Lifecycle Analysis of Plate Heat Exchanger Components

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Component Evolution

The evolution of plate heat exchanger (PHE) components has been marked by significant advancements in design, materials, and manufacturing processes over the past several decades. Initially, PHEs were primarily constructed with simple, flat plates made of stainless steel. These early designs offered limited heat transfer efficiency and were prone to fouling and corrosion.

In the 1960s and 1970s, the introduction of corrugated plates represented a major breakthrough in PHE technology. This innovation dramatically increased the heat transfer surface area and improved turbulence, leading to enhanced thermal performance. Simultaneously, manufacturers began experimenting with different plate patterns and geometries to optimize flow distribution and minimize pressure drop.

The 1980s saw the development of more sophisticated plate designs, including chevron patterns and asymmetrical corrugations. These advancements further improved heat transfer efficiency and allowed for better customization to specific application requirements. During this period, the use of titanium plates also gained popularity, particularly in marine and chemical processing applications, due to their excellent corrosion resistance.

The 1990s and early 2000s brought about significant improvements in gasket technology. New elastomer compounds were developed to withstand higher temperatures and pressures, extending the operational range of PHEs. Additionally, the introduction of laser-welded PHEs eliminated the need for gaskets in certain high-pressure applications, further expanding the versatility of these heat exchangers.

In recent years, the focus has shifted towards enhancing the sustainability and efficiency of PHE components. Advanced manufacturing techniques, such as 3D printing and precision stamping, have enabled the production of more complex plate geometries with tighter tolerances. This has resulted in PHEs with improved heat transfer coefficients and reduced material usage.

Material science advancements have also played a crucial role in PHE component evolution. The development of new alloys and composite materials has led to plates with superior thermal conductivity, corrosion resistance, and mechanical strength. These innovations have expanded the application range of PHEs into more demanding industries, such as petrochemical processing and nuclear power generation.

The integration of smart technologies and sensors into PHE components represents the latest frontier in their evolution. Real-time monitoring of heat transfer performance, fouling detection, and predictive maintenance capabilities are now being incorporated into modern PHE designs. This trend towards digitalization and Industry 4.0 principles is expected to continue, driving further improvements in PHE efficiency, reliability, and lifecycle management.

In the 1960s and 1970s, the introduction of corrugated plates represented a major breakthrough in PHE technology. This innovation dramatically increased the heat transfer surface area and improved turbulence, leading to enhanced thermal performance. Simultaneously, manufacturers began experimenting with different plate patterns and geometries to optimize flow distribution and minimize pressure drop.

The 1980s saw the development of more sophisticated plate designs, including chevron patterns and asymmetrical corrugations. These advancements further improved heat transfer efficiency and allowed for better customization to specific application requirements. During this period, the use of titanium plates also gained popularity, particularly in marine and chemical processing applications, due to their excellent corrosion resistance.

The 1990s and early 2000s brought about significant improvements in gasket technology. New elastomer compounds were developed to withstand higher temperatures and pressures, extending the operational range of PHEs. Additionally, the introduction of laser-welded PHEs eliminated the need for gaskets in certain high-pressure applications, further expanding the versatility of these heat exchangers.

In recent years, the focus has shifted towards enhancing the sustainability and efficiency of PHE components. Advanced manufacturing techniques, such as 3D printing and precision stamping, have enabled the production of more complex plate geometries with tighter tolerances. This has resulted in PHEs with improved heat transfer coefficients and reduced material usage.

Material science advancements have also played a crucial role in PHE component evolution. The development of new alloys and composite materials has led to plates with superior thermal conductivity, corrosion resistance, and mechanical strength. These innovations have expanded the application range of PHEs into more demanding industries, such as petrochemical processing and nuclear power generation.

The integration of smart technologies and sensors into PHE components represents the latest frontier in their evolution. Real-time monitoring of heat transfer performance, fouling detection, and predictive maintenance capabilities are now being incorporated into modern PHE designs. This trend towards digitalization and Industry 4.0 principles is expected to continue, driving further improvements in PHE efficiency, reliability, and lifecycle management.

