Schematics of Multi-Pass Plate Heat Exchanger Systems

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Evolution

The evolution of heat exchanger technology has been a continuous process of innovation and refinement, driven by the need for more efficient and compact designs. The journey of plate heat exchangers, particularly multi-pass systems, represents a significant leap in this evolution.

Early heat exchangers were primarily shell-and-tube designs, which, while effective, had limitations in terms of size and efficiency. The introduction of plate heat exchangers in the 1920s marked a turning point, offering improved heat transfer rates and more compact designs. However, it wasn't until the 1960s that multi-pass plate heat exchangers began to emerge, addressing the need for even greater efficiency in industrial processes.

The development of multi-pass plate heat exchanger systems was a response to the growing demands of various industries, including chemical processing, food and beverage production, and HVAC applications. These systems allowed for multiple fluid passes across the plates, significantly enhancing heat transfer efficiency and reducing the overall size of the equipment.

As materials science advanced, so did the capabilities of plate heat exchangers. The introduction of new plate materials and designs in the 1980s and 1990s allowed for higher operating temperatures and pressures, expanding the range of applications for multi-pass systems. Corrugated plate designs and improved gasket materials further enhanced performance and reliability.

The turn of the millennium saw a focus on optimizing flow distribution within multi-pass systems. Computational fluid dynamics (CFD) modeling became an essential tool in designing more efficient plate arrangements and flow paths. This led to the development of asymmetric plate designs and variable geometry configurations, allowing for customized solutions to specific heat transfer requirements.

In recent years, the evolution of multi-pass plate heat exchangers has been characterized by a push towards sustainability and energy efficiency. Manufacturers have focused on reducing material usage while maintaining or improving performance. Advanced manufacturing techniques, such as 3D printing, have opened up new possibilities for complex plate geometries that were previously impossible to produce.

The integration of smart technologies has also played a role in the recent evolution of these systems. Real-time monitoring and control systems now allow for dynamic adjustment of flow rates and temperatures, optimizing performance based on changing process conditions. This has led to the concept of "smart" heat exchangers, capable of self-diagnosis and predictive maintenance.

Looking forward, the evolution of multi-pass plate heat exchanger systems is likely to continue along the paths of increased efficiency, compactness, and adaptability. Research into novel materials, such as graphene-based composites, promises to push the boundaries of heat transfer capabilities even further. The ongoing development of multi-pass plate heat exchangers reflects the broader trend in industrial equipment towards more intelligent, efficient, and sustainable solutions.

Early heat exchangers were primarily shell-and-tube designs, which, while effective, had limitations in terms of size and efficiency. The introduction of plate heat exchangers in the 1920s marked a turning point, offering improved heat transfer rates and more compact designs. However, it wasn't until the 1960s that multi-pass plate heat exchangers began to emerge, addressing the need for even greater efficiency in industrial processes.

The development of multi-pass plate heat exchanger systems was a response to the growing demands of various industries, including chemical processing, food and beverage production, and HVAC applications. These systems allowed for multiple fluid passes across the plates, significantly enhancing heat transfer efficiency and reducing the overall size of the equipment.

As materials science advanced, so did the capabilities of plate heat exchangers. The introduction of new plate materials and designs in the 1980s and 1990s allowed for higher operating temperatures and pressures, expanding the range of applications for multi-pass systems. Corrugated plate designs and improved gasket materials further enhanced performance and reliability.

The turn of the millennium saw a focus on optimizing flow distribution within multi-pass systems. Computational fluid dynamics (CFD) modeling became an essential tool in designing more efficient plate arrangements and flow paths. This led to the development of asymmetric plate designs and variable geometry configurations, allowing for customized solutions to specific heat transfer requirements.

In recent years, the evolution of multi-pass plate heat exchangers has been characterized by a push towards sustainability and energy efficiency. Manufacturers have focused on reducing material usage while maintaining or improving performance. Advanced manufacturing techniques, such as 3D printing, have opened up new possibilities for complex plate geometries that were previously impossible to produce.

The integration of smart technologies has also played a role in the recent evolution of these systems. Real-time monitoring and control systems now allow for dynamic adjustment of flow rates and temperatures, optimizing performance based on changing process conditions. This has led to the concept of "smart" heat exchangers, capable of self-diagnosis and predictive maintenance.

