Ammonia Fuel and Environmental Impact: A Lifecycle Perspective

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Evolution and Research Objectives

Ammonia has emerged as a promising alternative fuel in the global pursuit of decarbonization and sustainable energy solutions. The evolution of ammonia as a fuel source can be traced back to the early 20th century, with its first applications in internal combustion engines during World War II due to petroleum shortages. However, it wasn't until the early 2000s that serious research into ammonia as a carbon-free energy carrier gained momentum, driven by growing concerns about climate change and the need for clean energy alternatives.

The technical evolution of ammonia fuel has progressed through several distinct phases. Initially, research focused on ammonia's direct use in combustion engines, facing challenges related to ignition properties and combustion efficiency. The second phase, beginning around 2010, saw increased interest in ammonia as a hydrogen carrier, leveraging existing infrastructure for storage and transport while overcoming hydrogen's inherent storage challenges. The current phase emphasizes ammonia's role in a comprehensive energy system, including its production from renewable electricity, integration with existing power systems, and use in various applications from shipping to power generation.

Recent technological breakthroughs have significantly enhanced ammonia's viability as a fuel. Advancements in catalyst technology have improved the efficiency of both ammonia synthesis and decomposition processes. Novel combustion technologies have addressed previous limitations in ammonia's combustion properties, while innovations in fuel cell technology have opened pathways for direct electricity generation from ammonia without combustion.

The primary research objectives in this field now center on several key areas. First, developing green ammonia production methods that utilize renewable energy sources to eliminate carbon emissions from the synthesis process. Second, enhancing ammonia's combustion properties through advanced engine designs and fuel additives to improve efficiency and reduce NOx emissions. Third, advancing ammonia cracking technologies to efficiently release hydrogen at point of use.

Additionally, research aims to optimize ammonia fuel cells for direct electricity generation and develop comprehensive lifecycle assessment methodologies to accurately quantify environmental impacts across the entire ammonia fuel value chain. These objectives collectively support the overarching goal of establishing ammonia as a viable, sustainable energy carrier that can contribute significantly to global decarbonization efforts while minimizing environmental impacts throughout its lifecycle.

The technical evolution of ammonia fuel has progressed through several distinct phases. Initially, research focused on ammonia's direct use in combustion engines, facing challenges related to ignition properties and combustion efficiency. The second phase, beginning around 2010, saw increased interest in ammonia as a hydrogen carrier, leveraging existing infrastructure for storage and transport while overcoming hydrogen's inherent storage challenges. The current phase emphasizes ammonia's role in a comprehensive energy system, including its production from renewable electricity, integration with existing power systems, and use in various applications from shipping to power generation.

Recent technological breakthroughs have significantly enhanced ammonia's viability as a fuel. Advancements in catalyst technology have improved the efficiency of both ammonia synthesis and decomposition processes. Novel combustion technologies have addressed previous limitations in ammonia's combustion properties, while innovations in fuel cell technology have opened pathways for direct electricity generation from ammonia without combustion.

The primary research objectives in this field now center on several key areas. First, developing green ammonia production methods that utilize renewable energy sources to eliminate carbon emissions from the synthesis process. Second, enhancing ammonia's combustion properties through advanced engine designs and fuel additives to improve efficiency and reduce NOx emissions. Third, advancing ammonia cracking technologies to efficiently release hydrogen at point of use.

Additionally, research aims to optimize ammonia fuel cells for direct electricity generation and develop comprehensive lifecycle assessment methodologies to accurately quantify environmental impacts across the entire ammonia fuel value chain. These objectives collectively support the overarching goal of establishing ammonia as a viable, sustainable energy carrier that can contribute significantly to global decarbonization efforts while minimizing environmental impacts throughout its lifecycle.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth driven by the urgent need for decarbonization across various sectors. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to expand at a compound annual growth rate of 5.3% through 2030, reaching an estimated $93.6 billion. This growth trajectory is primarily attributed to ammonia's potential as a carbon-free energy carrier with high energy density and established production infrastructure.

The transportation sector represents the most promising market segment, particularly maritime shipping which accounts for nearly 3% of global greenhouse gas emissions. Major shipping companies including Maersk, NYK Line, and COSCO have initiated pilot projects to test ammonia-powered vessels, with the first commercial ammonia-fueled ships expected to enter service by 2025. Industry analysts predict that ammonia could capture up to 25% of the marine fuel market by 2050.

