Innovative Materials Used in Plate Heat Exchanger Construction

PHE Material Evolution

The evolution of materials used in plate heat exchanger (PHE) construction has been a critical factor in advancing the efficiency and performance of these essential industrial components. Initially, PHEs were primarily constructed using stainless steel, which offered good corrosion resistance and thermal conductivity. However, as industrial processes became more demanding, the need for materials that could withstand higher temperatures, pressures, and corrosive environments grew.

In the 1970s and 1980s, titanium began to gain popularity in PHE construction, particularly in applications involving seawater or other highly corrosive fluids. Titanium's excellent corrosion resistance and strength-to-weight ratio made it an ideal choice for marine and chemical processing industries. This marked a significant step forward in PHE material evolution, enabling the technology to be applied in more challenging environments.

The 1990s saw the introduction of nickel alloys, such as Hastelloy and Inconel, in PHE construction. These materials offered superior resistance to both high temperatures and corrosive media, further expanding the application range of PHEs in industries such as petrochemicals and pharmaceuticals. The use of these advanced alloys allowed for the design of more compact and efficient heat exchangers capable of operating under extreme conditions.

As environmental concerns and energy efficiency became more prominent in the 2000s, the focus shifted towards developing materials that could enhance heat transfer while reducing the overall size and weight of PHEs. This led to the exploration of copper alloys and aluminum for certain applications, leveraging their high thermal conductivity properties. However, these materials were limited to less corrosive environments due to their susceptibility to chemical attack.

In recent years, the advent of advanced manufacturing techniques, such as 3D printing and powder metallurgy, has opened up new possibilities in PHE material selection and design. These technologies have enabled the creation of complex geometries and the use of novel materials, including metal matrix composites and high-entropy alloys. These innovative materials offer a combination of properties that were previously unattainable, such as high strength, excellent thermal conductivity, and superior corrosion resistance.

The latest frontier in PHE material evolution involves the development of nanomaterials and surface coatings. Researchers are exploring the potential of graphene and carbon nanotubes to enhance heat transfer properties when incorporated into traditional PHE materials. Additionally, advanced ceramic coatings are being developed to improve corrosion resistance and reduce fouling, addressing two of the most persistent challenges in PHE operation.

Market Demand Analysis

The market demand for innovative materials in plate heat exchanger construction has been steadily increasing due to the growing need for more efficient and durable heat transfer solutions across various industries. This demand is primarily driven by the rising focus on energy efficiency, sustainability, and cost-effectiveness in industrial processes.

In the chemical and petrochemical sectors, there is a significant push for materials that can withstand harsh operating conditions, including high temperatures and corrosive environments. This has led to a surge in demand for advanced alloys and composite materials that offer superior resistance to chemical degradation while maintaining excellent heat transfer properties.

The food and beverage industry, another major consumer of plate heat exchangers, is seeking materials that meet stringent hygiene standards while also providing enhanced thermal efficiency. This has created a market for innovative, food-grade materials that are easy to clean and resistant to fouling, thereby reducing maintenance costs and improving overall operational efficiency.

In the HVAC sector, the trend towards more compact and energy-efficient systems has fueled the demand for materials that can facilitate higher heat transfer rates in smaller form factors. This has led to increased interest in materials with improved thermal conductivity and reduced thickness, allowing for the design of more compact and efficient plate heat exchangers.

The renewable energy sector, particularly in applications such as geothermal power plants and solar thermal systems, has also contributed to the growing demand for innovative materials. These applications often require materials that can withstand extreme temperature fluctuations and maintain performance over extended periods, driving research into advanced ceramics and metal-matrix composites.

The global market for plate heat exchangers is expected to grow significantly in the coming years, with a corresponding increase in demand for innovative materials. This growth is attributed to the expanding industrial base in developing economies, stringent environmental regulations promoting energy-efficient technologies, and the ongoing modernization of existing industrial infrastructure in developed countries.

As industries continue to prioritize operational efficiency and sustainability, the market for innovative materials in plate heat exchanger construction is likely to expand further. This presents significant opportunities for material scientists and manufacturers to develop and commercialize novel solutions that address the evolving needs of various sectors, potentially reshaping the landscape of heat transfer technology.

Current Material Challenges

Plate heat exchangers (PHEs) have become increasingly popular in various industries due to their high efficiency and compact design. However, the materials used in their construction face several challenges that limit their performance and longevity. One of the primary issues is corrosion resistance, particularly in aggressive environments such as seawater desalination or chemical processing. Traditional materials like stainless steel and titanium, while offering good corrosion resistance, may not be sufficient for extreme conditions or prolonged exposure.

Another significant challenge is fouling, which occurs when deposits accumulate on the heat transfer surfaces, reducing efficiency and increasing maintenance costs. Current materials often lack inherent anti-fouling properties, necessitating frequent cleaning and downtime. This issue is particularly prevalent in applications involving high-temperature fluids or those with high mineral content.

