Impact of Nanotechnology on Plate Heat Exchanger Efficiency

Nanotechnology in Heat Exchange: Background and Objectives

Nanotechnology has emerged as a groundbreaking field with the potential to revolutionize various industries, including heat exchange technologies. The application of nanotechnology in plate heat exchangers represents a significant leap forward in enhancing energy efficiency and overall performance. This technological advancement builds upon decades of research in materials science and thermal engineering, aiming to address the growing demand for more efficient and compact heat transfer solutions.

The evolution of heat exchanger technology can be traced back to the early 20th century, with continuous improvements in design and materials. However, the introduction of nanotechnology in this domain marks a paradigm shift, offering unprecedented opportunities to optimize heat transfer at the molecular level. The primary objective of integrating nanotechnology into plate heat exchangers is to dramatically improve their efficiency, reduce their size, and enhance their overall performance in various applications.

Nanotechnology in heat exchange primarily focuses on two key areas: nanostructured surfaces and nanofluids. Nanostructured surfaces involve modifying the heat transfer surfaces at the nanoscale to increase the effective surface area and improve heat transfer coefficients. Nanofluids, on the other hand, are engineered colloidal suspensions of nanoparticles in base fluids, which exhibit enhanced thermophysical properties compared to conventional heat transfer fluids.

The development of nanotechnology in heat exchange is driven by several factors, including the need for more energy-efficient systems, the demand for compact and lightweight heat exchangers in various industries, and the push for sustainable technologies to reduce carbon footprints. As global energy consumption continues to rise, the importance of improving heat transfer efficiency becomes increasingly critical in addressing environmental concerns and resource conservation.

Current research in this field aims to overcome several challenges, such as the long-term stability of nanofluids, the scalability of nanostructured surface production, and the optimization of nanoparticle concentrations for maximum heat transfer enhancement. The ultimate goal is to develop plate heat exchangers that can achieve significantly higher heat transfer rates while maintaining or reducing pumping power requirements, thus leading to more energy-efficient and cost-effective systems across various applications.

As we delve deeper into the impact of nanotechnology on plate heat exchanger efficiency, it is essential to consider the multidisciplinary nature of this field, combining principles from physics, chemistry, materials science, and engineering. The ongoing research and development in this area promise to yield innovative solutions that could potentially transform industries ranging from HVAC systems and power generation to electronics cooling and chemical processing.

Market Analysis for Nanoenhanced Heat Exchangers

The market for nanoenhanced heat exchangers is experiencing significant growth, driven by the increasing demand for more efficient and compact thermal management solutions across various industries. The global plate heat exchanger market, which is a key segment for nanotechnology applications, was valued at approximately $5 billion in 2020 and is projected to reach $8 billion by 2026, with a compound annual growth rate (CAGR) of around 7%.

Nanotechnology's impact on plate heat exchanger efficiency has sparked considerable interest in industries such as power generation, chemical processing, HVAC, and automotive. The ability of nanoparticles to enhance thermal conductivity and heat transfer rates has led to the development of advanced nanofluids and nanocoatings, which are revolutionizing heat exchanger performance.

In the power generation sector, nanoenhanced heat exchangers are gaining traction due to their potential to improve overall plant efficiency. The market for these advanced heat exchangers in power plants is expected to grow at a CAGR of 9% from 2021 to 2026, as energy companies seek to reduce operational costs and meet stricter environmental regulations.

The chemical processing industry is another major adopter of nanoenhanced heat exchangers. With the need for precise temperature control in chemical reactions, the market for these advanced heat exchangers in this sector is forecasted to expand at a CAGR of 8% over the next five years. The improved efficiency and reduced fouling characteristics offered by nanotechnology are particularly valuable in this application.

In the HVAC industry, the adoption of nanoenhanced heat exchangers is driven by the push for energy-efficient buildings and stringent energy conservation standards. The market for these advanced heat exchangers in HVAC systems is expected to grow at a CAGR of 6% from 2021 to 2026, with a focus on reducing energy consumption and improving indoor air quality.

