pharmaceutical industry presents another substantial market for low-temperature plate heat exchangers. With the increasing production of temperature-sensitive biologics and the stringent requirements for maintaining cold chain logistics, the demand for advanced cooling solutions has surged. Plate heat exchangers offer the precision and reliability required for these critical processes.

In the chemical manufacturing sector, the push towards greener and more energy-efficient processes has led to increased adoption of plate heat exchangers for low-temperature applications. These include processes such as solvent recovery, gas liquefaction, and cryogenic separations, where efficient heat transfer at low temperatures is crucial for operational efficiency and product quality.

The HVAC industry has also been a significant driver of market demand, particularly in large-scale commercial and industrial applications. The need for energy-efficient cooling systems in data centers, which require constant low-temperature environments, has been a notable factor in market growth.

Geographically, the demand for low-temperature plate heat exchanger innovations is most pronounced in regions with stringent energy efficiency regulations and a strong focus on sustainable industrial practices. North America and Europe lead in adoption, driven by strict environmental policies and a mature industrial base. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are showing accelerated growth in demand as they upgrade their manufacturing capabilities and focus on energy-efficient technologies.

The market is also influenced by the global trend towards process intensification and miniaturization. This has led to a demand for compact, high-performance plate heat exchangers that can handle low-temperature processes in smaller footprints, particularly beneficial in space-constrained urban environments and offshore applications.

As industries continue to prioritize operational efficiency and environmental sustainability, the market for innovative low-temperature plate heat exchangers is expected to expand further. This growth is likely to be fueled by advancements in materials science, design optimization techniques, and the integration of smart technologies for improved performance monitoring and control.

In the food and beverage industry, there is a rising need for efficient cooling and pasteurization processes. Plate heat exchangers are increasingly preferred for their ability to maintain precise temperature control and minimize product degradation. The dairy sector, in particular, has shown significant demand growth, driven by the need for rapid cooling of milk and the production of various dairy products at low temperatures.

The pharmaceutical industry presents another substantial market for low-temperature plate heat exchangers. With the increasing production of temperature-sensitive biologics and the stringent requirements for maintaining cold chain logistics, the demand for advanced cooling solutions has surged. Plate heat exchangers offer the precision and reliability required for these critical processes.

In the chemical manufacturing sector, the push towards greener and more energy-efficient processes has led to increased adoption of plate heat exchangers for low-temperature applications. These include processes such as solvent recovery, gas liquefaction, and cryogenic separations, where efficient heat transfer at low temperatures is crucial for operational efficiency and product quality.

The HVAC industry has also been a significant driver of market demand, particularly in large-scale commercial and industrial applications. The need for energy-efficient cooling systems in data centers, which require constant low-temperature environments, has been a notable factor in market growth.

Geographically, the demand for low-temperature plate heat exchanger innovations is most pronounced in regions with stringent energy efficiency regulations and a strong focus on sustainable industrial practices. North America and Europe lead in adoption, driven by strict environmental policies and a mature industrial base. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are showing accelerated growth in demand as they upgrade their manufacturing capabilities and focus on energy-efficient technologies.

The market is also influenced by the global trend towards process intensification and miniaturization. This has led to a demand for compact, high-performance plate heat exchangers that can handle low-temperature processes in smaller footprints, particularly beneficial in space-constrained urban environments and offshore applications.

As industries continue to prioritize operational efficiency and environmental sustainability, the market for innovative low-temperature plate heat exchangers is expected to expand further. This growth is likely to be fueled by advancements in materials science, design optimization techniques, and the integration of smart technologies for improved performance monitoring and control.

Current PHE Challenges

Plate heat exchangers (PHEs) face several challenges in low-temperature processes, primarily due to the unique demands of these applications. One of the main issues is the increased risk of fouling and scaling at lower temperatures. As fluids cool, dissolved solids can precipitate and accumulate on heat transfer surfaces, reducing efficiency and increasing maintenance requirements. This problem is particularly acute in industries such as food processing and chemical manufacturing, where product quality and consistency are paramount.

