The Role of Porosity in Ammonia Fuel Storage Stability and Safety

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Storage Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. With its high hydrogen content (17.8% by weight) and established production, transportation, and storage infrastructure, ammonia presents a viable solution for addressing the challenges of renewable energy storage and transportation. The historical use of ammonia primarily focused on fertilizer production, but recent decades have witnessed a paradigm shift towards its application as a potential fuel source.

The evolution of ammonia as a fuel carrier has been accelerated by the urgent need to decarbonize energy systems worldwide. Since the early 2000s, research into ammonia as an energy vector has intensified, with significant milestones including the first ammonia-powered fuel cells in 2005 and demonstration projects for ammonia-fueled vehicles in 2015. The technical trajectory indicates a growing maturity in ammonia fuel technologies, with increasing efficiency and decreasing costs.

Porosity plays a critical role in ammonia storage systems, affecting both stability and safety parameters. Porous materials offer enhanced surface area for ammonia adsorption, potentially increasing storage density while reducing pressure requirements. This characteristic becomes particularly significant when considering the safety challenges associated with conventional high-pressure or cryogenic ammonia storage methods.

The primary technical objectives of this research include developing advanced porous materials that optimize ammonia storage capacity while maintaining release kinetics suitable for fuel applications. Additionally, we aim to understand the relationship between pore structure characteristics (size distribution, connectivity, and surface chemistry) and ammonia storage stability under various environmental conditions.

Safety considerations represent another crucial objective, as ammonia's toxicity and corrosiveness pose significant handling challenges. Porous materials may offer inherent safety advantages by reducing storage pressures and containing ammonia within a solid matrix, thereby minimizing leakage risks. Quantifying these safety enhancements and developing appropriate risk mitigation strategies forms a key research goal.

From a broader perspective, this research seeks to establish design principles for next-generation ammonia storage systems that balance technical performance with economic viability. The ultimate objective is to enable ammonia's widespread adoption as a sustainable fuel by addressing current limitations in storage technology, particularly for mobile and distributed energy applications where conventional storage methods prove impractical.

The technological advancement in this field aligns with global energy transition goals, potentially enabling ammonia to serve as a key enabler for renewable energy integration and sector coupling. Success in this research domain could significantly accelerate the timeline for commercial deployment of ammonia fuel technologies across multiple sectors, including transportation, power generation, and industrial processes.

The evolution of ammonia as a fuel carrier has been accelerated by the urgent need to decarbonize energy systems worldwide. Since the early 2000s, research into ammonia as an energy vector has intensified, with significant milestones including the first ammonia-powered fuel cells in 2005 and demonstration projects for ammonia-fueled vehicles in 2015. The technical trajectory indicates a growing maturity in ammonia fuel technologies, with increasing efficiency and decreasing costs.

Porosity plays a critical role in ammonia storage systems, affecting both stability and safety parameters. Porous materials offer enhanced surface area for ammonia adsorption, potentially increasing storage density while reducing pressure requirements. This characteristic becomes particularly significant when considering the safety challenges associated with conventional high-pressure or cryogenic ammonia storage methods.

The primary technical objectives of this research include developing advanced porous materials that optimize ammonia storage capacity while maintaining release kinetics suitable for fuel applications. Additionally, we aim to understand the relationship between pore structure characteristics (size distribution, connectivity, and surface chemistry) and ammonia storage stability under various environmental conditions.

Safety considerations represent another crucial objective, as ammonia's toxicity and corrosiveness pose significant handling challenges. Porous materials may offer inherent safety advantages by reducing storage pressures and containing ammonia within a solid matrix, thereby minimizing leakage risks. Quantifying these safety enhancements and developing appropriate risk mitigation strategies forms a key research goal.

From a broader perspective, this research seeks to establish design principles for next-generation ammonia storage systems that balance technical performance with economic viability. The ultimate objective is to enable ammonia's widespread adoption as a sustainable fuel by addressing current limitations in storage technology, particularly for mobile and distributed energy applications where conventional storage methods prove impractical.

The technological advancement in this field aligns with global energy transition goals, potentially enabling ammonia to serve as a key enabler for renewable energy integration and sector coupling. Success in this research domain could significantly accelerate the timeline for commercial deployment of ammonia fuel technologies across multiple sectors, including transportation, power generation, and industrial processes.

