Plate Heat Exchanger Integration in Cogeneration Plants

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Cogeneration Background

Plate heat exchangers (PHEs) have become increasingly integral to cogeneration plants, revolutionizing the efficiency and flexibility of combined heat and power generation. The integration of PHEs in cogeneration systems represents a significant technological advancement in the energy sector, addressing the growing demand for more sustainable and cost-effective power generation solutions.

Cogeneration, also known as combined heat and power (CHP), is the simultaneous production of electricity and useful thermal energy from a single fuel source. This process significantly improves overall energy efficiency by utilizing waste heat that would otherwise be lost in conventional power generation. The incorporation of plate heat exchangers in cogeneration plants has further enhanced this efficiency, allowing for more effective heat transfer and recovery.

The evolution of PHE technology in cogeneration can be traced back to the late 20th century, with significant advancements occurring in the past few decades. Initially, shell and tube heat exchangers were the primary choice for heat recovery in cogeneration systems. However, the compact design, higher heat transfer coefficients, and greater flexibility of plate heat exchangers have led to their widespread adoption in modern cogeneration plants.

PHEs offer several advantages in cogeneration applications, including improved heat transfer efficiency, reduced footprint, and easier maintenance. Their modular design allows for easy scaling and adaptation to varying heat loads, making them particularly suitable for diverse industrial and commercial cogeneration applications. The ability of PHEs to handle multiple fluid streams simultaneously has also contributed to their popularity in complex cogeneration systems.

The integration of PHEs in cogeneration plants has been driven by the increasing focus on energy efficiency and environmental sustainability. As global energy demands continue to rise and environmental regulations become more stringent, cogeneration with PHE technology has emerged as a viable solution for reducing carbon emissions and improving overall energy utilization.

Recent technological advancements in PHE design, such as improved plate patterns, enhanced sealing technologies, and the use of advanced materials, have further expanded their capabilities in cogeneration applications. These innovations have enabled PHEs to handle higher temperatures and pressures, making them suitable for a wider range of cogeneration scenarios, including industrial processes and district heating systems.

The growing adoption of PHEs in cogeneration plants reflects a broader trend towards more efficient and flexible energy systems. As the energy landscape continues to evolve, with an increasing emphasis on distributed generation and renewable integration, the role of PHEs in cogeneration is expected to become even more significant, driving further innovations in this field.

Cogeneration, also known as combined heat and power (CHP), is the simultaneous production of electricity and useful thermal energy from a single fuel source. This process significantly improves overall energy efficiency by utilizing waste heat that would otherwise be lost in conventional power generation. The incorporation of plate heat exchangers in cogeneration plants has further enhanced this efficiency, allowing for more effective heat transfer and recovery.

The evolution of PHE technology in cogeneration can be traced back to the late 20th century, with significant advancements occurring in the past few decades. Initially, shell and tube heat exchangers were the primary choice for heat recovery in cogeneration systems. However, the compact design, higher heat transfer coefficients, and greater flexibility of plate heat exchangers have led to their widespread adoption in modern cogeneration plants.

PHEs offer several advantages in cogeneration applications, including improved heat transfer efficiency, reduced footprint, and easier maintenance. Their modular design allows for easy scaling and adaptation to varying heat loads, making them particularly suitable for diverse industrial and commercial cogeneration applications. The ability of PHEs to handle multiple fluid streams simultaneously has also contributed to their popularity in complex cogeneration systems.

The integration of PHEs in cogeneration plants has been driven by the increasing focus on energy efficiency and environmental sustainability. As global energy demands continue to rise and environmental regulations become more stringent, cogeneration with PHE technology has emerged as a viable solution for reducing carbon emissions and improving overall energy utilization.

Recent technological advancements in PHE design, such as improved plate patterns, enhanced sealing technologies, and the use of advanced materials, have further expanded their capabilities in cogeneration applications. These innovations have enabled PHEs to handle higher temperatures and pressures, making them suitable for a wider range of cogeneration scenarios, including industrial processes and district heating systems.