Power generation constitutes another substantial market opportunity, with ammonia co-firing in existing coal plants gaining traction as a transitional technology. Japan leads this development with JERA implementing a 20% ammonia co-firing rate at the Hekinan thermal power plant, aiming to achieve 100% ammonia firing by 2030. Similar initiatives are underway in South Korea, Australia, and parts of Europe, collectively representing a potential market of $15 billion by 2028.

Regional market distribution shows Asia-Pacific dominating with 42% market share, driven by aggressive decarbonization policies in Japan, South Korea, and increasingly China. Europe follows at 28%, with particular interest from Scandinavian countries and Germany. North America represents 18% of the market, with growth accelerating following recent policy initiatives like the Inflation Reduction Act in the United States.

Market barriers include high production costs, with green ammonia currently priced at $600-900 per ton compared to $200-300 for conventional ammonia. Infrastructure limitations present another challenge, as specialized storage, transportation, and bunkering facilities require significant investment estimated at $30-50 billion globally by 2035.

Customer segments show varying adoption timelines, with early adopters including shipping companies under regulatory pressure, utilities seeking to reduce emissions from existing assets, and industrial users with high-temperature process heat requirements. Mass market adoption is expected to accelerate after 2030 when production scale and technology improvements are projected to bring costs within 15% of conventional alternatives.

The transportation sector represents the most promising market segment, particularly maritime shipping which accounts for nearly 3% of global greenhouse gas emissions. Major shipping companies including Maersk, NYK Line, and COSCO have initiated pilot projects to test ammonia-powered vessels, with the first commercial ammonia-fueled ships expected to enter service by 2025. Industry analysts predict that ammonia could capture up to 25% of the marine fuel market by 2050.

Power generation constitutes another substantial market opportunity, with ammonia co-firing in existing coal plants gaining traction as a transitional technology. Japan leads this development with JERA implementing a 20% ammonia co-firing rate at the Hekinan thermal power plant, aiming to achieve 100% ammonia firing by 2030. Similar initiatives are underway in South Korea, Australia, and parts of Europe, collectively representing a potential market of $15 billion by 2028.

Regional market distribution shows Asia-Pacific dominating with 42% market share, driven by aggressive decarbonization policies in Japan, South Korea, and increasingly China. Europe follows at 28%, with particular interest from Scandinavian countries and Germany. North America represents 18% of the market, with growth accelerating following recent policy initiatives like the Inflation Reduction Act in the United States.

Market barriers include high production costs, with green ammonia currently priced at $600-900 per ton compared to $200-300 for conventional ammonia. Infrastructure limitations present another challenge, as specialized storage, transportation, and bunkering facilities require significant investment estimated at $30-50 billion globally by 2035.

Customer segments show varying adoption timelines, with early adopters including shipping companies under regulatory pressure, utilities seeking to reduce emissions from existing assets, and industrial users with high-temperature process heat requirements. Mass market adoption is expected to accelerate after 2030 when production scale and technology improvements are projected to bring costs within 15% of conventional alternatives.

Ammonia Fuel Technology: Current Status and Barriers

Ammonia fuel technology currently faces several significant barriers despite its promising potential as a carbon-free energy carrier. The most fundamental challenge lies in ammonia production, which predominantly relies on the Haber-Bosch process—an energy-intensive method requiring high temperatures (400-500°C) and pressures (100-200 bar). This conventional production pathway accounts for approximately 1-2% of global energy consumption and generates substantial CO2 emissions, estimated at 1.8 tons of CO2 per ton of ammonia produced.

Technical barriers in ammonia utilization as a fuel are equally challenging. Ammonia's low flame speed, high ignition energy, and narrow flammability limits make direct combustion difficult in conventional engines and turbines. Current combustion systems require significant modifications or dual-fuel approaches to maintain stable operation. Additionally, ammonia's toxicity necessitates robust safety systems and specialized handling protocols, increasing system complexity and cost.

Infrastructure limitations present another major obstacle. The existing ammonia distribution network primarily serves agricultural applications and is not optimized for energy applications. Expanding this infrastructure to support widespread fuel use would require substantial investment in storage facilities, transportation systems, and refueling stations designed to handle ammonia's specific properties safely.