Market Demand Analysis

The market demand for plate heat exchanger components has been steadily growing due to their widespread applications across various industries. These components are crucial in sectors such as chemical processing, food and beverage, HVAC, power generation, and oil and gas, where efficient heat transfer is essential for operational success.

In the chemical processing industry, there is an increasing demand for corrosion-resistant plate heat exchanger components capable of handling aggressive fluids and high temperatures. This demand is driven by the need for improved process efficiency and reduced downtime. The food and beverage sector requires components that meet strict hygiene standards and can withstand frequent cleaning cycles, contributing to the market's growth.

The HVAC industry has seen a surge in demand for plate heat exchanger components due to the global focus on energy efficiency in buildings. As governments worldwide implement stricter energy regulations, the adoption of plate heat exchangers in heating and cooling systems has increased significantly. This trend is expected to continue, driving the market for components in the coming years.

In the power generation sector, the shift towards renewable energy sources has created new opportunities for plate heat exchanger components. Solar thermal power plants and geothermal energy systems rely heavily on efficient heat transfer, boosting the demand for high-performance components. Additionally, the growing interest in waste heat recovery systems across industries has further expanded the market for these components.

The oil and gas industry, despite fluctuations in global energy markets, continues to be a significant consumer of plate heat exchanger components. The need for efficient heat transfer in refining processes and offshore operations maintains a steady demand for these components, particularly those designed for high-pressure and corrosive environments.

Emerging markets in Asia-Pacific and Latin America are experiencing rapid industrialization, driving the demand for plate heat exchanger components across various sectors. These regions are witnessing increased investments in manufacturing facilities and infrastructure projects, which require efficient heat transfer solutions.

The lifecycle analysis of plate heat exchanger components has become increasingly important as end-users focus on total cost of ownership and sustainability. This has led to a growing demand for components with longer lifespans, improved corrosion resistance, and easier maintenance characteristics. Manufacturers are responding by developing innovative materials and designs that extend the operational life of these components while reducing maintenance requirements.

As industries strive for greater energy efficiency and reduced environmental impact, the market for plate heat exchanger components is expected to continue its growth trajectory. The demand for customized solutions tailored to specific industry needs is also on the rise, presenting opportunities for manufacturers to differentiate their offerings and capture market share.

In the chemical processing industry, there is an increasing demand for corrosion-resistant plate heat exchanger components capable of handling aggressive fluids and high temperatures. This demand is driven by the need for improved process efficiency and reduced downtime. The food and beverage sector requires components that meet strict hygiene standards and can withstand frequent cleaning cycles, contributing to the market's growth.

The HVAC industry has seen a surge in demand for plate heat exchanger components due to the global focus on energy efficiency in buildings. As governments worldwide implement stricter energy regulations, the adoption of plate heat exchangers in heating and cooling systems has increased significantly. This trend is expected to continue, driving the market for components in the coming years.

In the power generation sector, the shift towards renewable energy sources has created new opportunities for plate heat exchanger components. Solar thermal power plants and geothermal energy systems rely heavily on efficient heat transfer, boosting the demand for high-performance components. Additionally, the growing interest in waste heat recovery systems across industries has further expanded the market for these components.

The oil and gas industry, despite fluctuations in global energy markets, continues to be a significant consumer of plate heat exchanger components. The need for efficient heat transfer in refining processes and offshore operations maintains a steady demand for these components, particularly those designed for high-pressure and corrosive environments.

Emerging markets in Asia-Pacific and Latin America are experiencing rapid industrialization, driving the demand for plate heat exchanger components across various sectors. These regions are witnessing increased investments in manufacturing facilities and infrastructure projects, which require efficient heat transfer solutions.

The lifecycle analysis of plate heat exchanger components has become increasingly important as end-users focus on total cost of ownership and sustainability. This has led to a growing demand for components with longer lifespans, improved corrosion resistance, and easier maintenance characteristics. Manufacturers are responding by developing innovative materials and designs that extend the operational life of these components while reducing maintenance requirements.

