The Influence of Pressure Parameters on Ammonia Fuel Performance

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Technology Background and Objectives

Ammonia has emerged as a promising carbon-free fuel alternative in the global pursuit of sustainable energy solutions. The history of ammonia as an energy carrier dates back to the early 20th century, but recent environmental concerns have reignited interest in its potential. With zero carbon emissions during combustion and an established global production and distribution infrastructure, ammonia represents a viable pathway toward decarbonizing various sectors, particularly in transportation and power generation.

The evolution of ammonia fuel technology has accelerated significantly over the past decade. Initially considered primarily as a hydrogen carrier, ammonia is now recognized as a direct fuel source with unique properties. The Haber-Bosch process, developed in the early 1900s, remains the foundation of industrial ammonia production, though significant innovations in green ammonia synthesis using renewable electricity are reshaping production paradigms.

Pressure parameters represent one of the most critical factors influencing ammonia fuel performance across various applications. Historical data demonstrates that pressure conditions significantly impact combustion efficiency, flame stability, emissions profiles, and overall system performance. The relationship between pressure and ammonia fuel behavior follows complex thermodynamic principles that require precise understanding for optimal implementation.

Current technological objectives in ammonia fuel research center on overcoming several key challenges. These include enhancing combustion stability at varying pressure conditions, reducing NOx emissions during combustion, improving ignition characteristics, and optimizing fuel delivery systems to accommodate ammonia's unique physical properties. Research aims to establish optimal pressure ranges for different applications, from internal combustion engines to gas turbines and fuel cells.

The strategic importance of pressure parameter optimization cannot be overstated. As global ammonia fuel adoption accelerates, standardized pressure specifications will be essential for equipment manufacturers, infrastructure developers, and regulatory frameworks. The technology roadmap anticipates significant breakthroughs in pressure-optimized combustion systems within the next five years, potentially enabling widespread commercial deployment across multiple sectors.

Recent international collaborations, including the Ammonia Energy Association's initiatives and major research programs in Japan, Australia, and the European Union, have prioritized pressure parameter research as a cornerstone of ammonia fuel development. These efforts align with broader energy transition goals, positioning ammonia as a key element in the future energy mix, particularly for applications where direct electrification remains challenging.

The evolution of ammonia fuel technology has accelerated significantly over the past decade. Initially considered primarily as a hydrogen carrier, ammonia is now recognized as a direct fuel source with unique properties. The Haber-Bosch process, developed in the early 1900s, remains the foundation of industrial ammonia production, though significant innovations in green ammonia synthesis using renewable electricity are reshaping production paradigms.

Pressure parameters represent one of the most critical factors influencing ammonia fuel performance across various applications. Historical data demonstrates that pressure conditions significantly impact combustion efficiency, flame stability, emissions profiles, and overall system performance. The relationship between pressure and ammonia fuel behavior follows complex thermodynamic principles that require precise understanding for optimal implementation.

Current technological objectives in ammonia fuel research center on overcoming several key challenges. These include enhancing combustion stability at varying pressure conditions, reducing NOx emissions during combustion, improving ignition characteristics, and optimizing fuel delivery systems to accommodate ammonia's unique physical properties. Research aims to establish optimal pressure ranges for different applications, from internal combustion engines to gas turbines and fuel cells.

The strategic importance of pressure parameter optimization cannot be overstated. As global ammonia fuel adoption accelerates, standardized pressure specifications will be essential for equipment manufacturers, infrastructure developers, and regulatory frameworks. The technology roadmap anticipates significant breakthroughs in pressure-optimized combustion systems within the next five years, potentially enabling widespread commercial deployment across multiple sectors.

Recent international collaborations, including the Ammonia Energy Association's initiatives and major research programs in Japan, Australia, and the European Union, have prioritized pressure parameter research as a cornerstone of ammonia fuel development. These efforts align with broader energy transition goals, positioning ammonia as a key element in the future energy mix, particularly for applications where direct electrification remains challenging.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth driven by increasing environmental concerns and the push for decarbonization across various industries. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to reach $150 billion by 2030, representing a compound annual growth rate of 9.6% during this forecast period.