Material compatibility issues further complicate implementation. Ammonia's corrosive nature demands specialized materials for storage tanks, pipelines, and fuel system components. Standard metals like copper, brass, and zinc-containing alloys are particularly vulnerable to ammonia-induced corrosion, necessitating the use of stainless steel or specific polymers that increase system costs.

Economic barriers remain perhaps the most significant impediment to widespread adoption. Green ammonia production using renewable electricity for electrolysis remains 2-3 times more expensive than conventional methods. The levelized cost of ammonia as a fuel currently exceeds that of fossil alternatives, making market penetration difficult without substantial policy support or carbon pricing mechanisms.

Regulatory frameworks and standards for ammonia as an energy carrier are still underdeveloped in most regions. This regulatory uncertainty creates additional barriers for potential investors and technology developers, slowing commercialization efforts. The lack of harmonized safety standards, emissions regulations, and certification procedures specifically addressing ammonia fuel applications further complicates market development.

Public perception and acceptance represent a final but crucial barrier. Concerns about ammonia's toxicity and odor may create resistance to its adoption in consumer applications, particularly in transportation sectors where public interaction is unavoidable. Addressing these concerns through education, demonstration projects, and robust safety protocols will be essential for successful market introduction.

Technical barriers in ammonia utilization as a fuel are equally challenging. Ammonia's low flame speed, high ignition energy, and narrow flammability limits make direct combustion difficult in conventional engines and turbines. Current combustion systems require significant modifications or dual-fuel approaches to maintain stable operation. Additionally, ammonia's toxicity necessitates robust safety systems and specialized handling protocols, increasing system complexity and cost.

Infrastructure limitations present another major obstacle. The existing ammonia distribution network primarily serves agricultural applications and is not optimized for energy applications. Expanding this infrastructure to support widespread fuel use would require substantial investment in storage facilities, transportation systems, and refueling stations designed to handle ammonia's specific properties safely.

Material compatibility issues further complicate implementation. Ammonia's corrosive nature demands specialized materials for storage tanks, pipelines, and fuel system components. Standard metals like copper, brass, and zinc-containing alloys are particularly vulnerable to ammonia-induced corrosion, necessitating the use of stainless steel or specific polymers that increase system costs.

Economic barriers remain perhaps the most significant impediment to widespread adoption. Green ammonia production using renewable electricity for electrolysis remains 2-3 times more expensive than conventional methods. The levelized cost of ammonia as a fuel currently exceeds that of fossil alternatives, making market penetration difficult without substantial policy support or carbon pricing mechanisms.

Regulatory frameworks and standards for ammonia as an energy carrier are still underdeveloped in most regions. This regulatory uncertainty creates additional barriers for potential investors and technology developers, slowing commercialization efforts. The lack of harmonized safety standards, emissions regulations, and certification procedures specifically addressing ammonia fuel applications further complicates market development.

Public perception and acceptance represent a final but crucial barrier. Concerns about ammonia's toxicity and odor may create resistance to its adoption in consumer applications, particularly in transportation sectors where public interaction is unavoidable. Addressing these concerns through education, demonstration projects, and robust safety protocols will be essential for successful market introduction.

Current Ammonia Production and Utilization Methods

01 Ammonia as a carbon-free fuel alternative

Ammonia is being explored as a carbon-free alternative fuel that can help reduce greenhouse gas emissions. Unlike fossil fuels, ammonia combustion does not produce carbon dioxide, making it a promising option for addressing climate change concerns. When used as a fuel, ammonia can be burned directly or used in fuel cells, offering versatility in various applications including power generation and transportation.- Ammonia as a carbon-free fuel alternative: Ammonia is being explored as a carbon-free alternative fuel that can help reduce greenhouse gas emissions. Unlike fossil fuels, ammonia combustion does not produce carbon dioxide, making it a promising option for addressing climate change concerns. When used in power generation or as a transportation fuel, ammonia can significantly lower the carbon footprint compared to conventional fuels, contributing to environmental sustainability goals.

- Ammonia production and environmental considerations: While ammonia fuel itself produces zero carbon emissions when burned, its production process can have significant environmental impacts. Traditional ammonia production relies heavily on natural gas and generates substantial CO2 emissions. Green ammonia production methods using renewable energy sources for hydrogen generation via electrolysis are being developed to address this issue, creating a truly sustainable fuel cycle from production to consumption.

