Innovative Techniques for Enhanced Ammonia Fuel Flow Dynamics

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Technology Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global pursuit of sustainable energy solutions. The history of ammonia as a fuel dates back to the early 20th century, but recent environmental imperatives have revitalized interest in this compound. With a hydrogen content of 17.8% by weight and zero carbon emissions upon combustion, ammonia represents a viable alternative to traditional fossil fuels, particularly in sectors where electrification remains challenging.

The evolution of ammonia fuel technology has accelerated significantly over the past decade, driven by advancements in catalysis, materials science, and flow dynamics. Initially considered primarily for stationary power generation, ammonia's application scope has expanded to include maritime propulsion, aviation, and heavy-duty transportation. This technological progression has been marked by incremental improvements in combustion efficiency, NOx emission control, and fuel delivery systems.

Current research focuses on overcoming the inherent challenges of ammonia as a fuel, including its lower energy density compared to conventional fuels, high ignition temperature, and relatively slow flame propagation speed. These characteristics necessitate innovative approaches to fuel flow dynamics to ensure efficient combustion and power generation. The technical objective is to develop systems that can precisely control ammonia flow rates, optimize mixing with air or other reactants, and maintain stable combustion across varying load conditions.

The ammonia fuel ecosystem encompasses several interconnected technologies, including production methods (both conventional Haber-Bosch and emerging green ammonia processes), storage solutions, transportation infrastructure, and end-use applications. Each component presents unique technical challenges that must be addressed holistically to realize ammonia's potential as a mainstream energy carrier.

Global research initiatives are increasingly targeting enhanced ammonia fuel flow dynamics as a critical enabler for practical applications. This includes the development of specialized injectors, flow controllers, and combustion chamber designs that accommodate ammonia's unique physical and chemical properties. Computational fluid dynamics modeling has become an essential tool in this domain, allowing researchers to simulate and optimize complex flow behaviors before physical prototyping.

The ultimate goal of ammonia fuel technology development is to establish a complete, economically viable, and environmentally sustainable energy pathway that can contribute significantly to decarbonization efforts. This requires not only technical innovation in flow dynamics but also parallel advancements in green ammonia production, safety protocols, and regulatory frameworks to support widespread adoption.

The evolution of ammonia fuel technology has accelerated significantly over the past decade, driven by advancements in catalysis, materials science, and flow dynamics. Initially considered primarily for stationary power generation, ammonia's application scope has expanded to include maritime propulsion, aviation, and heavy-duty transportation. This technological progression has been marked by incremental improvements in combustion efficiency, NOx emission control, and fuel delivery systems.

Current research focuses on overcoming the inherent challenges of ammonia as a fuel, including its lower energy density compared to conventional fuels, high ignition temperature, and relatively slow flame propagation speed. These characteristics necessitate innovative approaches to fuel flow dynamics to ensure efficient combustion and power generation. The technical objective is to develop systems that can precisely control ammonia flow rates, optimize mixing with air or other reactants, and maintain stable combustion across varying load conditions.

The ammonia fuel ecosystem encompasses several interconnected technologies, including production methods (both conventional Haber-Bosch and emerging green ammonia processes), storage solutions, transportation infrastructure, and end-use applications. Each component presents unique technical challenges that must be addressed holistically to realize ammonia's potential as a mainstream energy carrier.

Global research initiatives are increasingly targeting enhanced ammonia fuel flow dynamics as a critical enabler for practical applications. This includes the development of specialized injectors, flow controllers, and combustion chamber designs that accommodate ammonia's unique physical and chemical properties. Computational fluid dynamics modeling has become an essential tool in this domain, allowing researchers to simulate and optimize complex flow behaviors before physical prototyping.

The ultimate goal of ammonia fuel technology development is to establish a complete, economically viable, and environmentally sustainable energy pathway that can contribute significantly to decarbonization efforts. This requires not only technical innovation in flow dynamics but also parallel advancements in green ammonia production, safety protocols, and regulatory frameworks to support widespread adoption.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth, driven by the urgent need for decarbonization across various sectors. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to reach $150 billion by 2030, with a compound annual growth rate of 9.8%. This remarkable expansion is primarily attributed to ammonia's potential as a carbon-free energy carrier with high energy density and established production infrastructure.