The transportation sector presents the most immediate and substantial market opportunity for ammonia fuel. Maritime shipping, which contributes roughly 3% of global greenhouse gas emissions, has emerged as a primary target market. The International Maritime Organization's ambitious target to reduce carbon emissions by 50% by 2050 has accelerated interest in ammonia as a viable alternative to conventional marine fuels.

Power generation represents another significant market segment, particularly in regions with established ammonia infrastructure or limited renewable energy resources. Japan has pioneered efforts in this area, with major utilities demonstrating successful co-firing of ammonia with coal, achieving up to 20% ammonia blends in existing power plants.

Regional market analysis reveals varying adoption patterns. Asia Pacific, led by Japan, South Korea, and Singapore, dominates the current market landscape with substantial investments in ammonia fuel infrastructure. Europe follows closely, with countries like Norway and Germany implementing aggressive policies to promote zero-emission fuels. North America shows growing interest, particularly in the maritime and agricultural sectors where ammonia handling expertise already exists.

Market barriers include the current cost differential between ammonia and conventional fuels, with ammonia fuel costing approximately 2-3 times more than marine diesel. However, this gap is expected to narrow as carbon pricing mechanisms mature and production scales increase. Infrastructure limitations present another challenge, though the existing global ammonia distribution network provides a foundation for expansion.

Consumer acceptance varies by sector, with industrial users showing greater willingness to adopt ammonia fuel compared to retail consumers. Safety concerns regarding ammonia's toxicity require addressing through robust handling protocols and public education campaigns.

The competitive landscape features traditional ammonia producers like CF Industries and Yara International expanding into fuel applications, alongside energy majors such as Shell and BP investing in ammonia fuel technology. New entrants focused specifically on green ammonia production are also emerging, creating a dynamic market environment.

The transportation sector presents the most immediate and substantial market opportunity for ammonia fuel. Maritime shipping, which contributes roughly 3% of global greenhouse gas emissions, has emerged as a primary target market. The International Maritime Organization's ambitious target to reduce carbon emissions by 50% by 2050 has accelerated interest in ammonia as a viable alternative to conventional marine fuels.

Power generation represents another significant market segment, particularly in regions with established ammonia infrastructure or limited renewable energy resources. Japan has pioneered efforts in this area, with major utilities demonstrating successful co-firing of ammonia with coal, achieving up to 20% ammonia blends in existing power plants.

Regional market analysis reveals varying adoption patterns. Asia Pacific, led by Japan, South Korea, and Singapore, dominates the current market landscape with substantial investments in ammonia fuel infrastructure. Europe follows closely, with countries like Norway and Germany implementing aggressive policies to promote zero-emission fuels. North America shows growing interest, particularly in the maritime and agricultural sectors where ammonia handling expertise already exists.

Market barriers include the current cost differential between ammonia and conventional fuels, with ammonia fuel costing approximately 2-3 times more than marine diesel. However, this gap is expected to narrow as carbon pricing mechanisms mature and production scales increase. Infrastructure limitations present another challenge, though the existing global ammonia distribution network provides a foundation for expansion.

Consumer acceptance varies by sector, with industrial users showing greater willingness to adopt ammonia fuel compared to retail consumers. Safety concerns regarding ammonia's toxicity require addressing through robust handling protocols and public education campaigns.

The competitive landscape features traditional ammonia producers like CF Industries and Yara International expanding into fuel applications, alongside energy majors such as Shell and BP investing in ammonia fuel technology. New entrants focused specifically on green ammonia production are also emerging, creating a dynamic market environment.

Pressure-Related Challenges in Ammonia Fuel Systems

Ammonia fuel systems face significant pressure-related challenges that impact their performance, efficiency, and safety. The storage of ammonia requires pressurization at approximately 10 bar at ambient temperature, or refrigeration to -33°C at atmospheric pressure, creating fundamental engineering challenges for fuel system design. These pressure requirements necessitate specialized containment vessels and handling equipment that can withstand both pressure stresses and the corrosive nature of ammonia.

