How Does Plate Arrangement Affect Heat Exchanger Efficiency?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Evolution

Heat exchangers have undergone significant evolution since their inception, driven by the need for improved efficiency and performance across various industries. The earliest forms of heat exchangers can be traced back to the 19th century, with the development of shell-and-tube designs for steam engines and industrial processes. These initial designs, while functional, were often bulky and limited in their heat transfer capabilities.

As industrial demands grew, so did the need for more efficient heat exchange solutions. The mid-20th century saw the introduction of plate heat exchangers, which marked a significant leap forward in heat transfer technology. These compact units offered greater surface area for heat exchange and improved thermal efficiency compared to their shell-and-tube counterparts. The ability to easily disassemble and clean plate heat exchangers also made them popular in industries with stringent hygiene requirements, such as food and beverage processing.

The late 20th century brought about further advancements in plate design and materials. The introduction of corrugated plates and chevron patterns significantly enhanced turbulence and heat transfer rates. This period also saw the development of gasket-free, fully welded plate heat exchangers, which expanded their application into high-pressure and high-temperature environments.

In recent decades, the focus has shifted towards optimizing plate arrangements to maximize heat exchanger efficiency. Researchers and engineers have explored various configurations, including multi-pass arrangements, mixed series-parallel flow patterns, and asymmetric plate designs. These innovations have led to substantial improvements in heat transfer coefficients and overall system performance.

The advent of computational fluid dynamics (CFD) and advanced modeling techniques has revolutionized the design process of heat exchangers. These tools allow for precise simulation of fluid flow and heat transfer within complex plate geometries, enabling engineers to fine-tune plate arrangements for specific applications. This has resulted in highly optimized designs that push the boundaries of heat exchanger efficiency.

Today, the evolution of heat exchangers continues with a focus on sustainability and energy efficiency. Researchers are exploring novel materials, such as graphene and advanced polymers, to create ultra-thin, highly conductive plates. Additionally, the integration of smart technologies and IoT sensors is paving the way for self-regulating, adaptive heat exchanger systems that can optimize their performance in real-time based on changing operating conditions.

As industrial demands grew, so did the need for more efficient heat exchange solutions. The mid-20th century saw the introduction of plate heat exchangers, which marked a significant leap forward in heat transfer technology. These compact units offered greater surface area for heat exchange and improved thermal efficiency compared to their shell-and-tube counterparts. The ability to easily disassemble and clean plate heat exchangers also made them popular in industries with stringent hygiene requirements, such as food and beverage processing.

The late 20th century brought about further advancements in plate design and materials. The introduction of corrugated plates and chevron patterns significantly enhanced turbulence and heat transfer rates. This period also saw the development of gasket-free, fully welded plate heat exchangers, which expanded their application into high-pressure and high-temperature environments.

In recent decades, the focus has shifted towards optimizing plate arrangements to maximize heat exchanger efficiency. Researchers and engineers have explored various configurations, including multi-pass arrangements, mixed series-parallel flow patterns, and asymmetric plate designs. These innovations have led to substantial improvements in heat transfer coefficients and overall system performance.

The advent of computational fluid dynamics (CFD) and advanced modeling techniques has revolutionized the design process of heat exchangers. These tools allow for precise simulation of fluid flow and heat transfer within complex plate geometries, enabling engineers to fine-tune plate arrangements for specific applications. This has resulted in highly optimized designs that push the boundaries of heat exchanger efficiency.

Today, the evolution of heat exchangers continues with a focus on sustainability and energy efficiency. Researchers are exploring novel materials, such as graphene and advanced polymers, to create ultra-thin, highly conductive plates. Additionally, the integration of smart technologies and IoT sensors is paving the way for self-regulating, adaptive heat exchanger systems that can optimize their performance in real-time based on changing operating conditions.

Market Demand Analysis

The market demand for efficient heat exchangers has been steadily increasing across various industries, driven by the growing emphasis on energy conservation and sustainable practices. As businesses and industries strive to optimize their processes and reduce operational costs, the efficiency of heat exchangers has become a critical factor in their decision-making process.

In the industrial sector, particularly in chemical processing, oil and gas, and power generation, there is a significant demand for heat exchangers with improved plate arrangements. These industries require heat transfer solutions that can handle high temperatures and pressures while maintaining optimal efficiency. The ability to customize plate arrangements to specific process requirements has become a key selling point for heat exchanger manufacturers.

The food and beverage industry has also shown increased interest in advanced heat exchanger designs. With stringent hygiene standards and the need for precise temperature control, plate heat exchangers with efficient arrangements are in high demand. The dairy, brewing, and pharmaceutical sectors, in particular, require heat exchangers that can maintain product quality while maximizing energy efficiency.