As industries strive for greater energy efficiency and reduced environmental impact, the market for plate heat exchanger components is expected to continue its growth trajectory. The demand for customized solutions tailored to specific industry needs is also on the rise, presenting opportunities for manufacturers to differentiate their offerings and capture market share.

Technical Challenges

The lifecycle analysis of plate heat exchanger components presents several technical challenges that researchers and engineers must address. One of the primary difficulties lies in accurately modeling the complex thermal and hydraulic processes occurring within the exchanger over its operational lifespan. The intricate geometry of plate heat exchangers, with their corrugated patterns and narrow flow channels, makes it challenging to predict fluid flow distribution, heat transfer coefficients, and pressure drops with high precision.

Material degradation and fouling pose significant hurdles in lifecycle analysis. The harsh operating conditions, including high temperatures, pressures, and potentially corrosive fluids, can lead to material fatigue, corrosion, and erosion of the plates and gaskets. Predicting the rate and extent of these degradation processes requires sophisticated models that account for various environmental factors and material properties. Furthermore, the accumulation of deposits on heat transfer surfaces (fouling) can significantly impact performance over time, necessitating complex models to forecast fouling rates and their effects on heat transfer efficiency.

Another technical challenge is the development of accurate and efficient computational methods for simulating long-term performance. Traditional computational fluid dynamics (CFD) approaches, while useful for short-term analysis, become computationally prohibitive when extended to cover the entire lifecycle of a plate heat exchanger. This necessitates the development of novel numerical methods or simplified models that can maintain accuracy while reducing computational complexity.

The variability in operating conditions throughout the lifecycle of a plate heat exchanger further complicates analysis. Fluctuations in flow rates, temperatures, and fluid properties due to changing process requirements or seasonal variations can significantly impact performance and longevity. Incorporating these dynamic operating conditions into lifecycle models requires sophisticated algorithms and extensive data on real-world operational patterns.

Integrating multiple physical phenomena into a cohesive lifecycle model presents another significant challenge. The interplay between thermal performance, mechanical stress, chemical reactions, and material properties necessitates a multiphysics approach. Developing models that can accurately capture these interdependent processes while remaining computationally tractable is a complex task that requires expertise across multiple disciplines.

Lastly, validating lifecycle models against real-world data poses a substantial challenge. The long timeframes involved in lifecycle analysis make it difficult to obtain comprehensive experimental data for model validation. This is compounded by the fact that accelerated aging tests may not accurately represent the true long-term behavior of plate heat exchangers in operational environments. Developing innovative methods for model validation and uncertainty quantification is crucial for ensuring the reliability and applicability of lifecycle analysis results.

Material degradation and fouling pose significant hurdles in lifecycle analysis. The harsh operating conditions, including high temperatures, pressures, and potentially corrosive fluids, can lead to material fatigue, corrosion, and erosion of the plates and gaskets. Predicting the rate and extent of these degradation processes requires sophisticated models that account for various environmental factors and material properties. Furthermore, the accumulation of deposits on heat transfer surfaces (fouling) can significantly impact performance over time, necessitating complex models to forecast fouling rates and their effects on heat transfer efficiency.

Another technical challenge is the development of accurate and efficient computational methods for simulating long-term performance. Traditional computational fluid dynamics (CFD) approaches, while useful for short-term analysis, become computationally prohibitive when extended to cover the entire lifecycle of a plate heat exchanger. This necessitates the development of novel numerical methods or simplified models that can maintain accuracy while reducing computational complexity.

The variability in operating conditions throughout the lifecycle of a plate heat exchanger further complicates analysis. Fluctuations in flow rates, temperatures, and fluid properties due to changing process requirements or seasonal variations can significantly impact performance and longevity. Incorporating these dynamic operating conditions into lifecycle models requires sophisticated algorithms and extensive data on real-world operational patterns.

Integrating multiple physical phenomena into a cohesive lifecycle model presents another significant challenge. The interplay between thermal performance, mechanical stress, chemical reactions, and material properties necessitates a multiphysics approach. Developing models that can accurately capture these interdependent processes while remaining computationally tractable is a complex task that requires expertise across multiple disciplines.