Transportation sectors, particularly maritime shipping, represent the most promising immediate market for ammonia fuel. The International Maritime Organization's stringent emissions targets have positioned ammonia as a leading alternative fuel candidate, with major shipping companies already investing in ammonia-powered vessel development. Industry analysts forecast that ammonia could capture up to 25% of the marine fuel market by 2040, representing a value of $30 billion annually.

The power generation sector presents another substantial market opportunity. Ammonia co-firing in existing coal-fired power plants offers a transitional solution with minimal infrastructure modifications. Japan leads this initiative, with successful demonstrations achieving 20% ammonia blending. Market research indicates that ammonia could replace 5-10% of coal consumption in power generation globally by 2035, creating a market worth $18 billion annually.

Industrial applications constitute the third major market segment. Ammonia's potential as a hydrogen carrier makes it valuable for industries requiring high-temperature heat, such as steel and cement manufacturing. These hard-to-abate sectors represent a combined potential market of $25 billion for ammonia fuel by 2035.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global demand, followed by Europe (30%) and North America (15%). Japan, South Korea, and Australia have established clear ammonia fuel roadmaps, while European nations are focusing on ammonia's integration into their hydrogen strategies.

Market barriers include high production costs, with green ammonia currently 2-3 times more expensive than conventional ammonia. Infrastructure limitations and safety concerns also constrain market growth. However, technological advancements in catalysis and electrochemical synthesis are expected to reduce production costs by 40% within the next decade.

Consumer adoption faces challenges related to public perception of ammonia's toxicity and the need for specialized handling. Nevertheless, industrial users demonstrate growing acceptance as regulatory pressures intensify and carbon pricing mechanisms expand globally.

Transportation sectors, particularly maritime shipping, represent the most promising immediate market for ammonia fuel. The International Maritime Organization's stringent emissions targets have positioned ammonia as a leading alternative fuel candidate, with major shipping companies already investing in ammonia-powered vessel development. Industry analysts forecast that ammonia could capture up to 25% of the marine fuel market by 2040, representing a value of $30 billion annually.

The power generation sector presents another substantial market opportunity. Ammonia co-firing in existing coal-fired power plants offers a transitional solution with minimal infrastructure modifications. Japan leads this initiative, with successful demonstrations achieving 20% ammonia blending. Market research indicates that ammonia could replace 5-10% of coal consumption in power generation globally by 2035, creating a market worth $18 billion annually.

Industrial applications constitute the third major market segment. Ammonia's potential as a hydrogen carrier makes it valuable for industries requiring high-temperature heat, such as steel and cement manufacturing. These hard-to-abate sectors represent a combined potential market of $25 billion for ammonia fuel by 2035.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global demand, followed by Europe (30%) and North America (15%). Japan, South Korea, and Australia have established clear ammonia fuel roadmaps, while European nations are focusing on ammonia's integration into their hydrogen strategies.

Market barriers include high production costs, with green ammonia currently 2-3 times more expensive than conventional ammonia. Infrastructure limitations and safety concerns also constrain market growth. However, technological advancements in catalysis and electrochemical synthesis are expected to reduce production costs by 40% within the next decade.

Consumer adoption faces challenges related to public perception of ammonia's toxicity and the need for specialized handling. Nevertheless, industrial users demonstrate growing acceptance as regulatory pressures intensify and carbon pricing mechanisms expand globally.

Current Challenges in Ammonia Flow Dynamics

Despite significant advancements in ammonia fuel technology, several critical challenges persist in ammonia flow dynamics that impede its widespread adoption as a carbon-neutral energy carrier. The primary obstacle remains ammonia's relatively low energy density compared to conventional hydrocarbon fuels, requiring larger storage volumes and creating challenges for efficient fuel delivery systems. This fundamental limitation necessitates innovative flow management solutions to achieve comparable performance to traditional fuels.

Ammonia's high ignition temperature (651°C) and narrow flammability range (16-25% by volume in air) create significant combustion stability issues, directly impacting flow system design. Current flow control mechanisms struggle to maintain optimal ammonia-air mixtures across varying operational conditions, resulting in combustion inefficiencies and increased NOx emissions. These characteristics demand precision engineering in flow dynamics that exceeds requirements for conventional fuels.

