Role of Plate Heat Exchangers in Combustion Engine Systems

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Plate heat exchangers have played a crucial role in combustion engine systems since their introduction in the early 20th century. These compact and efficient devices have revolutionized heat transfer processes in various industries, particularly in automotive and marine applications. The evolution of plate heat exchangers has been driven by the increasing demand for more efficient and environmentally friendly combustion engines.

The primary objective of integrating plate heat exchangers into combustion engine systems is to optimize thermal management, thereby enhancing overall engine performance and fuel efficiency. By effectively controlling heat transfer between different fluids, these exchangers contribute to maintaining optimal operating temperatures, reducing emissions, and extending engine life. The technology has progressed from simple designs to more sophisticated configurations, adapting to the changing needs of modern combustion engines.

Over the years, plate heat exchangers have undergone significant improvements in materials, design, and manufacturing processes. Early models were primarily constructed from stainless steel, but advancements in metallurgy have led to the use of more durable and corrosion-resistant alloys. The introduction of computer-aided design and simulation tools has enabled engineers to optimize plate geometries and flow patterns, resulting in enhanced heat transfer efficiency and reduced pressure drop.

The automotive industry has been a major driving force behind the development of plate heat exchangers for combustion engine systems. As vehicle manufacturers strive to meet increasingly stringent emissions regulations and fuel economy standards, the role of efficient heat management has become more critical. Plate heat exchangers have found applications in engine oil cooling, transmission fluid cooling, and exhaust gas recirculation (EGR) systems, contributing to improved engine performance and reduced environmental impact.

In recent years, the focus has shifted towards developing plate heat exchangers that can withstand higher temperatures and pressures, particularly for use in turbocharging and exhaust heat recovery systems. This trend aligns with the growing interest in waste heat recovery technologies, which aim to convert thermal energy from exhaust gases into useful mechanical or electrical power, further improving overall engine efficiency.

The marine sector has also embraced plate heat exchangers, particularly in large ship engines where efficient cooling is essential for maintaining optimal performance in challenging operating conditions. The compact design of plate heat exchangers offers significant advantages in terms of space savings and weight reduction, crucial factors in marine applications.

Looking ahead, the development of plate heat exchangers for combustion engine systems is expected to continue, with a focus on further improving efficiency, durability, and adaptability to emerging technologies. As the automotive industry transitions towards electrification and alternative fuels, plate heat exchangers will likely play a vital role in thermal management for hybrid powertrains and fuel cell systems, presenting new challenges and opportunities for innovation in this field.

The primary objective of integrating plate heat exchangers into combustion engine systems is to optimize thermal management, thereby enhancing overall engine performance and fuel efficiency. By effectively controlling heat transfer between different fluids, these exchangers contribute to maintaining optimal operating temperatures, reducing emissions, and extending engine life. The technology has progressed from simple designs to more sophisticated configurations, adapting to the changing needs of modern combustion engines.

Over the years, plate heat exchangers have undergone significant improvements in materials, design, and manufacturing processes. Early models were primarily constructed from stainless steel, but advancements in metallurgy have led to the use of more durable and corrosion-resistant alloys. The introduction of computer-aided design and simulation tools has enabled engineers to optimize plate geometries and flow patterns, resulting in enhanced heat transfer efficiency and reduced pressure drop.

The automotive industry has been a major driving force behind the development of plate heat exchangers for combustion engine systems. As vehicle manufacturers strive to meet increasingly stringent emissions regulations and fuel economy standards, the role of efficient heat management has become more critical. Plate heat exchangers have found applications in engine oil cooling, transmission fluid cooling, and exhaust gas recirculation (EGR) systems, contributing to improved engine performance and reduced environmental impact.

In recent years, the focus has shifted towards developing plate heat exchangers that can withstand higher temperatures and pressures, particularly for use in turbocharging and exhaust heat recovery systems. This trend aligns with the growing interest in waste heat recovery technologies, which aim to convert thermal energy from exhaust gases into useful mechanical or electrical power, further improving overall engine efficiency.