- Ammonia fuel infrastructure and safety considerations: Implementing ammonia as a fuel requires addressing infrastructure and safety challenges. Ammonia is toxic and corrosive, necessitating specialized handling, storage, and transportation systems. Environmental risk assessments must consider potential ammonia leaks and their impact on ecosystems and human health. Developing proper safety protocols and infrastructure modifications is essential to minimize environmental risks associated with widespread ammonia fuel adoption.

- Ammonia in maritime and transportation applications: Ammonia shows particular promise as an alternative fuel for maritime applications and heavy transportation, sectors that are difficult to decarbonize. Ships and heavy-duty vehicles powered by ammonia can significantly reduce sulfur oxides, nitrogen oxides, and particulate matter emissions compared to conventional marine fuels and diesel. This application could substantially improve air quality in port cities and along shipping routes, addressing both climate change and local pollution concerns.

- Life cycle assessment and economic impact of ammonia fuel: Comprehensive life cycle assessments of ammonia as a fuel reveal both environmental benefits and challenges. These assessments consider emissions and environmental impacts from production, transportation, storage, and end-use. Economic analyses evaluate the cost-effectiveness of ammonia compared to other alternative fuels and traditional fossil fuels. Understanding these factors is crucial for policy development and investment decisions that support environmentally beneficial energy transitions.

02 Ammonia production and environmental considerations

While ammonia fuel itself produces zero carbon emissions during combustion, its production process can have significant environmental impacts. Traditional ammonia production relies on the Haber-Bosch process, which is energy-intensive and typically uses natural gas as feedstock, resulting in substantial carbon emissions. Developing green ammonia production methods using renewable energy sources for hydrogen production and nitrogen separation is crucial for maximizing the environmental benefits of ammonia as a fuel.Expand Specific Solutions03 Ammonia fuel infrastructure and safety considerations

Implementing ammonia as a widespread fuel requires addressing infrastructure and safety challenges. Ammonia is toxic and corrosive, necessitating specialized handling, storage, and transportation systems. Safety protocols must be established to mitigate risks associated with ammonia leaks or spills. Additionally, retrofitting existing energy infrastructure or developing new systems compatible with ammonia fuel presents both technical and economic challenges that impact its environmental footprint.Expand Specific Solutions04 Ammonia in maritime and transportation applications

Ammonia shows particular promise as an alternative fuel for maritime transportation, which is a significant source of global emissions. Ships powered by ammonia could substantially reduce the environmental impact of shipping. Research is also exploring ammonia's potential in other transportation sectors, including as a hydrogen carrier for fuel cell vehicles. These applications could help reduce dependence on fossil fuels and decrease overall transportation-related emissions.Expand Specific Solutions05 Life cycle assessment and economic viability of ammonia fuel

Comprehensive life cycle assessments of ammonia fuel are essential for understanding its true environmental impact. These assessments consider emissions and resource use across the entire value chain, from production to end use. The economic viability of ammonia as a fuel alternative depends on production costs, infrastructure development, and policy incentives. Carbon pricing mechanisms and environmental regulations can significantly influence the competitiveness of ammonia compared to conventional fuels.Expand Specific Solutions

Leading Organizations in Ammonia Fuel Research

The ammonia fuel market is currently in an early growth phase, characterized by increasing research and development activities across academia and industry. The market size is expanding as ammonia gains recognition as a potential zero-carbon fuel alternative, particularly for hard-to-decarbonize sectors like maritime shipping and heavy transport. Companies like AMOGY, Yara International, and FuelCell Energy are leading technological innovation, while major shipbuilders including HD Hyundai Heavy Industries, Samsung Heavy Industries, and CSSC Huangpu Wenchong are developing ammonia-powered vessels. Academic institutions such as MIT and research organizations like Commonwealth Scientific & Industrial Research Organisation are advancing fundamental research on ammonia combustion efficiency and emissions reduction. The technology remains in development stage with commercial deployment beginning in targeted applications, requiring further advancements in safety, infrastructure, and cost-effectiveness.

AMOGY, Inc.