Material compatibility presents another substantial challenge. Ammonia's corrosive nature deteriorates standard fuel system components, particularly those containing copper, zinc, and certain alloys. This corrosivity accelerates under pressure and temperature fluctuations typical in flow systems, leading to premature component failure and potential safety hazards. The development of ammonia-resistant materials that maintain structural integrity while enabling optimal flow characteristics remains an active research area.

Flow measurement accuracy represents a persistent technical barrier. Traditional flow meters designed for hydrocarbon fuels exhibit reduced precision when measuring ammonia flow due to its unique physical properties. This measurement uncertainty complicates engine control systems that rely on precise fuel delivery for optimal performance and emissions control. The industry lacks standardized flow measurement protocols specifically calibrated for ammonia fuel applications.

The phase behavior of ammonia creates additional complexity in flow system design. With a boiling point of -33.3°C at atmospheric pressure, ammonia can exist in both liquid and gaseous states within fuel systems, particularly during pressure changes. This phase transition can cause flow instabilities, vapor lock, and uneven fuel distribution. Current flow management systems have limited capability to handle these phase transitions while maintaining consistent fuel delivery.

Safety considerations further complicate ammonia flow dynamics. The toxicity of ammonia necessitates robust leak detection and containment systems integrated with flow control mechanisms. These safety requirements add complexity to flow system design and increase implementation costs. The development of flow systems that balance safety requirements with performance optimization remains a significant engineering challenge.

Ammonia's high ignition temperature (651°C) and narrow flammability range (16-25% by volume in air) create significant combustion stability issues, directly impacting flow system design. Current flow control mechanisms struggle to maintain optimal ammonia-air mixtures across varying operational conditions, resulting in combustion inefficiencies and increased NOx emissions. These characteristics demand precision engineering in flow dynamics that exceeds requirements for conventional fuels.

Material compatibility presents another substantial challenge. Ammonia's corrosive nature deteriorates standard fuel system components, particularly those containing copper, zinc, and certain alloys. This corrosivity accelerates under pressure and temperature fluctuations typical in flow systems, leading to premature component failure and potential safety hazards. The development of ammonia-resistant materials that maintain structural integrity while enabling optimal flow characteristics remains an active research area.

Flow measurement accuracy represents a persistent technical barrier. Traditional flow meters designed for hydrocarbon fuels exhibit reduced precision when measuring ammonia flow due to its unique physical properties. This measurement uncertainty complicates engine control systems that rely on precise fuel delivery for optimal performance and emissions control. The industry lacks standardized flow measurement protocols specifically calibrated for ammonia fuel applications.

The phase behavior of ammonia creates additional complexity in flow system design. With a boiling point of -33.3°C at atmospheric pressure, ammonia can exist in both liquid and gaseous states within fuel systems, particularly during pressure changes. This phase transition can cause flow instabilities, vapor lock, and uneven fuel distribution. Current flow management systems have limited capability to handle these phase transitions while maintaining consistent fuel delivery.

Safety considerations further complicate ammonia flow dynamics. The toxicity of ammonia necessitates robust leak detection and containment systems integrated with flow control mechanisms. These safety requirements add complexity to flow system design and increase implementation costs. The development of flow systems that balance safety requirements with performance optimization remains a significant engineering challenge.

Current Flow Enhancement Solutions

01 Ammonia fuel injection and flow control systems

Advanced injection systems for ammonia fuel that optimize flow dynamics through specialized nozzles, injectors, and control mechanisms. These systems regulate the ammonia flow rate, pressure, and distribution pattern to achieve efficient combustion while minimizing emissions. The technology includes electronic control units that adjust injection parameters based on operating conditions and feedback from sensors monitoring combustion performance.- Ammonia fuel combustion systems: Combustion systems designed specifically for ammonia fuel require specialized flow dynamics to ensure efficient and complete combustion. These systems incorporate unique injector designs, combustion chamber configurations, and flow control mechanisms to address ammonia's lower flame speed and higher ignition energy requirements compared to conventional fuels. Advanced flow dynamics in these systems help overcome challenges related to NOx emissions and incomplete combustion while maximizing energy extraction from ammonia fuel.