The growing adoption of PHEs in cogeneration plants reflects a broader trend towards more efficient and flexible energy systems. As the energy landscape continues to evolve, with an increasing emphasis on distributed generation and renewable integration, the role of PHEs in cogeneration is expected to become even more significant, driving further innovations in this field.

Market Demand Analysis

The integration of plate heat exchangers in cogeneration plants has seen a significant rise in market demand over the past decade. This surge is primarily driven by the increasing global focus on energy efficiency and sustainable power generation. Cogeneration, also known as combined heat and power (CHP), has become a cornerstone of energy-efficient industrial processes, and plate heat exchangers play a crucial role in optimizing these systems.

The market for plate heat exchangers in cogeneration applications is closely tied to the growth of the CHP sector. According to recent industry reports, the global CHP market is expected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2026. This growth is particularly pronounced in regions with stringent energy efficiency regulations and high industrial energy consumption, such as Europe, North America, and parts of Asia.

In the industrial sector, there is a strong demand for plate heat exchangers in cogeneration plants due to their superior heat transfer efficiency and compact design. Industries such as chemical processing, food and beverage, and pulp and paper are increasingly adopting cogeneration systems to reduce energy costs and carbon emissions. The ability of plate heat exchangers to handle high-temperature differentials and their resistance to fouling make them particularly attractive for these applications.

The power generation sector is another key driver of market demand for plate heat exchangers in cogeneration. As countries worldwide shift towards decentralized power generation and district heating systems, the need for efficient heat recovery solutions has grown substantially. Plate heat exchangers are well-suited for these applications due to their ability to transfer heat between different fluid streams effectively, maximizing energy recovery from exhaust gases and process streams.

Environmental regulations and sustainability goals are also fueling the demand for plate heat exchangers in cogeneration plants. Many countries have implemented policies to promote CHP systems as a means of reducing greenhouse gas emissions and improving overall energy efficiency. This regulatory push has created a favorable market environment for technologies that enhance CHP performance, including advanced plate heat exchanger designs.

The market demand is further bolstered by the ongoing technological advancements in plate heat exchanger design. Manufacturers are developing innovative plate patterns, materials, and sealing technologies to improve heat transfer efficiency, reduce pressure drop, and extend operational lifetimes. These improvements are making plate heat exchangers increasingly attractive for a wider range of cogeneration applications, expanding their market potential.

In conclusion, the market demand for plate heat exchangers in cogeneration plants is robust and growing, driven by industrial energy efficiency needs, expansion of decentralized power generation, environmental regulations, and technological advancements. As the global focus on sustainable energy solutions intensifies, the integration of plate heat exchangers in cogeneration systems is expected to play an increasingly vital role in meeting energy efficiency and environmental targets across various sectors.

The market for plate heat exchangers in cogeneration applications is closely tied to the growth of the CHP sector. According to recent industry reports, the global CHP market is expected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2026. This growth is particularly pronounced in regions with stringent energy efficiency regulations and high industrial energy consumption, such as Europe, North America, and parts of Asia.

In the industrial sector, there is a strong demand for plate heat exchangers in cogeneration plants due to their superior heat transfer efficiency and compact design. Industries such as chemical processing, food and beverage, and pulp and paper are increasingly adopting cogeneration systems to reduce energy costs and carbon emissions. The ability of plate heat exchangers to handle high-temperature differentials and their resistance to fouling make them particularly attractive for these applications.

The power generation sector is another key driver of market demand for plate heat exchangers in cogeneration. As countries worldwide shift towards decentralized power generation and district heating systems, the need for efficient heat recovery solutions has grown substantially. Plate heat exchangers are well-suited for these applications due to their ability to transfer heat between different fluid streams effectively, maximizing energy recovery from exhaust gases and process streams.

Environmental regulations and sustainability goals are also fueling the demand for plate heat exchangers in cogeneration plants. Many countries have implemented policies to promote CHP systems as a means of reducing greenhouse gas emissions and improving overall energy efficiency. This regulatory push has created a favorable market environment for technologies that enhance CHP performance, including advanced plate heat exchanger designs.