Technical Solution: AMOGY has pioneered an innovative ammonia-to-power technology platform focused on mobile applications, particularly targeting the transportation sector. Their proprietary system employs a highly efficient ammonia cracking technology that converts ammonia to hydrogen at significantly lower temperatures (around 450°C versus traditional 850°C), reducing energy requirements by approximately 30%. The system integrates a compact ammonia cracker with PEM fuel cells to generate electricity, creating a complete power solution with zero carbon emissions during operation. AMOGY's technology addresses the full lifecycle by incorporating ammonia as an energy carrier that can be produced from renewable sources, transported using existing infrastructure, and converted efficiently to power. Their system achieves energy density approximately three times higher than compressed hydrogen and enables faster refueling compared to battery electric solutions. The company has successfully demonstrated their technology in various vehicles including tractors, trucks, and maritime vessels, proving the viability of ammonia as a practical alternative fuel across multiple transportation modes.

Strengths: High energy density solution compared to batteries or compressed hydrogen; leverages existing ammonia infrastructure; modular and scalable system design suitable for various applications. Weaknesses: Requires development of specialized cracking and purification components; potential ammonia toxicity concerns requiring robust safety systems; dependence on upstream green ammonia production to achieve full lifecycle benefits.

HD Hyundai Heavy Industries Co., Ltd.

Technical Solution: HD Hyundai Heavy Industries has developed advanced ammonia-powered marine propulsion systems specifically designed for large ocean-going vessels. Their technology centers on dual-fuel engines capable of operating on both conventional marine fuels and ammonia, with ammonia combustion rates reaching up to 70% in their latest designs. The system incorporates specialized fuel handling equipment, including cryogenic storage tanks maintaining ammonia at -33°C, vapor handling systems, and proprietary injection technology that optimizes combustion efficiency while minimizing slip (unburned ammonia). Their lifecycle approach includes onboard exhaust gas treatment systems specifically designed to capture and neutralize NOx emissions, which can be higher with ammonia combustion. HD Hyundai has conducted extensive material compatibility testing to address ammonia's corrosive properties, developing specialized alloys and coatings for fuel system components. The company has secured approval in principle from major classification societies for their ammonia-ready vessel designs and is currently constructing the world's first large ammonia-powered container vessels, scheduled for delivery by 2025.

Strengths: Extensive marine engineering expertise; practical dual-fuel approach allowing gradual transition; comprehensive safety systems addressing ammonia's hazardous properties. Weaknesses: Incomplete combustion challenges leading to potential ammonia slip; higher NOx emissions requiring additional treatment systems; significant vessel retrofitting costs for existing fleet.

Key Patents and Innovations in Ammonia Fuel Systems

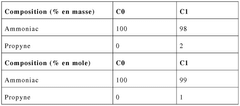

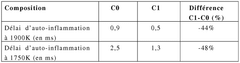

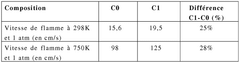

Fuel or combustible substance composition comprising ammonia and at least one alkyne

PatentWO2024218445A1

Innovation

- A fuel composition comprising ammonia and 0.01% to 20% by mass of C3 to C12 alkynes, which significantly reduces autoignition time, increases flame speed, and enhances combustion efficiency without the need for large hydrogen reserves or fossil fuels.

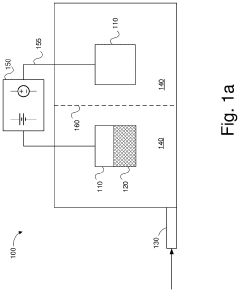

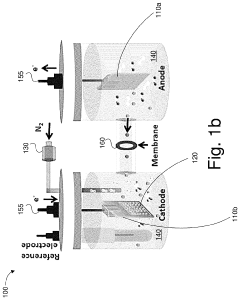

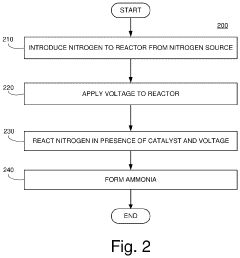

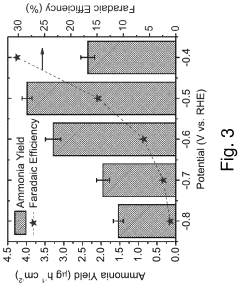

Systems and methods for forming nitrogen-based compounds

PatentActiveUS11885029B2

Innovation

- A system comprising an anode, cathode, and catalyst material with nanoparticles having interior cavities, configured to use nitrogen and water to generate ammonia, utilizing electrocatalytic fixation of nitrogen under ambient conditions with a voltage supply and electrolyte to enhance yield and Faradaic efficiency.

