Advancing Energy Efficiency With Tungsten Technologies

Tungsten Tech Evolution

Tungsten technologies have undergone significant evolution since their inception, marking key milestones in the pursuit of enhanced energy efficiency. The journey began in the late 19th century with the invention of the incandescent light bulb, where tungsten filaments revolutionized lighting technology. This marked the first major application of tungsten in energy-related fields, setting the stage for future advancements.

In the mid-20th century, tungsten found its way into more sophisticated applications, particularly in the realm of high-temperature materials. The development of tungsten alloys and composites led to improved performance in turbine blades, rocket nozzles, and other components exposed to extreme heat. These advancements significantly boosted the efficiency of power generation systems and aerospace technologies.

The late 20th century saw a shift towards nanotechnology, with researchers exploring the potential of tungsten nanostructures. This period witnessed the emergence of tungsten nanoparticles and nanowires, opening up new possibilities for energy storage and conversion. Concurrently, tungsten's role in nuclear fusion research gained prominence, with its high melting point and low sputtering yield making it an ideal material for plasma-facing components in fusion reactors.

The turn of the millennium brought about a renewed focus on tungsten in photovoltaic applications. Researchers began investigating tungsten oxide as a potential material for solar cells, aiming to harness its unique optical and electrical properties. This period also saw advancements in tungsten-based thermoelectric materials, exploring ways to convert waste heat into useful electricity.

In recent years, the evolution of tungsten technologies has accelerated, driven by the urgent need for more sustainable energy solutions. One significant development has been the refinement of tungsten disulfide (WS2) for energy storage applications. This two-dimensional material has shown promise in improving the performance of lithium-ion batteries and supercapacitors, potentially revolutionizing energy storage systems.

Another notable advancement has been the integration of tungsten in advanced nuclear reactor designs. Generation IV reactor concepts, such as molten salt reactors, are exploring the use of tungsten alloys to withstand the corrosive environments and high temperatures inherent in these systems. This application could significantly enhance the safety and efficiency of future nuclear power plants.

The most recent frontier in tungsten technology evolution lies in its application to quantum computing and spintronics. Researchers are investigating tungsten diselenide (WSe2) and other tungsten-based materials for their potential in creating more efficient quantum bits (qubits) and spintronic devices. These developments could lead to breakthroughs in ultra-low power computing and communication technologies, further advancing energy efficiency across various sectors.

Energy Efficiency Demand

The global demand for energy efficiency has been steadily increasing in recent years, driven by a combination of environmental concerns, economic pressures, and regulatory requirements. As industries and governments worldwide strive to reduce carbon emissions and combat climate change, the focus on energy-efficient technologies has intensified. This trend is particularly evident in sectors such as manufacturing, construction, transportation, and consumer electronics.

In the manufacturing sector, there is a growing need for energy-efficient processes and equipment to reduce operational costs and meet sustainability targets. Companies are increasingly investing in advanced technologies that can optimize energy consumption without compromising productivity. This includes the adoption of smart manufacturing systems, energy-efficient motors, and improved insulation materials.

The construction industry is experiencing a surge in demand for energy-efficient building materials and designs. With the rise of green building standards and regulations, there is a pressing need for technologies that can enhance the thermal performance of structures, reduce heat loss, and improve overall energy efficiency. This has led to increased interest in advanced insulation materials, energy-efficient lighting systems, and smart building management technologies.

In the transportation sector, the push for energy efficiency is driving innovation in vehicle design and propulsion systems. The automotive industry is witnessing a shift towards electric and hybrid vehicles, as well as the development of more fuel-efficient internal combustion engines. This trend extends to other modes of transportation, including aviation and shipping, where there is a growing demand for lightweight materials and more efficient propulsion technologies.

Consumer electronics represent another significant area of energy efficiency demand. As the number of electronic devices in households and offices continues to grow, there is an increasing focus on reducing their energy consumption. This has led to the development of more efficient display technologies, power management systems, and energy-saving modes in various electronic products.

The industrial sector, particularly in energy-intensive industries such as steel production, chemical manufacturing, and power generation, is also experiencing a strong demand for energy-efficient solutions. These industries are exploring advanced materials and processes that can significantly reduce energy consumption and improve overall efficiency.