The marine sector has also embraced plate heat exchangers, particularly in large ship engines where efficient cooling is essential for maintaining optimal performance in challenging operating conditions. The compact design of plate heat exchangers offers significant advantages in terms of space savings and weight reduction, crucial factors in marine applications.

Looking ahead, the development of plate heat exchangers for combustion engine systems is expected to continue, with a focus on further improving efficiency, durability, and adaptability to emerging technologies. As the automotive industry transitions towards electrification and alternative fuels, plate heat exchangers will likely play a vital role in thermal management for hybrid powertrains and fuel cell systems, presenting new challenges and opportunities for innovation in this field.

Market Analysis

The market for plate heat exchangers in combustion engine systems has been experiencing steady growth, driven by increasing demand for more efficient and compact cooling solutions. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the role of plate heat exchangers has become increasingly critical in managing engine thermal loads effectively.

The global market for plate heat exchangers in automotive applications is projected to expand significantly over the next decade. This growth is primarily attributed to the rising production of vehicles, particularly in emerging economies, and the increasing adoption of advanced thermal management systems in modern engines. The automotive sector represents a substantial portion of the overall plate heat exchanger market, with combustion engine systems being a key application area.

One of the primary drivers for the adoption of plate heat exchangers in combustion engine systems is the trend towards engine downsizing and turbocharging. These technologies require more efficient cooling solutions to manage the increased thermal loads generated by higher power densities. Plate heat exchangers offer superior heat transfer efficiency and compact design compared to traditional shell-and-tube heat exchangers, making them ideal for these applications.

The market is also being influenced by the growing focus on reducing vehicle weight to improve fuel economy. Plate heat exchangers, being lighter and more compact than their traditional counterparts, align well with this objective. Additionally, the increasing electrification of vehicles, including hybrid systems, has created new opportunities for plate heat exchangers in managing battery thermal loads and integrating with combustion engine cooling systems.

Geographically, the Asia-Pacific region is expected to witness the highest growth in the plate heat exchanger market for combustion engine systems. This is due to the rapid expansion of the automotive industry in countries like China and India, coupled with increasing investments in advanced manufacturing technologies. North America and Europe continue to be significant markets, driven by stringent emissions regulations and the push for more fuel-efficient vehicles.

The competitive landscape of the plate heat exchanger market for combustion engine systems is characterized by a mix of established players and innovative startups. Key market players are focusing on research and development to enhance the performance and efficiency of their products, as well as exploring new materials and manufacturing techniques to reduce costs and improve durability.

As the automotive industry continues to evolve, the demand for more sophisticated thermal management solutions in combustion engine systems is expected to grow. This presents significant opportunities for plate heat exchanger manufacturers to innovate and expand their market presence. However, challenges such as the gradual shift towards electric vehicles and the need for cost-effective solutions in price-sensitive markets will require ongoing adaptation and strategic positioning within the industry.

The global market for plate heat exchangers in automotive applications is projected to expand significantly over the next decade. This growth is primarily attributed to the rising production of vehicles, particularly in emerging economies, and the increasing adoption of advanced thermal management systems in modern engines. The automotive sector represents a substantial portion of the overall plate heat exchanger market, with combustion engine systems being a key application area.

One of the primary drivers for the adoption of plate heat exchangers in combustion engine systems is the trend towards engine downsizing and turbocharging. These technologies require more efficient cooling solutions to manage the increased thermal loads generated by higher power densities. Plate heat exchangers offer superior heat transfer efficiency and compact design compared to traditional shell-and-tube heat exchangers, making them ideal for these applications.

The market is also being influenced by the growing focus on reducing vehicle weight to improve fuel economy. Plate heat exchangers, being lighter and more compact than their traditional counterparts, align well with this objective. Additionally, the increasing electrification of vehicles, including hybrid systems, has created new opportunities for plate heat exchangers in managing battery thermal loads and integrating with combustion engine cooling systems.