In the HVAC sector, the push for energy-efficient buildings has led to a growing market for plate heat exchangers with optimized arrangements. As building codes become more stringent and energy costs continue to rise, property developers and facility managers are increasingly seeking heat exchange solutions that can provide superior performance with minimal energy consumption.

The automotive industry represents another significant market for efficient heat exchangers. With the rise of electric vehicles and the continuous improvement of internal combustion engines, there is a growing need for compact, lightweight heat exchangers that can effectively manage thermal loads. Plate arrangements that enhance cooling efficiency while reducing the overall size and weight of the heat exchanger are highly sought after in this sector.

Emerging markets, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization and urbanization, leading to increased demand for efficient heat transfer solutions. These regions present significant growth opportunities for heat exchanger manufacturers who can offer innovative plate arrangements that improve efficiency and reduce operational costs.

The global focus on reducing carbon emissions and meeting climate change targets has further amplified the demand for high-efficiency heat exchangers. Governments and regulatory bodies worldwide are implementing stricter energy efficiency standards, creating a favorable market environment for advanced heat exchanger technologies. This regulatory push is expected to drive continued innovation in plate arrangement designs to meet and exceed these evolving standards.

In the industrial sector, particularly in chemical processing, oil and gas, and power generation, there is a significant demand for heat exchangers with improved plate arrangements. These industries require heat transfer solutions that can handle high temperatures and pressures while maintaining optimal efficiency. The ability to customize plate arrangements to specific process requirements has become a key selling point for heat exchanger manufacturers.

The food and beverage industry has also shown increased interest in advanced heat exchanger designs. With stringent hygiene standards and the need for precise temperature control, plate heat exchangers with efficient arrangements are in high demand. The dairy, brewing, and pharmaceutical sectors, in particular, require heat exchangers that can maintain product quality while maximizing energy efficiency.

In the HVAC sector, the push for energy-efficient buildings has led to a growing market for plate heat exchangers with optimized arrangements. As building codes become more stringent and energy costs continue to rise, property developers and facility managers are increasingly seeking heat exchange solutions that can provide superior performance with minimal energy consumption.

The automotive industry represents another significant market for efficient heat exchangers. With the rise of electric vehicles and the continuous improvement of internal combustion engines, there is a growing need for compact, lightweight heat exchangers that can effectively manage thermal loads. Plate arrangements that enhance cooling efficiency while reducing the overall size and weight of the heat exchanger are highly sought after in this sector.

Emerging markets, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization and urbanization, leading to increased demand for efficient heat transfer solutions. These regions present significant growth opportunities for heat exchanger manufacturers who can offer innovative plate arrangements that improve efficiency and reduce operational costs.

The global focus on reducing carbon emissions and meeting climate change targets has further amplified the demand for high-efficiency heat exchangers. Governments and regulatory bodies worldwide are implementing stricter energy efficiency standards, creating a favorable market environment for advanced heat exchanger technologies. This regulatory push is expected to drive continued innovation in plate arrangement designs to meet and exceed these evolving standards.

Plate Arrangement Challenges

The arrangement of plates in heat exchangers presents several significant challenges that directly impact efficiency and performance. One of the primary issues is the optimization of flow distribution across the plates. Uneven flow can lead to reduced heat transfer rates and increased pressure drop, diminishing overall exchanger efficiency. Engineers must carefully consider plate geometry, spacing, and flow channel design to ensure uniform fluid distribution and minimize dead zones or areas of stagnation.

Another critical challenge lies in managing thermal stress and mechanical integrity. As heat exchangers operate under varying temperature gradients, thermal expansion and contraction can cause warping or deformation of plates. This not only affects the structural integrity of the exchanger but can also lead to leaks or reduced heat transfer efficiency. Designers must account for these thermal stresses when selecting materials and determining plate thickness and support structures.

Fouling and scaling present ongoing challenges in plate arrangement design. The accumulation of deposits on plate surfaces can significantly reduce heat transfer efficiency and increase pressure drop. While certain plate arrangements can help mitigate fouling by promoting turbulent flow, they may also increase pumping power requirements. Striking the right balance between fouling resistance and energy efficiency is a complex optimization problem that varies depending on the specific application and fluids involved.

Maintenance and cleaning accessibility is another crucial consideration in plate arrangement. The ability to disassemble and clean individual plates is essential for maintaining long-term performance, especially in applications prone to fouling. However, designs that facilitate easy maintenance may compromise on compactness or thermal efficiency. Engineers must weigh these trade-offs carefully, considering factors such as expected maintenance frequency and operational downtime costs.

The challenge of maximizing heat transfer area while minimizing overall exchanger size is ever-present in plate arrangement design. Compact designs are often desirable for space-constrained applications, but they can lead to increased pressure drop and reduced flow uniformity. Advanced plate patterns and corrugations can help increase surface area and turbulence, but they also introduce manufacturing complexities and potential cost increases.