The market demand is further bolstered by the ongoing technological advancements in plate heat exchanger design. Manufacturers are developing innovative plate patterns, materials, and sealing technologies to improve heat transfer efficiency, reduce pressure drop, and extend operational lifetimes. These improvements are making plate heat exchangers increasingly attractive for a wider range of cogeneration applications, expanding their market potential.

In conclusion, the market demand for plate heat exchangers in cogeneration plants is robust and growing, driven by industrial energy efficiency needs, expansion of decentralized power generation, environmental regulations, and technological advancements. As the global focus on sustainable energy solutions intensifies, the integration of plate heat exchangers in cogeneration systems is expected to play an increasingly vital role in meeting energy efficiency and environmental targets across various sectors.

PHE Tech Challenges

The integration of Plate Heat Exchangers (PHEs) in cogeneration plants presents several technical challenges that need to be addressed for optimal performance and efficiency. One of the primary challenges is the design and optimization of PHEs for the specific operating conditions of cogeneration plants. These conditions often involve high temperatures, pressures, and flow rates, which can push the limits of conventional PHE designs.

Material selection is another critical challenge in PHE integration. The heat transfer surfaces must withstand corrosive fluids, thermal cycling, and mechanical stresses while maintaining high thermal efficiency. Advanced materials such as titanium, high-grade stainless steel, or specialized alloys may be required, increasing costs and complexity.

Fouling and scaling pose significant operational challenges for PHEs in cogeneration plants. The accumulation of deposits on heat transfer surfaces can severely reduce thermal efficiency and increase pressure drop. Developing effective fouling mitigation strategies and designing PHEs with enhanced anti-fouling properties is crucial for maintaining long-term performance.

Flow distribution and maldistribution within PHEs can lead to reduced heat transfer efficiency and increased pressure drop. Achieving uniform flow across the entire heat transfer area is particularly challenging in large-scale cogeneration applications, where high flow rates and complex fluid dynamics are involved.

Thermal expansion and mechanical stress management present another set of challenges. The frequent thermal cycling in cogeneration plants can cause fatigue and potential failure of PHE components. Designing flexible mounting systems and implementing proper stress analysis are essential to ensure the longevity of the equipment.

Control and optimization of PHEs in dynamic cogeneration systems pose significant challenges. Rapid load changes and varying operating conditions require sophisticated control strategies to maintain optimal heat transfer efficiency and system stability. Developing advanced control algorithms and integrating them with plant-wide control systems is a complex task.

Maintenance and cleaning of PHEs in cogeneration plants can be challenging due to limited access and the need for minimal downtime. Innovative cleaning methods and PHE designs that facilitate easy maintenance are required to ensure consistent performance and reduce operational costs.

Lastly, the integration of PHEs with other cogeneration plant components, such as turbines, boilers, and cooling systems, presents system-level challenges. Optimizing the overall plant efficiency while considering the interdependencies between various subsystems requires a holistic approach to design and operation.

Material selection is another critical challenge in PHE integration. The heat transfer surfaces must withstand corrosive fluids, thermal cycling, and mechanical stresses while maintaining high thermal efficiency. Advanced materials such as titanium, high-grade stainless steel, or specialized alloys may be required, increasing costs and complexity.

Fouling and scaling pose significant operational challenges for PHEs in cogeneration plants. The accumulation of deposits on heat transfer surfaces can severely reduce thermal efficiency and increase pressure drop. Developing effective fouling mitigation strategies and designing PHEs with enhanced anti-fouling properties is crucial for maintaining long-term performance.

Flow distribution and maldistribution within PHEs can lead to reduced heat transfer efficiency and increased pressure drop. Achieving uniform flow across the entire heat transfer area is particularly challenging in large-scale cogeneration applications, where high flow rates and complex fluid dynamics are involved.

Thermal expansion and mechanical stress management present another set of challenges. The frequent thermal cycling in cogeneration plants can cause fatigue and potential failure of PHE components. Designing flexible mounting systems and implementing proper stress analysis are essential to ensure the longevity of the equipment.

Control and optimization of PHEs in dynamic cogeneration systems pose significant challenges. Rapid load changes and varying operating conditions require sophisticated control strategies to maintain optimal heat transfer efficiency and system stability. Developing advanced control algorithms and integrating them with plant-wide control systems is a complex task.