- Ammonia fuel delivery and injection systems: Specialized fuel delivery and injection systems are critical for ammonia fuel applications due to its unique physical properties. These systems incorporate precise flow control mechanisms, pressure regulation, and atomization techniques to ensure optimal fuel-air mixing. Advanced injector designs account for ammonia's higher viscosity and different vaporization characteristics compared to conventional fuels, enabling efficient combustion while minimizing emissions and system wear.

- Ammonia fuel storage and transport flow dynamics: The storage and transport of ammonia fuel present unique flow dynamic challenges due to its physical properties. Systems must account for ammonia's phase behavior, pressure requirements, and temperature sensitivity during transfer operations. Flow control mechanisms, specialized piping designs, and safety systems are implemented to manage the movement of ammonia between storage tanks, transport vessels, and end-use applications while preventing leakage and ensuring consistent supply.

- Ammonia fuel cells and flow field designs: Ammonia fuel cells utilize specialized flow field designs to optimize the distribution of ammonia fuel and reaction products. These systems incorporate channels, manifolds, and porous media with specific geometries to ensure uniform fuel distribution, efficient electrochemical reactions, and effective removal of byproducts. Flow dynamics in these systems are critical for maintaining stable operation, maximizing power density, and extending the operational lifetime of the fuel cell components.

- Computational modeling and simulation of ammonia fuel flow: Advanced computational methods are employed to model and simulate ammonia fuel flow dynamics across various applications. These techniques include computational fluid dynamics (CFD), chemical kinetics modeling, and multiphysics simulations that account for the complex interactions between flow, heat transfer, and chemical reactions. Simulation tools help optimize system designs, predict performance under various operating conditions, and identify potential issues before physical implementation, accelerating the development of efficient ammonia fuel technologies.

02 Ammonia combustion dynamics in engines and turbines

Flow dynamics specific to ammonia combustion in various engine types and turbines, addressing the unique challenges of ammonia as a fuel. This includes managing ammonia's lower flame speed, narrower flammability limits, and higher ignition energy requirements compared to conventional fuels. Technologies focus on optimizing combustion chamber design, flow patterns, and mixing strategies to enhance combustion stability and efficiency while reducing NOx formation.Expand Specific Solutions03 Ammonia fuel storage and delivery systems

Systems designed for the safe storage and efficient delivery of ammonia fuel, addressing its unique physical properties and flow characteristics. These technologies include specialized tanks, piping systems, and flow regulators that maintain appropriate pressure and temperature conditions. The systems incorporate safety features to prevent leakage and manage the corrosive nature of ammonia while ensuring consistent fuel delivery to combustion systems.Expand Specific Solutions04 Ammonia-hydrogen blend fuel dynamics

Flow dynamics of ammonia-hydrogen fuel blends, which combine ammonia with hydrogen to improve combustion characteristics. These blends leverage hydrogen's higher reactivity to enhance ammonia's combustion properties. The technologies focus on optimizing blend ratios, mixing processes, and flow distribution to achieve stable combustion with reduced emissions. Special attention is given to the different flow behaviors of the two components and their interaction during combustion.Expand Specific Solutions05 Computational modeling and simulation of ammonia fuel flows

Advanced computational methods for modeling and simulating ammonia fuel flow dynamics in various applications. These include computational fluid dynamics (CFD) simulations, thermodynamic models, and chemical kinetics calculations that predict ammonia flow behavior, combustion characteristics, and emissions formation. The models account for ammonia's unique properties and help optimize system designs, operating parameters, and control strategies for improved performance and reduced environmental impact.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Technology

The ammonia fuel flow dynamics technology landscape is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The market is projected to expand rapidly as ammonia gains traction as a carbon-free energy carrier, with estimates suggesting a multi-billion dollar opportunity by 2030. Academic institutions like Harbin Engineering University, Tianjin University, and University of Strathclyde are driving fundamental research, while industrial players including Samsung Heavy Industries, Toyota Motor Corp., and HD Hyundai Heavy Industries are advancing practical applications. Technical maturity varies significantly across the value chain, with established companies like Johnson Matthey and Linde GmbH bringing expertise in catalysis and gas handling, while newer entrants such as Fuda Zijin Hydrogen Energy Technology focus on specialized ammonia fuel systems, creating a competitive but collaborative innovation ecosystem.