Lastly, the selection of appropriate gasket materials and sealing methods poses a significant challenge in plate heat exchanger design. Gaskets must withstand operating temperatures and pressures while maintaining a tight seal to prevent leakage between fluid streams. The arrangement of plates directly affects gasket compression and sealing effectiveness, requiring careful consideration of plate edge design and clamping mechanisms.

Another critical challenge lies in managing thermal stress and mechanical integrity. As heat exchangers operate under varying temperature gradients, thermal expansion and contraction can cause warping or deformation of plates. This not only affects the structural integrity of the exchanger but can also lead to leaks or reduced heat transfer efficiency. Designers must account for these thermal stresses when selecting materials and determining plate thickness and support structures.

Fouling and scaling present ongoing challenges in plate arrangement design. The accumulation of deposits on plate surfaces can significantly reduce heat transfer efficiency and increase pressure drop. While certain plate arrangements can help mitigate fouling by promoting turbulent flow, they may also increase pumping power requirements. Striking the right balance between fouling resistance and energy efficiency is a complex optimization problem that varies depending on the specific application and fluids involved.

Maintenance and cleaning accessibility is another crucial consideration in plate arrangement. The ability to disassemble and clean individual plates is essential for maintaining long-term performance, especially in applications prone to fouling. However, designs that facilitate easy maintenance may compromise on compactness or thermal efficiency. Engineers must weigh these trade-offs carefully, considering factors such as expected maintenance frequency and operational downtime costs.

The challenge of maximizing heat transfer area while minimizing overall exchanger size is ever-present in plate arrangement design. Compact designs are often desirable for space-constrained applications, but they can lead to increased pressure drop and reduced flow uniformity. Advanced plate patterns and corrugations can help increase surface area and turbulence, but they also introduce manufacturing complexities and potential cost increases.

Lastly, the selection of appropriate gasket materials and sealing methods poses a significant challenge in plate heat exchanger design. Gaskets must withstand operating temperatures and pressures while maintaining a tight seal to prevent leakage between fluid streams. The arrangement of plates directly affects gasket compression and sealing effectiveness, requiring careful consideration of plate edge design and clamping mechanisms.

Current Plate Designs

01 Design optimization for improved heat transfer

Enhancing heat exchanger efficiency through optimized design features such as improved flow patterns, increased surface area, and better material selection. This includes modifications to tube arrangements, fin designs, and overall geometry to maximize heat transfer while minimizing pressure drop.- Design optimization for improved heat transfer: Enhancing heat exchanger efficiency through optimized design features such as improved flow patterns, increased surface area, and better material selection. This includes modifications to tube arrangements, fin designs, and overall geometry to maximize heat transfer while minimizing pressure drop.

- Advanced heat transfer fluids and coatings: Utilizing innovative heat transfer fluids or applying specialized coatings to heat exchanger surfaces to enhance thermal conductivity and reduce fouling. This approach can significantly improve overall efficiency by facilitating better heat transfer and maintaining performance over time.

- Smart control systems and monitoring: Implementing intelligent control systems and real-time monitoring technologies to optimize heat exchanger operation. This includes adaptive control algorithms, predictive maintenance, and performance analytics to ensure the heat exchanger operates at peak efficiency under varying conditions.

- Modular and scalable designs: Developing modular and scalable heat exchanger designs that can be easily adapted to different applications and capacity requirements. This approach allows for more efficient customization and optimization of heat exchangers for specific operational needs.

- Energy recovery and integration systems: Incorporating energy recovery and integration systems to maximize overall system efficiency. This includes techniques such as waste heat recovery, cascading heat utilization, and integration with other processes to minimize energy losses and improve overall thermal efficiency.

02 Advanced materials and coatings

Utilizing advanced materials and coatings to improve thermal conductivity and reduce fouling. This involves the application of high-performance materials or surface treatments that enhance heat transfer properties, resist corrosion, and minimize scaling or deposit formation on heat exchange surfaces.Expand Specific Solutions03 Smart control systems and monitoring

Implementing intelligent control systems and real-time monitoring to optimize heat exchanger performance. This includes the use of sensors, data analytics, and adaptive control algorithms to adjust operating parameters based on current conditions, ensuring maximum efficiency across varying loads and environments.Expand Specific Solutions04 Enhanced fluid dynamics and turbulence

Improving fluid dynamics within the heat exchanger to enhance turbulence and mixing. This involves the incorporation of turbulence promoters, vortex generators, or other flow-enhancing features to increase heat transfer coefficients and overall efficiency without significantly increasing pressure drop.Expand Specific Solutions05 Hybrid and multi-stage heat exchanger systems