Maintenance and cleaning of PHEs in cogeneration plants can be challenging due to limited access and the need for minimal downtime. Innovative cleaning methods and PHE designs that facilitate easy maintenance are required to ensure consistent performance and reduce operational costs.

Lastly, the integration of PHEs with other cogeneration plant components, such as turbines, boilers, and cooling systems, presents system-level challenges. Optimizing the overall plant efficiency while considering the interdependencies between various subsystems requires a holistic approach to design and operation.

Current PHE Solutions

01 Improved plate design for heat exchangers

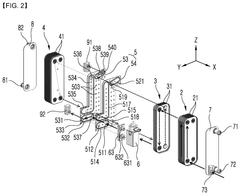

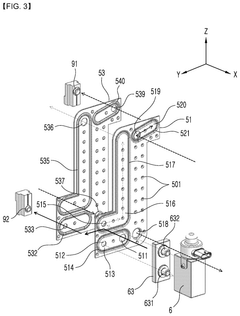

Advanced plate designs enhance heat transfer efficiency and fluid distribution in plate heat exchangers. These designs may include optimized corrugation patterns, innovative plate shapes, or specialized surface treatments to improve thermal performance and reduce fouling.- Improved plate design for heat exchangers: Advanced plate designs are being developed to enhance the efficiency of heat exchangers. These designs focus on optimizing flow distribution, reducing pressure drop, and increasing heat transfer rates. Innovations include specialized corrugation patterns, strategic placement of flow channels, and improved plate geometries to maximize surface area for heat exchange.

- Novel sealing mechanisms for plate heat exchangers: New sealing technologies are being implemented to improve the reliability and performance of plate heat exchangers. These innovations aim to prevent leakage, enhance durability, and allow for easier maintenance. Developments include advanced gasket materials, improved sealing techniques, and novel plate edge designs that ensure better sealing under various operating conditions.

- Integration of phase change materials in plate heat exchangers: Researchers are exploring the incorporation of phase change materials (PCMs) into plate heat exchangers to enhance thermal energy storage and improve overall system efficiency. This innovation allows for better temperature control, increased heat transfer rates during peak loads, and improved energy management in various applications.

- Modular and customizable plate heat exchanger designs: Manufacturers are developing modular and customizable plate heat exchanger designs to meet specific industry needs. These designs allow for easy scaling, quick assembly, and flexibility in configuration. The modular approach enables better adaptation to various applications, from small-scale residential use to large industrial processes.

- Advanced materials for plate heat exchangers: New materials are being utilized in the construction of plate heat exchangers to improve corrosion resistance, thermal conductivity, and overall performance. These materials include advanced alloys, composites, and surface treatments that can withstand harsh operating conditions while maintaining high heat transfer efficiency.

02 Sealing and gasket innovations

Novel sealing and gasket technologies improve the reliability and performance of plate heat exchangers. These innovations may include advanced materials, unique gasket designs, or improved sealing methods to prevent leaks and enhance overall system integrity.Expand Specific Solutions03 Modular and customizable configurations

Modular designs allow for easy customization and scalability of plate heat exchangers. These configurations enable adaptability to various applications, simplified maintenance, and the ability to adjust capacity as needed.Expand Specific Solutions04 Enhanced flow distribution systems

Improved flow distribution systems optimize fluid flow within plate heat exchangers. These innovations may include advanced manifold designs, flow guides, or distribution channels to ensure uniform fluid distribution and maximize heat transfer efficiency.Expand Specific Solutions05 Integration of smart technologies

Incorporation of smart technologies and sensors in plate heat exchangers enables real-time monitoring, predictive maintenance, and performance optimization. These advancements may include IoT connectivity, advanced control systems, or self-diagnostic capabilities.Expand Specific Solutions

Key Industry Players

The integration of plate heat exchangers in cogeneration plants is at a mature stage, with a well-established market and proven technology. The global market for this application is substantial, driven by increasing demand for energy efficiency and sustainable power generation. Key players like Danfoss, Alfa Laval, and Kelvion dominate the market, offering advanced solutions. Emerging companies such as Haldor Topsøe and Osaka Gas are also making significant contributions, particularly in innovative designs and materials. The technology's maturity is evident in its widespread adoption across various industries, with ongoing research focusing on enhancing efficiency and reducing environmental impact.