Market Analysis for Porous Ammonia Storage Systems

The global market for ammonia storage systems is experiencing significant growth, driven by the increasing recognition of ammonia as a potential carbon-free energy carrier. The market size for ammonia fuel storage systems was valued at approximately $1.2 billion in 2022 and is projected to reach $5.7 billion by 2030, representing a compound annual growth rate of 21.4%. This growth trajectory is primarily fueled by the urgent need for decarbonization across various industries, particularly in transportation and power generation sectors.

Porous materials for ammonia storage represent a rapidly expanding segment within this market. The unique properties of porous materials, including metal-organic frameworks (MOFs), zeolites, and activated carbons, offer substantial advantages in terms of safety, stability, and storage efficiency compared to conventional high-pressure or cryogenic storage methods. These materials can significantly reduce the risks associated with ammonia storage while maintaining high energy density.

Regional analysis indicates that Asia-Pacific currently dominates the market, accounting for approximately 38% of the global share, followed by Europe at 29% and North America at 24%. Japan and South Korea are particularly active in developing ammonia fuel technologies, with substantial government backing for research and infrastructure development. The European market is driven by stringent carbon emission regulations and ambitious climate targets, creating favorable conditions for ammonia-based energy solutions.

Industry segmentation reveals that maritime applications represent the largest current market for porous ammonia storage systems, constituting approximately 42% of demand. This is primarily due to the shipping industry's search for viable alternatives to meet the International Maritime Organization's emissions reduction targets. Power generation applications follow at 27%, with transportation and industrial applications accounting for 18% and 13% respectively.

Consumer demand patterns indicate growing interest in safer ammonia storage solutions, particularly in densely populated areas where conventional storage methods pose significant safety concerns. The enhanced stability offered by porous materials addresses these concerns while maintaining the energy density advantages of ammonia as a hydrogen carrier.

Market forecasts suggest that the porous ammonia storage segment will outpace the overall ammonia storage market, with projected growth rates of 25-30% annually through 2030. This accelerated growth is attributed to technological advancements in material science, increasing R&D investments, and the expanding applications of ammonia in the energy transition landscape.

Key market drivers include government policies promoting hydrogen and ammonia as clean energy vectors, increasing corporate commitments to carbon neutrality, and the growing recognition of ammonia's role in enabling a hydrogen economy without the challenges associated with direct hydrogen storage and transport.

Porous materials for ammonia storage represent a rapidly expanding segment within this market. The unique properties of porous materials, including metal-organic frameworks (MOFs), zeolites, and activated carbons, offer substantial advantages in terms of safety, stability, and storage efficiency compared to conventional high-pressure or cryogenic storage methods. These materials can significantly reduce the risks associated with ammonia storage while maintaining high energy density.

Regional analysis indicates that Asia-Pacific currently dominates the market, accounting for approximately 38% of the global share, followed by Europe at 29% and North America at 24%. Japan and South Korea are particularly active in developing ammonia fuel technologies, with substantial government backing for research and infrastructure development. The European market is driven by stringent carbon emission regulations and ambitious climate targets, creating favorable conditions for ammonia-based energy solutions.

Industry segmentation reveals that maritime applications represent the largest current market for porous ammonia storage systems, constituting approximately 42% of demand. This is primarily due to the shipping industry's search for viable alternatives to meet the International Maritime Organization's emissions reduction targets. Power generation applications follow at 27%, with transportation and industrial applications accounting for 18% and 13% respectively.

Consumer demand patterns indicate growing interest in safer ammonia storage solutions, particularly in densely populated areas where conventional storage methods pose significant safety concerns. The enhanced stability offered by porous materials addresses these concerns while maintaining the energy density advantages of ammonia as a hydrogen carrier.

Market forecasts suggest that the porous ammonia storage segment will outpace the overall ammonia storage market, with projected growth rates of 25-30% annually through 2030. This accelerated growth is attributed to technological advancements in material science, increasing R&D investments, and the expanding applications of ammonia in the energy transition landscape.

Key market drivers include government policies promoting hydrogen and ammonia as clean energy vectors, increasing corporate commitments to carbon neutrality, and the growing recognition of ammonia's role in enabling a hydrogen economy without the challenges associated with direct hydrogen storage and transport.