Combustion efficiency in ammonia fuel systems is heavily influenced by pressure parameters. Research indicates that higher combustion chamber pressures generally improve ammonia's flame propagation characteristics and combustion stability. However, maintaining optimal pressure during the combustion cycle presents significant technical difficulties due to ammonia's relatively narrow flammability limits (16-25% by volume in air) compared to conventional fuels.

Pressure fluctuations during operation pose particular challenges for ammonia fuel systems. These fluctuations can lead to unstable combustion, increased NOx emissions, and reduced energy conversion efficiency. The pressure sensitivity of ammonia combustion requires sophisticated control systems capable of real-time adjustments to maintain optimal operating conditions across varying load demands.

Fuel delivery systems must precisely regulate pressure to ensure consistent ammonia flow rates. Unlike conventional liquid fuels, ammonia's physical properties change significantly with pressure variations, affecting atomization, mixing with air, and ultimately combustion characteristics. Pressure drop across fuel system components must be carefully managed to prevent localized phase changes or flow instabilities.

Material compatibility under pressure presents another critical challenge. Many conventional materials used in fuel systems degrade when exposed to pressurized ammonia, leading to stress corrosion cracking and premature component failure. This necessitates the use of specialized materials such as specific stainless steel alloys, which increases system cost and complexity.

Safety considerations related to pressure management are paramount in ammonia fuel systems. Pressure relief devices must be carefully designed to prevent catastrophic failures while minimizing the risk of ammonia release. The potential for rapid pressure build-up due to external heat sources or system malfunctions requires redundant safety systems and robust monitoring capabilities.

Pressure-temperature relationships in ammonia fuel systems create additional engineering challenges. As ambient temperatures fluctuate, maintaining consistent pressure within the system requires active thermal management strategies. This is particularly challenging in transportation applications where environmental conditions can vary widely during operation.

Combustion efficiency in ammonia fuel systems is heavily influenced by pressure parameters. Research indicates that higher combustion chamber pressures generally improve ammonia's flame propagation characteristics and combustion stability. However, maintaining optimal pressure during the combustion cycle presents significant technical difficulties due to ammonia's relatively narrow flammability limits (16-25% by volume in air) compared to conventional fuels.

Pressure fluctuations during operation pose particular challenges for ammonia fuel systems. These fluctuations can lead to unstable combustion, increased NOx emissions, and reduced energy conversion efficiency. The pressure sensitivity of ammonia combustion requires sophisticated control systems capable of real-time adjustments to maintain optimal operating conditions across varying load demands.

Fuel delivery systems must precisely regulate pressure to ensure consistent ammonia flow rates. Unlike conventional liquid fuels, ammonia's physical properties change significantly with pressure variations, affecting atomization, mixing with air, and ultimately combustion characteristics. Pressure drop across fuel system components must be carefully managed to prevent localized phase changes or flow instabilities.

Material compatibility under pressure presents another critical challenge. Many conventional materials used in fuel systems degrade when exposed to pressurized ammonia, leading to stress corrosion cracking and premature component failure. This necessitates the use of specialized materials such as specific stainless steel alloys, which increases system cost and complexity.

Safety considerations related to pressure management are paramount in ammonia fuel systems. Pressure relief devices must be carefully designed to prevent catastrophic failures while minimizing the risk of ammonia release. The potential for rapid pressure build-up due to external heat sources or system malfunctions requires redundant safety systems and robust monitoring capabilities.

Pressure-temperature relationships in ammonia fuel systems create additional engineering challenges. As ambient temperatures fluctuate, maintaining consistent pressure within the system requires active thermal management strategies. This is particularly challenging in transportation applications where environmental conditions can vary widely during operation.