Looking forward, the evolution of multi-pass plate heat exchanger systems is likely to continue along the paths of increased efficiency, compactness, and adaptability. Research into novel materials, such as graphene-based composites, promises to push the boundaries of heat transfer capabilities even further. The ongoing development of multi-pass plate heat exchangers reflects the broader trend in industrial equipment towards more intelligent, efficient, and sustainable solutions.

Market Demand Analysis

The market demand for multi-pass plate heat exchanger systems has been steadily growing across various industries due to their superior efficiency and compact design. These systems are particularly sought after in sectors such as chemical processing, food and beverage, pharmaceuticals, and HVAC applications. The global plate heat exchanger market, which includes multi-pass systems, is projected to experience significant growth in the coming years.

One of the primary drivers for this increased demand is the growing emphasis on energy efficiency and sustainability in industrial processes. Multi-pass plate heat exchangers offer higher heat transfer rates and lower energy consumption compared to traditional shell-and-tube heat exchangers, making them an attractive option for companies looking to reduce their carbon footprint and operational costs.

In the chemical processing industry, there is a rising demand for multi-pass plate heat exchangers due to their ability to handle corrosive fluids and operate under high-pressure conditions. The food and beverage sector is another key market, where these systems are valued for their hygienic design and ease of cleaning, crucial factors in maintaining product quality and safety standards.

The pharmaceutical industry is also contributing to the market growth, as multi-pass plate heat exchangers are essential in temperature-sensitive processes such as fermentation and sterilization. Their ability to provide precise temperature control and maintain product integrity is highly valued in this sector.

HVAC applications represent another significant market segment, with multi-pass plate heat exchangers being increasingly adopted in large-scale cooling and heating systems for commercial and industrial buildings. The trend towards energy-efficient and environmentally friendly building designs is driving the demand for these systems in the construction industry.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in the multi-pass plate heat exchanger market. This is primarily due to rapid industrialization, increasing investments in manufacturing sectors, and stringent energy efficiency regulations in countries like China and India.

The market is also seeing a shift towards customized solutions, with end-users demanding heat exchanger systems tailored to their specific process requirements. This trend is creating opportunities for manufacturers to differentiate their offerings and capture higher market share.

However, the market faces challenges such as high initial costs and the need for skilled personnel for installation and maintenance. Despite these obstacles, the long-term benefits of energy savings and improved process efficiency continue to drive the adoption of multi-pass plate heat exchanger systems across industries.

One of the primary drivers for this increased demand is the growing emphasis on energy efficiency and sustainability in industrial processes. Multi-pass plate heat exchangers offer higher heat transfer rates and lower energy consumption compared to traditional shell-and-tube heat exchangers, making them an attractive option for companies looking to reduce their carbon footprint and operational costs.

In the chemical processing industry, there is a rising demand for multi-pass plate heat exchangers due to their ability to handle corrosive fluids and operate under high-pressure conditions. The food and beverage sector is another key market, where these systems are valued for their hygienic design and ease of cleaning, crucial factors in maintaining product quality and safety standards.

The pharmaceutical industry is also contributing to the market growth, as multi-pass plate heat exchangers are essential in temperature-sensitive processes such as fermentation and sterilization. Their ability to provide precise temperature control and maintain product integrity is highly valued in this sector.

HVAC applications represent another significant market segment, with multi-pass plate heat exchangers being increasingly adopted in large-scale cooling and heating systems for commercial and industrial buildings. The trend towards energy-efficient and environmentally friendly building designs is driving the demand for these systems in the construction industry.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in the multi-pass plate heat exchanger market. This is primarily due to rapid industrialization, increasing investments in manufacturing sectors, and stringent energy efficiency regulations in countries like China and India.

The market is also seeing a shift towards customized solutions, with end-users demanding heat exchanger systems tailored to their specific process requirements. This trend is creating opportunities for manufacturers to differentiate their offerings and capture higher market share.

However, the market faces challenges such as high initial costs and the need for skilled personnel for installation and maintenance. Despite these obstacles, the long-term benefits of energy savings and improved process efficiency continue to drive the adoption of multi-pass plate heat exchanger systems across industries.