Lifecycle Assessment Methodologies for Ammonia Fuel

Lifecycle Assessment Methodologies for Ammonia Fuel

The comprehensive evaluation of ammonia as a sustainable fuel alternative necessitates robust lifecycle assessment (LCA) methodologies that capture its environmental impacts from production to end-use. Current LCA frameworks for ammonia fuel typically follow ISO 14040 and 14044 standards, which provide structured approaches for inventory analysis, impact assessment, and interpretation phases.

Traditional LCA methodologies for ammonia fuel focus on four key environmental impact categories: global warming potential (GWP), acidification potential, eutrophication potential, and energy resource depletion. These assessments typically employ a cradle-to-grave boundary that encompasses feedstock extraction, ammonia synthesis, transportation, storage, and combustion or utilization in fuel cells.

The Well-to-Wheel (WTW) analysis represents a specialized LCA approach particularly relevant for ammonia fuel applications. This methodology divides the assessment into Well-to-Tank (production and distribution) and Tank-to-Wheel (utilization) phases, enabling more targeted identification of environmental hotspots within the fuel lifecycle. Recent methodological advances have incorporated dynamic modeling to account for temporal variations in emissions and environmental impacts.

Consequential LCA approaches have emerged as particularly valuable for ammonia fuel assessment, as they consider market-mediated effects and potential displacement of conventional fuels. This methodology provides insights into broader system-level impacts that might be overlooked in attributional approaches, including land-use change implications and economic ripple effects across industrial sectors.

Methodological challenges persist in ammonia fuel LCAs, particularly regarding system boundary definition, allocation procedures for co-products, and data quality issues. The Haber-Bosch process, central to conventional ammonia production, presents particular complexity for accurate modeling due to its energy-intensive nature and variable energy sources across global production facilities.

Harmonization efforts are underway to standardize ammonia fuel LCA methodologies, with organizations like the International Energy Agency (IEA) and Ammonia Energy Association developing sector-specific guidelines. These initiatives aim to improve comparability between studies and establish consistent metrics for environmental performance evaluation across different ammonia production pathways and end-use applications.

Advanced LCA methodologies increasingly incorporate social and economic dimensions through Life Cycle Sustainability Assessment (LCSA) frameworks, providing more holistic evaluation of ammonia fuel systems. These approaches integrate environmental LCA with social life cycle assessment (S-LCA) and life cycle costing (LCC) to capture broader sustainability implications beyond environmental impacts alone.

The comprehensive evaluation of ammonia as a sustainable fuel alternative necessitates robust lifecycle assessment (LCA) methodologies that capture its environmental impacts from production to end-use. Current LCA frameworks for ammonia fuel typically follow ISO 14040 and 14044 standards, which provide structured approaches for inventory analysis, impact assessment, and interpretation phases.

Traditional LCA methodologies for ammonia fuel focus on four key environmental impact categories: global warming potential (GWP), acidification potential, eutrophication potential, and energy resource depletion. These assessments typically employ a cradle-to-grave boundary that encompasses feedstock extraction, ammonia synthesis, transportation, storage, and combustion or utilization in fuel cells.

The Well-to-Wheel (WTW) analysis represents a specialized LCA approach particularly relevant for ammonia fuel applications. This methodology divides the assessment into Well-to-Tank (production and distribution) and Tank-to-Wheel (utilization) phases, enabling more targeted identification of environmental hotspots within the fuel lifecycle. Recent methodological advances have incorporated dynamic modeling to account for temporal variations in emissions and environmental impacts.

Consequential LCA approaches have emerged as particularly valuable for ammonia fuel assessment, as they consider market-mediated effects and potential displacement of conventional fuels. This methodology provides insights into broader system-level impacts that might be overlooked in attributional approaches, including land-use change implications and economic ripple effects across industrial sectors.

Methodological challenges persist in ammonia fuel LCAs, particularly regarding system boundary definition, allocation procedures for co-products, and data quality issues. The Haber-Bosch process, central to conventional ammonia production, presents particular complexity for accurate modeling due to its energy-intensive nature and variable energy sources across global production facilities.