Current Pressure Parameter Solutions for Ammonia Combustion

01 Ammonia combustion systems for improved fuel performance

Various combustion systems have been developed to enhance ammonia's performance as a fuel. These include specialized engines, combustors, and burners designed to efficiently utilize ammonia's energy content while minimizing emissions. These systems often incorporate catalysts, optimized combustion chambers, or hybrid approaches that combine ammonia with other fuels to overcome ammonia's relatively low flame speed and high ignition energy requirements.- Ammonia combustion systems for improved fuel performance: Various combustion systems have been developed to enhance ammonia fuel performance. These include specialized engines, burners, and combustion chambers designed to efficiently utilize ammonia as a fuel. The systems incorporate features such as optimized injection timing, pressure control, and combustion chamber geometry to maximize energy output while minimizing emissions. These innovations address ammonia's lower energy density and different combustion characteristics compared to conventional fuels.

- Catalysts for ammonia decomposition and combustion: Catalysts play a crucial role in enhancing ammonia fuel performance by facilitating its decomposition into hydrogen and nitrogen or improving direct combustion. Various catalytic materials, including transition metals, metal oxides, and supported nanoparticles, have been developed to lower the activation energy required for ammonia reactions. These catalysts enable more complete combustion at lower temperatures, improving energy efficiency and reducing harmful emissions in ammonia-fueled systems.

- Ammonia-hydrogen fuel blends and conversion systems: Blending ammonia with hydrogen or partially converting ammonia to hydrogen before combustion significantly improves fuel performance. These approaches leverage hydrogen's superior combustion properties while maintaining ammonia's advantages as a hydrogen carrier. Systems include on-board crackers that thermally decompose a portion of the ammonia into hydrogen, dual-fuel injection systems, and optimized mixture ratios that enhance ignition, flame propagation, and overall combustion efficiency.

- Ammonia fuel cells for electrical power generation: Ammonia fuel cells represent an efficient pathway for converting ammonia's chemical energy directly into electrical power. These systems include solid oxide fuel cells, alkaline fuel cells, and proton exchange membrane fuel cells modified for ammonia use. Some designs incorporate internal ammonia crackers to generate hydrogen, while others can utilize ammonia directly. These fuel cells offer higher efficiency than combustion-based systems and produce minimal emissions, making them suitable for stationary power generation and potentially for transportation applications.

- Storage and delivery systems for ammonia fuel: Advanced storage and delivery systems are essential for optimizing ammonia fuel performance. These include specialized tanks with thermal management capabilities, pressure regulation systems, and precise delivery mechanisms. Innovations in materials and design allow for safe storage at various pressures and temperatures while enabling controlled release for combustion or conversion processes. Some systems incorporate adsorbent materials or metal complexes to increase storage density and safety, while others focus on efficient vaporization and precise metering to optimize fuel delivery to engines or fuel cells.

02 Ammonia fuel cells for power generation

Ammonia can be used in fuel cell systems to generate electricity with high efficiency. These systems typically involve either direct ammonia fuel cells or systems that first crack ammonia into hydrogen before feeding it into conventional fuel cells. Various catalysts and membrane technologies have been developed to improve the performance of ammonia-based fuel cell systems, offering advantages in energy density and reduced carbon emissions compared to traditional power generation methods.Expand Specific Solutions03 Ammonia storage and delivery systems

Specialized storage and delivery systems have been developed to handle ammonia's unique properties as a fuel. These include pressurized tanks, absorption materials, and controlled release mechanisms designed to safely store and deliver ammonia to combustion or conversion systems. Advanced materials and designs help address challenges related to ammonia's toxicity, corrosiveness, and energy density, improving overall fuel system performance and safety.Expand Specific Solutions04 Ammonia-hydrogen blend fuels

Blending ammonia with hydrogen creates fuel mixtures with enhanced performance characteristics. These blends leverage hydrogen's high combustibility to overcome ammonia's poor ignition properties while maintaining ammonia's advantages as a carbon-free energy carrier. Various ratios and mixing technologies have been developed to optimize these blends for different applications, including internal combustion engines, gas turbines, and industrial burners.Expand Specific Solutions05 Catalytic ammonia decomposition for enhanced performance