Another significant challenge is the potential for freezing or solidification of process fluids. In low-temperature applications, even small temperature fluctuations can lead to phase changes, causing blockages and potential damage to the exchanger. This necessitates careful control of flow rates and temperature differentials, which can be difficult to maintain consistently in industrial settings.

The mechanical design of PHEs also presents challenges at low temperatures. Traditional gasket materials may become brittle and lose their sealing properties, leading to leaks and reduced performance. Additionally, thermal contraction of metal components can cause misalignment and uneven stress distribution, potentially compromising the integrity of the exchanger over time.

Energy efficiency is a critical concern in low-temperature processes. PHEs must be designed to minimize heat loss to the environment, which becomes more challenging as the temperature differential between the process fluid and ambient conditions increases. This often requires advanced insulation techniques and careful consideration of materials with low thermal conductivity.

Corrosion resistance is another key challenge, particularly in applications involving aggressive chemicals or salt-laden environments. Low temperatures can exacerbate corrosion issues by altering the electrochemical properties of materials and slowing down protective oxide formation processes. This necessitates the use of specialized, often expensive, corrosion-resistant alloys or coatings.

The need for precise temperature control in low-temperature processes also poses challenges for PHE design. Achieving uniform heat distribution and avoiding localized cold spots requires careful flow channel design and optimization. This is particularly important in applications such as cryogenic gas processing or pharmaceutical manufacturing, where even small temperature variations can have significant impacts on product quality or process efficiency.

Lastly, the increased viscosity of many fluids at low temperatures can lead to higher pressure drops across the exchanger. This necessitates more powerful pumping systems and can limit the achievable flow rates, potentially reducing overall heat transfer efficiency. Balancing these factors while maintaining cost-effectiveness and operational reliability remains a significant challenge in the development of PHEs for low-temperature applications.

Another significant challenge is the potential for freezing or solidification of process fluids. In low-temperature applications, even small temperature fluctuations can lead to phase changes, causing blockages and potential damage to the exchanger. This necessitates careful control of flow rates and temperature differentials, which can be difficult to maintain consistently in industrial settings.

The mechanical design of PHEs also presents challenges at low temperatures. Traditional gasket materials may become brittle and lose their sealing properties, leading to leaks and reduced performance. Additionally, thermal contraction of metal components can cause misalignment and uneven stress distribution, potentially compromising the integrity of the exchanger over time.

Energy efficiency is a critical concern in low-temperature processes. PHEs must be designed to minimize heat loss to the environment, which becomes more challenging as the temperature differential between the process fluid and ambient conditions increases. This often requires advanced insulation techniques and careful consideration of materials with low thermal conductivity.

Corrosion resistance is another key challenge, particularly in applications involving aggressive chemicals or salt-laden environments. Low temperatures can exacerbate corrosion issues by altering the electrochemical properties of materials and slowing down protective oxide formation processes. This necessitates the use of specialized, often expensive, corrosion-resistant alloys or coatings.

The need for precise temperature control in low-temperature processes also poses challenges for PHE design. Achieving uniform heat distribution and avoiding localized cold spots requires careful flow channel design and optimization. This is particularly important in applications such as cryogenic gas processing or pharmaceutical manufacturing, where even small temperature variations can have significant impacts on product quality or process efficiency.

Lastly, the increased viscosity of many fluids at low temperatures can lead to higher pressure drops across the exchanger. This necessitates more powerful pumping systems and can limit the achievable flow rates, potentially reducing overall heat transfer efficiency. Balancing these factors while maintaining cost-effectiveness and operational reliability remains a significant challenge in the development of PHEs for low-temperature applications.

Existing Low-Temp Solutions

01 Temperature control in plate heat exchangers

Plate heat exchangers employ various methods to control and maintain optimal temperature levels. These may include advanced sensors, automated control systems, and precise flow regulation mechanisms to ensure efficient heat transfer and prevent overheating or undercooling.- Temperature control in plate heat exchangers: Plate heat exchangers employ various methods to control and maintain optimal temperature levels. These methods may include advanced sensors, automated control systems, and precise flow regulation to ensure efficient heat transfer between fluids. The temperature control mechanisms help in maintaining desired thermal conditions for different industrial processes.