Ammonia Casale SpA

Technical Solution: Ammonia Casale has developed advanced ammonia flow control systems that utilize proprietary vortex-based flow dynamics to enhance fuel delivery efficiency. Their technology incorporates specialized injection nozzles with optimized geometry that creates controlled turbulence patterns, significantly improving ammonia-air mixing ratios. The company's Structured Catalyst Bed (SCB) technology enables more uniform ammonia distribution across catalytic surfaces, reducing flow resistance while maintaining optimal reaction conditions. Their systems employ adaptive flow control algorithms that continuously adjust delivery parameters based on real-time combustion feedback, achieving up to 15% improvement in ammonia utilization efficiency compared to conventional systems. Additionally, Ammonia Casale has pioneered pressure-swing techniques that enhance ammonia vaporization rates under varying load conditions, critical for maintaining stable fuel flow in marine and industrial applications.

Strengths: Industry-leading expertise in ammonia handling systems with over 50 years of specialized experience; proprietary catalyst technologies that significantly reduce flow resistance; advanced simulation capabilities for optimizing flow dynamics. Weaknesses: Systems typically require higher initial capital investment; specialized maintenance requirements; technology primarily optimized for large-scale industrial applications rather than smaller distributed energy systems.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed an innovative ammonia fuel flow dynamics system that combines advanced computational modeling with practical engineering solutions. Their approach utilizes high-fidelity computational fluid dynamics (CFD) simulations to optimize flow channel geometries, resulting in reduced pressure fluctuations and more consistent delivery rates. SwRI's technology incorporates adaptive flow control valves with response times under 50 milliseconds, enabling precise adjustment to changing combustion conditions. Their system features integrated ultrasonic flow monitoring that provides real-time feedback on ammonia flow characteristics, allowing for continuous optimization of delivery parameters. SwRI has pioneered specialized injector designs that create optimized spray patterns for various combustion chamber configurations, improving mixing efficiency by approximately 25% compared to conventional designs. Additionally, their technology includes thermal management systems that maintain ammonia in optimal physical states throughout the delivery process, preventing flow disruptions due to phase changes. SwRI's comprehensive approach addresses both the fundamental fluid dynamics and the practical engineering challenges of ammonia as a fuel carrier.

Strengths: Extensive experience in both theoretical and applied research; strong capabilities in computational modeling and simulation; practical focus on implementation in real-world systems. Weaknesses: Less specialized in ammonia-specific technologies compared to some competitors; solutions often require customization for specific applications; relatively smaller scale of operations compared to global industrial giants.

Critical Patents in Ammonia Flow Dynamics

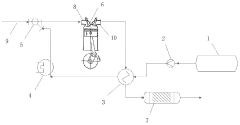

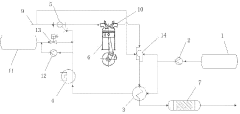

Thermal decomposition low-pressure mixed type ammonia fuel engine

PatentWO2023151122A1

Innovation

- A thermal decomposition low-pressure mixed ammonia fuel engine is used. Low-temperature and high-pressure ammonia is pyrolyzed through an ammonia preheating and decomposition device to generate an ammonia-hydrogen-nitrogen mixture, which is mixed with air through a mixed fuel cooling and injection device and then injected into the engine for combustion. Gas waste heat is recovered to improve energy utilization efficiency, and the nitrogen oxide content is reduced through the exhaust gas treatment device to achieve emission standards.