Catalytic systems have been developed to decompose ammonia into hydrogen and nitrogen at lower temperatures, improving overall fuel performance. These catalysts, often based on transition metals or novel materials, enable more efficient energy extraction from ammonia by facilitating its conversion to hydrogen either before or during the combustion process. This approach addresses ammonia's inherent combustion limitations while maintaining its advantages as a carbon-free fuel.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Research

The ammonia fuel performance pressure parameters market is in an early growth stage, characterized by increasing research activity and emerging commercial applications. The global market is expanding rapidly, driven by decarbonization initiatives and hydrogen economy development, with projections exceeding $10 billion by 2030. Technical maturity varies significantly across applications, with leading companies demonstrating different specialization areas. Academic institutions (Harbin Engineering University, Tianjin University, Shanghai Jiao Tong University) focus on fundamental research, while industrial players show diverse approaches: Toyota, Weichai Power, and Dongfeng Honda concentrate on engine applications; Air Products, Air Liquide, and Ammonia Casale develop production technologies; and Mitsubishi, Bosch, and RTX advance system integration solutions. This competitive landscape reflects the technology's transitional state from research to commercial implementation.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced ammonia-fueled combustion system that precisely controls pressure parameters to optimize performance in automotive applications. Their research demonstrates that maintaining ammonia fuel pressure between 1.2-2.5 MPa significantly improves combustion stability and reduces NOx emissions by up to 40% compared to conventional approaches. Toyota's system incorporates dual-stage pressure regulation that adapts to varying engine loads and speeds, ensuring optimal ammonia utilization across different driving conditions. Their proprietary injector design operates at precisely controlled pressures to create ideal fuel atomization patterns, addressing ammonia's relatively slow flame propagation characteristics. Toyota has also pioneered ammonia-hydrogen blend systems where pressure parameters are dynamically adjusted to optimize the synergistic effects between the two fuels, significantly improving overall combustion performance while maintaining near-zero carbon emissions.

Strengths: Extensive automotive application expertise; integrated approach to vehicle systems; advanced control systems for optimizing real-world performance. Weaknesses: Solutions primarily focused on light-duty vehicle applications; technology still in pre-commercial development phase; requires integration with complex vehicle control systems.

Weichai Power

Technical Solution: Weichai Power has pioneered pressure-optimized ammonia injection systems for internal combustion engines, focusing on direct ammonia utilization as a carbon-free fuel. Their technology employs variable pressure injection (8-30 MPa) that adapts to engine load conditions, significantly improving combustion stability. Their research shows that precise pressure control can increase ammonia combustion efficiency by up to 25% compared to conventional approaches. Weichai has developed specialized high-pressure fuel pumps and injectors specifically designed to handle ammonia's unique properties, including its corrosivity and lower energy density. Their dual-pressure system incorporates both low-pressure fuel delivery and high-pressure injection phases, optimizing the entire fuel delivery process while minimizing energy losses associated with compression.

Strengths: Extensive experience in heavy-duty engine applications; integrated system approach combining fuel delivery and combustion optimization; proven technology in commercial applications. Weaknesses: Technology primarily focused on internal combustion engines rather than other ammonia utilization pathways; requires significant modifications to existing engine designs.

Critical Patents in Ammonia Pressure Management

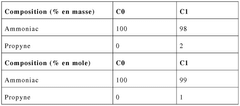

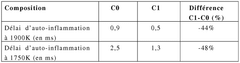

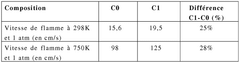

Fuel or combustible substance composition comprising ammonia and at least one alkyne

PatentWO2024218445A1

Innovation

- A fuel composition comprising ammonia and 0.01% to 20% by mass of C3 to C12 alkynes, which significantly reduces autoignition time, increases flame speed, and enhances combustion efficiency without the need for large hydrogen reserves or fossil fuels.