Osaka Gas Co., Ltd.

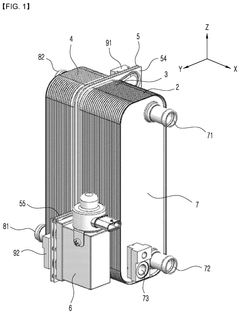

Technical Solution: Osaka Gas Co., Ltd. has developed an innovative plate heat exchanger integration system for cogeneration plants, focusing on optimizing heat recovery from exhaust gases. Their PHEs feature a unique plate material composition that enhances heat transfer while resisting high-temperature corrosion. Osaka Gas has implemented a modular design approach, allowing for easy expansion and maintenance of the heat exchanger system. The company's PHEs incorporate advanced flow distribution technology, ensuring uniform heat transfer across the entire plate surface. Osaka Gas has reported that their integrated PHE system can increase overall plant efficiency by up to 8% in combined heat and power applications[5].

Strengths: Specialized for exhaust gas heat recovery, modular design, and high-temperature corrosion resistance. Weaknesses: May be less versatile for other types of heat transfer applications in cogeneration plants.

Toshiba Corp.

Technical Solution: Toshiba Corp. has developed a compact, high-efficiency plate heat exchanger system for cogeneration plants. Their design incorporates advanced materials such as titanium alloys for improved corrosion resistance and longevity. Toshiba's PHEs feature a unique plate corrugation pattern that enhances turbulence and heat transfer while minimizing pressure drop. The company has also implemented a smart monitoring system that uses AI algorithms to optimize heat exchanger performance in real-time, potentially increasing overall plant efficiency by up to 5%[3]. Toshiba's PHEs are designed to handle a wide range of working fluids, including those with high viscosity, making them versatile for various cogeneration applications.

Strengths: Advanced materials, innovative plate design, and smart monitoring system. Weaknesses: Potentially higher maintenance requirements due to complex technology.

PHE Core Innovations

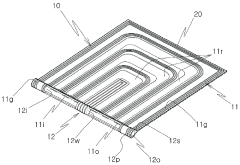

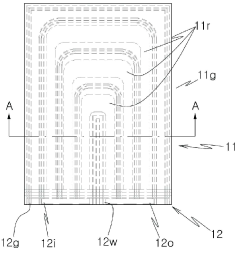

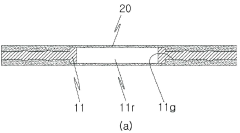

Plate heat exchanger integrated pipeline

PatentActiveKR1020170004736A

Innovation

- A flow path-integrated heat exchange plate with integrated flow paths on both sides and cover pouches, featuring a refrigerant inlet and discharge system, and a thermoplastic cover pouch for secure attachment, along with a heat transfer plate for enhanced heat transfer.

Integrated plate-type heat exchanger

PatentPendingUS20250003698A1

Innovation

- An integrated plate-type heat exchanger with a connecting plate unit that forms multiple refrigerant pathways between the condenser, internal heat exchanger, chiller, and expansion valve, reducing the need for lengthy piping and simplifying the assembly process while minimizing pressure drops.

Cogeneration Efficiency

Cogeneration efficiency is a critical factor in the overall performance and economic viability of combined heat and power (CHP) plants. The integration of plate heat exchangers in cogeneration systems has shown significant potential for improving overall plant efficiency. These compact and highly efficient heat transfer devices offer several advantages over traditional shell-and-tube heat exchangers, particularly in terms of heat recovery and thermal management.

