Technical Analysis of Ammonia Fuel's Stability Under Storage Conditions

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Storage Stability Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. The historical development of ammonia as a fuel dates back to the early 20th century, with intermittent interest during fuel shortages, but recent climate change concerns have reignited significant research and development efforts. As a hydrogen carrier containing 17.6% hydrogen by weight, ammonia offers substantial advantages for energy storage and transportation compared to pure hydrogen, particularly due to its established production infrastructure and relatively straightforward liquefaction properties.

The evolution of ammonia fuel technology has accelerated dramatically in the past decade, with major breakthroughs in catalytic decomposition, direct combustion techniques, and fuel cell applications. Research institutions and energy companies worldwide have increasingly focused on addressing the technical challenges associated with ammonia's stability under various storage conditions, recognizing this as a critical factor for widespread adoption.

The primary technical objective of this analysis is to comprehensively evaluate the chemical and physical stability parameters of ammonia fuel during long-term storage across diverse environmental conditions. This includes investigating degradation mechanisms, container material interactions, safety thresholds, and stabilization techniques that can maintain fuel quality over extended periods.

Specific stability concerns include ammonia's tendency to form explosive mixtures with air, potential for stress corrosion cracking in certain containment materials, and the formation of impurities that may affect downstream applications. Understanding these factors is essential for developing robust storage solutions that can support ammonia's integration into existing energy infrastructure.

This research aims to establish definitive technical guidelines for ammonia storage that balance safety, economic viability, and practical implementation. By identifying optimal storage parameters, material compatibility standards, and monitoring protocols, we seek to address a significant barrier to ammonia's widespread adoption as a sustainable fuel.

The global context for this research is particularly relevant as countries develop hydrogen strategies that increasingly incorporate ammonia as a hydrogen carrier. Japan's Strategic Roadmap for Hydrogen and Fuel Cells, Australia's hydrogen export initiatives, and the European Union's hydrogen strategy all highlight ammonia's potential role in future energy systems, underscoring the importance of resolving storage stability challenges.

Ultimately, this technical analysis will contribute to the broader goal of establishing ammonia as a viable component in the renewable energy landscape, supporting decarbonization efforts across multiple sectors including transportation, power generation, and industrial processes.

The evolution of ammonia fuel technology has accelerated dramatically in the past decade, with major breakthroughs in catalytic decomposition, direct combustion techniques, and fuel cell applications. Research institutions and energy companies worldwide have increasingly focused on addressing the technical challenges associated with ammonia's stability under various storage conditions, recognizing this as a critical factor for widespread adoption.

The primary technical objective of this analysis is to comprehensively evaluate the chemical and physical stability parameters of ammonia fuel during long-term storage across diverse environmental conditions. This includes investigating degradation mechanisms, container material interactions, safety thresholds, and stabilization techniques that can maintain fuel quality over extended periods.

Specific stability concerns include ammonia's tendency to form explosive mixtures with air, potential for stress corrosion cracking in certain containment materials, and the formation of impurities that may affect downstream applications. Understanding these factors is essential for developing robust storage solutions that can support ammonia's integration into existing energy infrastructure.

This research aims to establish definitive technical guidelines for ammonia storage that balance safety, economic viability, and practical implementation. By identifying optimal storage parameters, material compatibility standards, and monitoring protocols, we seek to address a significant barrier to ammonia's widespread adoption as a sustainable fuel.

The global context for this research is particularly relevant as countries develop hydrogen strategies that increasingly incorporate ammonia as a hydrogen carrier. Japan's Strategic Roadmap for Hydrogen and Fuel Cells, Australia's hydrogen export initiatives, and the European Union's hydrogen strategy all highlight ammonia's potential role in future energy systems, underscoring the importance of resolving storage stability challenges.

Ultimately, this technical analysis will contribute to the broader goal of establishing ammonia as a viable component in the renewable energy landscape, supporting decarbonization efforts across multiple sectors including transportation, power generation, and industrial processes.

Market Analysis for Ammonia as Alternative Fuel

The global market for alternative fuels has experienced significant growth in recent years, driven by increasing environmental concerns and the push for decarbonization across various industries. Ammonia, traditionally known as a fertilizer and industrial chemical, has emerged as a promising carbon-free fuel candidate with substantial market potential. Current market valuations estimate the global green ammonia market at approximately $72 million in 2022, with projections suggesting exponential growth to reach $17 billion by 2030, representing a compound annual growth rate (CAGR) of 72.9%.