Thermal conductivity is a crucial factor in PHE performance, and existing materials often struggle to balance heat transfer efficiency with other desirable properties such as corrosion resistance and mechanical strength. This limitation can result in suboptimal heat exchange rates and increased energy consumption.

Mechanical strength and durability pose additional challenges, especially in high-pressure applications or those subject to thermal cycling. The thin plates used in PHEs must withstand significant stress without deformation or failure, which can be difficult to achieve with current materials while maintaining other essential properties.

Cost-effectiveness is an ongoing concern in material selection for PHEs. High-performance materials that address the aforementioned challenges often come at a premium, making them economically unfeasible for widespread adoption. This creates a need for innovative materials that can offer superior performance at competitive prices.

Environmental sustainability is becoming increasingly important in material selection. Many current materials used in PHEs are not easily recyclable or have a significant environmental footprint in their production. This challenge is driving research into more eco-friendly alternatives that maintain or improve upon the performance of traditional materials.

Lastly, the ability to customize material properties for specific applications remains limited. Different industries and processes require varying combinations of properties, and current materials often represent a compromise rather than an optimal solution. The development of tailored materials that can be fine-tuned for specific operating conditions and requirements is a significant challenge facing the PHE industry.

Existing Material Solutions

01 Stainless steel plates

Stainless steel is a common material used in plate heat exchangers due to its corrosion resistance, durability, and thermal conductivity. It is suitable for a wide range of applications, including food processing, chemical industries, and HVAC systems.- Stainless steel plates: Stainless steel is a common material used in plate heat exchangers due to its excellent corrosion resistance, durability, and heat transfer properties. It is suitable for a wide range of applications, including food processing, chemical industries, and HVAC systems.

- Titanium plates: Titanium plates are used in plate heat exchangers for applications requiring high corrosion resistance, especially in seawater and aggressive chemical environments. Titanium offers excellent heat transfer efficiency and longevity in harsh conditions.

- Composite materials: Composite materials, such as carbon fiber reinforced polymers or metal matrix composites, are being explored for use in plate heat exchangers. These materials offer advantages like lightweight construction, improved thermal conductivity, and resistance to corrosion and fouling.

- Copper and copper alloys: Copper and its alloys are used in plate heat exchangers for applications requiring high thermal conductivity and antimicrobial properties. These materials are particularly suitable for HVAC systems, refrigeration, and some food processing applications.

- Surface treatments and coatings: Various surface treatments and coatings are applied to plate heat exchanger materials to enhance their performance. These treatments can improve corrosion resistance, reduce fouling, increase heat transfer efficiency, and extend the lifespan of the heat exchanger plates.

02 Titanium plates

Titanium plates are used in plate heat exchangers for applications requiring high corrosion resistance, such as seawater cooling systems or processes involving aggressive chemicals. Titanium offers excellent heat transfer properties and longevity in harsh environments.Expand Specific Solutions03 Polymer-based materials

Polymer-based materials, such as polypropylene or PVDF, are used in plate heat exchangers for low-temperature applications or when chemical compatibility is crucial. These materials offer good corrosion resistance and are lightweight compared to metal alternatives.Expand Specific Solutions04 Composite materials

Composite materials, combining metals and polymers or ceramics, are being developed for plate heat exchangers to enhance performance and durability. These materials can offer improved heat transfer efficiency, reduced fouling, and increased chemical resistance.Expand Specific Solutions05 Surface treatments and coatings

Various surface treatments and coatings are applied to plate heat exchanger materials to improve their performance and longevity. These treatments can enhance corrosion resistance, reduce fouling, and improve heat transfer efficiency. Examples include electropolishing, passivation, and specialized anti-fouling coatings.Expand Specific Solutions

Key Industry Players

The research on innovative materials for plate heat exchanger construction is in a dynamic phase, with significant market growth potential. The global plate heat exchanger market is expanding due to increasing demand in various industries, including HVAC, chemical, and food processing. Key players like Alfa Laval, Vahterus, and SWEP are driving technological advancements, focusing on materials that enhance heat transfer efficiency and durability. The technology's maturity varies, with established companies like Alfa Laval leading in traditional materials, while newer entrants such as Extek Energy Equipment and Zhejiang Sanhua Intelligent Controls are exploring novel materials and designs. Academic institutions like Shandong University and South China University of Technology are contributing to research, indicating a collaborative ecosystem for innovation in this field.

Alfa Laval Corporate AB

Vahterus Oy

Core Material Innovations

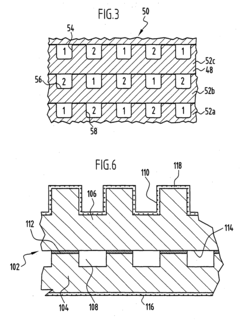

- The heat-exchanger plates are produced from a conventional material like steel and selectively coated with a higher-grade, corrosion-resistant material only in regions that come into contact with aggressive media, such as high-alloy steels, titanium, or tantalum, using methods like aluminization or soldering, to enhance corrosion resistance without the need for the entire plate to be made of expensive materials.