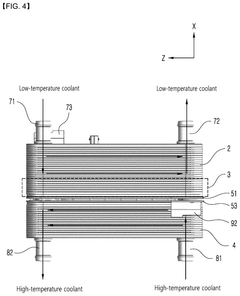

Plate heat exchangers contribute to enhanced cogeneration efficiency through their superior heat transfer capabilities. The design of these exchangers, featuring thin metal plates with corrugated patterns, creates turbulent flow and increases the surface area for heat transfer. This results in higher overall heat transfer coefficients compared to conventional heat exchangers, allowing for more effective heat recovery from both the primary energy source and waste heat streams.

The compact nature of plate heat exchangers also plays a crucial role in improving plant efficiency. Their smaller footprint and lower weight enable easier integration into existing cogeneration systems, reducing installation costs and space requirements. This compactness also translates to lower thermal inertia, allowing for quicker response times to load changes and improved system flexibility.

In cogeneration plants, plate heat exchangers can be strategically placed to optimize heat recovery at various stages of the process. For instance, they can be used to recover heat from engine exhaust gases, jacket water cooling systems, and lubricating oil circuits. This multi-stage heat recovery approach maximizes the utilization of available thermal energy, significantly boosting overall plant efficiency.

The ability of plate heat exchangers to operate with small temperature differences (approach temperatures) further enhances cogeneration efficiency. This characteristic allows for more effective utilization of low-grade heat sources, which might otherwise be wasted in systems using conventional heat exchangers. By capturing and utilizing this low-temperature heat, plate heat exchangers contribute to increased overall energy recovery and improved plant performance.

Moreover, the modular design of plate heat exchangers offers flexibility in capacity adjustment. This feature allows cogeneration plants to adapt to varying load demands more efficiently, maintaining optimal performance across a wide range of operating conditions. The ability to easily add or remove plates also facilitates maintenance and cleaning operations, ensuring sustained high efficiency over the plant's lifetime.

In conclusion, the integration of plate heat exchangers in cogeneration plants presents a promising approach to enhancing overall system efficiency. Their superior heat transfer capabilities, compact design, and operational flexibility contribute to improved energy recovery, reduced footprint, and increased adaptability to varying load conditions. As cogeneration technology continues to evolve, the role of plate heat exchangers in optimizing plant efficiency is likely to become increasingly significant, driving further innovations in CHP system design and operation.

Plate heat exchangers contribute to enhanced cogeneration efficiency through their superior heat transfer capabilities. The design of these exchangers, featuring thin metal plates with corrugated patterns, creates turbulent flow and increases the surface area for heat transfer. This results in higher overall heat transfer coefficients compared to conventional heat exchangers, allowing for more effective heat recovery from both the primary energy source and waste heat streams.

The compact nature of plate heat exchangers also plays a crucial role in improving plant efficiency. Their smaller footprint and lower weight enable easier integration into existing cogeneration systems, reducing installation costs and space requirements. This compactness also translates to lower thermal inertia, allowing for quicker response times to load changes and improved system flexibility.

In cogeneration plants, plate heat exchangers can be strategically placed to optimize heat recovery at various stages of the process. For instance, they can be used to recover heat from engine exhaust gases, jacket water cooling systems, and lubricating oil circuits. This multi-stage heat recovery approach maximizes the utilization of available thermal energy, significantly boosting overall plant efficiency.

The ability of plate heat exchangers to operate with small temperature differences (approach temperatures) further enhances cogeneration efficiency. This characteristic allows for more effective utilization of low-grade heat sources, which might otherwise be wasted in systems using conventional heat exchangers. By capturing and utilizing this low-temperature heat, plate heat exchangers contribute to increased overall energy recovery and improved plant performance.

Moreover, the modular design of plate heat exchangers offers flexibility in capacity adjustment. This feature allows cogeneration plants to adapt to varying load demands more efficiently, maintaining optimal performance across a wide range of operating conditions. The ability to easily add or remove plates also facilitates maintenance and cleaning operations, ensuring sustained high efficiency over the plant's lifetime.

In conclusion, the integration of plate heat exchangers in cogeneration plants presents a promising approach to enhancing overall system efficiency. Their superior heat transfer capabilities, compact design, and operational flexibility contribute to improved energy recovery, reduced footprint, and increased adaptability to varying load conditions. As cogeneration technology continues to evolve, the role of plate heat exchangers in optimizing plant efficiency is likely to become increasingly significant, driving further innovations in CHP system design and operation.