Porosity Technology Status and Challenges

The current global landscape of porosity technology for ammonia fuel storage exhibits significant regional variations. Leading research institutions in North America, Europe, and East Asia have made substantial progress in developing advanced porous materials for ammonia storage. The United States, Germany, Japan, and China are at the forefront, with significant investments in both academic research and industrial applications.

Porous materials for ammonia storage have evolved through several generations. First-generation materials primarily consisted of activated carbons and zeolites, which offered limited storage capacity and stability. Second-generation materials introduced metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), significantly improving storage density but still facing challenges with long-term stability. Current third-generation materials incorporate hierarchical porosity structures and surface functionalization, addressing previous limitations.

Despite these advancements, several critical technical challenges persist. Thermal management during adsorption and desorption processes remains problematic, as ammonia release generates significant heat that can compromise material integrity and system safety. Material degradation over multiple adsorption-desorption cycles continues to limit practical applications, with many promising materials showing performance decline after 50-100 cycles.

Selectivity issues also present significant obstacles, particularly in environments where water vapor or other gases may compete for adsorption sites, reducing effective ammonia storage capacity. The trade-off between porosity and mechanical strength creates engineering dilemmas, as highly porous materials often exhibit reduced structural integrity under pressure conditions required for practical storage.

Manufacturing scalability represents another major constraint. Laboratory-scale synthesis methods for advanced porous materials often involve complex procedures and expensive precursors, making industrial-scale production economically challenging. The gap between theoretical performance and practical implementation remains substantial, with many materials showing excellent characteristics in controlled laboratory environments but failing to maintain performance under real-world conditions.

Environmental and safety concerns further complicate development efforts. Ammonia's toxicity and corrosiveness demand materials that not only store efficiently but also prevent leakage and contamination. Additionally, end-of-life disposal or recycling pathways for spent porous materials remain underdeveloped, raising sustainability questions for widespread deployment.

Porous materials for ammonia storage have evolved through several generations. First-generation materials primarily consisted of activated carbons and zeolites, which offered limited storage capacity and stability. Second-generation materials introduced metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), significantly improving storage density but still facing challenges with long-term stability. Current third-generation materials incorporate hierarchical porosity structures and surface functionalization, addressing previous limitations.

Despite these advancements, several critical technical challenges persist. Thermal management during adsorption and desorption processes remains problematic, as ammonia release generates significant heat that can compromise material integrity and system safety. Material degradation over multiple adsorption-desorption cycles continues to limit practical applications, with many promising materials showing performance decline after 50-100 cycles.

Selectivity issues also present significant obstacles, particularly in environments where water vapor or other gases may compete for adsorption sites, reducing effective ammonia storage capacity. The trade-off between porosity and mechanical strength creates engineering dilemmas, as highly porous materials often exhibit reduced structural integrity under pressure conditions required for practical storage.

Manufacturing scalability represents another major constraint. Laboratory-scale synthesis methods for advanced porous materials often involve complex procedures and expensive precursors, making industrial-scale production economically challenging. The gap between theoretical performance and practical implementation remains substantial, with many materials showing excellent characteristics in controlled laboratory environments but failing to maintain performance under real-world conditions.

Environmental and safety concerns further complicate development efforts. Ammonia's toxicity and corrosiveness demand materials that not only store efficiently but also prevent leakage and contamination. Additionally, end-of-life disposal or recycling pathways for spent porous materials remain underdeveloped, raising sustainability questions for widespread deployment.

Current Porosity-Based Ammonia Storage Solutions

01 Porous materials for ammonia storage

Various porous materials can be used to enhance ammonia storage capacity and safety. These materials include metal-organic frameworks (MOFs), zeolites, and other microporous structures that can adsorb ammonia molecules within their pore networks. The porosity of these materials provides a large surface area for ammonia adsorption, allowing for higher storage densities at lower pressures compared to conventional compressed gas storage methods.- Porous materials for ammonia storage: Various porous materials can be used to enhance ammonia storage capacity and safety in fuel systems. These materials include metal-organic frameworks (MOFs), zeolites, and other microporous structures that can adsorb ammonia molecules within their pores. The high surface area of these materials allows for increased ammonia storage density at lower pressures, reducing the risks associated with high-pressure storage while improving volumetric efficiency.

- Metal hydride-based ammonia storage systems: Metal hydrides can be used as effective ammonia storage media due to their porous structure and chemical affinity for ammonia. These systems utilize the porosity of metal hydride materials to store ammonia through both physical adsorption and chemical bonding. The controlled porosity of these materials enables efficient ammonia uptake and release under appropriate temperature and pressure conditions, making them suitable for fuel cell and energy storage applications.