Developing hybrid or multi-stage heat exchanger systems that combine different types of heat exchangers or utilize cascading arrangements. This approach allows for optimized heat transfer across a wider range of temperature differentials and flow rates, improving overall system efficiency.Expand Specific Solutions

Key Industry Players

The heat exchanger efficiency market is in a mature growth phase, with a global market size expected to reach $20 billion by 2025. The technology's maturity is evident from the diverse range of established players across different regions. Companies like Alfa Laval, SWEP International, and Danfoss are leading innovators in plate heat exchanger technology, continuously improving efficiency through advanced plate designs and materials. Asian manufacturers such as Mitsubishi Electric, Daikin Industries, and Sanhua are also making significant contributions, particularly in HVAC applications. The competitive landscape is characterized by a mix of large conglomerates and specialized heat exchanger manufacturers, with ongoing research focused on enhancing heat transfer rates, reducing fouling, and improving overall system performance.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative plate arrangements for their heat exchangers, focusing on optimizing flow distribution and thermal efficiency. Their AlfaNova fusion-bonded plate heat exchangers utilize a unique corrugated plate design that creates turbulent flow, enhancing heat transfer rates[1]. The company has also introduced asymmetrical plate patterns that improve fluid distribution and reduce pressure drop[2]. Their latest designs incorporate advanced computational fluid dynamics (CFD) simulations to optimize plate geometry, resulting in up to 25% higher thermal efficiency compared to conventional designs[3].

Strengths: Superior thermal efficiency, reduced fouling, and compact design. Weaknesses: Higher initial cost and potential complexity in maintenance for some models.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has focused on developing microchannel heat exchangers with innovative plate arrangements. Their approach involves creating multiple small channels within the heat exchanger plates, significantly increasing the surface area for heat transfer. This design has shown to improve heat transfer efficiency by up to 30% compared to traditional tube-and-fin heat exchangers[4]. Daikin has also implemented variable refrigerant flow (VRF) systems that optimize refrigerant distribution across the heat exchanger plates, further enhancing efficiency[5]. Their latest models incorporate AI-driven control systems that dynamically adjust plate arrangements based on real-time operating conditions[6].

Strengths: High efficiency, compact size, and adaptability to varying conditions. Weaknesses: Potentially higher manufacturing costs and increased complexity in repair.