Technical Challenges

Multi-pass plate heat exchanger systems, while highly efficient, face several technical challenges that require innovative solutions. One of the primary issues is the complexity of flow distribution within the exchanger. Achieving uniform flow across all plates is crucial for optimal heat transfer, yet it becomes increasingly difficult as the number of passes increases. This non-uniform flow can lead to reduced thermal performance and increased pressure drop.

Another significant challenge lies in the design of plate corrugations. While these enhance heat transfer by promoting turbulence, they also increase pressure drop. Striking the right balance between heat transfer enhancement and acceptable pressure loss remains a key area of research. Moreover, the intricate geometry of corrugated plates complicates manufacturing processes, potentially increasing production costs and limiting design flexibility.

Fouling and scaling present ongoing challenges in multi-pass plate heat exchangers. The narrow channels between plates are particularly susceptible to blockage from deposits, which can severely impact heat transfer efficiency and increase maintenance requirements. Developing effective fouling mitigation strategies, such as improved plate designs or advanced cleaning techniques, is crucial for long-term performance.

Thermal stress and fatigue are also significant concerns, especially in applications with frequent temperature fluctuations. The thin plates used in these systems are vulnerable to deformation and cracking under thermal cycling, potentially leading to leaks and system failure. Enhancing material selection and improving plate design to better distribute thermal stresses are active areas of research.

Sealing technology presents another challenge, particularly for high-pressure or corrosive applications. Ensuring leak-free operation while maintaining the ability to disassemble the exchanger for maintenance requires advanced gasket materials and designs. The development of reliable, long-lasting seals that can withstand a wide range of operating conditions remains a priority.

Computational modeling and simulation of multi-pass plate heat exchangers pose significant challenges due to the complex geometry and flow patterns. Accurate prediction of heat transfer and fluid dynamics within these systems requires sophisticated numerical methods and substantial computational resources. Improving simulation techniques to better inform design decisions is an ongoing area of development in the field.

Another significant challenge lies in the design of plate corrugations. While these enhance heat transfer by promoting turbulence, they also increase pressure drop. Striking the right balance between heat transfer enhancement and acceptable pressure loss remains a key area of research. Moreover, the intricate geometry of corrugated plates complicates manufacturing processes, potentially increasing production costs and limiting design flexibility.

Fouling and scaling present ongoing challenges in multi-pass plate heat exchangers. The narrow channels between plates are particularly susceptible to blockage from deposits, which can severely impact heat transfer efficiency and increase maintenance requirements. Developing effective fouling mitigation strategies, such as improved plate designs or advanced cleaning techniques, is crucial for long-term performance.

Thermal stress and fatigue are also significant concerns, especially in applications with frequent temperature fluctuations. The thin plates used in these systems are vulnerable to deformation and cracking under thermal cycling, potentially leading to leaks and system failure. Enhancing material selection and improving plate design to better distribute thermal stresses are active areas of research.

Sealing technology presents another challenge, particularly for high-pressure or corrosive applications. Ensuring leak-free operation while maintaining the ability to disassemble the exchanger for maintenance requires advanced gasket materials and designs. The development of reliable, long-lasting seals that can withstand a wide range of operating conditions remains a priority.

Computational modeling and simulation of multi-pass plate heat exchangers pose significant challenges due to the complex geometry and flow patterns. Accurate prediction of heat transfer and fluid dynamics within these systems requires sophisticated numerical methods and substantial computational resources. Improving simulation techniques to better inform design decisions is an ongoing area of development in the field.