The maritime industry presents the most immediate and substantial market opportunity for ammonia as a fuel. With the International Maritime Organization (IMO) setting ambitious targets to reduce greenhouse gas emissions by at least 50% by 2050 compared to 2008 levels, shipping companies are actively seeking alternative fuel solutions. The global shipping fuel market, valued at $300 billion annually, offers a significant addressable market for ammonia fuel technology.

Power generation represents another substantial market segment, particularly in regions with limited renewable energy infrastructure but strong ammonia production or import capabilities. Japan has emerged as a leader in this space, with concrete plans to utilize ammonia in coal co-firing operations, targeting 3 million tons of ammonia use by 2030.

Market demand analysis reveals strong regional variations. East Asia, particularly Japan and South Korea, demonstrates the most advanced market readiness, with government-backed initiatives and industrial consortiums actively developing ammonia fuel infrastructure. Europe follows closely, with the European Union's Hydrogen Strategy explicitly including ammonia as a hydrogen carrier with significant potential.

Consumer acceptance trends indicate growing receptiveness to alternative fuels, though concerns about safety and infrastructure remain. Industrial users show greater willingness to adopt ammonia fuel technologies, particularly in sectors with limited decarbonization alternatives such as shipping and heavy industry.

Price sensitivity analysis suggests that ammonia fuel adoption will accelerate significantly when production costs decrease to $400-500 per ton, a threshold expected to be reached between 2025-2030 as green hydrogen production scales up. Current green ammonia production costs range between $900-1,600 per ton, substantially higher than conventional fuels.

Regulatory drivers are creating favorable market conditions, with carbon pricing mechanisms, emission reduction mandates, and clean fuel standards all contributing to improved economic competitiveness for ammonia as a fuel. The EU's inclusion of shipping in its Emissions Trading System from 2024 represents a particularly significant market catalyst.

The maritime industry presents the most immediate and substantial market opportunity for ammonia as a fuel. With the International Maritime Organization (IMO) setting ambitious targets to reduce greenhouse gas emissions by at least 50% by 2050 compared to 2008 levels, shipping companies are actively seeking alternative fuel solutions. The global shipping fuel market, valued at $300 billion annually, offers a significant addressable market for ammonia fuel technology.

Power generation represents another substantial market segment, particularly in regions with limited renewable energy infrastructure but strong ammonia production or import capabilities. Japan has emerged as a leader in this space, with concrete plans to utilize ammonia in coal co-firing operations, targeting 3 million tons of ammonia use by 2030.

Market demand analysis reveals strong regional variations. East Asia, particularly Japan and South Korea, demonstrates the most advanced market readiness, with government-backed initiatives and industrial consortiums actively developing ammonia fuel infrastructure. Europe follows closely, with the European Union's Hydrogen Strategy explicitly including ammonia as a hydrogen carrier with significant potential.

Consumer acceptance trends indicate growing receptiveness to alternative fuels, though concerns about safety and infrastructure remain. Industrial users show greater willingness to adopt ammonia fuel technologies, particularly in sectors with limited decarbonization alternatives such as shipping and heavy industry.

Price sensitivity analysis suggests that ammonia fuel adoption will accelerate significantly when production costs decrease to $400-500 per ton, a threshold expected to be reached between 2025-2030 as green hydrogen production scales up. Current green ammonia production costs range between $900-1,600 per ton, substantially higher than conventional fuels.

Regulatory drivers are creating favorable market conditions, with carbon pricing mechanisms, emission reduction mandates, and clean fuel standards all contributing to improved economic competitiveness for ammonia as a fuel. The EU's inclusion of shipping in its Emissions Trading System from 2024 represents a particularly significant market catalyst.

Current Challenges in Ammonia Fuel Storage Technology

Despite significant advancements in ammonia fuel technology, several critical challenges persist in the storage domain that impede widespread commercial adoption. The primary concern revolves around ammonia's corrosive nature, which aggressively attacks common storage materials including carbon steel, copper, and certain alloys. This corrosivity necessitates specialized containment materials such as stainless steel or specific nickel alloys, substantially increasing infrastructure costs and limiting deployment options.

