How Digital Twins are Transforming Plate Heat Exchanger Management?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution in Heat Exchanger Industry

The concept of digital twins has revolutionized the management of plate heat exchangers, marking a significant milestone in the industry's technological evolution. This transformation began in the early 2000s with the introduction of basic digital models, which provided rudimentary representations of physical heat exchangers. These initial models were primarily used for design optimization and basic performance predictions.

As computational power increased and data collection methods improved, the digital twin concept for heat exchangers evolved rapidly. By the mid-2010s, more sophisticated digital twins emerged, incorporating real-time data from sensors and advanced simulation capabilities. This development allowed for more accurate performance monitoring and predictive maintenance, significantly reducing downtime and improving operational efficiency.

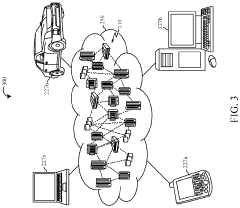

The integration of Internet of Things (IoT) technologies in the late 2010s marked another pivotal moment in the evolution of digital twins for plate heat exchangers. IoT sensors enabled continuous data collection on various parameters such as temperature, pressure, and flow rates. This real-time data feed enhanced the accuracy of digital twin models, allowing for more precise performance optimization and fault detection.

Machine learning and artificial intelligence technologies began to play a crucial role in the early 2020s. These advancements enabled digital twins to not only monitor and predict but also to learn from historical data and suggest optimal operational parameters. This leap forward in capability transformed digital twins from passive monitoring tools to active decision-support systems.

The most recent developments in digital twin technology for plate heat exchangers include the integration of augmented reality (AR) and virtual reality (VR) interfaces. These technologies allow operators and engineers to interact with digital representations of heat exchangers in immersive environments, facilitating more intuitive maintenance procedures and training programs.

Looking ahead, the evolution of digital twins in the heat exchanger industry is expected to continue at a rapid pace. Future developments are likely to include more advanced AI algorithms for autonomous operation, improved integration with broader plant-wide digital twin ecosystems, and the incorporation of quantum computing for handling increasingly complex simulations and optimizations.

As computational power increased and data collection methods improved, the digital twin concept for heat exchangers evolved rapidly. By the mid-2010s, more sophisticated digital twins emerged, incorporating real-time data from sensors and advanced simulation capabilities. This development allowed for more accurate performance monitoring and predictive maintenance, significantly reducing downtime and improving operational efficiency.

The integration of Internet of Things (IoT) technologies in the late 2010s marked another pivotal moment in the evolution of digital twins for plate heat exchangers. IoT sensors enabled continuous data collection on various parameters such as temperature, pressure, and flow rates. This real-time data feed enhanced the accuracy of digital twin models, allowing for more precise performance optimization and fault detection.

Machine learning and artificial intelligence technologies began to play a crucial role in the early 2020s. These advancements enabled digital twins to not only monitor and predict but also to learn from historical data and suggest optimal operational parameters. This leap forward in capability transformed digital twins from passive monitoring tools to active decision-support systems.

The most recent developments in digital twin technology for plate heat exchangers include the integration of augmented reality (AR) and virtual reality (VR) interfaces. These technologies allow operators and engineers to interact with digital representations of heat exchangers in immersive environments, facilitating more intuitive maintenance procedures and training programs.

Looking ahead, the evolution of digital twins in the heat exchanger industry is expected to continue at a rapid pace. Future developments are likely to include more advanced AI algorithms for autonomous operation, improved integration with broader plant-wide digital twin ecosystems, and the incorporation of quantum computing for handling increasingly complex simulations and optimizations.

Market Demand for Smart Heat Exchanger Solutions

The market demand for smart heat exchanger solutions, particularly in the context of plate heat exchangers (PHEs), has been experiencing significant growth in recent years. This surge is driven by several factors, including the increasing need for energy efficiency, the push for sustainability in industrial processes, and the advent of Industry 4.0 technologies.

Industries such as chemical processing, food and beverage, HVAC, and power generation are increasingly recognizing the value of intelligent heat exchanger management systems. These smart solutions offer real-time monitoring, predictive maintenance capabilities, and optimization of heat transfer processes, which are crucial for improving operational efficiency and reducing downtime.