The automotive sector is also showing increased interest in nanoenhanced heat exchangers, particularly for electric vehicle (EV) thermal management systems. As the EV market expands, the demand for compact and efficient heat exchangers is rising. The market for nanoenhanced heat exchangers in the automotive industry is projected to grow at a CAGR of 12% over the next five years, outpacing other sectors.

Geographically, Asia-Pacific is expected to be the fastest-growing market for nanoenhanced heat exchangers, driven by rapid industrialization and increasing investments in energy-efficient technologies. North America and Europe follow closely, with strong demand from the chemical processing and power generation sectors.

Current Challenges in Plate Heat Exchanger Efficiency

Despite significant advancements in plate heat exchanger (PHE) technology, several challenges persist in achieving optimal efficiency. One of the primary issues is fouling, which occurs when deposits accumulate on heat transfer surfaces, reducing thermal conductivity and increasing pressure drop. This problem is particularly acute in applications involving high-temperature fluids or those with suspended particles.

Another challenge is the limitation of current materials used in PHE construction. While stainless steel and titanium are common choices, they have inherent thermal conductivity limitations that restrict heat transfer rates. Additionally, the corrosion resistance of these materials can be compromised in certain aggressive environments, leading to reduced lifespan and efficiency.

The design of flow channels presents another hurdle. Current geometries, while effective, still struggle to achieve an optimal balance between heat transfer enhancement and pressure drop minimization. This trade-off becomes more critical as industries demand higher efficiency and lower pumping costs.

Thermal stress and fatigue are significant concerns, especially in applications with frequent temperature fluctuations. The repeated expansion and contraction of PHE components can lead to mechanical failures, reducing overall system reliability and efficiency.

Scaling up PHEs for larger industrial applications poses challenges in maintaining uniform flow distribution across all plates. Maldistribution can result in reduced thermal performance and increased fouling in certain areas of the exchanger.

The limitations of current manufacturing techniques also impact PHE efficiency. Precision in plate corrugation patterns and port designs is crucial for optimal performance, but achieving consistent quality at scale remains challenging.

Energy efficiency in PHEs is further hampered by heat losses to the environment, particularly in high-temperature applications. Current insulation methods are often inadequate or impractical for certain designs.

Lastly, the complexity of fluid dynamics within PHEs makes accurate modeling and prediction of performance challenging. This limitation hinders the optimization process and can lead to suboptimal designs in real-world applications.

These challenges collectively represent significant barriers to improving PHE efficiency. Addressing them requires innovative approaches in materials science, design optimization, manufacturing techniques, and modeling capabilities. The integration of nanotechnology offers promising avenues for overcoming these limitations, potentially revolutionizing PHE performance across various industries.

Existing Nanotech Solutions for Heat Exchanger Efficiency

01 Plate design optimization

Improving plate heat exchanger efficiency through optimized plate designs. This includes modifications to plate geometry, corrugation patterns, and surface features to enhance heat transfer and reduce pressure drop. Advanced plate designs can increase turbulence, improve fluid distribution, and maximize heat transfer area.- Improved plate design for enhanced heat transfer: Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids. Advanced manufacturing techniques allow for optimized plate geometries that minimize pressure drop while maximizing heat transfer.

- Flow distribution optimization: Efficient flow distribution within the plate heat exchanger is crucial for maximizing heat transfer. This can be achieved through carefully designed inlet and outlet ports, as well as internal flow channels. Proper flow distribution ensures uniform fluid velocity across the plates, reducing dead zones and improving overall exchanger efficiency.

- Material selection for enhanced thermal conductivity: The choice of materials for plate construction plays a significant role in heat exchanger efficiency. High thermal conductivity materials, such as certain alloys or composite materials, can improve heat transfer rates. Additionally, surface treatments or coatings can be applied to plates to enhance their thermal properties and resistance to fouling.