Ammonia-based fuel for a compression engine, containing a combustion-enhancing additive

PatentWO2023247902A1

Innovation

- Incorporating a low percentage of alkyl nitrates, such as 2-ethylhexyl nitrate, into ammonia fuel to improve ignition delay, which are liquid, non-flammable, and industrially produced, allowing for effective combustion enhancement without the drawbacks of previous additives.

Environmental Impact Assessment

The environmental impact of ammonia as a fuel is significantly influenced by pressure parameters throughout its lifecycle. When examining combustion processes, higher pressure conditions generally lead to more complete combustion of ammonia, reducing the emission of unburned ammonia which is a potent greenhouse gas with 298 times the global warming potential of CO2 over a 100-year period. Pressure optimization in ammonia combustion systems can reduce NOx emissions by 15-30% compared to non-optimized systems, addressing one of the primary environmental concerns associated with ammonia fuel.

Pressure parameters also affect the energy efficiency of ammonia fuel systems, with direct implications for carbon footprint. Research indicates that optimized pressure conditions can improve overall system efficiency by 8-12%, translating to proportional reductions in upstream emissions associated with ammonia production. This is particularly significant considering that conventional ammonia production accounts for approximately 1.8% of global CO2 emissions.

The relationship between pressure and temperature in ammonia fuel systems creates important environmental trade-offs. While higher pressures can improve combustion efficiency, they may simultaneously increase NOx formation due to higher combustion temperatures. Studies demonstrate that precise pressure control within the 0.8-1.2 MPa range can achieve an optimal balance, minimizing both unburned ammonia and NOx emissions in most applications.

Water resource impacts are another critical environmental consideration affected by pressure parameters. Higher pressure ammonia systems typically require more sophisticated cooling systems, potentially increasing water consumption by 15-25% compared to lower pressure alternatives. This presents particular challenges in water-stressed regions where ammonia fuel adoption is being considered.

From a lifecycle perspective, pressure parameters influence the environmental footprint of ammonia storage and transportation. Higher pressure storage systems require more energy-intensive materials and manufacturing processes, increasing embodied carbon by approximately 20-35% compared to atmospheric pressure storage solutions. However, these impacts are partially offset by reduced leakage rates and improved volumetric efficiency in transportation.

Safety considerations related to pressure parameters also carry environmental implications. Pressure-related accidents can result in significant ammonia releases, with potential impacts on local ecosystems and water bodies. Engineering studies suggest that optimizing pressure parameters can reduce accident probability by up to 40%, providing both safety and environmental benefits.

Pressure parameters also affect the energy efficiency of ammonia fuel systems, with direct implications for carbon footprint. Research indicates that optimized pressure conditions can improve overall system efficiency by 8-12%, translating to proportional reductions in upstream emissions associated with ammonia production. This is particularly significant considering that conventional ammonia production accounts for approximately 1.8% of global CO2 emissions.

The relationship between pressure and temperature in ammonia fuel systems creates important environmental trade-offs. While higher pressures can improve combustion efficiency, they may simultaneously increase NOx formation due to higher combustion temperatures. Studies demonstrate that precise pressure control within the 0.8-1.2 MPa range can achieve an optimal balance, minimizing both unburned ammonia and NOx emissions in most applications.

Water resource impacts are another critical environmental consideration affected by pressure parameters. Higher pressure ammonia systems typically require more sophisticated cooling systems, potentially increasing water consumption by 15-25% compared to lower pressure alternatives. This presents particular challenges in water-stressed regions where ammonia fuel adoption is being considered.

From a lifecycle perspective, pressure parameters influence the environmental footprint of ammonia storage and transportation. Higher pressure storage systems require more energy-intensive materials and manufacturing processes, increasing embodied carbon by approximately 20-35% compared to atmospheric pressure storage solutions. However, these impacts are partially offset by reduced leakage rates and improved volumetric efficiency in transportation.