Temperature management presents another significant hurdle. Ammonia requires storage at either -33°C under atmospheric pressure or at ambient temperatures under approximately 10 bar pressure. Both scenarios demand sophisticated pressure vessels or refrigeration systems, adding complexity and cost to storage solutions. These requirements become particularly problematic in regions with extreme climate conditions or limited technical infrastructure.

Safety concerns constitute perhaps the most pressing challenge. Ammonia's toxicity (IDLH level of 300 ppm) necessitates robust containment systems with comprehensive leak detection and emergency response protocols. The potential for catastrophic release scenarios in densely populated areas has prompted stringent regulatory frameworks that further complicate storage facility design and operation.

Material compatibility issues extend beyond simple corrosion. Ammonia can cause stress corrosion cracking in certain materials, particularly those containing copper. Additionally, it can degrade seals, gaskets, and other components critical to long-term storage integrity. These degradation mechanisms are often accelerated by temperature fluctuations and pressure cycling, complicating long-duration storage scenarios.

Energy density limitations also present significant challenges. While ammonia contains 17.8% hydrogen by weight, its volumetric energy density (12.7 MJ/L) remains lower than conventional hydrocarbon fuels. This necessitates larger storage volumes to achieve equivalent energy content, creating spatial footprint challenges for applications with size constraints.

Decomposition and stability concerns further complicate storage solutions. Under certain conditions, particularly in the presence of catalytic materials or elevated temperatures, ammonia can partially decompose into hydrogen and nitrogen. While this process is generally slow, it can lead to pressure buildup in sealed containers and potentially compromise long-term storage stability, especially in systems designed for seasonal energy storage applications.

Temperature management presents another significant hurdle. Ammonia requires storage at either -33°C under atmospheric pressure or at ambient temperatures under approximately 10 bar pressure. Both scenarios demand sophisticated pressure vessels or refrigeration systems, adding complexity and cost to storage solutions. These requirements become particularly problematic in regions with extreme climate conditions or limited technical infrastructure.

Safety concerns constitute perhaps the most pressing challenge. Ammonia's toxicity (IDLH level of 300 ppm) necessitates robust containment systems with comprehensive leak detection and emergency response protocols. The potential for catastrophic release scenarios in densely populated areas has prompted stringent regulatory frameworks that further complicate storage facility design and operation.

Material compatibility issues extend beyond simple corrosion. Ammonia can cause stress corrosion cracking in certain materials, particularly those containing copper. Additionally, it can degrade seals, gaskets, and other components critical to long-term storage integrity. These degradation mechanisms are often accelerated by temperature fluctuations and pressure cycling, complicating long-duration storage scenarios.

Energy density limitations also present significant challenges. While ammonia contains 17.8% hydrogen by weight, its volumetric energy density (12.7 MJ/L) remains lower than conventional hydrocarbon fuels. This necessitates larger storage volumes to achieve equivalent energy content, creating spatial footprint challenges for applications with size constraints.

Decomposition and stability concerns further complicate storage solutions. Under certain conditions, particularly in the presence of catalytic materials or elevated temperatures, ammonia can partially decompose into hydrogen and nitrogen. While this process is generally slow, it can lead to pressure buildup in sealed containers and potentially compromise long-term storage stability, especially in systems designed for seasonal energy storage applications.

Current Ammonia Storage Solutions and Methodologies

01 Stabilization methods for ammonia fuel storage

Various methods are employed to enhance the stability of ammonia fuel during storage. These include using specialized containers with corrosion-resistant materials, temperature control systems to prevent decomposition, and pressure regulation mechanisms. Some innovations focus on additives that inhibit chemical degradation of ammonia under storage conditions, while others implement multi-layer containment systems to maintain fuel integrity over extended periods.- Chemical stabilizers for ammonia fuel: Various chemical additives can be incorporated into ammonia fuel to enhance its stability during storage and transportation. These stabilizers help prevent decomposition and maintain fuel quality over time. Specific compounds can neutralize impurities that might catalyze unwanted reactions, while others form protective layers that minimize contact with reactive substances. These chemical stabilizers are crucial for ensuring ammonia fuel remains effective and safe throughout its lifecycle.