Current Design Solutions

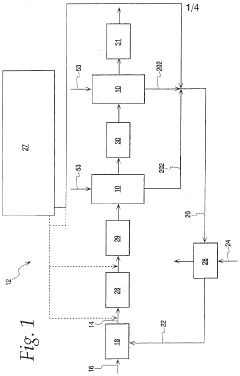

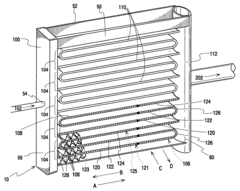

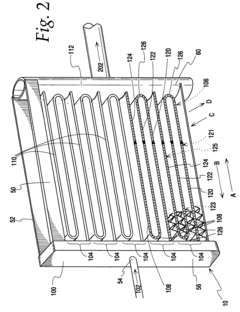

01 Multi-pass plate heat exchanger design

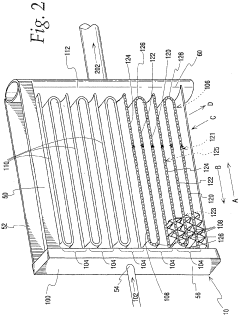

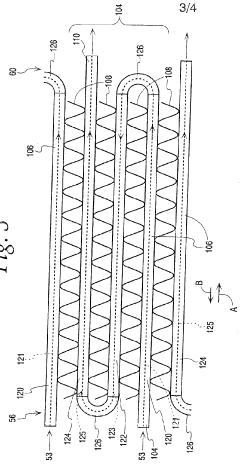

Multi-pass plate heat exchangers are designed to improve heat transfer efficiency by allowing fluids to pass through multiple channels. This design increases the contact time between fluids and the heat transfer surface, resulting in better thermal performance. The arrangement of plates and flow paths can be optimized to suit specific applications and fluid properties.- Design and configuration of multi-pass plate heat exchangers: Multi-pass plate heat exchangers are designed with multiple flow paths for improved heat transfer efficiency. The configuration typically includes a series of parallel plates with channels for fluid flow, allowing for multiple passes of hot and cold fluids. This design enhances heat transfer by increasing the contact time between fluids and the heat transfer surface area.

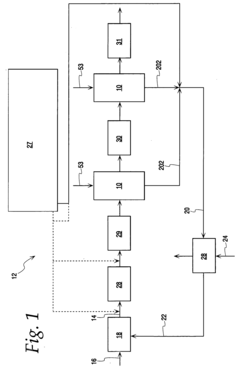

- Flow distribution and control in multi-pass systems: Effective flow distribution and control are crucial in multi-pass plate heat exchanger systems. This involves the use of specialized manifolds, baffles, and flow distributors to ensure uniform fluid distribution across the plates. Advanced control systems may be implemented to optimize flow rates and temperatures for maximum heat transfer efficiency.

- Materials and construction for enhanced performance: The choice of materials and construction techniques plays a significant role in the performance of multi-pass plate heat exchangers. High thermal conductivity materials, corrosion-resistant alloys, and specialized surface treatments are used to improve heat transfer and durability. Advanced manufacturing methods may be employed to create complex plate geometries for improved efficiency.

- Integration of multi-pass systems in industrial applications: Multi-pass plate heat exchanger systems are integrated into various industrial processes for efficient heat recovery and energy management. These systems are adapted for specific applications such as HVAC, chemical processing, and power generation. The integration often involves customized designs to meet the unique requirements of each industrial setting.

- Maintenance and performance optimization: Maintaining and optimizing the performance of multi-pass plate heat exchanger systems is essential for long-term efficiency. This includes regular cleaning to prevent fouling, monitoring of pressure drops and heat transfer rates, and periodic replacement of gaskets or plates. Advanced monitoring systems and predictive maintenance techniques may be employed to ensure optimal operation.

02 Flow distribution and control in multi-pass systems

Effective flow distribution and control are crucial in multi-pass plate heat exchanger systems. This involves the use of specialized manifolds, baffles, and flow guides to ensure uniform fluid distribution across the plates. Advanced control systems can be implemented to regulate flow rates and temperatures, optimizing heat transfer and preventing issues such as fouling or uneven thermal stress.Expand Specific Solutions03 Enhanced heat transfer surfaces

Multi-pass plate heat exchangers often incorporate enhanced heat transfer surfaces to improve efficiency. These can include corrugated plates, dimpled surfaces, or other geometrical modifications that increase turbulence and heat transfer area. Such enhancements can significantly boost the overall performance of the heat exchanger while maintaining a compact design.Expand Specific Solutions04 Modular and scalable configurations

Many multi-pass plate heat exchanger systems are designed to be modular and scalable. This allows for easy customization to meet specific capacity requirements and facilitates future expansion or modification. Modular designs also simplify maintenance and cleaning procedures, as individual sections can be isolated or replaced without affecting the entire system.Expand Specific Solutions05 Integration with energy recovery systems