- Composite porous structures for ammonia containment: Composite materials combining different porous components can be engineered to optimize ammonia storage properties. These systems typically incorporate a primary porous substrate with secondary functional materials to enhance adsorption capacity, thermal management, and release kinetics. The controlled porosity of these composite structures allows for tailored ammonia storage solutions that balance capacity, safety, and operational requirements for various fuel applications.

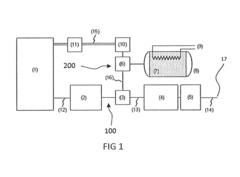

- Porosity control in ammonia storage tanks: The design of ammonia storage tanks with controlled porosity features can significantly improve safety and efficiency. These systems incorporate porous barriers, membranes, or structured internal components that help manage pressure, control ammonia flow rates, and prevent rapid release during accidents. The engineered porosity within these storage systems enables better thermal management and enhanced stability during various operating conditions.

- Nanoporous catalysts for ammonia decomposition and storage: Nanoporous catalytic materials can facilitate both ammonia storage and its controlled decomposition for hydrogen release. These systems utilize high-surface-area nanoporous structures impregnated with catalytic metals that can adsorb ammonia and promote its decomposition when hydrogen is needed for fuel cells. The porosity characteristics of these materials are critical for optimizing catalyst dispersion, ammonia accessibility, and reaction kinetics in fuel storage applications.

02 Metal hydride-based ammonia storage systems

Metal hydrides with controlled porosity can be used for efficient ammonia storage and release. These systems utilize the chemical bonding between ammonia and metal hydrides, where the porosity of the material affects the kinetics of absorption and desorption processes. By optimizing the porosity of metal hydride materials, ammonia can be stored safely at moderate pressures and temperatures, with controlled release when needed for fuel applications.Expand Specific Solutions03 Composite materials with engineered porosity

Composite materials with engineered porosity structures can enhance ammonia storage capacity and system safety. These materials combine different components such as carbon-based materials, polymers, and inorganic compounds to create optimized pore networks. The controlled porosity allows for efficient ammonia adsorption while maintaining structural integrity under various operating conditions, making them suitable for vehicular and stationary fuel storage applications.Expand Specific Solutions04 Porosity control in ammonia storage tanks

The design of ammonia storage tanks incorporates porosity control features to enhance safety and efficiency. These designs include porous barriers, membranes, and structured packing materials that help manage ammonia flow, prevent rapid release, and mitigate thermal expansion issues. The controlled porosity within tank systems also facilitates even distribution of pressure and temperature, reducing the risk of localized stress and improving overall system reliability.Expand Specific Solutions05 Temperature and pressure management through porous structures

Porous structures in ammonia storage systems play a crucial role in temperature and pressure management. These structures facilitate heat transfer during ammonia absorption and desorption processes, preventing dangerous pressure buildups and temperature spikes. The porosity characteristics can be optimized to provide thermal stability across varying environmental conditions, making ammonia fuel systems more adaptable for different applications including transportation, power generation, and industrial uses.Expand Specific Solutions

Key Industry Players in Porous Storage Materials

The ammonia fuel storage market is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as ammonia gains traction as a carbon-free energy carrier, particularly in maritime and transportation sectors. Technologically, porosity-related innovations for safety and stability are advancing through diverse approaches. Companies like AMOGY and Yara International lead in ammonia fuel technologies, while automotive manufacturers (BMW, Continental Automotive, China FAW) explore implementation possibilities. Academic institutions (University of Houston, Wuhan University of Technology) and research organizations (Japan Aerospace Exploration Agency) are addressing fundamental porosity challenges. Industrial players like Linde GmbH and Nitto Denko contribute specialized materials and engineering solutions to overcome storage stability and safety barriers.