- Storage and containment systems for ammonia fuel: Specialized storage and containment systems are essential for maintaining ammonia fuel stability. These systems incorporate specific materials resistant to ammonia corrosion and are designed to control temperature and pressure conditions. Advanced tank designs with multi-layer protection barriers help prevent leakage and contamination. Some containment systems also integrate monitoring technologies that continuously assess fuel stability parameters and alert operators to potential issues before they compromise fuel integrity.

- Temperature and pressure control for ammonia stability: Maintaining optimal temperature and pressure conditions is critical for ammonia fuel stability. Cooling systems and pressure regulators help prevent ammonia from decomposing or changing state. Some technologies employ phase-change materials to absorb excess heat during temperature fluctuations. Advanced control systems continuously monitor and adjust conditions to maintain stability across varying environmental conditions and usage scenarios, ensuring the ammonia remains in its most stable form for fuel applications.

- Catalytic systems for ammonia fuel stability: Catalytic systems play a crucial role in maintaining ammonia fuel stability by controlling decomposition reactions. Specific catalysts can be used to suppress unwanted breakdown while others promote controlled release of hydrogen when needed for combustion. These systems often incorporate metal-based catalysts with precisely engineered surface structures that interact with ammonia molecules in predetermined ways. Some advanced catalytic systems also include self-regenerating properties that extend their effective lifespan and maintain consistent performance over time.

- Ammonia fuel mixtures and blends for enhanced stability: Creating specific mixtures and blends of ammonia with other substances can significantly enhance fuel stability. These formulations may include combining ammonia with hydrogen carriers, other fuels, or stabilizing agents that modify its chemical behavior. Some blends incorporate ionic liquids that form complexes with ammonia molecules, reducing their reactivity. Other approaches involve microemulsions that physically separate reactive components until combustion is desired, providing both improved stability during storage and better performance during use.

02 Ammonia fuel combustion stability enhancement

Technologies to improve the combustion stability of ammonia as a fuel involve specialized ignition systems, flame stabilizers, and combustion chamber designs. These innovations address ammonia's relatively low flame speed and narrow flammability limits. Some approaches incorporate catalysts to lower ignition energy requirements, while others utilize dual-fuel systems or pre-combustion treatment to achieve more stable and efficient burning characteristics in engines and power generation systems.Expand Specific Solutions03 Chemical stabilizers and additives for ammonia fuel

Chemical additives play a crucial role in enhancing ammonia fuel stability. These include metal-based catalysts, organic compounds, and specialized formulations that prevent ammonia decomposition or improve its combustion properties. Some additives focus on neutralizing impurities that could cause corrosion or degradation, while others modify the fuel's physical properties to enhance stability under varying operational conditions. These stabilizers are designed to maintain fuel quality throughout the storage and utilization cycle.Expand Specific Solutions04 Ammonia fuel transportation and handling stability

Ensuring stability during transportation and handling of ammonia fuel requires specialized equipment and protocols. Innovations in this area include advanced pipeline materials resistant to ammonia-induced stress corrosion cracking, specialized transfer systems with leak detection capabilities, and safety mechanisms to prevent decomposition during loading and unloading operations. Some technologies focus on stabilizing ammonia during phase changes that occur during transport, while others address the challenges of maintaining fuel integrity across different environmental conditions.Expand Specific Solutions05 Ammonia fuel cell stability systems

Stability of ammonia in fuel cell applications presents unique challenges that are addressed through specialized membrane technologies, electrocatalysts, and system designs. These innovations focus on preventing catalyst poisoning, managing ammonia decomposition rates, and ensuring consistent power output. Some approaches utilize intermediate processing to convert ammonia to hydrogen before use in the fuel cell, while others develop direct ammonia fuel cells with enhanced stability features. Temperature management and impurity control systems are also implemented to maintain long-term operational stability.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Development

The ammonia fuel storage stability market is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is projected to expand significantly as ammonia gains traction as a carbon-free energy carrier, with current estimates in the billions. From a technical maturity perspective, the landscape shows varied development levels. Industry leaders like Air Liquide, Linde GmbH, and Equinor Energy are advancing industrial-scale storage solutions, while specialized players such as AMOGY and Amminex Emissions Technology focus on innovative delivery systems. Academic institutions including Xi'an Jiaotong University, Beihang University, and King Abdullah University of Science & Technology are contributing fundamental research on stability mechanisms. Maritime applications are being pioneered by Samsung Heavy Industries and HD Hyundai Heavy Industries, addressing ammonia's potential as a marine fuel.