Government policies and regulations play a crucial role in driving the demand for energy efficiency. Many countries have implemented stringent energy efficiency standards and incentives to encourage the adoption of energy-saving technologies. This regulatory landscape is creating new market opportunities for innovative energy-efficient solutions across various sectors.

Tungsten Tech Challenges

Tungsten technologies face several significant challenges in advancing energy efficiency. One of the primary obstacles is the high melting point of tungsten, which, while beneficial for many applications, complicates manufacturing processes and increases energy consumption during production. This characteristic necessitates specialized equipment and techniques, often leading to higher costs and environmental concerns.

Another challenge lies in the limited ductility of tungsten at room temperature, making it difficult to form into complex shapes required for certain energy-efficient applications. This brittleness can result in reduced durability and potential failure under stress, limiting its use in some dynamic energy systems.

The development of tungsten alloys and composites to enhance its properties presents its own set of challenges. Balancing the need for improved ductility and formability while maintaining tungsten's inherent strength and heat resistance requires extensive research and testing. Additionally, ensuring the compatibility of these new materials with existing manufacturing processes and end-use applications adds another layer of complexity.

Recycling and sustainability pose significant challenges in the tungsten industry. The high energy requirements for processing tungsten, coupled with the difficulty in separating it from other materials in end-of-life products, create obstacles for establishing efficient recycling systems. This issue is particularly pressing as the demand for tungsten in energy-efficient technologies continues to grow.

The scarcity and geopolitical concentration of tungsten resources present strategic challenges. With China dominating global tungsten production, concerns about supply chain stability and price volatility affect long-term planning and investment in tungsten-based energy efficiency technologies.

Lastly, the development of alternative materials that could potentially replace tungsten in certain applications poses a competitive challenge. Research into materials with similar properties but lower production costs or improved sustainability profiles could disrupt the tungsten market and necessitate continuous innovation in tungsten technologies to maintain their relevance in energy efficiency applications.

Current Tungsten Solutions

01 Energy-efficient tungsten lighting technologies

Advancements in tungsten-based lighting technologies focus on improving energy efficiency. This includes developing new filament designs, optimizing gas mixtures in bulbs, and enhancing thermal management to reduce energy loss. These innovations aim to increase the luminous efficacy of tungsten lamps while maintaining their warm light characteristics.- Energy-efficient tungsten lighting technologies: Advancements in tungsten-based lighting technologies focus on improving energy efficiency. This includes developing new filament designs, optimizing gas mixtures in bulbs, and enhancing heat management to reduce energy loss. These innovations aim to increase the luminous efficacy of tungsten lamps while maintaining their warm light characteristics.

- Tungsten-based energy storage systems: Tungsten's high melting point and durability make it suitable for energy storage applications. Research is being conducted on tungsten-based electrodes for batteries and supercapacitors, as well as thermal energy storage systems. These technologies aim to improve energy density, charge-discharge efficiency, and overall system longevity.

- Energy-efficient tungsten processing methods: Developing more energy-efficient methods for tungsten extraction, refining, and processing is crucial for reducing the overall energy footprint of tungsten production. This includes optimizing ore beneficiation techniques, improving reduction processes, and implementing advanced recycling methods to minimize energy consumption in the tungsten industry.

- Tungsten-based thermoelectric materials: Research on tungsten-based thermoelectric materials aims to improve energy efficiency by converting waste heat into electricity. These materials can be used in various applications, including automotive exhaust systems and industrial processes, to recover waste heat and increase overall energy efficiency.

- Energy-efficient tungsten thin film technologies: Advancements in tungsten thin film deposition techniques focus on improving energy efficiency in various applications, such as microelectronics and solar cells. This includes developing low-temperature deposition methods, optimizing film thickness, and enhancing the electrical and thermal properties of tungsten thin films to reduce energy consumption in devices.