Geographically, the Asia-Pacific region is expected to witness the highest growth in the plate heat exchanger market for combustion engine systems. This is due to the rapid expansion of the automotive industry in countries like China and India, coupled with increasing investments in advanced manufacturing technologies. North America and Europe continue to be significant markets, driven by stringent emissions regulations and the push for more fuel-efficient vehicles.

The competitive landscape of the plate heat exchanger market for combustion engine systems is characterized by a mix of established players and innovative startups. Key market players are focusing on research and development to enhance the performance and efficiency of their products, as well as exploring new materials and manufacturing techniques to reduce costs and improve durability.

As the automotive industry continues to evolve, the demand for more sophisticated thermal management solutions in combustion engine systems is expected to grow. This presents significant opportunities for plate heat exchanger manufacturers to innovate and expand their market presence. However, challenges such as the gradual shift towards electric vehicles and the need for cost-effective solutions in price-sensitive markets will require ongoing adaptation and strategic positioning within the industry.

Technical Challenges

The integration of plate heat exchangers in combustion engine systems presents several technical challenges that require innovative solutions. One of the primary obstacles is the need for efficient heat transfer within the limited space available in modern engine compartments. As engines become more compact and powerful, the demand for effective cooling increases, putting pressure on heat exchanger design to maximize performance while minimizing size.

Material selection poses another significant challenge. The heat exchanger must withstand high temperatures, pressure fluctuations, and corrosive fluids typical in engine environments. Engineers must balance durability with thermal conductivity, often exploring advanced alloys or composite materials to meet these conflicting requirements. The cost-effectiveness of these materials also plays a crucial role in the overall system design.

Fouling and scaling are persistent issues that can severely impact the efficiency of plate heat exchangers in engine systems. The accumulation of deposits on heat transfer surfaces reduces thermal performance over time, necessitating the development of self-cleaning mechanisms or anti-fouling coatings. These solutions must be robust enough to withstand the harsh operating conditions without compromising heat transfer capabilities.

The dynamic nature of combustion engine operation presents challenges in maintaining optimal heat exchanger performance across various load conditions. Fluctuating flow rates and temperatures require adaptive control strategies to ensure consistent cooling efficiency. This may involve the integration of smart sensors and actuators to modulate heat transfer based on real-time engine parameters.

Manufacturability and assembly complexity are additional hurdles in plate heat exchanger design for engine systems. The intricate channel geometries that enhance heat transfer can be difficult to produce consistently at scale. Innovations in manufacturing processes, such as additive manufacturing or advanced forming techniques, are being explored to address these challenges.

Vibration and thermal stress management are critical considerations, as the heat exchanger must maintain structural integrity and sealing under the constant mechanical and thermal cycling inherent in engine operation. This requires careful analysis of material fatigue properties and the development of robust mounting and sealing solutions.

Lastly, the integration of plate heat exchangers with other engine subsystems presents challenges in optimizing overall system performance. Balancing the cooling needs of various components, such as the engine block, oil circuits, and exhaust gas recirculation systems, requires a holistic approach to thermal management. This often involves complex modeling and simulation to predict system behavior under diverse operating conditions.

Material selection poses another significant challenge. The heat exchanger must withstand high temperatures, pressure fluctuations, and corrosive fluids typical in engine environments. Engineers must balance durability with thermal conductivity, often exploring advanced alloys or composite materials to meet these conflicting requirements. The cost-effectiveness of these materials also plays a crucial role in the overall system design.

Fouling and scaling are persistent issues that can severely impact the efficiency of plate heat exchangers in engine systems. The accumulation of deposits on heat transfer surfaces reduces thermal performance over time, necessitating the development of self-cleaning mechanisms or anti-fouling coatings. These solutions must be robust enough to withstand the harsh operating conditions without compromising heat transfer capabilities.

The dynamic nature of combustion engine operation presents challenges in maintaining optimal heat exchanger performance across various load conditions. Fluctuating flow rates and temperatures require adaptive control strategies to ensure consistent cooling efficiency. This may involve the integration of smart sensors and actuators to modulate heat transfer based on real-time engine parameters.