- Enhancing heat transfer efficiency: Techniques to improve heat transfer efficiency in plate heat exchangers focus on optimizing plate design, surface area, and flow patterns. This may involve using specially designed plate geometries, turbulence promoters, or advanced materials to maximize heat exchange rates while minimizing pressure drop and fouling.

- Temperature monitoring and measurement: Accurate temperature monitoring and measurement are crucial for plate heat exchanger performance. Advanced sensors and measurement techniques are employed to provide real-time temperature data across different sections of the exchanger. This information is used for process control, performance optimization, and predictive maintenance.

- Temperature-based flow control: Plate heat exchangers often incorporate temperature-based flow control systems to maintain desired output temperatures. These systems adjust fluid flow rates based on temperature readings, ensuring consistent thermal performance across varying operating conditions. This approach helps in optimizing energy efficiency and process stability.

- High-temperature applications: Specialized plate heat exchangers are designed for high-temperature applications in industries such as power generation, chemical processing, and oil refining. These exchangers use materials and designs capable of withstanding extreme temperatures while maintaining efficient heat transfer. They may incorporate advanced sealing technologies and thermal expansion compensation mechanisms.

02 Enhancing heat transfer efficiency

Techniques to improve heat transfer efficiency in plate heat exchangers involve optimizing plate design, using advanced materials, and implementing turbulence-inducing features. These enhancements aim to maximize the heat exchange rate while minimizing pressure drop and energy consumption.Expand Specific Solutions03 Temperature monitoring and measurement

Accurate temperature monitoring and measurement are crucial for plate heat exchanger performance. Advanced sensors, thermocouples, and digital monitoring systems are employed to provide real-time temperature data, enabling precise control and optimization of the heat exchange process.Expand Specific Solutions04 Temperature distribution and uniformity

Achieving uniform temperature distribution across plate heat exchangers is essential for optimal performance. Various design features and flow arrangements are implemented to minimize temperature gradients and ensure consistent heat transfer throughout the exchanger.Expand Specific Solutions05 High-temperature applications

Plate heat exchangers designed for high-temperature applications require specialized materials and construction techniques. These exchangers incorporate features to withstand thermal stress, prevent leakage, and maintain efficiency under extreme temperature conditions.Expand Specific Solutions

Key Industry Players

The plate heat exchanger market for low-temperature processes is in a growth phase, driven by increasing demand for energy-efficient solutions across various industries. The market size is expanding, with a focus on innovations to improve performance and reduce environmental impact. Technologically, the field is advancing rapidly, with companies like Alfa Laval, SWEP International, and Haldor Topsøe leading the way in developing more efficient and compact designs. These firms are investing in R&D to enhance heat transfer capabilities, reduce fouling, and optimize materials for extreme temperature conditions. Emerging players such as Mikros Technologies are introducing novel micro-channel designs, while established manufacturers like Linde and Praxair are integrating advanced heat exchanger technologies into their broader process solutions.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative plate heat exchanger solutions for low-temperature processes, focusing on enhancing efficiency and sustainability. Their AlfaNova fusion-bonded plate heat exchangers utilize a patented fusion bonding technology, creating an all-stainless steel construction that can withstand extreme temperatures and pressures[1]. This technology allows for improved heat transfer efficiency in cryogenic applications, with the ability to operate at temperatures as low as -196°C[2]. Alfa Laval has also introduced the T25 plate heat exchanger, specifically designed for low-temperature duties in the food and beverage industry, featuring an optimized plate design that enhances thermal efficiency by up to 30% compared to traditional models[3].

Strengths: Superior thermal efficiency, extreme temperature resistance, and versatility across various industries. Weaknesses: Higher initial cost compared to traditional heat exchangers, potential limitations in very large-scale applications.