02 Tungsten-based energy storage systems

Tungsten is being explored for use in energy storage applications due to its high melting point and durability. Research is focused on developing tungsten-based electrodes for batteries and supercapacitors, as well as using tungsten compounds in thermal energy storage systems. These technologies aim to improve energy density and cycle life in energy storage devices.Expand Specific Solutions03 Tungsten in energy-efficient manufacturing processes

Innovations in tungsten-based manufacturing processes are aimed at reducing energy consumption in industrial applications. This includes developing more efficient sintering techniques for tungsten parts, optimizing tungsten recycling processes, and improving tungsten coating methods for wear-resistant components. These advancements contribute to overall energy savings in various industries.Expand Specific Solutions04 Tungsten alloys for high-temperature energy applications

Research is focused on developing tungsten alloys that can withstand extreme temperatures while maintaining their properties. These alloys are being explored for use in high-temperature energy applications such as nuclear fusion reactors, advanced gas turbines, and concentrated solar power systems. The goal is to improve energy efficiency and durability in these demanding environments.Expand Specific Solutions05 Energy-efficient tungsten processing and recycling

Efforts are being made to improve the energy efficiency of tungsten processing and recycling methods. This includes developing new extraction techniques, optimizing purification processes, and enhancing recycling technologies to recover tungsten from scrap materials. These advancements aim to reduce the overall energy footprint of tungsten production and promote sustainable use of this valuable resource.Expand Specific Solutions

Key Tungsten Tech Players

The advancement of energy efficiency through tungsten technologies is currently in a growth phase, with increasing market size and technological maturity. The global tungsten market is projected to expand significantly, driven by demand in various industries. Technological maturity varies across applications, with companies like Applied Materials, Inc., Xiamen Tungsten Co., Ltd., and Toshiba Corp. leading in innovation. Central South University and Jiangxi University of Science & Technology contribute to academic research, while companies such as Chongyi Zhangyuan Tungsten Co., Ltd. and Jiangwu H.C. Starck Tungsten Products Co., Ltd. focus on production and application. The competitive landscape is diverse, with players from different sectors collaborating to push the boundaries of tungsten technology for enhanced energy efficiency.

Applied Materials, Inc.

Chongyi Zhangyuan Tungsten Co., Ltd.

Tungsten Tech Innovations

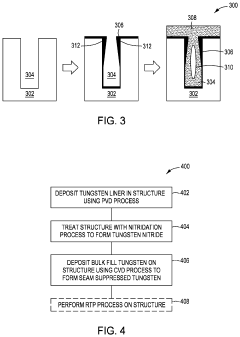

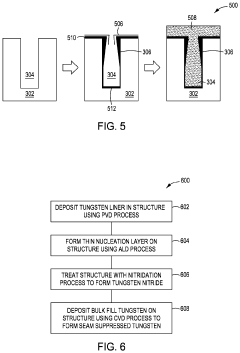

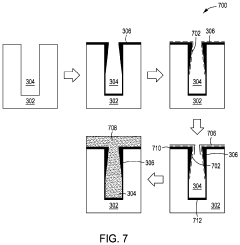

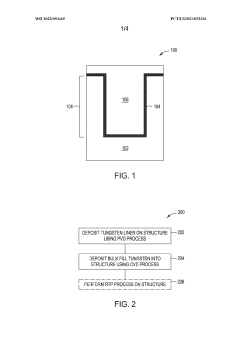

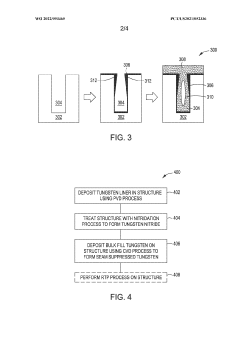

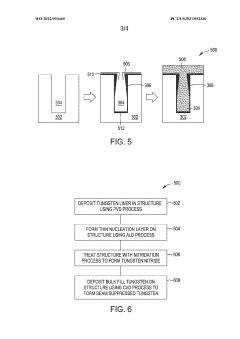

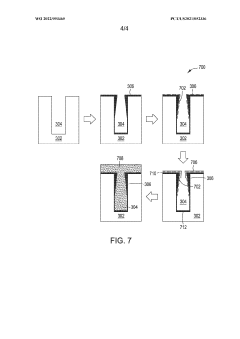

- The proposed method involves a physical vapor deposition of a tungsten liner, followed by an atomic layer deposition nucleation layer and a chemical vapor deposition bulk fill process, with a nitridation step and optional rapid thermal processing to reduce internal stresses and lower resistivity, using argon or krypton as ambient gases and optimizing temperature, pressure, and nitridation conditions.