Innovative Arrangement Patents

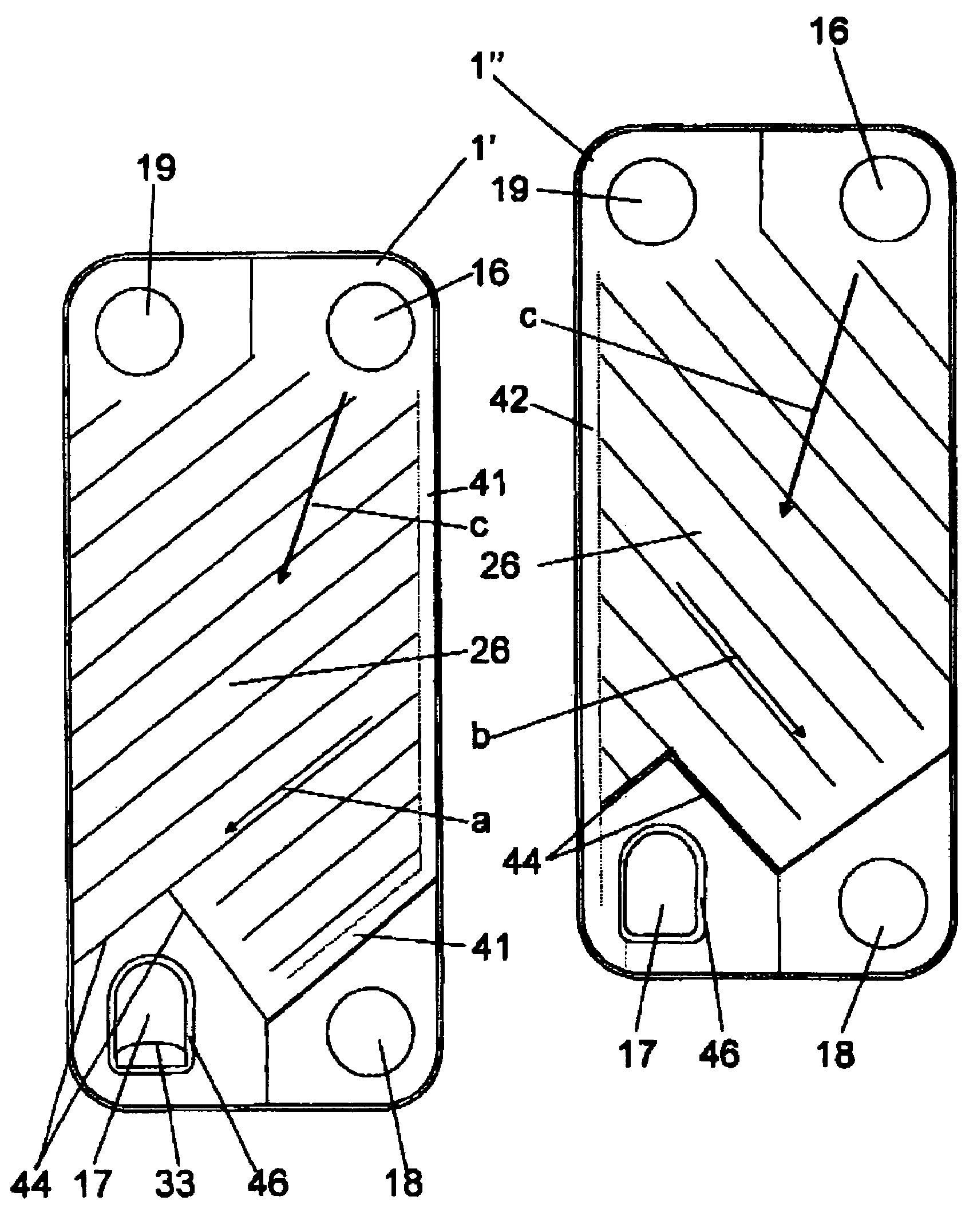

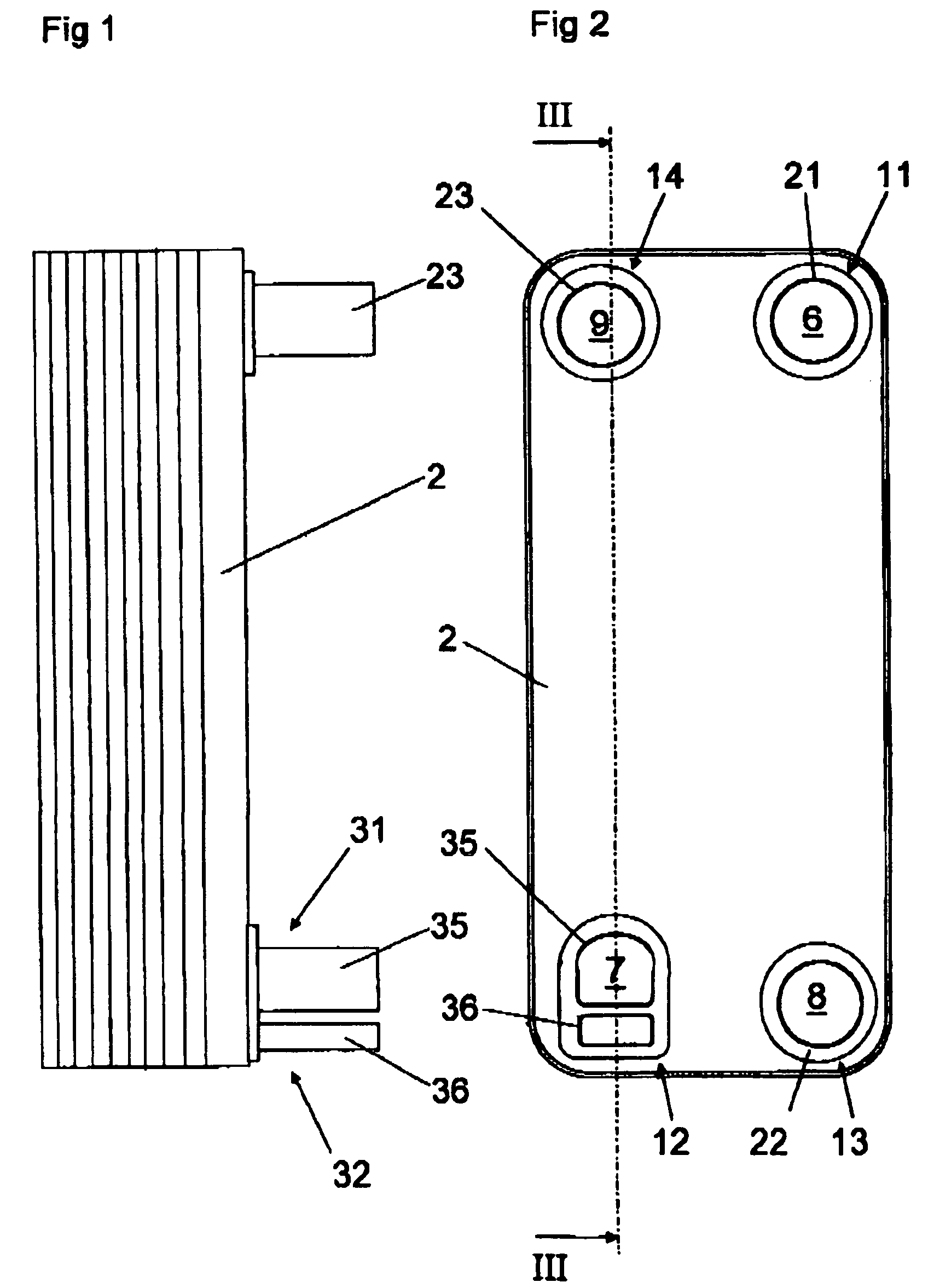

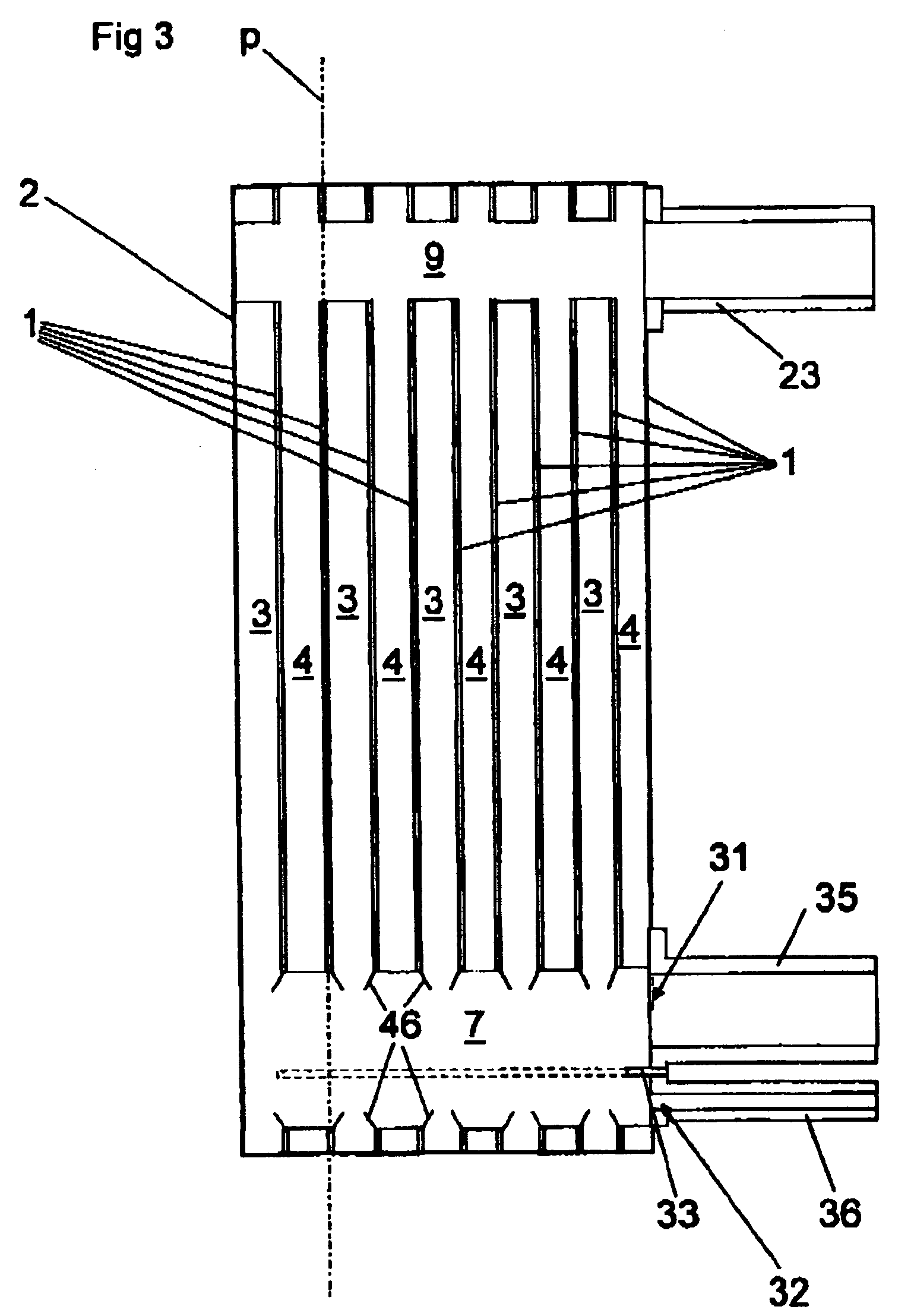

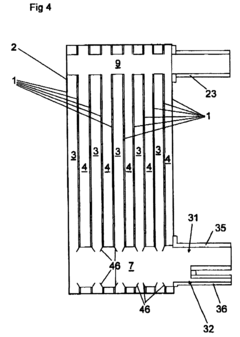

Plate heat exchanger device and a heat exchanger plate

PatentInactiveUS7669643B2

Innovation

- A compact plate heat exchanger design with a single unit that incorporates both cooling and separation functions, featuring a gas outlet and a separate liquid outlet, where the liquid outlet is designed to collect and convey liquid from the heat exchanger plates before it reaches the gas outlet, using corrugations and transversal ridges to redirect flow and prevent remixing.