Manufacturability and assembly complexity are additional hurdles in plate heat exchanger design for engine systems. The intricate channel geometries that enhance heat transfer can be difficult to produce consistently at scale. Innovations in manufacturing processes, such as additive manufacturing or advanced forming techniques, are being explored to address these challenges.

Vibration and thermal stress management are critical considerations, as the heat exchanger must maintain structural integrity and sealing under the constant mechanical and thermal cycling inherent in engine operation. This requires careful analysis of material fatigue properties and the development of robust mounting and sealing solutions.

Lastly, the integration of plate heat exchangers with other engine subsystems presents challenges in optimizing overall system performance. Balancing the cooling needs of various components, such as the engine block, oil circuits, and exhaust gas recirculation systems, requires a holistic approach to thermal management. This often involves complex modeling and simulation to predict system behavior under diverse operating conditions.

Current Solutions

01 Design improvements for plate heat exchangers

Various design improvements have been developed for plate heat exchangers to enhance their efficiency and performance. These include modifications to plate geometry, flow distribution, and sealing mechanisms. Such improvements aim to optimize heat transfer, reduce pressure drop, and increase overall system effectiveness.- Design improvements for plate heat exchangers: Various design improvements have been developed for plate heat exchangers to enhance their efficiency and performance. These include modifications to plate geometry, flow distribution, and sealing mechanisms. Such improvements aim to optimize heat transfer, reduce pressure drop, and increase overall system effectiveness.

- Materials and coatings for plate heat exchangers: Advanced materials and coatings are being utilized in plate heat exchangers to improve corrosion resistance, fouling mitigation, and thermal conductivity. These innovations extend the lifespan of the exchangers and maintain their efficiency over time, particularly in challenging operating environments.

- Modular and customizable plate heat exchanger systems: Modular designs for plate heat exchangers allow for easy customization and scalability. These systems can be adapted to various industrial applications and can be easily expanded or modified as needed. The modular approach also facilitates maintenance and replacement of individual components.

- Energy efficiency and heat recovery in plate heat exchangers: Innovations in plate heat exchanger design focus on improving energy efficiency and heat recovery capabilities. These advancements include optimized flow patterns, enhanced surface area utilization, and integration with other energy systems to maximize overall thermal efficiency in industrial processes.

- Smart monitoring and control systems for plate heat exchangers: Integration of smart monitoring and control systems in plate heat exchangers enables real-time performance optimization, predictive maintenance, and fault detection. These systems utilize sensors, data analytics, and automation to enhance operational efficiency and reduce downtime.

02 Materials and manufacturing processes for heat exchanger plates

Advancements in materials and manufacturing processes have led to improved plate heat exchangers. This includes the use of novel materials with enhanced thermal conductivity, corrosion resistance, and durability. Additionally, innovative manufacturing techniques have been developed to produce more efficient and cost-effective heat exchanger plates.Expand Specific Solutions03 Specialized plate heat exchangers for specific applications

Plate heat exchangers have been adapted for various specialized applications, such as in the automotive, chemical, and food processing industries. These specialized designs take into account unique requirements like temperature ranges, pressure conditions, and fluid properties to optimize performance in specific contexts.Expand Specific Solutions04 Modular and scalable plate heat exchanger systems

Modular and scalable plate heat exchanger systems have been developed to provide flexibility in capacity and configuration. These systems allow for easy expansion, maintenance, and customization to meet varying heat transfer requirements across different industries and applications.Expand Specific Solutions05 Integration of plate heat exchangers with other technologies

Plate heat exchangers have been integrated with other technologies to create more comprehensive and efficient thermal management solutions. This includes combining plate heat exchangers with heat pumps, energy recovery systems, and smart control systems to optimize overall system performance and energy efficiency.Expand Specific Solutions

Industry Players

The role of plate heat exchangers in combustion engine systems is evolving within a competitive landscape characterized by technological advancements and market expansion. The industry is in a growth phase, with increasing demand for more efficient and compact heat exchange solutions. The global market for plate heat exchangers in automotive applications is projected to grow significantly, driven by stringent emissions regulations and the push for improved fuel efficiency. Technologically, companies like Alfa Laval, Valeo, and Mahle are leading innovation, developing advanced materials and designs to enhance thermal management in combustion engines. Other key players such as BYD, Honeywell, and Dana are also contributing to the field's rapid progression, focusing on integration with electric and hybrid powertrains.