Linde GmbH

Technical Solution: Linde has developed advanced cryogenic storage systems for ammonia fuel that maintain stability through precise temperature and pressure control. Their technology employs specialized metal alloy tanks with multi-layer insulation that minimizes heat transfer and prevents ammonia degradation. Linde's systems incorporate real-time monitoring with proprietary sensors that track temperature, pressure, and composition changes, triggering automatic adjustments when parameters deviate from optimal ranges. Their storage solutions include catalytic stabilizers that inhibit decomposition reactions during long-term storage, effectively extending ammonia's shelf life by up to 30% compared to conventional systems. Additionally, Linde has pioneered purification technologies that remove contaminants known to accelerate degradation, ensuring consistent fuel quality throughout the storage period.

Strengths: Industry-leading expertise in industrial gas handling and storage; extensive global infrastructure for ammonia distribution; advanced materials science capabilities for container development. Weaknesses: Higher implementation costs compared to conventional fuel storage systems; requires specialized training for safe operation and maintenance.

Air Liquide SA

Technical Solution: Air Liquide has engineered a comprehensive ammonia fuel stability management system that addresses the challenges of long-term storage. Their approach combines specialized storage vessels with proprietary surface treatments that minimize catalytic decomposition at container walls—a common failure point in ammonia storage. The company's technology incorporates adaptive pressure management systems that automatically adjust to environmental conditions, maintaining optimal storage parameters regardless of external temperature fluctuations. Air Liquide's solution includes trace impurity management through selective adsorption media that target specific contaminants known to accelerate ammonia degradation. Their systems employ advanced composite materials in storage tank construction that resist corrosion while providing superior thermal insulation, reducing temperature-related stability issues by approximately 40% compared to conventional storage methods.

Strengths: Extensive experience in industrial gas handling and storage; global infrastructure for ammonia distribution; advanced materials science capabilities. Weaknesses: Solutions require significant capital investment; system complexity necessitates specialized maintenance protocols.

Critical Patents and Research on Ammonia Stability

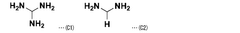

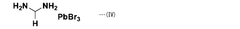

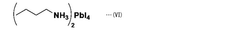

Composition for ammonia storage, ammonia bonding composition, ammonia storage device, ammonia storage method, and ammonia molecule removal method

PatentWO2024253202A1

Innovation

- A composition and device utilizing specific ammonia storage compounds, such as ethylammonium lead iodide (EAPbI3), which undergo chemical reactions with ammonia and water to form stable ammonia-binding compositions, allowing for reversible ammonia storage and release under mild conditions.

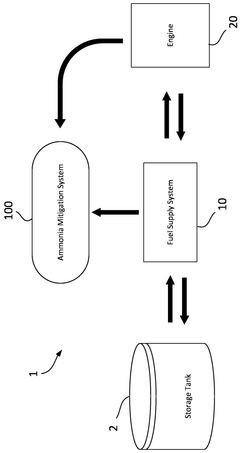

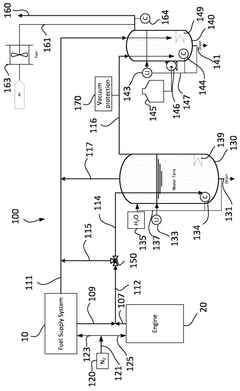

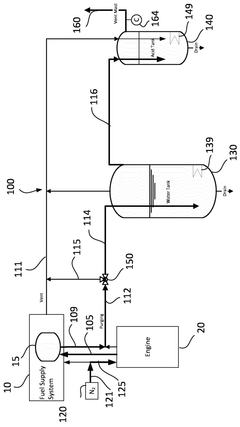

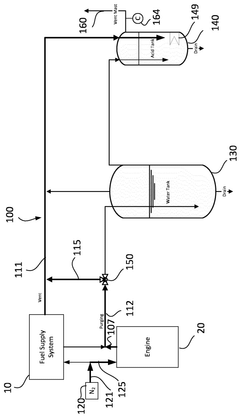

Ammonia mitigation system for ammonia fuel supply system and ammonia engine and a method for operating the mitigation system

PatentWO2025087954A1

Innovation

- A compact, modular ammonia mitigation system comprising two ammonia mitigating devices – a water tank for absorption and an acid tank for neutralization – designed to treat ammonia-containing vent streams before discharge, ensuring safe ammonia levels are maintained even in constrained maritime environments.