- Gasket and sealing improvements: Advanced gasket designs and sealing technologies can significantly impact plate heat exchanger efficiency. Improved gaskets reduce the risk of leaks and allow for higher operating pressures, enabling more efficient heat transfer. Novel sealing methods can also contribute to better plate alignment and reduced thermal resistance between plates.

- Smart control systems for optimized performance: Integration of smart control systems and sensors can greatly enhance plate heat exchanger efficiency. These systems can monitor and adjust flow rates, temperatures, and pressures in real-time, ensuring optimal performance under varying conditions. Advanced algorithms can predict and prevent fouling, schedule maintenance, and optimize energy consumption.

02 Flow distribution enhancement

Enhancing flow distribution within plate heat exchangers to improve efficiency. This involves designing inlet and outlet manifolds, implementing flow guides, and optimizing channel configurations to ensure uniform fluid distribution across plates. Improved flow distribution reduces dead zones and enhances overall heat transfer performance.Expand Specific Solutions03 Material selection and coating

Selecting appropriate materials and applying specialized coatings to improve plate heat exchanger efficiency. This includes using high thermal conductivity materials, corrosion-resistant alloys, and advanced surface treatments to enhance heat transfer, reduce fouling, and extend equipment lifespan.Expand Specific Solutions04 Sealing and gasket improvements

Enhancing sealing mechanisms and gasket designs to minimize leakage and improve overall efficiency. This involves developing advanced gasket materials, optimizing gasket profiles, and implementing innovative sealing techniques to ensure proper fluid separation and prevent cross-contamination between channels.Expand Specific Solutions05 Multi-pass and hybrid configurations

Implementing multi-pass arrangements and hybrid configurations to enhance plate heat exchanger efficiency. This includes designing multi-pass flow patterns, combining different plate types within a single unit, and integrating additional heat transfer elements to optimize performance for specific applications and operating conditions.Expand Specific Solutions

Key Players in Nanoenhanced Heat Exchanger Industry

The impact of nanotechnology on plate heat exchanger efficiency is at an early stage of development, with significant potential for growth. The market size is expanding as industries recognize the benefits of nanotech-enhanced heat exchangers. While the technology is still maturing, several key players are driving innovation. Companies like LG Innotek, Alfa Laval, and Danfoss are investing in research and development to improve heat transfer efficiency using nanomaterials. Academic institutions such as Shandong University and South China University of Technology are collaborating with industry partners to advance the field. The competitive landscape is diverse, with both established manufacturers and emerging startups vying for market share in this promising sector.

Alfa Laval Corporate AB

South China University of Technology

Core Innovations in Nanomaterials for Heat Transfer

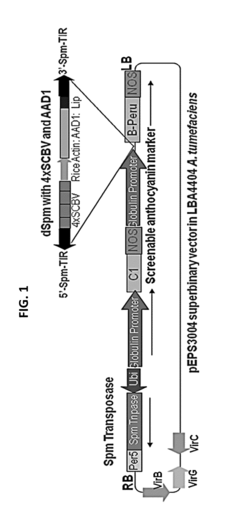

- An activation tagging platform using transposon technology is developed for maize, enabling transposons with enhancers to be mobilized to near-saturation levels in the maize genome, allowing for the discovery of genes affecting valuable traits by randomly upregulating genes and creating altered phenotypes.

Environmental Impact of Nanotech in Heat Exchangers

The integration of nanotechnology in plate heat exchangers has raised concerns about potential environmental impacts. As these advanced heat exchangers become more prevalent in industrial applications, it is crucial to assess their ecological footprint throughout their lifecycle. Nanoparticles used in heat transfer fluids or surface coatings may pose risks to ecosystems if released into the environment during manufacturing, operation, or disposal.

One primary concern is the potential for nanoparticle leaching from heat exchanger systems. Although nanomaterials are typically embedded in coatings or suspended in fluids, there is a risk of gradual release over time. This could lead to the accumulation of nanoparticles in water systems or soil, potentially affecting aquatic life and terrestrial ecosystems. The long-term effects of such accumulation are not yet fully understood, necessitating ongoing research and monitoring.