Mahle-Metal Leve SA

Technical Solution: Mahle-Metal Leve has developed innovative plate heat exchanger solutions for combustion engine systems, focusing on improving engine efficiency and reducing emissions. Their technology incorporates advanced brazing techniques to create robust, leak-free plate heat exchangers capable of withstanding high pressures and temperatures in engine environments. Mahle's plate heat exchangers feature optimized plate geometries that enhance turbulent flow, resulting in improved heat transfer coefficients and reduced fouling[5]. The company has also introduced multi-stream plate heat exchangers that can simultaneously manage multiple fluid circuits within the engine, such as oil cooling, charge air cooling, and exhaust gas recirculation (EGR) cooling, in a single compact unit[6].

Strengths: High-pressure capability, multi-stream functionality, and advanced brazing technology. Weaknesses: Potentially higher manufacturing costs and limited flexibility for field repairs compared to traditional heat exchangers.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for combustion engine systems. Their technology utilizes compact, high-efficiency plates with optimized flow patterns to enhance heat transfer in engine cooling systems. The company's plate heat exchangers feature a modular design that allows for easy scalability and customization to fit various engine sizes and configurations[1]. Alfa Laval's solutions incorporate corrosion-resistant materials and gasket-free construction to withstand high temperatures and pressures typical in combustion engine environments. Their plate heat exchangers also employ a cross-flow arrangement that maximizes thermal efficiency while minimizing pressure drop, contributing to overall engine performance improvement[2].

Strengths: High thermal efficiency, compact design, scalability, and durability in harsh engine conditions. Weaknesses: Potentially higher initial cost compared to traditional shell-and-tube heat exchangers, may require more frequent maintenance in some applications.

Key Innovations

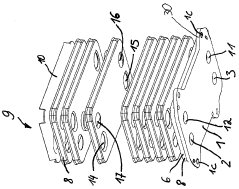

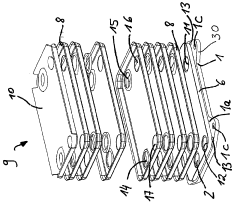

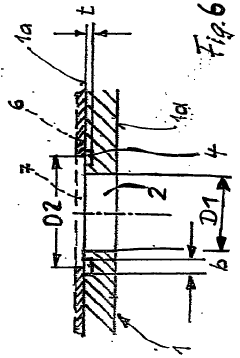

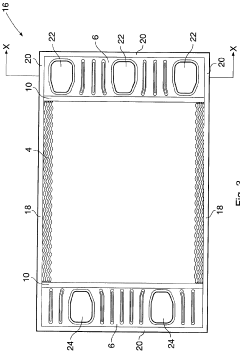

Heat exchanger for internal combustion engine has several plates arranged one above another whereby baseplate has opening for removal of heat transfer medium and heat exchanger has reservoir for process medium

PatentInactiveDE102005048452A1

Innovation

- The heat exchanger design incorporates a base plate with openings and a reservoir to collect excess process medium, such as solder, during joining processes, preventing it from escaping and contaminating the exterior surfaces, thereby eliminating the need for additional cleaning and testing steps.

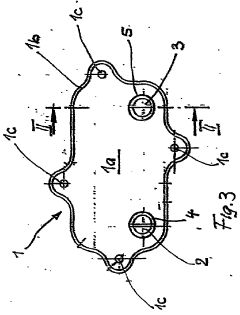

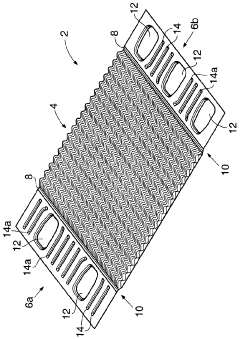

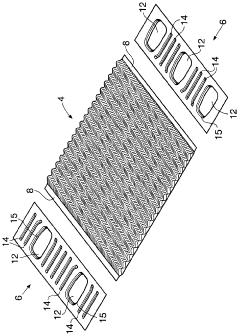

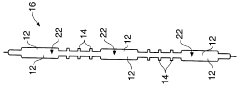

Plate heat exchanger having a corrugated portion joined to a separate header portion