The integration of digital twin technology with plate heat exchangers represents a paradigm shift in how these critical components are managed. Digital twins provide a virtual replica of the physical heat exchanger, allowing for continuous monitoring and analysis of its performance. This technology enables operators to simulate various scenarios, predict potential issues, and optimize operating parameters without risking the actual equipment.

One of the key drivers for the adoption of smart heat exchanger solutions is the potential for significant cost savings. By implementing predictive maintenance strategies enabled by digital twins, companies can reduce unplanned downtime, extend the lifespan of their equipment, and optimize energy consumption. These benefits translate directly into improved bottom lines and enhanced competitiveness in the market.

Environmental regulations and sustainability goals are also fueling the demand for smart heat exchanger solutions. As industries face increasing pressure to reduce their carbon footprint, the ability to optimize heat transfer processes and minimize energy waste becomes paramount. Smart PHE management systems offer the tools necessary to achieve these environmental objectives while maintaining or even improving production efficiency.

The market is also seeing a growing interest in remote monitoring and management capabilities. With the rise of remote work and the need for flexible operations, solutions that allow for off-site monitoring and control of heat exchangers are becoming increasingly valuable. This trend is particularly relevant in the context of global operations where centralized expertise can be leveraged across multiple sites.

As the Internet of Things (IoT) and artificial intelligence (AI) technologies continue to mature, their integration with heat exchanger management systems is opening up new possibilities. These technologies enable more sophisticated data analysis, leading to better decision-making and autonomous optimization of heat exchange processes. The market is responding positively to these advancements, with a growing number of companies seeking to upgrade their existing infrastructure to incorporate these smart capabilities.

Industries such as chemical processing, food and beverage, HVAC, and power generation are increasingly recognizing the value of intelligent heat exchanger management systems. These smart solutions offer real-time monitoring, predictive maintenance capabilities, and optimization of heat transfer processes, which are crucial for improving operational efficiency and reducing downtime.

The integration of digital twin technology with plate heat exchangers represents a paradigm shift in how these critical components are managed. Digital twins provide a virtual replica of the physical heat exchanger, allowing for continuous monitoring and analysis of its performance. This technology enables operators to simulate various scenarios, predict potential issues, and optimize operating parameters without risking the actual equipment.

One of the key drivers for the adoption of smart heat exchanger solutions is the potential for significant cost savings. By implementing predictive maintenance strategies enabled by digital twins, companies can reduce unplanned downtime, extend the lifespan of their equipment, and optimize energy consumption. These benefits translate directly into improved bottom lines and enhanced competitiveness in the market.

Environmental regulations and sustainability goals are also fueling the demand for smart heat exchanger solutions. As industries face increasing pressure to reduce their carbon footprint, the ability to optimize heat transfer processes and minimize energy waste becomes paramount. Smart PHE management systems offer the tools necessary to achieve these environmental objectives while maintaining or even improving production efficiency.

The market is also seeing a growing interest in remote monitoring and management capabilities. With the rise of remote work and the need for flexible operations, solutions that allow for off-site monitoring and control of heat exchangers are becoming increasingly valuable. This trend is particularly relevant in the context of global operations where centralized expertise can be leveraged across multiple sites.

As the Internet of Things (IoT) and artificial intelligence (AI) technologies continue to mature, their integration with heat exchanger management systems is opening up new possibilities. These technologies enable more sophisticated data analysis, leading to better decision-making and autonomous optimization of heat exchange processes. The market is responding positively to these advancements, with a growing number of companies seeking to upgrade their existing infrastructure to incorporate these smart capabilities.

Current Challenges in Plate Heat Exchanger Management

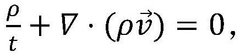

Plate heat exchanger (PHE) management faces several significant challenges in today's industrial landscape. One of the primary issues is the difficulty in accurately predicting and preventing fouling, which can severely impact heat transfer efficiency and overall system performance. Traditional methods of monitoring and maintenance often rely on scheduled inspections and reactive approaches, leading to unexpected downtime and increased operational costs.

Another critical challenge is the lack of real-time performance data and insights. Many PHE systems operate without continuous monitoring, making it challenging to optimize their performance or detect early signs of degradation. This limitation often results in suboptimal energy efficiency and missed opportunities for process improvements.

The complexity of PHE systems, especially in large-scale industrial applications, poses a significant challenge in terms of maintenance and troubleshooting. With numerous plates and intricate flow patterns, identifying the exact location and nature of issues can be time-consuming and resource-intensive. This complexity also makes it difficult to implement precise control strategies for varying operational conditions.