Swep International AB

Technical Solution: SWEP has pioneered the development of Brazed Plate Heat Exchangers (BPHEs) for low-temperature applications. Their innovative True Dual function allows a single BPHE to operate as both an evaporator and condenser, significantly reducing system complexity and footprint[4]. SWEP's B85S model, designed for low-temperature refrigeration, features asymmetric plate channels that optimize heat transfer and minimize pressure drop in single-phase applications[5]. The company has also introduced a new range of BPHEs with larger port sizes, enabling higher capacities and improved efficiency in low-temperature industrial processes[6]. SWEP's focus on material selection and manufacturing processes has resulted in BPHEs capable of withstanding temperatures as low as -196°C without compromising performance.

Strengths: Compact design, high efficiency in low-temperature applications, and versatility in system integration. Weaknesses: Limited to smaller and medium-sized applications, potential for higher maintenance requirements in certain environments.

Core PHE Innovations

Plate heat exchanger condenser-evaporator and process for low-temperature air separation

PatentInactiveUS20180112913A1

Innovation

- The arrangement of fluid feed and collecting lines on specific outer surfaces of the heat-exchanger block, along with the design of fluid-distribution and -collecting structures, ensures homogeneous fluid distribution and prevents unmixing, enhancing heat-exchange efficiency by displacing openings from covered regions and using central distributors.

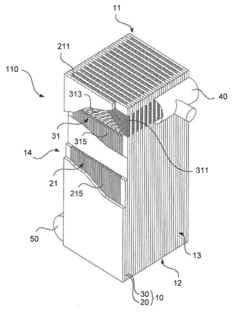

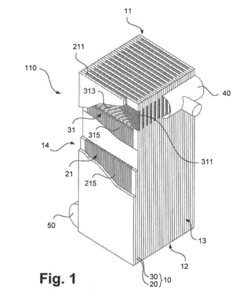

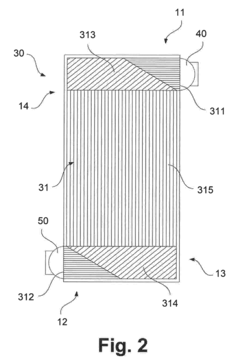

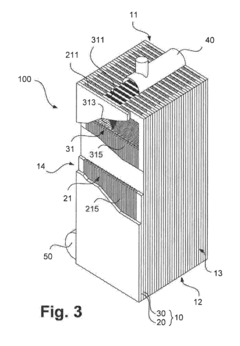

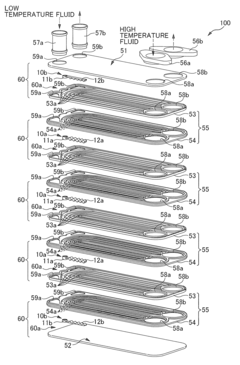

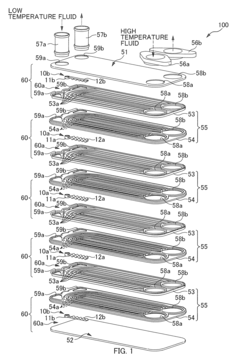

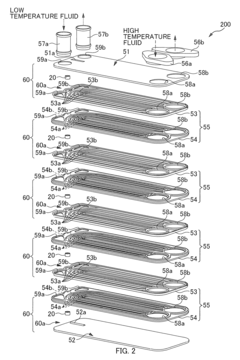

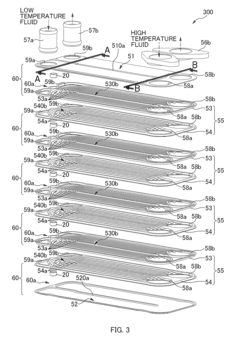

Plate stacking type heat exchanger

PatentActiveUS20100258285A1

Innovation

- The introduction of partition parts within the low temperature fluid compartments to position the inlet and outlet ports closer together in the longitudinal direction, while maintaining effective fluid flow through U-turn regions, reduces the longitudinal dimension and enhances heat transfer area.