Lastly, validating lifecycle models against real-world data poses a substantial challenge. The long timeframes involved in lifecycle analysis make it difficult to obtain comprehensive experimental data for model validation. This is compounded by the fact that accelerated aging tests may not accurately represent the true long-term behavior of plate heat exchangers in operational environments. Developing innovative methods for model validation and uncertainty quantification is crucial for ensuring the reliability and applicability of lifecycle analysis results.

Current LCA Methods

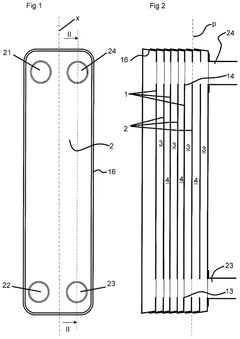

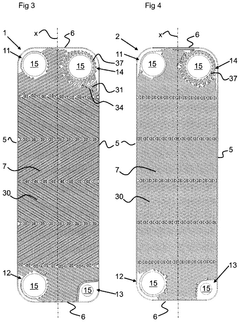

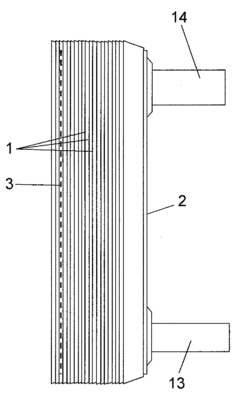

01 Plate design and configuration

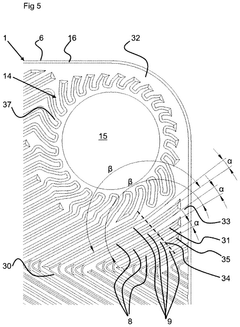

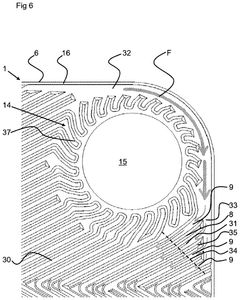

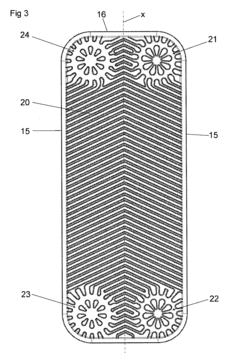

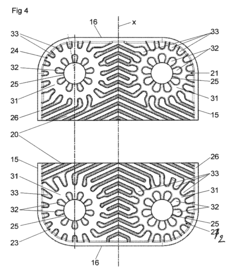

Plate heat exchangers utilize specially designed plates to enhance heat transfer efficiency. These plates often feature corrugated or chevron patterns to increase turbulence and surface area. The configuration of plates, including their arrangement and spacing, plays a crucial role in optimizing heat exchange performance.- Plate design and configuration: Plate heat exchangers utilize specially designed plates to enhance heat transfer efficiency. These plates often feature corrugated or chevron patterns to increase surface area and turbulence. The configuration of plates, including their arrangement and spacing, plays a crucial role in optimizing heat exchange performance and fluid flow distribution.

- Sealing and gasket systems: Effective sealing is essential in plate heat exchangers to prevent fluid leakage between channels. Various gasket designs and materials are employed to ensure proper sealing under different operating conditions. Some advanced designs incorporate gasketless solutions or welded plate pairs to enhance reliability and reduce maintenance requirements.

- Frame and support structures: The frame of a plate heat exchanger provides structural support and allows for easy assembly and disassembly. It typically consists of fixed and movable end plates, carrying and guide bars, and tightening bolts. The design of these components affects the overall robustness, ease of maintenance, and expandability of the heat exchanger.

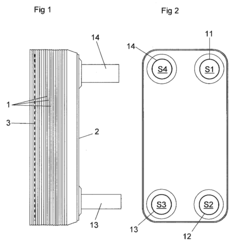

- Flow distribution and port design: Efficient flow distribution is crucial for optimal heat transfer in plate heat exchangers. This is achieved through carefully designed inlet and outlet ports, as well as internal flow channels. Advanced port designs can help minimize pressure drop, reduce fouling, and improve overall thermal performance.