Aging infrastructure and the need for modernization present another set of challenges. Many existing PHE installations lack the necessary sensors and connectivity required for advanced monitoring and control systems. Upgrading these systems can be costly and disruptive to ongoing operations, creating a barrier to adopting new technologies.

Environmental concerns and regulatory pressures add another layer of complexity to PHE management. There is an increasing need to optimize energy consumption, reduce carbon footprint, and ensure compliance with stringent environmental standards. Traditional management approaches often struggle to meet these evolving requirements effectively.

The shortage of skilled personnel with expertise in PHE systems compounds these challenges. As technology advances, there is a growing gap between the skills required for effective PHE management and the available workforce. This skills gap can lead to suboptimal operation, maintenance, and decision-making processes.

Lastly, the integration of PHE systems with broader plant operations and enterprise-level systems remains a significant challenge. Many PHE units operate in isolation, with limited data exchange and coordination with other plant processes. This lack of integration hinders holistic optimization efforts and limits the potential for system-wide improvements in efficiency and productivity.

Another critical challenge is the lack of real-time performance data and insights. Many PHE systems operate without continuous monitoring, making it challenging to optimize their performance or detect early signs of degradation. This limitation often results in suboptimal energy efficiency and missed opportunities for process improvements.

The complexity of PHE systems, especially in large-scale industrial applications, poses a significant challenge in terms of maintenance and troubleshooting. With numerous plates and intricate flow patterns, identifying the exact location and nature of issues can be time-consuming and resource-intensive. This complexity also makes it difficult to implement precise control strategies for varying operational conditions.

Aging infrastructure and the need for modernization present another set of challenges. Many existing PHE installations lack the necessary sensors and connectivity required for advanced monitoring and control systems. Upgrading these systems can be costly and disruptive to ongoing operations, creating a barrier to adopting new technologies.

Environmental concerns and regulatory pressures add another layer of complexity to PHE management. There is an increasing need to optimize energy consumption, reduce carbon footprint, and ensure compliance with stringent environmental standards. Traditional management approaches often struggle to meet these evolving requirements effectively.

The shortage of skilled personnel with expertise in PHE systems compounds these challenges. As technology advances, there is a growing gap between the skills required for effective PHE management and the available workforce. This skills gap can lead to suboptimal operation, maintenance, and decision-making processes.

Lastly, the integration of PHE systems with broader plant operations and enterprise-level systems remains a significant challenge. Many PHE units operate in isolation, with limited data exchange and coordination with other plant processes. This lack of integration hinders holistic optimization efforts and limits the potential for system-wide improvements in efficiency and productivity.

Existing Digital Twin Solutions for Heat Exchangers

01 Digital Twin Creation and Modeling

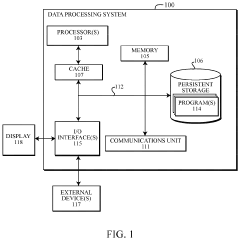

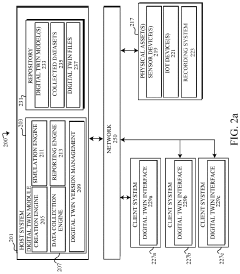

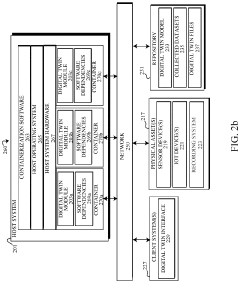

This involves the development of virtual representations of physical assets or systems. The process includes data collection, integration, and modeling techniques to create accurate digital replicas. These twins can simulate real-world conditions, enabling predictive analysis and optimization of the physical counterparts.- Digital Twin Creation and Modeling: This involves the development of virtual representations of physical assets or systems. The process includes data collection, integration, and modeling techniques to create accurate digital replicas. These digital twins can simulate real-world conditions, enabling predictive analysis and optimization of the physical counterparts.

- Real-time Data Synchronization and Analysis: This aspect focuses on maintaining a continuous connection between the physical asset and its digital twin. It involves real-time data collection, processing, and analysis to ensure the digital twin accurately reflects the current state of the physical asset. Advanced analytics and machine learning algorithms are often employed to derive insights from the synchronized data.