Environmental Impact

The integration of plate heat exchangers in cogeneration plants has significant environmental implications, both positive and negative. On the positive side, this technology contributes to improved energy efficiency and reduced greenhouse gas emissions. Cogeneration plants with plate heat exchangers can achieve higher overall energy efficiency by recovering waste heat that would otherwise be lost in conventional power generation systems. This increased efficiency translates to lower fuel consumption and, consequently, reduced carbon dioxide emissions per unit of energy produced.

Furthermore, the compact design of plate heat exchangers allows for smaller plant footprints, potentially reducing land use and associated environmental impacts. The modular nature of these exchangers also facilitates easier maintenance and replacement of components, which can lead to extended plant lifespans and reduced waste generation over time.

However, the environmental impact of plate heat exchanger integration is not without challenges. The manufacturing process of these exchangers, particularly the production of high-grade materials such as stainless steel or titanium, can have significant environmental footprints. The extraction and processing of these materials contribute to resource depletion and may involve energy-intensive processes that generate their own set of emissions.

Additionally, the use of certain working fluids or heat transfer media in plate heat exchangers may pose environmental risks. Some fluids, if leaked, can have detrimental effects on soil and water ecosystems. Proper handling, maintenance, and disposal protocols are crucial to mitigate these potential hazards.

The end-of-life management of plate heat exchangers also warrants consideration. While many components are recyclable, the process of separating and recycling the various materials used in these exchangers can be complex and energy-intensive. Developing efficient recycling technologies and implementing comprehensive waste management strategies are essential to minimize the environmental impact of decommissioned units.

In the context of water usage, plate heat exchangers in cogeneration plants can have both positive and negative effects. On one hand, their high efficiency can lead to reduced cooling water requirements compared to traditional heat exchange systems. On the other hand, in applications where water is used as the heat transfer medium, there may be concerns about water consumption and thermal pollution of water bodies used for cooling.

Overall, while the integration of plate heat exchangers in cogeneration plants offers substantial environmental benefits through increased energy efficiency and reduced emissions, a holistic approach is necessary to address and mitigate the potential negative impacts associated with their production, operation, and disposal. Continuous research and development efforts are needed to further enhance the environmental performance of these systems throughout their lifecycle.

Furthermore, the compact design of plate heat exchangers allows for smaller plant footprints, potentially reducing land use and associated environmental impacts. The modular nature of these exchangers also facilitates easier maintenance and replacement of components, which can lead to extended plant lifespans and reduced waste generation over time.

However, the environmental impact of plate heat exchanger integration is not without challenges. The manufacturing process of these exchangers, particularly the production of high-grade materials such as stainless steel or titanium, can have significant environmental footprints. The extraction and processing of these materials contribute to resource depletion and may involve energy-intensive processes that generate their own set of emissions.

Additionally, the use of certain working fluids or heat transfer media in plate heat exchangers may pose environmental risks. Some fluids, if leaked, can have detrimental effects on soil and water ecosystems. Proper handling, maintenance, and disposal protocols are crucial to mitigate these potential hazards.

The end-of-life management of plate heat exchangers also warrants consideration. While many components are recyclable, the process of separating and recycling the various materials used in these exchangers can be complex and energy-intensive. Developing efficient recycling technologies and implementing comprehensive waste management strategies are essential to minimize the environmental impact of decommissioned units.

In the context of water usage, plate heat exchangers in cogeneration plants can have both positive and negative effects. On one hand, their high efficiency can lead to reduced cooling water requirements compared to traditional heat exchange systems. On the other hand, in applications where water is used as the heat transfer medium, there may be concerns about water consumption and thermal pollution of water bodies used for cooling.

Overall, while the integration of plate heat exchangers in cogeneration plants offers substantial environmental benefits through increased energy efficiency and reduced emissions, a holistic approach is necessary to address and mitigate the potential negative impacts associated with their production, operation, and disposal. Continuous research and development efforts are needed to further enhance the environmental performance of these systems throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!