Plate-type heat exchanger

PatentWO1989008814A1

Innovation

- The design features parallel slotted channels in each section with intermediary manifolds and specific geometric arrangements, allowing for non-uniform fluid distribution and turbulization, which enhances heat exchange efficiency by equalizing temperature and reducing thermal resistance.

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) has emerged as a powerful tool in analyzing and optimizing heat exchanger efficiency, particularly in relation to plate arrangement. This advanced simulation technique allows engineers to model complex fluid flow and heat transfer processes within heat exchangers, providing valuable insights into the impact of various plate configurations on overall system performance.

CFD simulations enable the visualization of fluid flow patterns, temperature distributions, and pressure drops across different plate arrangements. By utilizing numerical methods to solve the governing equations of fluid dynamics and heat transfer, CFD can accurately predict the thermal-hydraulic behavior of heat exchangers under various operating conditions. This capability is especially crucial when investigating the effects of plate geometry, spacing, and orientation on heat transfer rates and pressure losses.

One of the key advantages of CFD in studying plate arrangement is its ability to perform parametric studies efficiently. Engineers can quickly evaluate multiple design iterations, varying factors such as plate spacing, corrugation patterns, and flow channel geometries. This approach significantly reduces the need for costly and time-consuming physical prototyping, accelerating the design optimization process and leading to more efficient heat exchanger configurations.

CFD simulations also provide detailed information on local phenomena within the heat exchanger, such as flow maldistribution, recirculation zones, and areas of high or low heat transfer. This level of detail is often difficult or impossible to obtain through experimental methods alone. By identifying these critical areas, engineers can make informed decisions on plate arrangement modifications to enhance overall heat transfer efficiency and minimize pressure drops.

Furthermore, CFD analysis allows for the investigation of novel plate arrangements and innovative designs that may be challenging to test experimentally. This includes the exploration of asymmetric plate configurations, mixed corrugation patterns, or the integration of turbulence-enhancing features. By leveraging CFD, researchers and engineers can push the boundaries of heat exchanger design, potentially uncovering new approaches to improve efficiency beyond traditional configurations.

As computational power continues to increase, the role of CFD in heat exchanger design and optimization is expected to grow. Advanced modeling techniques, such as conjugate heat transfer analysis and multiphase flow simulations, are becoming more accessible, enabling even more accurate predictions of heat exchanger performance. These developments will further enhance our understanding of how plate arrangement affects heat exchanger efficiency, leading to the design of more compact, energy-efficient, and cost-effective heat transfer solutions across various industries.

CFD simulations enable the visualization of fluid flow patterns, temperature distributions, and pressure drops across different plate arrangements. By utilizing numerical methods to solve the governing equations of fluid dynamics and heat transfer, CFD can accurately predict the thermal-hydraulic behavior of heat exchangers under various operating conditions. This capability is especially crucial when investigating the effects of plate geometry, spacing, and orientation on heat transfer rates and pressure losses.

One of the key advantages of CFD in studying plate arrangement is its ability to perform parametric studies efficiently. Engineers can quickly evaluate multiple design iterations, varying factors such as plate spacing, corrugation patterns, and flow channel geometries. This approach significantly reduces the need for costly and time-consuming physical prototyping, accelerating the design optimization process and leading to more efficient heat exchanger configurations.

CFD simulations also provide detailed information on local phenomena within the heat exchanger, such as flow maldistribution, recirculation zones, and areas of high or low heat transfer. This level of detail is often difficult or impossible to obtain through experimental methods alone. By identifying these critical areas, engineers can make informed decisions on plate arrangement modifications to enhance overall heat transfer efficiency and minimize pressure drops.

Furthermore, CFD analysis allows for the investigation of novel plate arrangements and innovative designs that may be challenging to test experimentally. This includes the exploration of asymmetric plate configurations, mixed corrugation patterns, or the integration of turbulence-enhancing features. By leveraging CFD, researchers and engineers can push the boundaries of heat exchanger design, potentially uncovering new approaches to improve efficiency beyond traditional configurations.