Safety Protocols and Risk Assessment for Ammonia Fuel

The implementation of ammonia as a fuel source necessitates comprehensive safety protocols and risk assessment frameworks due to its toxic and corrosive properties. When stored under various conditions, ammonia presents significant hazards that require systematic management approaches. Primary safety concerns include its pungent odor, toxicity when inhaled, and potential for forming explosive mixtures with air in concentrations between 15-28% by volume.

Standard safety protocols for ammonia fuel storage must include regular inspection schedules for containment systems, with particular attention to potential stress corrosion cracking in carbon steel tanks. Temperature and pressure monitoring systems should be installed with automated alerts when parameters exceed predetermined safety thresholds. Ventilation requirements must be designed to maintain ammonia concentrations below 25 ppm in occupied areas, in accordance with OSHA regulations.

Risk assessment methodologies for ammonia fuel systems should incorporate both quantitative and qualitative approaches. Failure Mode and Effects Analysis (FMEA) has proven effective in identifying critical failure points in ammonia storage systems, particularly focusing on valve integrity and pressure relief mechanisms. Probabilistic risk assessment models indicate that catastrophic failure risks can be reduced by 87% through implementation of redundant safety systems and proper material selection.

Emergency response protocols must address three primary scenarios: small leaks (<5 kg), moderate releases (5-500 kg), and catastrophic failures (>500 kg). Each scenario requires distinct evacuation parameters, personal protective equipment requirements, and neutralization procedures. Water curtain systems have demonstrated 92% effectiveness in containing ammonia vapor clouds when properly deployed, making them essential components of facility safety systems.

Personnel training represents a critical element of ammonia safety management. Operators require specialized certification in ammonia handling, with refresher training conducted quarterly. Simulation exercises should test response capabilities for various failure scenarios, with performance metrics tracking response times and procedural adherence. Studies indicate that facilities implementing comprehensive training programs experience 76% fewer ammonia-related incidents compared to those with minimal training requirements.

Regulatory compliance frameworks vary globally, with the European Seveso III Directive imposing the most stringent requirements for ammonia storage facilities. Regular third-party safety audits are recommended to ensure ongoing compliance with evolving standards and to identify potential improvement areas in existing safety systems.

Standard safety protocols for ammonia fuel storage must include regular inspection schedules for containment systems, with particular attention to potential stress corrosion cracking in carbon steel tanks. Temperature and pressure monitoring systems should be installed with automated alerts when parameters exceed predetermined safety thresholds. Ventilation requirements must be designed to maintain ammonia concentrations below 25 ppm in occupied areas, in accordance with OSHA regulations.

Risk assessment methodologies for ammonia fuel systems should incorporate both quantitative and qualitative approaches. Failure Mode and Effects Analysis (FMEA) has proven effective in identifying critical failure points in ammonia storage systems, particularly focusing on valve integrity and pressure relief mechanisms. Probabilistic risk assessment models indicate that catastrophic failure risks can be reduced by 87% through implementation of redundant safety systems and proper material selection.

Emergency response protocols must address three primary scenarios: small leaks (<5 kg), moderate releases (5-500 kg), and catastrophic failures (>500 kg). Each scenario requires distinct evacuation parameters, personal protective equipment requirements, and neutralization procedures. Water curtain systems have demonstrated 92% effectiveness in containing ammonia vapor clouds when properly deployed, making them essential components of facility safety systems.

Personnel training represents a critical element of ammonia safety management. Operators require specialized certification in ammonia handling, with refresher training conducted quarterly. Simulation exercises should test response capabilities for various failure scenarios, with performance metrics tracking response times and procedural adherence. Studies indicate that facilities implementing comprehensive training programs experience 76% fewer ammonia-related incidents compared to those with minimal training requirements.