Harmonization efforts are underway to standardize ammonia fuel LCA methodologies, with organizations like the International Energy Agency (IEA) and Ammonia Energy Association developing sector-specific guidelines. These initiatives aim to improve comparability between studies and establish consistent metrics for environmental performance evaluation across different ammonia production pathways and end-use applications.

Advanced LCA methodologies increasingly incorporate social and economic dimensions through Life Cycle Sustainability Assessment (LCSA) frameworks, providing more holistic evaluation of ammonia fuel systems. These approaches integrate environmental LCA with social life cycle assessment (S-LCA) and life cycle costing (LCC) to capture broader sustainability implications beyond environmental impacts alone.

Policy Frameworks for Ammonia in Energy Transition

The global transition to sustainable energy systems requires robust policy frameworks to guide the adoption of alternative fuels like ammonia. Current policy landscapes for ammonia as an energy carrier vary significantly across regions, with some nations taking proactive approaches while others remain in early development stages.

Japan stands as a frontrunner with its Strategic Roadmap for Hydrogen and Ammonia, which explicitly targets ammonia co-firing in coal power plants and establishes clear milestones for ammonia utilization through 2050. The European Union has integrated ammonia into its broader hydrogen strategy through the European Green Deal, focusing on ammonia's role in energy storage and as a hydrogen carrier, supported by carbon pricing mechanisms and the Emissions Trading System.

In the United States, policy support has been more fragmented, though recent legislation including the Inflation Reduction Act provides significant tax incentives for clean hydrogen production, indirectly benefiting ammonia production pathways. Australia has positioned itself strategically through its National Hydrogen Strategy, which specifically addresses ammonia export opportunities.

Regulatory frameworks addressing safety standards, transportation protocols, and emissions monitoring for ammonia fuel systems remain underdeveloped in most jurisdictions. This regulatory gap presents a significant barrier to widespread adoption and requires urgent attention from policymakers.

Financial incentives represent another critical policy lever, with various mechanisms being deployed including production tax credits, capital grants for infrastructure development, and carbon pricing schemes that enhance the competitiveness of low-carbon ammonia against conventional fuels. The effectiveness of these incentives varies considerably based on design and implementation.

International collaboration frameworks are emerging to standardize ammonia fuel specifications, harmonize regulations, and facilitate global trade. Notable examples include the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and bilateral agreements between potential ammonia exporting and importing nations.

Policy recommendations for accelerating ammonia's role in energy transition include establishing technology-neutral carbon pricing mechanisms, developing dedicated ammonia fuel standards, creating regulatory sandboxes for pilot projects, implementing lifecycle assessment requirements for emissions accounting, and fostering international cooperation on infrastructure development and trade protocols.

Japan stands as a frontrunner with its Strategic Roadmap for Hydrogen and Ammonia, which explicitly targets ammonia co-firing in coal power plants and establishes clear milestones for ammonia utilization through 2050. The European Union has integrated ammonia into its broader hydrogen strategy through the European Green Deal, focusing on ammonia's role in energy storage and as a hydrogen carrier, supported by carbon pricing mechanisms and the Emissions Trading System.

In the United States, policy support has been more fragmented, though recent legislation including the Inflation Reduction Act provides significant tax incentives for clean hydrogen production, indirectly benefiting ammonia production pathways. Australia has positioned itself strategically through its National Hydrogen Strategy, which specifically addresses ammonia export opportunities.

Regulatory frameworks addressing safety standards, transportation protocols, and emissions monitoring for ammonia fuel systems remain underdeveloped in most jurisdictions. This regulatory gap presents a significant barrier to widespread adoption and requires urgent attention from policymakers.

Financial incentives represent another critical policy lever, with various mechanisms being deployed including production tax credits, capital grants for infrastructure development, and carbon pricing schemes that enhance the competitiveness of low-carbon ammonia against conventional fuels. The effectiveness of these incentives varies considerably based on design and implementation.

International collaboration frameworks are emerging to standardize ammonia fuel specifications, harmonize regulations, and facilitate global trade. Notable examples include the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and bilateral agreements between potential ammonia exporting and importing nations.

Policy recommendations for accelerating ammonia's role in energy transition include establishing technology-neutral carbon pricing mechanisms, developing dedicated ammonia fuel standards, creating regulatory sandboxes for pilot projects, implementing lifecycle assessment requirements for emissions accounting, and fostering international cooperation on infrastructure development and trade protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!