PatentInactiveGB2418481A

Innovation

- A heat exchanger comprising compound plates with a corrugated heat exchange portion and a thicker, planar header portion, joined by welding, featuring projections as flow guides to enhance fluid flow and turbulence, and a unique corrugation pattern to prevent interlocking and improve stiffness.

Efficiency Improvements

Plate heat exchangers play a crucial role in improving the efficiency of combustion engine systems. These compact and versatile devices facilitate effective heat transfer between different fluids, contributing significantly to overall system performance. In combustion engines, plate heat exchangers are primarily utilized for cooling and heat recovery purposes, enabling substantial improvements in fuel efficiency and emissions reduction.

One of the key efficiency improvements offered by plate heat exchangers is their ability to optimize engine cooling. By efficiently transferring heat from the engine coolant to a secondary cooling medium, these exchangers help maintain optimal operating temperatures, reducing thermal stress on engine components and enhancing overall performance. This improved thermal management leads to increased engine longevity and reduced maintenance requirements.

Furthermore, plate heat exchangers contribute to waste heat recovery in combustion engine systems. By capturing and utilizing waste heat from exhaust gases, these exchangers can preheat incoming air or fuel, improving combustion efficiency and reducing fuel consumption. This process, known as exhaust gas heat recovery, can result in fuel savings of up to 5-10% in some applications.

The compact design of plate heat exchangers also contributes to efficiency improvements by reducing the overall size and weight of the engine system. This reduction in mass translates to improved power-to-weight ratios and enhanced fuel economy, particularly in mobile applications such as automotive and marine engines.

In addition to their thermal management capabilities, plate heat exchangers offer superior heat transfer efficiency compared to traditional shell-and-tube designs. The corrugated plates and narrow flow channels create turbulent flow conditions, enhancing heat transfer coefficients and minimizing fouling. This increased efficiency allows for more compact heat exchanger designs, further contributing to space and weight savings in engine systems.

The integration of plate heat exchangers in combustion engine systems also enables more effective charge air cooling in turbocharged engines. By efficiently cooling the compressed air before it enters the combustion chamber, these exchangers increase air density, allowing for improved engine power output and fuel efficiency. This is particularly beneficial in high-performance and heavy-duty engine applications.

Moreover, plate heat exchangers facilitate the implementation of advanced thermal management strategies in modern engine systems. By enabling precise control of coolant temperatures across different engine components, these exchangers support variable coolant flow systems and split cooling circuits, further optimizing engine performance and efficiency across various operating conditions.

One of the key efficiency improvements offered by plate heat exchangers is their ability to optimize engine cooling. By efficiently transferring heat from the engine coolant to a secondary cooling medium, these exchangers help maintain optimal operating temperatures, reducing thermal stress on engine components and enhancing overall performance. This improved thermal management leads to increased engine longevity and reduced maintenance requirements.

Furthermore, plate heat exchangers contribute to waste heat recovery in combustion engine systems. By capturing and utilizing waste heat from exhaust gases, these exchangers can preheat incoming air or fuel, improving combustion efficiency and reducing fuel consumption. This process, known as exhaust gas heat recovery, can result in fuel savings of up to 5-10% in some applications.

The compact design of plate heat exchangers also contributes to efficiency improvements by reducing the overall size and weight of the engine system. This reduction in mass translates to improved power-to-weight ratios and enhanced fuel economy, particularly in mobile applications such as automotive and marine engines.

In addition to their thermal management capabilities, plate heat exchangers offer superior heat transfer efficiency compared to traditional shell-and-tube designs. The corrugated plates and narrow flow channels create turbulent flow conditions, enhancing heat transfer coefficients and minimizing fouling. This increased efficiency allows for more compact heat exchanger designs, further contributing to space and weight savings in engine systems.