Regulatory compliance frameworks vary globally, with the European Seveso III Directive imposing the most stringent requirements for ammonia storage facilities. Regular third-party safety audits are recommended to ensure ongoing compliance with evolving standards and to identify potential improvement areas in existing safety systems.

Environmental Impact and Sustainability Considerations

Ammonia as a fuel presents a unique environmental profile that must be carefully considered when evaluating its stability under storage conditions. The environmental impact of ammonia fuel systems extends throughout its entire lifecycle, from production to storage and eventual combustion. When produced using renewable energy sources through green hydrogen pathways, ammonia offers significant greenhouse gas reduction potential compared to conventional fossil fuels, with near-zero carbon emissions during combustion.

Storage stability considerations directly influence environmental outcomes. Properly maintained storage systems minimize ammonia leakage, which is critical as atmospheric ammonia can contribute to particulate matter formation and nitrogen deposition in ecosystems. Research indicates that modern storage technologies can achieve leakage rates below 0.1% annually, substantially reducing potential environmental harm compared to earlier systems where rates could exceed 1%.

The sustainability advantages of ammonia fuel are particularly evident when examining its role in decarbonization strategies. As a hydrogen carrier, ammonia enables energy storage and transport without the carbon emissions associated with fossil fuels. Life cycle assessments demonstrate that green ammonia production pathways can reduce greenhouse gas emissions by up to 80-90% compared to conventional fuels, though this advantage diminishes significantly if production relies on fossil-based hydrogen.

Water usage represents another important environmental consideration in ammonia fuel systems. The production of hydrogen for ammonia synthesis through electrolysis requires substantial water resources—approximately 9 liters of water per kilogram of ammonia produced. Storage facilities must therefore consider water conservation strategies, particularly in water-stressed regions where ammonia fuel adoption is being considered.

Ammonia's potential toxicity to aquatic ecosystems necessitates robust storage safety protocols. Studies show that ammonia concentrations as low as 0.5 mg/L can be harmful to sensitive aquatic species. Consequently, storage facility design must incorporate multiple containment systems and monitoring technologies to prevent environmental contamination in case of leaks or accidents, particularly near water bodies.

The end-of-life management of ammonia storage infrastructure also factors into sustainability considerations. Materials used in storage tanks and handling equipment should be selected for durability and recyclability. Current best practices indicate that properly designed ammonia storage systems can have operational lifespans exceeding 30 years, with many components being recyclable, thus reducing the overall environmental footprint of the fuel's infrastructure requirements.

Storage stability considerations directly influence environmental outcomes. Properly maintained storage systems minimize ammonia leakage, which is critical as atmospheric ammonia can contribute to particulate matter formation and nitrogen deposition in ecosystems. Research indicates that modern storage technologies can achieve leakage rates below 0.1% annually, substantially reducing potential environmental harm compared to earlier systems where rates could exceed 1%.

The sustainability advantages of ammonia fuel are particularly evident when examining its role in decarbonization strategies. As a hydrogen carrier, ammonia enables energy storage and transport without the carbon emissions associated with fossil fuels. Life cycle assessments demonstrate that green ammonia production pathways can reduce greenhouse gas emissions by up to 80-90% compared to conventional fuels, though this advantage diminishes significantly if production relies on fossil-based hydrogen.

Water usage represents another important environmental consideration in ammonia fuel systems. The production of hydrogen for ammonia synthesis through electrolysis requires substantial water resources—approximately 9 liters of water per kilogram of ammonia produced. Storage facilities must therefore consider water conservation strategies, particularly in water-stressed regions where ammonia fuel adoption is being considered.

Ammonia's potential toxicity to aquatic ecosystems necessitates robust storage safety protocols. Studies show that ammonia concentrations as low as 0.5 mg/L can be harmful to sensitive aquatic species. Consequently, storage facility design must incorporate multiple containment systems and monitoring technologies to prevent environmental contamination in case of leaks or accidents, particularly near water bodies.

The end-of-life management of ammonia storage infrastructure also factors into sustainability considerations. Materials used in storage tanks and handling equipment should be selected for durability and recyclability. Current best practices indicate that properly designed ammonia storage systems can have operational lifespans exceeding 30 years, with many components being recyclable, thus reducing the overall environmental footprint of the fuel's infrastructure requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!