- The use of short-fiber-reinforced ceramic composite materials, such as C/C-SiC, with channels formed in plates made of silicon carbide or silicon nitride, and an anti-corrosion layer like cordierite or yttrium silicate, which reduces brittleness and provides high-temperature resistance and corrosion protection.

Environmental Impact

The environmental impact of plate heat exchangers (PHEs) is a critical consideration in their design and material selection. Innovative materials used in PHE construction can significantly reduce the environmental footprint of these devices throughout their lifecycle.

One of the primary environmental benefits of using advanced materials in PHEs is the potential for improved energy efficiency. High-performance materials with enhanced thermal conductivity can facilitate more effective heat transfer, reducing the energy required for heating or cooling processes. This increased efficiency translates to lower energy consumption and, consequently, reduced greenhouse gas emissions associated with power generation.

Durability and corrosion resistance of innovative materials also contribute to environmental sustainability. Materials that can withstand harsh operating conditions and resist degradation extend the lifespan of PHEs, reducing the frequency of replacements and the associated environmental costs of manufacturing and disposal. This longevity minimizes waste generation and conserves resources that would otherwise be used in producing replacement units.

The use of lightweight materials in PHE construction can have cascading environmental benefits. Reduced weight translates to lower transportation costs and emissions during shipping and installation. Additionally, lighter PHEs may require less structural support, potentially reducing the overall material requirements for the entire system.

Innovative materials can also address environmental concerns related to fluid leakage. Advanced polymer composites or metal alloys with superior sealing properties can minimize the risk of leaks, preventing the release of potentially harmful fluids into the environment. This is particularly crucial in applications involving hazardous or environmentally sensitive materials.

Recyclability and end-of-life considerations are increasingly important aspects of material selection for PHEs. Materials that can be easily recycled or repurposed at the end of their useful life contribute to a circular economy approach, reducing the demand for virgin resources and minimizing waste sent to landfills.

Some innovative materials used in PHE construction may have inherently lower environmental impact in their production processes. For example, bio-based polymers or materials derived from recycled sources can reduce the carbon footprint associated with raw material extraction and processing.

In conclusion, the environmental impact of innovative materials in PHE construction extends beyond the operational phase to encompass the entire lifecycle of the equipment. By considering factors such as energy efficiency, durability, weight reduction, leak prevention, recyclability, and production processes, manufacturers can develop PHEs that not only perform better but also contribute to broader environmental sustainability goals.

Cost-Benefit Analysis

The cost-benefit analysis of innovative materials in plate heat exchanger construction reveals a complex interplay of factors that influence both initial investments and long-term operational efficiency. Advanced materials, such as titanium alloys and high-performance polymers, often come with higher upfront costs compared to traditional stainless steel. However, these materials offer significant advantages in terms of heat transfer efficiency, corrosion resistance, and overall lifespan of the equipment.

Initial material costs for innovative options can be 30-50% higher than conventional choices. This price premium is primarily due to the specialized manufacturing processes and limited availability of these advanced materials. However, the enhanced properties of these materials translate into tangible benefits that can offset the initial investment over time.

Improved heat transfer efficiency is a key advantage of innovative materials. Some advanced polymers and metal alloys can increase heat transfer rates by up to 20-25% compared to standard stainless steel plates. This improvement in efficiency directly impacts operational costs, reducing energy consumption and potentially lowering utility expenses by 15-20% annually.

Corrosion resistance is another critical factor in the cost-benefit equation. Innovative materials like titanium alloys or certain high-performance polymers exhibit superior resistance to a wide range of corrosive media. This property extends the operational life of heat exchangers by 2-3 times compared to traditional materials, significantly reducing replacement and maintenance costs over the equipment's lifetime.

The lightweight nature of some advanced materials, particularly engineered polymers, offers additional benefits. Reduced weight can lead to savings in transportation and installation costs, which can be substantial for large industrial applications. Moreover, the lighter weight allows for easier handling during maintenance procedures, potentially reducing labor costs and downtime.

When considering the total cost of ownership, innovative materials often present a more favorable long-term economic proposition. While the initial investment may be higher, the combination of improved efficiency, reduced maintenance, and extended lifespan can result in a return on investment within 3-5 years, depending on the specific application and operating conditions.

Environmental considerations also play a role in the cost-benefit analysis. The increased efficiency and longevity of heat exchangers constructed with innovative materials contribute to reduced energy consumption and less frequent replacements. This aligns with sustainability goals and may provide additional value in terms of regulatory compliance and corporate social responsibility initiatives.