As computational power continues to increase, the role of CFD in heat exchanger design and optimization is expected to grow. Advanced modeling techniques, such as conjugate heat transfer analysis and multiphase flow simulations, are becoming more accessible, enabling even more accurate predictions of heat exchanger performance. These developments will further enhance our understanding of how plate arrangement affects heat exchanger efficiency, leading to the design of more compact, energy-efficient, and cost-effective heat transfer solutions across various industries.

Material Science Advancements

Material science advancements have played a crucial role in enhancing heat exchanger efficiency through innovative plate arrangements. The development of new materials and manufacturing techniques has enabled the creation of more complex and effective plate geometries, significantly improving heat transfer rates and overall system performance.

One of the most significant advancements in this field has been the introduction of advanced composite materials. These materials offer superior thermal conductivity and corrosion resistance compared to traditional metals, allowing for thinner plates and more compact designs. Composite plates can also be engineered to have specific properties tailored to the heat exchanger's operating conditions, such as enhanced resistance to fouling or improved chemical compatibility with process fluids.

Nanotechnology has also made substantial contributions to plate material science. Nanocoatings applied to plate surfaces can dramatically alter their wetting characteristics, promoting dropwise condensation instead of film condensation. This change in condensation behavior can lead to heat transfer coefficients up to 20 times higher than those of uncoated surfaces, significantly boosting heat exchanger efficiency.

The development of additive manufacturing techniques, such as 3D printing, has revolutionized the production of heat exchanger plates. These methods allow for the creation of complex, three-dimensional surface structures that were previously impossible or impractical to manufacture. For example, plates with intricate internal channels or surface textures can now be produced, maximizing the heat transfer area while minimizing pressure drop.

Advanced materials have also enabled the implementation of novel plate arrangements. Shape memory alloys, for instance, can be used to create adaptive plate geometries that respond to changes in temperature or flow conditions. This dynamic adjustment capability allows heat exchangers to maintain optimal performance across a wide range of operating parameters.

Furthermore, the development of high-performance ceramics has opened up new possibilities for plate arrangements in extreme temperature applications. These materials can withstand temperatures far beyond the capabilities of traditional metallic plates, allowing for more efficient heat recovery in high-temperature industrial processes.

Biomimetic approaches inspired by natural heat transfer systems have led to innovative plate designs. For example, plates mimicking the structure of shark skin or lotus leaves have demonstrated enhanced heat transfer properties and reduced fouling tendencies, contributing to sustained efficiency over longer operational periods.

In conclusion, material science advancements have significantly expanded the possibilities for plate arrangements in heat exchangers. By enabling the creation of more efficient, durable, and adaptable plate designs, these innovations have paved the way for substantial improvements in heat exchanger performance across various industries and applications.

One of the most significant advancements in this field has been the introduction of advanced composite materials. These materials offer superior thermal conductivity and corrosion resistance compared to traditional metals, allowing for thinner plates and more compact designs. Composite plates can also be engineered to have specific properties tailored to the heat exchanger's operating conditions, such as enhanced resistance to fouling or improved chemical compatibility with process fluids.

Nanotechnology has also made substantial contributions to plate material science. Nanocoatings applied to plate surfaces can dramatically alter their wetting characteristics, promoting dropwise condensation instead of film condensation. This change in condensation behavior can lead to heat transfer coefficients up to 20 times higher than those of uncoated surfaces, significantly boosting heat exchanger efficiency.

The development of additive manufacturing techniques, such as 3D printing, has revolutionized the production of heat exchanger plates. These methods allow for the creation of complex, three-dimensional surface structures that were previously impossible or impractical to manufacture. For example, plates with intricate internal channels or surface textures can now be produced, maximizing the heat transfer area while minimizing pressure drop.

Advanced materials have also enabled the implementation of novel plate arrangements. Shape memory alloys, for instance, can be used to create adaptive plate geometries that respond to changes in temperature or flow conditions. This dynamic adjustment capability allows heat exchangers to maintain optimal performance across a wide range of operating parameters.

Furthermore, the development of high-performance ceramics has opened up new possibilities for plate arrangements in extreme temperature applications. These materials can withstand temperatures far beyond the capabilities of traditional metallic plates, allowing for more efficient heat recovery in high-temperature industrial processes.

Biomimetic approaches inspired by natural heat transfer systems have led to innovative plate designs. For example, plates mimicking the structure of shark skin or lotus leaves have demonstrated enhanced heat transfer properties and reduced fouling tendencies, contributing to sustained efficiency over longer operational periods.

In conclusion, material science advancements have significantly expanded the possibilities for plate arrangements in heat exchangers. By enabling the creation of more efficient, durable, and adaptable plate designs, these innovations have paved the way for substantial improvements in heat exchanger performance across various industries and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!