- Materials and corrosion resistance: The selection of materials for plate heat exchanger components is critical for ensuring durability and performance. Corrosion-resistant materials such as stainless steel, titanium, or specialized alloys are often used for plates and other components exposed to potentially corrosive fluids. The choice of materials impacts heat transfer efficiency, longevity, and compatibility with various process fluids.

02 Sealing and gasket systems

Effective sealing is essential in plate heat exchangers to prevent leakage and maintain separation between fluid streams. Various gasket materials and designs are employed to ensure proper sealing under different operating conditions. Advanced sealing systems may incorporate features for improved durability and ease of maintenance.Expand Specific Solutions03 Frame and support structures

The frame of a plate heat exchanger provides structural support and allows for compression of the plate pack. Components such as fixed and movable end plates, tie rods, and support columns are crucial for maintaining proper alignment and pressure distribution across the plates. Design considerations include ease of assembly, disassembly, and resistance to thermal expansion.Expand Specific Solutions04 Flow distribution systems

Efficient distribution of fluids across the plate pack is critical for optimal heat transfer. Components such as inlet and outlet ports, distribution channels, and flow directors are designed to ensure uniform flow patterns and minimize dead zones. Advanced distribution systems may incorporate features to reduce pressure drop and improve overall exchanger performance.Expand Specific Solutions05 Materials and coatings

The selection of materials for plate heat exchanger components is crucial for ensuring durability, corrosion resistance, and thermal efficiency. Various metals, alloys, and composite materials may be used depending on the application. Specialized coatings can be applied to enhance surface properties, improve heat transfer, or provide additional protection against fouling and corrosion.Expand Specific Solutions

Key Industry Players

The lifecycle analysis of plate heat exchanger components is in a mature stage of industry development, with a substantial global market size estimated to be in the billions of dollars. The technology is well-established, with several key players dominating the market. Companies like Alfa Laval, Danfoss, and Mitsubishi Electric have extensive experience and advanced capabilities in this field. Emerging players such as LHE Co. and Vahterus Oy are also making significant contributions with innovative designs. The market is characterized by ongoing research and development efforts to improve efficiency, durability, and sustainability of plate heat exchanger components, driven by increasing demand for energy-efficient solutions across various industries.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced lifecycle analysis techniques for plate heat exchanger components, focusing on sustainability and efficiency. Their approach includes comprehensive material analysis, performance modeling, and predictive maintenance strategies. They utilize advanced computational fluid dynamics (CFD) simulations to optimize plate designs, reducing material usage while maintaining or improving heat transfer efficiency[1]. Alfa Laval's lifecycle analysis also incorporates real-time monitoring systems that track component wear and performance degradation, allowing for proactive maintenance and replacement scheduling[3]. This holistic approach considers the environmental impact of materials used, manufacturing processes, operational energy consumption, and end-of-life recycling potential[5].

Strengths: Comprehensive approach integrating design, performance, and sustainability; Advanced simulation and monitoring technologies. Weaknesses: Potentially higher initial costs; Complexity in implementing across diverse industrial applications.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a sophisticated lifecycle analysis system for plate heat exchanger components, leveraging their expertise in industrial automation and IoT. Their approach combines advanced sensors, machine learning algorithms, and big data analytics to provide real-time performance monitoring and predictive maintenance capabilities[2]. The system analyzes factors such as thermal efficiency, pressure drop, and material degradation over time, enabling accurate lifespan predictions and optimization of replacement schedules. Mitsubishi's lifecycle analysis also incorporates environmental impact assessments, considering factors like energy consumption, carbon footprint, and recyclability of components throughout their lifecycle[4].

Strengths: Integration with existing industrial automation systems; Advanced predictive maintenance capabilities. Weaknesses: May require significant infrastructure upgrades; Potential data security concerns with IoT integration.