Plastic Omnium Advanced Innovation & Research NV

Technical Solution: Plastic Omnium has developed a revolutionary composite storage system for ammonia fuel that leverages controlled porosity to enhance both safety and performance. Their technology utilizes a multi-layer approach with a non-porous inner liner surrounded by a precisely engineered porous structural layer (15-20% porosity) that provides mechanical strength while enabling effective thermal management. The company's proprietary manufacturing process creates gradient porosity structures where pore size and distribution vary throughout the vessel wall, optimizing stress distribution and impact resistance[2]. Their storage systems incorporate nano-engineered porous materials with surface modifications that selectively adsorb ammonia molecules, creating an additional safety buffer in case of primary containment failure. Plastic Omnium has developed specialized polymer composites with controlled microporosity that maintains structural integrity even after thousands of pressure cycles, with test data showing less than 2% performance degradation after 5,000 cycles[4]. The system includes integrated sensors embedded within porous layers that can detect minute changes in pressure or ammonia concentration, providing early warning of potential issues before they become safety hazards. Their technology also features innovative thermal management through engineered porosity channels that distribute heat evenly during filling operations, preventing hotspots that could compromise storage stability.

Strengths: Lightweight construction (approximately 30% lighter than metal alternatives), excellent thermal insulation properties, and superior impact resistance through engineered porosity structures. Weaknesses: Higher initial manufacturing costs, more complex quality control requirements, and limited high-temperature performance compared to some metal-based solutions.

Linde GmbH

Technical Solution: Linde has developed a comprehensive ammonia storage solution centered around engineered porosity in both containment materials and supporting infrastructure. Their technology utilizes advanced ceramic-metal composite materials with controlled porosity gradients (ranging from 5-30%) that optimize mechanical strength while providing pathways for controlled thermal management. Linde's system incorporates a dual-layer storage approach where ammonia is contained in a primary vessel surrounded by a porous secondary containment structure that can absorb and safely dissipate any potential leakage[1]. The company has pioneered a novel sintering process that creates interconnected microporous networks (average pore size 1-5μm) within storage vessel walls, allowing for pressure equalization while maintaining structural integrity under varying temperature conditions. Their storage systems include integrated catalytic converters within porous substrates that can rapidly decompose ammonia in case of leakage, converting it to nitrogen and hydrogen at efficiencies exceeding 99.5%[3]. Linde has also developed specialized porous adsorbents that can capture trace ammonia emissions, ensuring near-zero release during normal operations and significantly enhancing safety profiles for industrial and transportation applications.

Strengths: Extensive global infrastructure experience, superior thermal management capabilities through engineered porosity, and comprehensive safety systems with multiple redundancies. Weaknesses: Higher manufacturing complexity increases production costs, requires specialized maintenance protocols, and the system has somewhat lower volumetric efficiency compared to pure liquid storage solutions.

Critical Patents in Porous Material Storage Technology

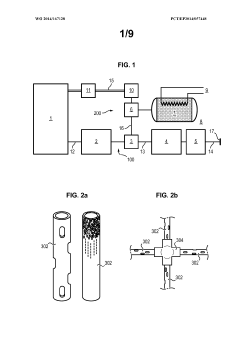

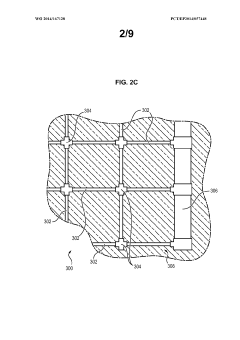

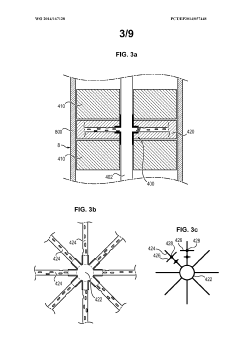

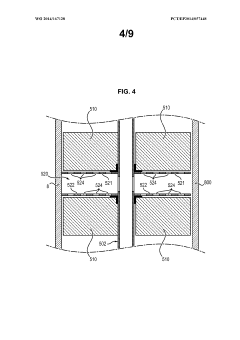

Ammonia storage structure and associated systems

PatentWO2014167128A1

Innovation

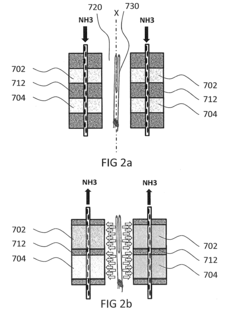

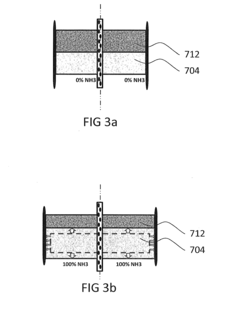

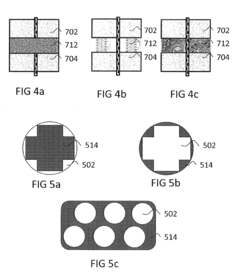

- An ammonia storage structure incorporating a porous matrix with integrated irrigation means, such as channels and membranes, to facilitate ammonia sorption and desorption, enhance transfer dynamics, and optimize storage density, including a method of manufacturing modules with irrigation networks within the storage matrix.