Material Advancements

Material advancements play a crucial role in enhancing the performance and efficiency of plate heat exchangers for low-temperature processes. Recent innovations in this field have focused on developing materials that can withstand extreme conditions while maintaining optimal heat transfer properties.

One significant area of progress is the development of advanced stainless steel alloys. These new alloys offer improved corrosion resistance and mechanical strength, making them ideal for use in harsh environments often encountered in low-temperature applications. For instance, super duplex stainless steels have shown exceptional resistance to pitting and crevice corrosion, even in chloride-rich environments.

Composite materials have also gained traction in plate heat exchanger design. Carbon fiber reinforced polymers (CFRP) are being explored for their high strength-to-weight ratio and excellent thermal conductivity. These properties allow for the creation of lighter, more compact heat exchangers without compromising on performance.

Nanomaterials are emerging as a promising avenue for enhancing heat transfer efficiency. Researchers have demonstrated that incorporating nanoparticles into the base fluid can significantly improve its thermal conductivity. For example, the addition of graphene oxide nanoparticles to water has shown to enhance heat transfer coefficients by up to 25% in some studies.

Surface modifications and coatings represent another frontier in material advancements. Hydrophobic coatings, inspired by nature, are being applied to plate surfaces to reduce fouling and improve overall heat transfer efficiency. These coatings minimize the adhesion of particles and biological growth, extending the operational life of the heat exchanger.

Advanced ceramics are also finding applications in plate heat exchangers for low-temperature processes. Materials such as silicon carbide and alumina offer excellent thermal conductivity and chemical resistance, making them suitable for use in corrosive environments where traditional metallic materials may fail.

The integration of phase change materials (PCMs) into plate heat exchanger designs is an innovative approach to thermal energy storage and management. These materials can absorb or release large amounts of latent heat during phase transitions, providing a means to stabilize temperature fluctuations in low-temperature processes.

As research in material science continues to advance, we can expect further innovations in plate heat exchanger materials. The focus will likely remain on developing materials that offer improved thermal efficiency, durability, and resistance to fouling and corrosion, while also addressing sustainability concerns through the use of recyclable and environmentally friendly materials.

One significant area of progress is the development of advanced stainless steel alloys. These new alloys offer improved corrosion resistance and mechanical strength, making them ideal for use in harsh environments often encountered in low-temperature applications. For instance, super duplex stainless steels have shown exceptional resistance to pitting and crevice corrosion, even in chloride-rich environments.

Composite materials have also gained traction in plate heat exchanger design. Carbon fiber reinforced polymers (CFRP) are being explored for their high strength-to-weight ratio and excellent thermal conductivity. These properties allow for the creation of lighter, more compact heat exchangers without compromising on performance.

Nanomaterials are emerging as a promising avenue for enhancing heat transfer efficiency. Researchers have demonstrated that incorporating nanoparticles into the base fluid can significantly improve its thermal conductivity. For example, the addition of graphene oxide nanoparticles to water has shown to enhance heat transfer coefficients by up to 25% in some studies.

Surface modifications and coatings represent another frontier in material advancements. Hydrophobic coatings, inspired by nature, are being applied to plate surfaces to reduce fouling and improve overall heat transfer efficiency. These coatings minimize the adhesion of particles and biological growth, extending the operational life of the heat exchanger.

Advanced ceramics are also finding applications in plate heat exchangers for low-temperature processes. Materials such as silicon carbide and alumina offer excellent thermal conductivity and chemical resistance, making them suitable for use in corrosive environments where traditional metallic materials may fail.

The integration of phase change materials (PCMs) into plate heat exchanger designs is an innovative approach to thermal energy storage and management. These materials can absorb or release large amounts of latent heat during phase transitions, providing a means to stabilize temperature fluctuations in low-temperature processes.

As research in material science continues to advance, we can expect further innovations in plate heat exchanger materials. The focus will likely remain on developing materials that offer improved thermal efficiency, durability, and resistance to fouling and corrosion, while also addressing sustainability concerns through the use of recyclable and environmentally friendly materials.