The production of nanomaterials for heat exchanger applications also raises environmental considerations. The synthesis of nanoparticles often requires energy-intensive processes and the use of potentially hazardous chemicals. This could contribute to increased carbon emissions and chemical waste if not properly managed. However, it is important to note that the improved efficiency of nanotech-enhanced heat exchangers may offset these impacts by reducing overall energy consumption in industrial processes.

End-of-life disposal of nanotech-enhanced heat exchangers presents another environmental challenge. The presence of nanomaterials may complicate recycling processes or require specialized disposal methods to prevent environmental contamination. This highlights the need for developing appropriate recycling and disposal protocols specifically tailored to nanotech-enhanced equipment.

On the positive side, the increased efficiency of nanotech-enhanced heat exchangers can lead to significant environmental benefits. By improving heat transfer rates and reducing energy consumption, these advanced systems can contribute to lower greenhouse gas emissions in various industries. This aligns with global efforts to combat climate change and promote sustainable industrial practices.

Furthermore, the enhanced durability and corrosion resistance offered by nanotech coatings may extend the lifespan of heat exchangers. This could reduce the frequency of replacements, thereby decreasing the overall material consumption and associated environmental impacts of manufacturing new equipment.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments of nanotech-enhanced heat exchangers. These studies should consider the environmental impacts from raw material extraction to final disposal, providing a holistic view of their ecological footprint. Such assessments will be crucial in guiding the development of more sustainable nanotechnology applications in heat exchange systems and informing regulatory frameworks to mitigate potential environmental risks.

Scalability and Cost Analysis of Nanotech Solutions

The scalability and cost analysis of nanotechnology solutions for plate heat exchangers is a critical consideration in determining the feasibility of widespread adoption. As nanotechnology advances, the potential for enhancing heat exchanger efficiency through nanostructured surfaces or nanofluid coolants becomes increasingly promising. However, the scalability of these solutions from laboratory settings to industrial applications presents significant challenges.

One of the primary concerns in scaling up nanotech solutions is the consistency of nanomaterial production. Maintaining uniform quality and properties of nanoparticles or nanostructures at larger scales can be problematic. This inconsistency may lead to variations in performance across different batches or units, potentially negating the efficiency gains observed in smaller-scale experiments.

The manufacturing processes for nanotech-enhanced heat exchangers also face scalability issues. Current methods for creating nanostructured surfaces or integrating nanomaterials into heat exchanger designs may not be suitable for mass production. Developing new manufacturing techniques that can maintain nanoscale precision while accommodating high-volume production is essential for widespread implementation.

Cost considerations play a crucial role in the viability of nanotech solutions. While the potential efficiency gains are significant, the initial investment required for research, development, and implementation of nanotechnology in heat exchangers can be substantial. The cost of raw materials, specialized equipment, and skilled labor needed for nanomaterial production and integration must be carefully weighed against the long-term energy savings and performance improvements.

Moreover, the lifecycle costs of nanotech-enhanced heat exchangers need to be evaluated. This includes not only the initial manufacturing costs but also maintenance, potential replacement of nanostructured components, and end-of-life disposal or recycling considerations. The environmental impact and safety concerns associated with nanomaterials must also be factored into the overall cost analysis.

Despite these challenges, there are promising avenues for improving scalability and reducing costs. Advances in nanomaterial synthesis techniques, such as continuous-flow processes, offer the potential for more efficient and cost-effective production at scale. Additionally, the development of hybrid solutions that combine conventional materials with strategic use of nanotechnology may provide a balance between performance enhancement and economic viability.

As the field progresses, economies of scale are likely to play a significant role in reducing costs. Increased demand for nanotech solutions in heat exchangers could drive down production costs and stimulate further innovation in manufacturing processes. Collaborative efforts between research institutions and industry partners may also accelerate the development of scalable and cost-effective solutions, paving the way for broader adoption of nanotechnology in plate heat exchanger applications.