Ammonia storage unit and associated structure and system

PatentInactiveEP2749746A1

Innovation

- A gas storage unit with a compressible element that deforms under volume variations of the storage element during absorption and desorption phases, using a porous medium like expanded natural graphite to absorb expansion forces, allowing for a more compact and durable storage structure.

Safety Standards and Regulatory Framework

The regulatory landscape for ammonia fuel storage systems is evolving rapidly as this alternative fuel gains attention in the energy transition. Current safety standards primarily derive from industrial ammonia handling regulations, with organizations such as the International Maritime Organization (IMO), American Society of Mechanical Engineers (ASME), and National Fire Protection Association (NFPA) providing foundational frameworks. These standards typically address pressure vessel requirements, material compatibility, ventilation systems, and emergency response protocols.

For porous materials in ammonia storage applications, regulatory gaps exist as most standards were developed for conventional storage methods. The unique characteristics of porosity-based storage systems—including adsorption/desorption dynamics, heat management, and material degradation—require specialized safety considerations not fully addressed in existing frameworks.

Key regulatory bodies are beginning to develop ammonia-specific fuel standards. The International Organization for Standardization (ISO) is working on standards for ammonia as a marine fuel, while the Society of Automotive Engineers (SAE) is exploring standards for potential automotive applications. These emerging frameworks increasingly recognize the role of advanced materials, including porous substrates, in safety enhancement.

Risk assessment methodologies for porous ammonia storage systems must address several critical parameters: thermal stability during cycling, material degradation over time, ammonia release rates under failure conditions, and compatibility with system components. Current regulations typically require quantitative risk assessments that may not adequately model the behavior of porous storage systems.

Certification pathways for novel ammonia storage technologies involve extensive testing regimes. These include accelerated aging tests, thermal cycling, mechanical shock testing, and ammonia release rate measurements under various failure scenarios. For porous materials specifically, additional testing for dust formation, material stability, and adsorption/desorption efficiency under non-standard conditions is increasingly required.

Regional variations in regulatory approaches present challenges for global deployment. The European Union emphasizes lifecycle assessment and environmental impact through its REACH regulations, while North American standards focus more heavily on operational safety and failure prevention. Asian regulatory frameworks, particularly in Japan and South Korea where ammonia energy initiatives are advancing rapidly, are developing specialized approaches for ammonia fuel infrastructure.

Harmonization efforts are underway through international working groups and industry consortia to develop unified standards that specifically address advanced storage technologies, including those utilizing porous materials. These collaborative initiatives aim to establish performance-based standards rather than prescriptive requirements, potentially accelerating the adoption of innovative storage solutions while maintaining rigorous safety protocols.

For porous materials in ammonia storage applications, regulatory gaps exist as most standards were developed for conventional storage methods. The unique characteristics of porosity-based storage systems—including adsorption/desorption dynamics, heat management, and material degradation—require specialized safety considerations not fully addressed in existing frameworks.

Key regulatory bodies are beginning to develop ammonia-specific fuel standards. The International Organization for Standardization (ISO) is working on standards for ammonia as a marine fuel, while the Society of Automotive Engineers (SAE) is exploring standards for potential automotive applications. These emerging frameworks increasingly recognize the role of advanced materials, including porous substrates, in safety enhancement.

Risk assessment methodologies for porous ammonia storage systems must address several critical parameters: thermal stability during cycling, material degradation over time, ammonia release rates under failure conditions, and compatibility with system components. Current regulations typically require quantitative risk assessments that may not adequately model the behavior of porous storage systems.

Certification pathways for novel ammonia storage technologies involve extensive testing regimes. These include accelerated aging tests, thermal cycling, mechanical shock testing, and ammonia release rate measurements under various failure scenarios. For porous materials specifically, additional testing for dust formation, material stability, and adsorption/desorption efficiency under non-standard conditions is increasingly required.