Energy Efficiency Impacts

The energy efficiency impacts of plate heat exchanger innovations for low-temperature processes are significant and far-reaching. These advancements have led to substantial improvements in overall system performance and reduced energy consumption across various industries.

One of the primary benefits of innovative plate heat exchangers is their ability to achieve higher heat transfer coefficients compared to traditional designs. This enhanced efficiency allows for more effective heat recovery and utilization, particularly in low-temperature applications where energy losses can be critical. By maximizing the transfer of thermal energy between fluids, these innovations contribute to reduced energy requirements for heating and cooling processes.

The compact design of modern plate heat exchangers also plays a crucial role in energy efficiency. Their smaller footprint and reduced internal volume result in lower fluid hold-up, which translates to faster system response times and reduced thermal inertia. This characteristic is especially advantageous in low-temperature processes where precise temperature control is essential, as it allows for more rapid and accurate adjustments to changing process conditions.

Furthermore, the improved flow distribution and reduced pressure drop in advanced plate heat exchanger designs contribute to lower pumping power requirements. This reduction in parasitic energy consumption enhances the overall efficiency of the system, leading to decreased operational costs and a smaller carbon footprint for industrial processes.

The incorporation of novel materials and surface enhancements in plate heat exchangers has also yielded significant energy efficiency gains. These innovations have resulted in improved heat transfer performance, reduced fouling tendencies, and extended operational lifetimes. By minimizing the impact of fouling and maintaining optimal heat transfer rates over extended periods, these advancements ensure sustained energy efficiency throughout the equipment's lifecycle.

In the context of low-temperature processes, the ability of innovative plate heat exchangers to handle close temperature approaches is particularly valuable. This capability allows for more effective utilization of low-grade heat sources and enables the implementation of cascading heat recovery systems. Such arrangements maximize energy recovery and minimize waste heat, contributing to overall process efficiency and sustainability.

The integration of plate heat exchanger innovations into broader energy management strategies has led to synergistic efficiency improvements. When combined with advanced control systems and process optimization techniques, these heat exchangers enable more sophisticated energy recovery schemes and facilitate the implementation of heat integration across entire industrial complexes.

One of the primary benefits of innovative plate heat exchangers is their ability to achieve higher heat transfer coefficients compared to traditional designs. This enhanced efficiency allows for more effective heat recovery and utilization, particularly in low-temperature applications where energy losses can be critical. By maximizing the transfer of thermal energy between fluids, these innovations contribute to reduced energy requirements for heating and cooling processes.

The compact design of modern plate heat exchangers also plays a crucial role in energy efficiency. Their smaller footprint and reduced internal volume result in lower fluid hold-up, which translates to faster system response times and reduced thermal inertia. This characteristic is especially advantageous in low-temperature processes where precise temperature control is essential, as it allows for more rapid and accurate adjustments to changing process conditions.

Furthermore, the improved flow distribution and reduced pressure drop in advanced plate heat exchanger designs contribute to lower pumping power requirements. This reduction in parasitic energy consumption enhances the overall efficiency of the system, leading to decreased operational costs and a smaller carbon footprint for industrial processes.

The incorporation of novel materials and surface enhancements in plate heat exchangers has also yielded significant energy efficiency gains. These innovations have resulted in improved heat transfer performance, reduced fouling tendencies, and extended operational lifetimes. By minimizing the impact of fouling and maintaining optimal heat transfer rates over extended periods, these advancements ensure sustained energy efficiency throughout the equipment's lifecycle.

In the context of low-temperature processes, the ability of innovative plate heat exchangers to handle close temperature approaches is particularly valuable. This capability allows for more effective utilization of low-grade heat sources and enables the implementation of cascading heat recovery systems. Such arrangements maximize energy recovery and minimize waste heat, contributing to overall process efficiency and sustainability.

The integration of plate heat exchanger innovations into broader energy management strategies has led to synergistic efficiency improvements. When combined with advanced control systems and process optimization techniques, these heat exchangers enable more sophisticated energy recovery schemes and facilitate the implementation of heat integration across entire industrial complexes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!