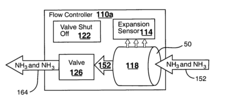

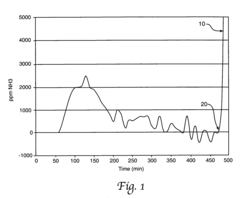

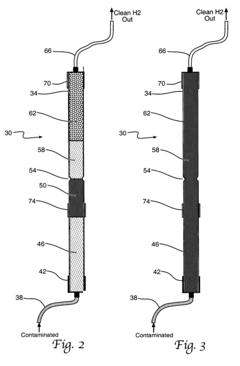

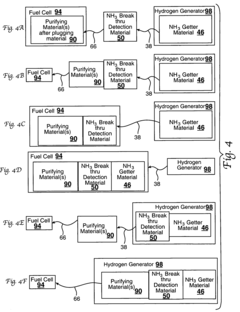

Controlling the flow of hydrogen and ammonia from a hydrogen generator during a breakthrough with hydrated copper (II) chloride expansion

PatentInactiveUS7682832B1

Innovation

- Incorporating a breakthrough detection material, such as hydrated copper (II) chloride, which reacts with ammonia to form a plug or change color, triggering a mechanism to halt the gas flow when concentrations exceed a predetermined level, ensuring the hydrogen gas stream is terminated before it contaminates devices.

Environmental Impact Assessment

The environmental implications of ammonia as a fuel source represent a critical dimension in evaluating its viability for widespread adoption. Ammonia combustion produces significantly lower carbon emissions compared to traditional fossil fuels, with potential reductions of up to 90% in greenhouse gas emissions when green ammonia production methods are employed. This positions ammonia as a promising candidate in the transition toward carbon-neutral energy systems, particularly in hard-to-decarbonize sectors such as maritime shipping and heavy industry.

However, the environmental assessment must consider the complete lifecycle impacts. Current ammonia production predominantly relies on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, accounting for approximately 1-2% of global carbon emissions. The transition to green ammonia production using renewable energy sources remains essential to realize the full environmental benefits of ammonia fuel systems.

Nitrogen oxide (NOx) emissions present a significant environmental challenge in ammonia combustion. Enhanced flow dynamics techniques, particularly staged combustion and selective catalytic reduction systems, have demonstrated potential to reduce NOx formation by 60-85% in experimental settings. These innovations are crucial as NOx contributes to air pollution, acid rain, and ozone depletion.

Water usage represents another environmental consideration, particularly for cooling systems in ammonia production facilities. Advanced flow dynamics that optimize thermal management can reduce water requirements by 30-40% compared to conventional systems, mitigating stress on local water resources in regions where ammonia production is concentrated.

Ammonia's toxicity to aquatic ecosystems necessitates robust safety protocols throughout the fuel supply chain. Improved flow dynamics that minimize the risk of leakage through enhanced sealing technologies and monitoring systems are essential to prevent environmental contamination. Recent advancements in leak detection systems have improved response times by 75%, significantly reducing potential environmental exposure during incidents.

Land use impacts for ammonia infrastructure development must be evaluated against alternative fuel systems. The higher energy density of ammonia compared to hydrogen means smaller storage facilities are required, potentially reducing the environmental footprint of fuel distribution networks by 40-50% compared to equivalent hydrogen systems.

However, the environmental assessment must consider the complete lifecycle impacts. Current ammonia production predominantly relies on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, accounting for approximately 1-2% of global carbon emissions. The transition to green ammonia production using renewable energy sources remains essential to realize the full environmental benefits of ammonia fuel systems.

Nitrogen oxide (NOx) emissions present a significant environmental challenge in ammonia combustion. Enhanced flow dynamics techniques, particularly staged combustion and selective catalytic reduction systems, have demonstrated potential to reduce NOx formation by 60-85% in experimental settings. These innovations are crucial as NOx contributes to air pollution, acid rain, and ozone depletion.

Water usage represents another environmental consideration, particularly for cooling systems in ammonia production facilities. Advanced flow dynamics that optimize thermal management can reduce water requirements by 30-40% compared to conventional systems, mitigating stress on local water resources in regions where ammonia production is concentrated.

Ammonia's toxicity to aquatic ecosystems necessitates robust safety protocols throughout the fuel supply chain. Improved flow dynamics that minimize the risk of leakage through enhanced sealing technologies and monitoring systems are essential to prevent environmental contamination. Recent advancements in leak detection systems have improved response times by 75%, significantly reducing potential environmental exposure during incidents.

Land use impacts for ammonia infrastructure development must be evaluated against alternative fuel systems. The higher energy density of ammonia compared to hydrogen means smaller storage facilities are required, potentially reducing the environmental footprint of fuel distribution networks by 40-50% compared to equivalent hydrogen systems.