Critical LCA Metrics

Heat exchanger plate, and a plate heat exchanger

PatentActiveUS12215937B2

Innovation

- The heat exchanger plate features tapering valleys in the local part area that decrease in width towards the longitudinal central axis, reducing flow resistance for fluids flowing around portholes and into the main heat exchanger area.

Plate Heat Exchanger

PatentInactiveUS20110036549A1

Innovation

- The plate heat exchanger design features a continuous outer contour with varying radius (0.8R to 1.2R) and flat extensions at porthole areas for enhanced strength, along with a specific arrangement of inner and outer portions and ridges/valleys for improved joining between plates, allowing for high-pressure operation.

Environmental Regulations

Environmental regulations play a crucial role in shaping the lifecycle analysis of plate heat exchanger components. These regulations are designed to minimize the environmental impact of industrial processes and products throughout their entire lifecycle, from raw material extraction to disposal or recycling.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, particularly in developed countries. The European Union's Ecodesign Directive, for instance, sets mandatory ecological requirements for energy-using and energy-related products. This directive has direct implications for plate heat exchangers, as it requires manufacturers to consider the environmental impact of their products during the design phase.

The Restriction of Hazardous Substances (RoHS) Directive is another important regulation that affects the production of plate heat exchanger components. This directive restricts the use of certain hazardous materials in electrical and electronic equipment, including lead, mercury, and cadmium. Manufacturers must ensure that their components comply with these restrictions, which may necessitate changes in material selection and production processes.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU also impacts the lifecycle analysis of plate heat exchanger components. This regulation requires companies to identify and manage the risks associated with substances they manufacture and market in the EU. For plate heat exchanger manufacturers, this means carefully evaluating the chemicals used in their products and processes.

In the United States, the Environmental Protection Agency (EPA) has implemented regulations that affect the lifecycle of industrial equipment, including plate heat exchangers. The Clean Air Act and Clean Water Act set standards for emissions and effluents, which manufacturers must consider when designing and producing their components. Additionally, the EPA's Energy Star program promotes energy-efficient products, which can influence the design and marketing of plate heat exchangers.

Waste management regulations also play a significant role in the lifecycle analysis of plate heat exchanger components. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electrical goods. This directive encourages manufacturers to design products with end-of-life considerations in mind, promoting easier disassembly and recycling.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. Manufacturers of plate heat exchanger components must stay informed about these evolving regulations and adapt their processes accordingly. This may involve investing in cleaner technologies, developing more sustainable materials, and improving the overall efficiency of their products to meet increasingly strict environmental standards.

In recent years, there has been a significant increase in the stringency of environmental regulations worldwide, particularly in developed countries. The European Union's Ecodesign Directive, for instance, sets mandatory ecological requirements for energy-using and energy-related products. This directive has direct implications for plate heat exchangers, as it requires manufacturers to consider the environmental impact of their products during the design phase.

The Restriction of Hazardous Substances (RoHS) Directive is another important regulation that affects the production of plate heat exchanger components. This directive restricts the use of certain hazardous materials in electrical and electronic equipment, including lead, mercury, and cadmium. Manufacturers must ensure that their components comply with these restrictions, which may necessitate changes in material selection and production processes.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU also impacts the lifecycle analysis of plate heat exchanger components. This regulation requires companies to identify and manage the risks associated with substances they manufacture and market in the EU. For plate heat exchanger manufacturers, this means carefully evaluating the chemicals used in their products and processes.

In the United States, the Environmental Protection Agency (EPA) has implemented regulations that affect the lifecycle of industrial equipment, including plate heat exchangers. The Clean Air Act and Clean Water Act set standards for emissions and effluents, which manufacturers must consider when designing and producing their components. Additionally, the EPA's Energy Star program promotes energy-efficient products, which can influence the design and marketing of plate heat exchangers.

Waste management regulations also play a significant role in the lifecycle analysis of plate heat exchanger components. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electrical goods. This directive encourages manufacturers to design products with end-of-life considerations in mind, promoting easier disassembly and recycling.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. Manufacturers of plate heat exchanger components must stay informed about these evolving regulations and adapt their processes accordingly. This may involve investing in cleaner technologies, developing more sustainable materials, and improving the overall efficiency of their products to meet increasingly strict environmental standards.