- Lifecycle Management of Digital Twins: This encompasses the entire lifecycle of digital twins, from creation to retirement. It includes version control, updates, and maintenance of digital twins as the physical assets evolve. The management system ensures that digital twins remain relevant and accurate throughout the lifecycle of the physical asset they represent.

- Integration with IoT and Cloud Platforms: This involves the seamless integration of digital twins with Internet of Things (IoT) devices and cloud computing platforms. It enables efficient data collection from sensors, storage in cloud environments, and utilization of cloud-based processing power for complex simulations and analyses. This integration enhances the scalability and accessibility of digital twin systems.

- Security and Access Control in Digital Twin Environments: This focuses on implementing robust security measures and access control mechanisms in digital twin systems. It includes data encryption, authentication protocols, and role-based access control to protect sensitive information and prevent unauthorized access or manipulation of digital twins. These measures ensure the integrity and confidentiality of digital twin data and operations.

02 Real-time Data Synchronization and Analysis

This aspect focuses on maintaining a continuous connection between the physical asset and its digital twin. It involves real-time data collection, processing, and analysis to ensure the digital twin accurately reflects the current state of the physical asset. Advanced analytics and machine learning algorithms are often employed to derive insights from the synchronized data.Expand Specific Solutions03 Lifecycle Management of Digital Twins

This encompasses the entire lifecycle of digital twins, from creation to retirement. It includes version control, updates, and maintenance of the digital models as the physical assets evolve. The management system ensures that the digital twin remains relevant and accurate throughout the lifecycle of the physical asset it represents.Expand Specific Solutions04 Integration with IoT and Cloud Platforms

This involves the seamless integration of digital twins with Internet of Things (IoT) devices and cloud computing platforms. It enables efficient data collection from sensors, storage in cloud environments, and distributed processing. This integration enhances the scalability and accessibility of digital twin systems across various applications and industries.Expand Specific Solutions05 Security and Access Control in Digital Twin Environments

This focuses on implementing robust security measures and access control mechanisms for digital twin systems. It includes data encryption, authentication protocols, and role-based access control to protect sensitive information and prevent unauthorized manipulation of digital twin models. Ensuring the integrity and confidentiality of digital twin data is crucial for their effective management and utilization.Expand Specific Solutions

Key Players in Digital Twin and Heat Exchanger Sectors

The digital twin technology for plate heat exchanger management is in its early growth stage, with a rapidly expanding market driven by increasing industrial digitalization. The global market size for this technology is projected to grow significantly over the next few years, fueled by the need for improved efficiency and predictive maintenance in various industries. While the technology is still evolving, several key players are emerging as leaders in this space. Companies like Simacro LLC, Mitsubishi Electric Corp., and State Grid Corp. of China are at the forefront, developing advanced digital twin solutions for heat exchanger management. These firms are leveraging their expertise in process modeling, automation, and power systems to create sophisticated digital representations that optimize performance and reduce downtime.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric's digital twin solution for plate heat exchangers utilizes their e-F@ctory concept, which combines factory automation technology with IT systems. Their approach integrates SCADA systems, edge computing devices, and AI-driven analytics to create accurate virtual models of heat exchangers[2]. The system employs high-precision sensors and Mitsubishi's MELSOFT iQ Works software suite for real-time monitoring and simulation. Their digital twin can predict thermal performance, detect anomalies, and optimize energy efficiency. Mitsubishi's solution also incorporates their MAPS SCADA system for comprehensive visualization and control, enabling predictive maintenance and remote operation capabilities[4].

Strengths: Strong integration with industrial automation systems, robust hardware-software ecosystem, and extensive experience in energy management. Weaknesses: May be less flexible for non-Mitsubishi equipment integration.

State Grid Corp. of China

Technical Solution: State Grid's digital twin solution for plate heat exchangers is part of their broader smart grid initiative. Their approach combines big data analytics, AI, and IoT technologies to create comprehensive digital representations of heat exchange systems within power plants and substations. The digital twin incorporates real-time data from SCADA systems, smart meters, and thermal imaging cameras to monitor heat exchanger performance[5]. State Grid's platform uses advanced algorithms to simulate various operational scenarios, predict equipment failures, and optimize energy distribution. The system also integrates with their grid management software for holistic energy system optimization, including demand response and load balancing considerations[6].

Strengths: Vast data resources from nationwide grid operations, strong government support for innovation, and integrated approach to energy system management. Weaknesses: Potential challenges in adapting the system for use outside of China's regulatory environment.