Multi-pass plate heat exchangers can be effectively integrated with energy recovery systems to maximize overall efficiency. This may involve coupling with heat pumps, waste heat recovery units, or renewable energy sources. Such integrations can significantly reduce energy consumption and operating costs in industrial processes or HVAC applications.Expand Specific Solutions

Key Industry Players

The multi-pass plate heat exchanger systems market is in a mature stage, with established players and proven technology. The global market size is estimated to be in the billions of dollars, driven by increasing demand for energy-efficient heat transfer solutions across industries. Technologically, the field is well-developed but continues to evolve, with companies like Alfa Laval, Danfoss, and Vahterus leading innovation. These firms, along with others such as Mitsubishi Electric and Air Liquide, are focusing on enhancing efficiency, compactness, and sustainability of heat exchanger designs. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, with ongoing research and development efforts aimed at improving performance and expanding applications in various sectors.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval's multi-pass plate heat exchanger systems utilize advanced corrugated plate designs to enhance heat transfer efficiency. Their technology incorporates asymmetric plate patterns that create turbulent flow, maximizing heat transfer while minimizing fouling[1]. The company's AlfaNova fusion-bonded plate heat exchangers offer high thermal efficiency and compact design, suitable for high-temperature and high-pressure applications[2]. Alfa Laval's systems often feature a modular design, allowing for easy scalability and maintenance. They have also developed specialized plate geometries for different fluid viscosities and flow rates, optimizing performance across various industries[3].

Strengths: High thermal efficiency, compact design, scalability, and adaptability to various industrial applications. Weaknesses: Higher initial cost compared to traditional shell-and-tube exchangers, potential for leakage in gasket-sealed models.

Vahterus Oy

Technical Solution: Vahterus specializes in Plate & Shell Heat Exchanger (PSHE) technology, which combines the benefits of plate and shell-and-tube heat exchangers. Their multi-pass systems feature a fully welded plate pack enclosed within a pressure vessel, allowing for high-pressure and high-temperature applications[1]. The company's patented circular plate design creates a cross-flow configuration, enhancing heat transfer efficiency while reducing the risk of fouling[2]. Vahterus' systems often incorporate multiple passes on both the plate and shell sides, enabling precise temperature control and optimized heat recovery. Their technology is particularly well-suited for phase-change applications and processes involving challenging fluids[3].

Strengths: High pressure and temperature tolerance, excellent fouling resistance, compact design. Weaknesses: Limited flexibility for expansion once installed, potentially higher manufacturing costs due to welded construction.

Core Innovations Review

Multi-pass heat exchanger

PatentWO2005100894A1

Innovation

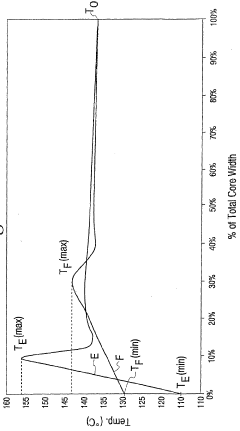

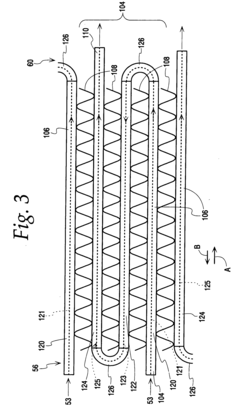

- A multi-pass heat exchanger design with aligned and spaced tube run groups and serpentine fins, where each tube run group consists of three tube runs arranged in a serpentine configuration, allowing for a more uniform temperature distribution by flowing the coolant through multiple passes, thereby optimizing the temperature control of the reformate flow.

Multi-pass heat exchanger

PatentInactiveUS20050217834A1

Innovation

- A multi-pass heat exchanger design with aligned and spaced tube run groups and serpentine fins is used, allowing for a more uniform temperature distribution by directing the coolant flow through multiple passes and maintaining partial vaporization to enhance heat transfer and reduce temperature variance.