Material Sustainability

Material sustainability is a critical aspect of the lifecycle analysis of plate heat exchanger components. The selection and management of materials used in these components significantly impact their environmental footprint, performance, and longevity. Plate heat exchangers typically utilize materials such as stainless steel, titanium, or nickel alloys, each chosen for specific operational requirements and environmental conditions.

The sustainability of these materials is evaluated through various metrics, including resource depletion, energy consumption during production, recyclability, and end-of-life disposal impacts. Stainless steel, for instance, offers excellent corrosion resistance and durability, contributing to extended component lifespans. Its high recyclability further enhances its sustainability profile, as it can be reprocessed multiple times without significant loss of quality.

Titanium, while more energy-intensive to produce, provides superior resistance to aggressive media and high temperatures. Its exceptional durability often justifies the initial environmental cost by extending the operational life of heat exchanger components. The lightweight nature of titanium also contributes to reduced transportation-related emissions throughout the lifecycle.

Nickel alloys, prized for their resistance to extreme temperatures and corrosive environments, present a more complex sustainability picture. While they offer extended service life in harsh conditions, their production is energy-intensive and resource-demanding. The limited availability of nickel as a resource necessitates careful consideration of its use and potential alternatives.

Innovations in material science are continually improving the sustainability of plate heat exchanger components. Advanced manufacturing techniques, such as additive manufacturing, are enabling the production of components with optimized geometries, reducing material waste and enhancing performance. Surface treatments and coatings are being developed to improve corrosion resistance and heat transfer efficiency, potentially extending component lifespan and reducing the need for frequent replacements.

The concept of circular economy is increasingly influencing material choices for plate heat exchangers. Designers are now considering not only the initial performance characteristics but also the ease of disassembly, material separation, and recyclability at the end of the component's life. This holistic approach aims to minimize waste and maximize resource efficiency throughout the entire lifecycle.

As environmental regulations become more stringent, manufacturers are exploring bio-based and renewable materials for certain components, where applicable. While not suitable for the main heat transfer surfaces, these materials may find applications in gaskets, insulation, or auxiliary components, contributing to an overall reduction in the environmental impact of plate heat exchangers.

The sustainability of these materials is evaluated through various metrics, including resource depletion, energy consumption during production, recyclability, and end-of-life disposal impacts. Stainless steel, for instance, offers excellent corrosion resistance and durability, contributing to extended component lifespans. Its high recyclability further enhances its sustainability profile, as it can be reprocessed multiple times without significant loss of quality.

Titanium, while more energy-intensive to produce, provides superior resistance to aggressive media and high temperatures. Its exceptional durability often justifies the initial environmental cost by extending the operational life of heat exchanger components. The lightweight nature of titanium also contributes to reduced transportation-related emissions throughout the lifecycle.

Nickel alloys, prized for their resistance to extreme temperatures and corrosive environments, present a more complex sustainability picture. While they offer extended service life in harsh conditions, their production is energy-intensive and resource-demanding. The limited availability of nickel as a resource necessitates careful consideration of its use and potential alternatives.

Innovations in material science are continually improving the sustainability of plate heat exchanger components. Advanced manufacturing techniques, such as additive manufacturing, are enabling the production of components with optimized geometries, reducing material waste and enhancing performance. Surface treatments and coatings are being developed to improve corrosion resistance and heat transfer efficiency, potentially extending component lifespan and reducing the need for frequent replacements.

The concept of circular economy is increasingly influencing material choices for plate heat exchangers. Designers are now considering not only the initial performance characteristics but also the ease of disassembly, material separation, and recyclability at the end of the component's life. This holistic approach aims to minimize waste and maximize resource efficiency throughout the entire lifecycle.

As environmental regulations become more stringent, manufacturers are exploring bio-based and renewable materials for certain components, where applicable. While not suitable for the main heat transfer surfaces, these materials may find applications in gaskets, insulation, or auxiliary components, contributing to an overall reduction in the environmental impact of plate heat exchangers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!