The integration of plate heat exchangers in combustion engine systems also enables more effective charge air cooling in turbocharged engines. By efficiently cooling the compressed air before it enters the combustion chamber, these exchangers increase air density, allowing for improved engine power output and fuel efficiency. This is particularly beneficial in high-performance and heavy-duty engine applications.

Moreover, plate heat exchangers facilitate the implementation of advanced thermal management strategies in modern engine systems. By enabling precise control of coolant temperatures across different engine components, these exchangers support variable coolant flow systems and split cooling circuits, further optimizing engine performance and efficiency across various operating conditions.

Environmental Impact

The integration of plate heat exchangers in combustion engine systems has significant environmental implications, primarily due to their role in improving engine efficiency and reducing emissions. These compact and efficient heat transfer devices contribute to the overall reduction of fuel consumption, which in turn leads to decreased greenhouse gas emissions. By effectively managing engine heat, plate heat exchangers help maintain optimal operating temperatures, resulting in more complete combustion and reduced formation of pollutants such as carbon monoxide and nitrogen oxides.

Furthermore, the use of plate heat exchangers in engine cooling systems allows for more precise temperature control, which can extend engine life and reduce the need for frequent replacements. This longevity contributes to a reduction in the environmental impact associated with manufacturing and disposing of engine components. The compact design of plate heat exchangers also means less material is required for their production, further minimizing their environmental footprint.

In the context of waste heat recovery systems, plate heat exchangers play a crucial role in capturing and utilizing thermal energy that would otherwise be lost to the environment. This recovered energy can be used to power auxiliary systems or converted into electrical energy, improving the overall energy efficiency of the vehicle or industrial process. By maximizing energy utilization, these systems reduce the reliance on primary energy sources, thereby decreasing the overall carbon footprint of combustion engine applications.

The materials used in plate heat exchangers, typically stainless steel or titanium, are highly durable and recyclable. This characteristic aligns with circular economy principles, as these components can be easily refurbished or recycled at the end of their operational life, reducing waste and conserving resources. Additionally, the corrosion resistance of these materials ensures long-term performance, minimizing the need for replacement and associated environmental impacts.

In terms of refrigerants and coolants, plate heat exchangers in combustion engine systems often facilitate the use of more environmentally friendly options. Their efficient heat transfer capabilities allow for the use of lower volumes of coolants, and in some cases, enable the adoption of natural refrigerants with lower global warming potential. This shift away from traditional, high-impact refrigerants contributes to the reduction of potential environmental harm from leaks or improper disposal.

Furthermore, the use of plate heat exchangers in engine cooling systems allows for more precise temperature control, which can extend engine life and reduce the need for frequent replacements. This longevity contributes to a reduction in the environmental impact associated with manufacturing and disposing of engine components. The compact design of plate heat exchangers also means less material is required for their production, further minimizing their environmental footprint.

In the context of waste heat recovery systems, plate heat exchangers play a crucial role in capturing and utilizing thermal energy that would otherwise be lost to the environment. This recovered energy can be used to power auxiliary systems or converted into electrical energy, improving the overall energy efficiency of the vehicle or industrial process. By maximizing energy utilization, these systems reduce the reliance on primary energy sources, thereby decreasing the overall carbon footprint of combustion engine applications.

The materials used in plate heat exchangers, typically stainless steel or titanium, are highly durable and recyclable. This characteristic aligns with circular economy principles, as these components can be easily refurbished or recycled at the end of their operational life, reducing waste and conserving resources. Additionally, the corrosion resistance of these materials ensures long-term performance, minimizing the need for replacement and associated environmental impacts.

In terms of refrigerants and coolants, plate heat exchangers in combustion engine systems often facilitate the use of more environmentally friendly options. Their efficient heat transfer capabilities allow for the use of lower volumes of coolants, and in some cases, enable the adoption of natural refrigerants with lower global warming potential. This shift away from traditional, high-impact refrigerants contributes to the reduction of potential environmental harm from leaks or improper disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!