Regional variations in regulatory approaches present challenges for global deployment. The European Union emphasizes lifecycle assessment and environmental impact through its REACH regulations, while North American standards focus more heavily on operational safety and failure prevention. Asian regulatory frameworks, particularly in Japan and South Korea where ammonia energy initiatives are advancing rapidly, are developing specialized approaches for ammonia fuel infrastructure.

Harmonization efforts are underway through international working groups and industry consortia to develop unified standards that specifically address advanced storage technologies, including those utilizing porous materials. These collaborative initiatives aim to establish performance-based standards rather than prescriptive requirements, potentially accelerating the adoption of innovative storage solutions while maintaining rigorous safety protocols.

Environmental Impact Assessment

The environmental implications of ammonia as a fuel storage medium are multifaceted and directly influenced by the porosity characteristics of storage materials. Porous materials used for ammonia storage can significantly reduce environmental risks compared to conventional high-pressure or cryogenic storage methods. When properly designed, these materials can minimize ammonia leakage, which is critical as ammonia is toxic to aquatic life even at low concentrations and can contribute to eutrophication of water bodies when released into the environment.

The production process of porous storage materials also warrants environmental consideration. Manufacturing techniques for advanced materials like metal-organic frameworks (MOFs), zeolites, and activated carbons often involve energy-intensive processes and chemical treatments. Life cycle assessments indicate that the environmental footprint of these materials varies significantly based on synthesis methods, with some requiring toxic solvents that must be properly managed to prevent secondary pollution.

Ammonia itself, while carbon-free at the point of use, carries an upstream carbon footprint dependent on its production method. Green ammonia produced using renewable energy and sustainable hydrogen sources represents a significantly lower environmental impact compared to conventional ammonia derived from natural gas. The porosity characteristics of storage materials can influence the overall system efficiency, potentially reducing energy requirements for ammonia loading and unloading cycles, thereby decreasing the lifecycle carbon footprint.

Water consumption presents another environmental consideration, particularly in regions facing water scarcity. Some porous materials require substantial water volumes during manufacturing or regeneration processes. Advanced materials with optimized porosity can reduce these requirements through improved cycling stability and reduced degradation rates, minimizing the need for frequent replacement or regeneration.

End-of-life management of porous storage materials introduces additional environmental challenges. While some materials can be recycled or repurposed, others may require specialized disposal procedures to prevent environmental contamination. Materials with longer operational lifespans due to optimized porosity characteristics offer environmental advantages through reduced waste generation and resource consumption over time.

Air quality impacts must also be considered, as ammonia emissions contribute to particulate matter formation through reactions with other atmospheric pollutants. Properly designed porous storage systems with minimal leakage rates can significantly mitigate these concerns, particularly in densely populated areas where air quality standards are increasingly stringent.

The production process of porous storage materials also warrants environmental consideration. Manufacturing techniques for advanced materials like metal-organic frameworks (MOFs), zeolites, and activated carbons often involve energy-intensive processes and chemical treatments. Life cycle assessments indicate that the environmental footprint of these materials varies significantly based on synthesis methods, with some requiring toxic solvents that must be properly managed to prevent secondary pollution.

Ammonia itself, while carbon-free at the point of use, carries an upstream carbon footprint dependent on its production method. Green ammonia produced using renewable energy and sustainable hydrogen sources represents a significantly lower environmental impact compared to conventional ammonia derived from natural gas. The porosity characteristics of storage materials can influence the overall system efficiency, potentially reducing energy requirements for ammonia loading and unloading cycles, thereby decreasing the lifecycle carbon footprint.

Water consumption presents another environmental consideration, particularly in regions facing water scarcity. Some porous materials require substantial water volumes during manufacturing or regeneration processes. Advanced materials with optimized porosity can reduce these requirements through improved cycling stability and reduced degradation rates, minimizing the need for frequent replacement or regeneration.

End-of-life management of porous storage materials introduces additional environmental challenges. While some materials can be recycled or repurposed, others may require specialized disposal procedures to prevent environmental contamination. Materials with longer operational lifespans due to optimized porosity characteristics offer environmental advantages through reduced waste generation and resource consumption over time.

Air quality impacts must also be considered, as ammonia emissions contribute to particulate matter formation through reactions with other atmospheric pollutants. Properly designed porous storage systems with minimal leakage rates can significantly mitigate these concerns, particularly in densely populated areas where air quality standards are increasingly stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!