- The method involves depositing a tungsten liner using physical vapor deposition, followed by a nitridation process and bulk fill tungsten using chemical vapor deposition, with optional rapid thermal processing to reduce internal stresses and lower resistivity, while eliminating boron to prevent adhesion issues.

Environmental Impact

Tungsten technologies have significant potential to advance energy efficiency, but their environmental impact must be carefully considered. The production and use of tungsten-based products can have both positive and negative effects on the environment.

On the positive side, tungsten's durability and high melting point make it an excellent material for energy-efficient applications. Tungsten filaments in light bulbs, for instance, have contributed to the development of more efficient lighting solutions. LED lights, which often incorporate tungsten, consume significantly less energy than traditional incandescent bulbs, leading to reduced electricity consumption and lower carbon emissions.

In industrial applications, tungsten's hardness and heat resistance allow for the creation of more efficient cutting tools and machinery parts. This increased efficiency translates to reduced energy consumption in manufacturing processes, ultimately lowering the overall environmental footprint of industrial operations.

However, the environmental impact of tungsten mining and processing cannot be overlooked. Tungsten extraction often involves open-pit mining, which can lead to habitat destruction and soil erosion. The mining process also requires substantial amounts of water and energy, potentially straining local resources and contributing to greenhouse gas emissions.

Furthermore, the refining of tungsten ore produces waste materials that may contain harmful substances. Proper management of these byproducts is crucial to prevent soil and water contamination. Some tungsten mining operations have been associated with acid mine drainage, which can have long-lasting negative effects on local ecosystems.

Recycling tungsten products presents an opportunity to mitigate some of these environmental concerns. Tungsten's recyclability is relatively high, and the recycling process typically requires less energy than primary production. Encouraging the development of efficient recycling technologies and implementing robust recycling programs can help reduce the demand for new tungsten extraction, thereby lessening the environmental impact of the industry.

As tungsten technologies continue to advance, it is essential to prioritize sustainable practices throughout the entire lifecycle of tungsten products. This includes implementing more environmentally friendly mining techniques, optimizing processing methods to reduce waste and energy consumption, and designing products with end-of-life recycling in mind. By balancing the energy efficiency benefits of tungsten technologies with responsible environmental stewardship, the industry can work towards a more sustainable future.

Tungsten Supply Chain

The tungsten supply chain plays a crucial role in advancing energy efficiency technologies. Tungsten, known for its high melting point and exceptional strength, is a key component in various energy-efficient applications. The supply chain for this strategic metal involves several stages, from mining to processing and distribution.

Primary tungsten deposits are geographically concentrated, with China dominating global production. Other significant producers include Vietnam, Russia, and Bolivia. This concentration of resources presents potential supply risks and geopolitical challenges for countries relying on tungsten imports.

The extraction process begins with mining tungsten ores, primarily wolframite and scheelite. These ores undergo beneficiation to increase tungsten content before being processed into intermediate products like ammonium paratungstate (APT) or tungsten oxide. Further refining yields tungsten metal powder or tungsten carbide, which are essential for manufacturing energy-efficient components.

Recycling plays an increasingly important role in the tungsten supply chain, helping to mitigate supply risks and reduce environmental impact. Scrap tungsten from various sources, including used cutting tools and spent catalysts, is collected and reprocessed to recover valuable tungsten content.

The global tungsten market is influenced by factors such as industrial demand, technological advancements, and geopolitical tensions. Price fluctuations can significantly impact the supply chain, affecting everything from mining operations to end-product manufacturing.

As energy efficiency becomes a greater priority worldwide, the demand for tungsten in applications such as LED lighting, more efficient turbines, and advanced electronics is expected to grow. This increasing demand underscores the importance of a robust and diversified tungsten supply chain.

Efforts to improve the sustainability of the tungsten supply chain are ongoing. These include developing more efficient extraction and processing technologies, increasing recycling rates, and exploring alternative sources of tungsten. Additionally, there is a growing focus on ensuring responsible sourcing practices throughout the supply chain, addressing environmental and social concerns associated with tungsten mining and processing.