Safety Standards and Regulations

The regulatory landscape for ammonia as a fuel is evolving rapidly as its potential for decarbonization gains recognition. Currently, the International Maritime Organization (IMO) is developing specific guidelines for ammonia as a marine fuel under the International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code). These regulations focus on containment systems, material compatibility, and ventilation requirements due to ammonia's toxicity and corrosive properties.

The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) have established pressure vessel codes and material compatibility standards that apply to ammonia fuel systems. These standards specify requirements for storage tanks, piping systems, and handling equipment to ensure structural integrity under various operating conditions.

Occupational safety frameworks from organizations like OSHA in the United States and similar bodies internationally mandate specific exposure limits for ammonia. The current permissible exposure limit (PEL) is set at 50 ppm for an 8-hour time-weighted average, with a short-term exposure limit (STEL) of 35 ppm for 15 minutes. These thresholds necessitate robust detection systems and emergency protocols in any ammonia fuel application.

For enhanced ammonia fuel flow dynamics, specialized standards are emerging that address the unique challenges of controlling ammonia's flow characteristics. The National Fire Protection Association (NFPA) has developed NFPA 400 (Hazardous Materials Code) with provisions applicable to ammonia handling. Additionally, the Compressed Gas Association (CGA) provides detailed guidelines for ammonia transfer systems in publication G-2.1.

Regulatory gaps remain in areas specific to ammonia as an energy carrier. Current efforts by the International Association of Classification Societies (IACS) aim to develop unified requirements for ammonia fuel systems that address these gaps. These emerging standards focus particularly on flow control systems, pressure regulation, and phase change management—all critical aspects of ammonia fuel flow dynamics.

The European Industrial Gases Association (EIGA) has published Document 37, which provides guidance on safe handling and transfer of ammonia that has implications for fuel flow system design. This document emphasizes the importance of material selection, joint integrity, and flow control mechanisms to prevent leakage and ensure operational safety.

Compliance with these evolving regulations requires innovative approaches to ammonia fuel flow dynamics that balance safety requirements with performance objectives. Future regulatory developments are expected to address more specifically the unique challenges of ammonia as a carbon-neutral fuel, including standardized protocols for flow measurement, control systems, and safety interlocks tailored to ammonia's physical properties.

The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) have established pressure vessel codes and material compatibility standards that apply to ammonia fuel systems. These standards specify requirements for storage tanks, piping systems, and handling equipment to ensure structural integrity under various operating conditions.

Occupational safety frameworks from organizations like OSHA in the United States and similar bodies internationally mandate specific exposure limits for ammonia. The current permissible exposure limit (PEL) is set at 50 ppm for an 8-hour time-weighted average, with a short-term exposure limit (STEL) of 35 ppm for 15 minutes. These thresholds necessitate robust detection systems and emergency protocols in any ammonia fuel application.

For enhanced ammonia fuel flow dynamics, specialized standards are emerging that address the unique challenges of controlling ammonia's flow characteristics. The National Fire Protection Association (NFPA) has developed NFPA 400 (Hazardous Materials Code) with provisions applicable to ammonia handling. Additionally, the Compressed Gas Association (CGA) provides detailed guidelines for ammonia transfer systems in publication G-2.1.

Regulatory gaps remain in areas specific to ammonia as an energy carrier. Current efforts by the International Association of Classification Societies (IACS) aim to develop unified requirements for ammonia fuel systems that address these gaps. These emerging standards focus particularly on flow control systems, pressure regulation, and phase change management—all critical aspects of ammonia fuel flow dynamics.

The European Industrial Gases Association (EIGA) has published Document 37, which provides guidance on safe handling and transfer of ammonia that has implications for fuel flow system design. This document emphasizes the importance of material selection, joint integrity, and flow control mechanisms to prevent leakage and ensure operational safety.

Compliance with these evolving regulations requires innovative approaches to ammonia fuel flow dynamics that balance safety requirements with performance objectives. Future regulatory developments are expected to address more specifically the unique challenges of ammonia as a carbon-neutral fuel, including standardized protocols for flow measurement, control systems, and safety interlocks tailored to ammonia's physical properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!