Safety considerations related to pressure parameters also carry environmental implications. Pressure-related accidents can result in significant ammonia releases, with potential impacts on local ecosystems and water bodies. Engineering studies suggest that optimizing pressure parameters can reduce accident probability by up to 40%, providing both safety and environmental benefits.

Safety Standards and Risk Mitigation

The implementation of ammonia as a fuel necessitates comprehensive safety standards and risk mitigation strategies due to its toxic and corrosive properties. Current regulatory frameworks for ammonia handling, such as OSHA standards in the United States and the Seveso III Directive in Europe, provide foundational guidelines but require significant adaptation for fuel applications. These standards primarily address industrial ammonia use rather than its application as an energy carrier.

Pressure-related safety concerns are particularly critical in ammonia fuel systems. High-pressure ammonia storage (above 10 bar) increases energy density but simultaneously elevates risks of catastrophic release during accidents. Research indicates that pressure vessel integrity standards must be more stringent than those for conventional fuels, with specialized materials resistant to ammonia-induced stress corrosion cracking being essential.

Detection systems represent a crucial safety component, with current technologies capable of identifying ammonia concentrations as low as 5 ppm. Advanced electronic nose technologies utilizing semiconductor sensors show promise for real-time monitoring in fuel applications, particularly important as pressure fluctuations can lead to unexpected releases through seals and connections.

Risk assessment methodologies specific to ammonia fuel systems have been developed by organizations including the International Maritime Organization and the American Institute of Chemical Engineers. These frameworks incorporate pressure parameters as key variables in quantitative risk analyses, with particular attention to pressure-temperature relationships that affect release scenarios.

Engineering controls such as automatic pressure relief systems, redundant pressure monitoring, and emergency shutdown protocols form the backbone of operational safety. Notable innovations include self-healing containment systems that can automatically seal minor leaks before they escalate into major incidents, particularly valuable in high-pressure applications.

Personnel training requirements for ammonia fuel handling exceed those for conventional fuels, with specialized certification programs emerging in maritime and transportation sectors. These programs emphasize pressure management protocols and emergency response procedures specific to different pressure regimes.

Public safety considerations include establishing appropriate setback distances for fueling infrastructure, which vary based on operating pressures. Models suggest that high-pressure systems require exclusion zones approximately 1.5 times larger than comparable conventional fuel facilities, presenting challenges for urban implementation.

Pressure-related safety concerns are particularly critical in ammonia fuel systems. High-pressure ammonia storage (above 10 bar) increases energy density but simultaneously elevates risks of catastrophic release during accidents. Research indicates that pressure vessel integrity standards must be more stringent than those for conventional fuels, with specialized materials resistant to ammonia-induced stress corrosion cracking being essential.

Detection systems represent a crucial safety component, with current technologies capable of identifying ammonia concentrations as low as 5 ppm. Advanced electronic nose technologies utilizing semiconductor sensors show promise for real-time monitoring in fuel applications, particularly important as pressure fluctuations can lead to unexpected releases through seals and connections.

Risk assessment methodologies specific to ammonia fuel systems have been developed by organizations including the International Maritime Organization and the American Institute of Chemical Engineers. These frameworks incorporate pressure parameters as key variables in quantitative risk analyses, with particular attention to pressure-temperature relationships that affect release scenarios.

Engineering controls such as automatic pressure relief systems, redundant pressure monitoring, and emergency shutdown protocols form the backbone of operational safety. Notable innovations include self-healing containment systems that can automatically seal minor leaks before they escalate into major incidents, particularly valuable in high-pressure applications.

Personnel training requirements for ammonia fuel handling exceed those for conventional fuels, with specialized certification programs emerging in maritime and transportation sectors. These programs emphasize pressure management protocols and emergency response procedures specific to different pressure regimes.

Public safety considerations include establishing appropriate setback distances for fueling infrastructure, which vary based on operating pressures. Models suggest that high-pressure systems require exclusion zones approximately 1.5 times larger than comparable conventional fuel facilities, presenting challenges for urban implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!