Efficiency Optimization

Efficiency optimization in multi-pass plate heat exchanger systems is a critical aspect of their design and operation. These systems are widely used in various industries due to their compact size, high heat transfer rates, and flexibility. However, maximizing their efficiency requires careful consideration of several factors and the implementation of advanced techniques.

One key approach to optimizing efficiency is through the enhancement of heat transfer coefficients. This can be achieved by modifying the plate geometry, such as incorporating corrugated patterns or chevron designs. These modifications increase turbulence and promote better fluid mixing, leading to improved heat transfer rates. Additionally, the use of nanofluids as heat transfer media has shown promising results in recent studies, offering higher thermal conductivity compared to conventional fluids.

Flow distribution is another crucial factor in efficiency optimization. Uneven flow distribution can lead to reduced heat transfer performance and increased pressure drop. To address this, designers are implementing advanced flow distribution systems, including the use of flow distributors and optimized header designs. Computational Fluid Dynamics (CFD) simulations play a vital role in analyzing and improving flow patterns within the exchanger.

Fouling mitigation is essential for maintaining long-term efficiency. Fouling can significantly reduce heat transfer rates and increase pressure drop over time. Innovative surface coatings and materials that resist fouling are being developed and implemented. Furthermore, the integration of online cleaning systems and the optimization of cleaning schedules can help maintain peak performance.

The arrangement of passes in multi-pass systems also impacts overall efficiency. Optimizing the number of passes and their configuration can lead to improved heat transfer while minimizing pressure drop. This often involves a trade-off between heat transfer enhancement and pumping power requirements. Advanced optimization algorithms and machine learning techniques are being employed to determine the ideal pass arrangements for specific applications.

Energy recovery and integration strategies are increasingly being incorporated into multi-pass plate heat exchanger systems. This includes the use of heat pumps to upgrade low-grade heat and the integration of these systems with renewable energy sources. Such approaches not only improve the overall system efficiency but also contribute to sustainability goals.

Lastly, the implementation of smart monitoring and control systems is revolutionizing efficiency optimization. Real-time monitoring of key parameters, predictive maintenance algorithms, and adaptive control strategies enable dynamic optimization of system performance. These technologies allow for continuous adjustment of operating conditions to maintain optimal efficiency across varying load conditions and environmental factors.

One key approach to optimizing efficiency is through the enhancement of heat transfer coefficients. This can be achieved by modifying the plate geometry, such as incorporating corrugated patterns or chevron designs. These modifications increase turbulence and promote better fluid mixing, leading to improved heat transfer rates. Additionally, the use of nanofluids as heat transfer media has shown promising results in recent studies, offering higher thermal conductivity compared to conventional fluids.

Flow distribution is another crucial factor in efficiency optimization. Uneven flow distribution can lead to reduced heat transfer performance and increased pressure drop. To address this, designers are implementing advanced flow distribution systems, including the use of flow distributors and optimized header designs. Computational Fluid Dynamics (CFD) simulations play a vital role in analyzing and improving flow patterns within the exchanger.

Fouling mitigation is essential for maintaining long-term efficiency. Fouling can significantly reduce heat transfer rates and increase pressure drop over time. Innovative surface coatings and materials that resist fouling are being developed and implemented. Furthermore, the integration of online cleaning systems and the optimization of cleaning schedules can help maintain peak performance.

The arrangement of passes in multi-pass systems also impacts overall efficiency. Optimizing the number of passes and their configuration can lead to improved heat transfer while minimizing pressure drop. This often involves a trade-off between heat transfer enhancement and pumping power requirements. Advanced optimization algorithms and machine learning techniques are being employed to determine the ideal pass arrangements for specific applications.

Energy recovery and integration strategies are increasingly being incorporated into multi-pass plate heat exchanger systems. This includes the use of heat pumps to upgrade low-grade heat and the integration of these systems with renewable energy sources. Such approaches not only improve the overall system efficiency but also contribute to sustainability goals.

Lastly, the implementation of smart monitoring and control systems is revolutionizing efficiency optimization. Real-time monitoring of key parameters, predictive maintenance algorithms, and adaptive control strategies enable dynamic optimization of system performance. These technologies allow for continuous adjustment of operating conditions to maintain optimal efficiency across varying load conditions and environmental factors.