Core Innovations in Heat Exchanger Digital Twins

Digital twin workflow simulation

PatentActiveUS20210374032A1

Innovation

- A computer-implemented method for simulating digital twin performance that allows users to selectively bypass certain input parameters and components, using customizable configurations to focus on specific parts, substitute alternative components, and provide overriding values for intermediate simulation results, enabling more targeted analysis and optimization.

A management method for a heat exchanger system based on digital twin technology

PatentPendingCN120197436A

Innovation

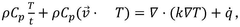

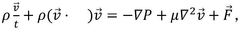

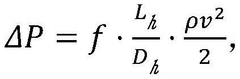

- By building a multi-physics simulation model based on digital twin technology, the operating parameters of the heat exchanger are collected in real time, including the inlet and outlet temperature, pressure, flow rate on the hot and cold sides, as well as the vibration deformation parameters of the tube bundle, a thermal system simulation model and a vibration stress simulation model are established, and a digital twin is generated after dynamic calibration to achieve real-time monitoring, fault prediction and operation optimization.

Energy Efficiency Impact of Digital Twin Technology

Digital twin technology is revolutionizing plate heat exchanger management, with significant implications for energy efficiency. By creating virtual replicas of physical heat exchangers, digital twins enable real-time monitoring, predictive maintenance, and optimization of operational parameters. This advanced approach to heat exchanger management has the potential to dramatically reduce energy consumption and improve overall system performance.

The implementation of digital twins in plate heat exchanger systems allows for continuous monitoring of key performance indicators, such as heat transfer rates, pressure drops, and fouling factors. By analyzing this data in real-time, operators can identify inefficiencies and make informed decisions to optimize energy usage. For instance, adjustments to flow rates or cleaning schedules can be made based on actual performance data rather than predetermined maintenance intervals, leading to more efficient operation and reduced energy waste.

Predictive maintenance enabled by digital twin technology further contributes to energy efficiency improvements. By accurately forecasting when maintenance is required, unnecessary downtime and energy-intensive cleaning processes can be avoided. This proactive approach ensures that heat exchangers operate at peak efficiency for longer periods, minimizing energy losses associated with fouling and degradation.

Digital twins also facilitate the optimization of heat exchanger design and operation through advanced simulation capabilities. Engineers can test various configurations and operating conditions virtually, identifying the most energy-efficient setups without the need for physical prototypes or costly trial-and-error processes. This capability accelerates the development of more efficient heat exchanger designs and operational strategies, leading to significant energy savings across industries.

Moreover, the integration of digital twins with machine learning algorithms enables continuous improvement in energy efficiency. As these systems collect and analyze more data over time, they can identify patterns and trends that human operators might miss, suggesting increasingly sophisticated optimization strategies. This self-learning aspect of digital twin technology promises ongoing enhancements in energy efficiency, potentially leading to substantial cumulative energy savings over the lifecycle of plate heat exchangers.

The impact of digital twin technology on energy efficiency extends beyond individual heat exchangers to entire thermal systems and industrial processes. By providing a holistic view of system performance, digital twins enable better integration of heat exchangers with other components, optimizing overall energy utilization. This system-level approach to energy management can result in significant reductions in energy consumption and associated costs for industrial facilities.

The implementation of digital twins in plate heat exchanger systems allows for continuous monitoring of key performance indicators, such as heat transfer rates, pressure drops, and fouling factors. By analyzing this data in real-time, operators can identify inefficiencies and make informed decisions to optimize energy usage. For instance, adjustments to flow rates or cleaning schedules can be made based on actual performance data rather than predetermined maintenance intervals, leading to more efficient operation and reduced energy waste.

Predictive maintenance enabled by digital twin technology further contributes to energy efficiency improvements. By accurately forecasting when maintenance is required, unnecessary downtime and energy-intensive cleaning processes can be avoided. This proactive approach ensures that heat exchangers operate at peak efficiency for longer periods, minimizing energy losses associated with fouling and degradation.

Digital twins also facilitate the optimization of heat exchanger design and operation through advanced simulation capabilities. Engineers can test various configurations and operating conditions virtually, identifying the most energy-efficient setups without the need for physical prototypes or costly trial-and-error processes. This capability accelerates the development of more efficient heat exchanger designs and operational strategies, leading to significant energy savings across industries.

Moreover, the integration of digital twins with machine learning algorithms enables continuous improvement in energy efficiency. As these systems collect and analyze more data over time, they can identify patterns and trends that human operators might miss, suggesting increasingly sophisticated optimization strategies. This self-learning aspect of digital twin technology promises ongoing enhancements in energy efficiency, potentially leading to substantial cumulative energy savings over the lifecycle of plate heat exchangers.

The impact of digital twin technology on energy efficiency extends beyond individual heat exchangers to entire thermal systems and industrial processes. By providing a holistic view of system performance, digital twins enable better integration of heat exchangers with other components, optimizing overall energy utilization. This system-level approach to energy management can result in significant reductions in energy consumption and associated costs for industrial facilities.

Data Security in Industrial Digital Twin Applications

As digital twin technology continues to revolutionize industrial processes, data security has become a paramount concern in industrial digital twin applications. The integration of digital twins in plate heat exchanger management brings forth significant advancements in monitoring, predictive maintenance, and optimization. However, it also introduces new vulnerabilities and potential risks to sensitive industrial data.

Industrial digital twins rely on vast amounts of real-time data collected from physical assets, including operational parameters, performance metrics, and environmental conditions. This data is often critical to the organization's competitive advantage and operational efficiency. Consequently, protecting this information from unauthorized access, manipulation, or theft is crucial for maintaining the integrity and confidentiality of industrial processes.

One of the primary security challenges in industrial digital twin applications is the protection of data in transit. As information flows between physical assets, sensors, edge devices, and cloud-based digital twin platforms, it becomes susceptible to interception and tampering. Implementing robust encryption protocols and secure communication channels is essential to safeguard data as it moves through various network layers.

Another critical aspect of data security in industrial digital twin applications is access control and authentication. With multiple stakeholders involved in managing and utilizing digital twins, establishing granular access rights and multi-factor authentication mechanisms is vital. This ensures that only authorized personnel can view, modify, or interact with sensitive data and digital twin models.

Data integrity is also a significant concern in industrial digital twin applications. Ensuring the accuracy and consistency of data throughout its lifecycle is crucial for maintaining the reliability of digital twin models. Implementing data validation techniques, checksums, and blockchain-based solutions can help prevent data corruption and unauthorized modifications.

Furthermore, the integration of digital twins with existing industrial control systems and operational technology (OT) networks introduces new attack vectors. Securing the interfaces between IT and OT systems, implementing robust firewalls, and regularly updating software and firmware are essential steps in mitigating these risks.

As industrial digital twins often leverage cloud-based platforms for data storage and processing, cloud security becomes a critical consideration. Organizations must carefully evaluate cloud service providers' security measures, data residency policies, and compliance with industry standards to ensure the protection of sensitive industrial data.

Industrial digital twins rely on vast amounts of real-time data collected from physical assets, including operational parameters, performance metrics, and environmental conditions. This data is often critical to the organization's competitive advantage and operational efficiency. Consequently, protecting this information from unauthorized access, manipulation, or theft is crucial for maintaining the integrity and confidentiality of industrial processes.

One of the primary security challenges in industrial digital twin applications is the protection of data in transit. As information flows between physical assets, sensors, edge devices, and cloud-based digital twin platforms, it becomes susceptible to interception and tampering. Implementing robust encryption protocols and secure communication channels is essential to safeguard data as it moves through various network layers.

Another critical aspect of data security in industrial digital twin applications is access control and authentication. With multiple stakeholders involved in managing and utilizing digital twins, establishing granular access rights and multi-factor authentication mechanisms is vital. This ensures that only authorized personnel can view, modify, or interact with sensitive data and digital twin models.

Data integrity is also a significant concern in industrial digital twin applications. Ensuring the accuracy and consistency of data throughout its lifecycle is crucial for maintaining the reliability of digital twin models. Implementing data validation techniques, checksums, and blockchain-based solutions can help prevent data corruption and unauthorized modifications.

Furthermore, the integration of digital twins with existing industrial control systems and operational technology (OT) networks introduces new attack vectors. Securing the interfaces between IT and OT systems, implementing robust firewalls, and regularly updating software and firmware are essential steps in mitigating these risks.

As industrial digital twins often leverage cloud-based platforms for data storage and processing, cloud security becomes a critical consideration. Organizations must carefully evaluate cloud service providers' security measures, data residency policies, and compliance with industry standards to ensure the protection of sensitive industrial data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!