Material Advancements

Material advancements play a crucial role in enhancing the performance and efficiency of multi-pass plate heat exchanger systems. Recent developments in material science have led to significant improvements in heat transfer capabilities, corrosion resistance, and overall system durability.

One of the most notable advancements is the use of high-performance polymers in plate construction. These materials offer excellent thermal conductivity while maintaining low weight and high resistance to chemical corrosion. Polymers such as polyether ether ketone (PEEK) and polyphenylene sulfide (PPS) have shown promising results in experimental setups, demonstrating improved heat transfer rates compared to traditional metallic plates.

Nanocomposite materials have also emerged as a potential game-changer in plate heat exchanger design. By incorporating nanoparticles into the base material, researchers have achieved enhanced thermal conductivity and improved mechanical properties. For instance, carbon nanotube-reinforced aluminum composites have shown a significant increase in heat transfer efficiency while maintaining the lightweight characteristics of aluminum.

Surface modification techniques have been developed to further optimize heat transfer performance. Advanced coatings, such as hydrophobic or hydrophilic nanocoatings, can be applied to plate surfaces to manipulate fluid flow and reduce fouling. These coatings not only improve heat transfer rates but also extend the operational life of the heat exchanger by minimizing maintenance requirements.

In the realm of metallic materials, high-entropy alloys (HEAs) have gained attention for their exceptional properties. These alloys, composed of five or more principal elements in near-equiatomic ratios, exhibit superior mechanical strength, corrosion resistance, and thermal stability compared to conventional alloys. HEAs show promise for use in extreme operating conditions, potentially expanding the application range of multi-pass plate heat exchangers.

Additive manufacturing techniques have opened up new possibilities for plate design and material selection. 3D printing allows for the creation of complex geometries and internal structures that were previously impossible to manufacture. This technology enables the use of novel materials and composite structures, potentially revolutionizing heat exchanger design and performance.

Biomimetic materials inspired by natural heat transfer systems are also being explored. For example, materials mimicking the structure of shark skin or lotus leaves have shown potential for enhancing fluid flow and reducing fouling in heat exchanger plates. These bio-inspired designs could lead to more efficient and self-cleaning heat exchanger systems in the future.

One of the most notable advancements is the use of high-performance polymers in plate construction. These materials offer excellent thermal conductivity while maintaining low weight and high resistance to chemical corrosion. Polymers such as polyether ether ketone (PEEK) and polyphenylene sulfide (PPS) have shown promising results in experimental setups, demonstrating improved heat transfer rates compared to traditional metallic plates.

Nanocomposite materials have also emerged as a potential game-changer in plate heat exchanger design. By incorporating nanoparticles into the base material, researchers have achieved enhanced thermal conductivity and improved mechanical properties. For instance, carbon nanotube-reinforced aluminum composites have shown a significant increase in heat transfer efficiency while maintaining the lightweight characteristics of aluminum.

Surface modification techniques have been developed to further optimize heat transfer performance. Advanced coatings, such as hydrophobic or hydrophilic nanocoatings, can be applied to plate surfaces to manipulate fluid flow and reduce fouling. These coatings not only improve heat transfer rates but also extend the operational life of the heat exchanger by minimizing maintenance requirements.

In the realm of metallic materials, high-entropy alloys (HEAs) have gained attention for their exceptional properties. These alloys, composed of five or more principal elements in near-equiatomic ratios, exhibit superior mechanical strength, corrosion resistance, and thermal stability compared to conventional alloys. HEAs show promise for use in extreme operating conditions, potentially expanding the application range of multi-pass plate heat exchangers.

Additive manufacturing techniques have opened up new possibilities for plate design and material selection. 3D printing allows for the creation of complex geometries and internal structures that were previously impossible to manufacture. This technology enables the use of novel materials and composite structures, potentially revolutionizing heat exchanger design and performance.

Biomimetic materials inspired by natural heat transfer systems are also being explored. For example, materials mimicking the structure of shark skin or lotus leaves have shown potential for enhancing fluid flow and reducing fouling in heat exchanger plates. These bio-inspired designs could lead to more efficient and self-cleaning heat exchanger systems in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!