The Dynamics of Ammonia Fuel Reactivity Under Varying Conditions

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Technology Background and Objectives

Ammonia has emerged as a promising carbon-free fuel alternative in the global pursuit of sustainable energy solutions. The history of ammonia as an energy carrier dates back to the early 20th century, with intermittent interest during fuel shortages. However, the current focus on ammonia fuel technology has intensified significantly since 2015, driven by urgent climate change mitigation needs and the search for hydrogen carriers that overcome storage and transportation challenges.

The fundamental appeal of ammonia (NH₃) lies in its zero-carbon composition, high hydrogen density (17.8% by weight), and established global production and distribution infrastructure. Currently, over 180 million tons of ammonia are produced annually worldwide, primarily for fertilizer applications. This existing infrastructure provides a substantial foundation for its transition to energy applications.

The reactivity dynamics of ammonia as a fuel present unique challenges and opportunities. Unlike conventional hydrocarbon fuels, ammonia exhibits lower flame speed, higher ignition energy requirements, and narrower flammability limits. These characteristics necessitate specialized combustion strategies and catalyst systems to efficiently release its energy content. Understanding these dynamics under varying conditions of temperature, pressure, catalyst presence, and mixture composition is crucial for practical implementation.

Recent technological advancements have accelerated ammonia fuel development across multiple sectors. In power generation, ammonia-fired gas turbines and dual-fuel boilers are being developed by major manufacturers. The maritime industry has identified ammonia as a leading candidate for decarbonizing shipping, with several major classification societies approving ammonia-powered vessel designs. Additionally, ammonia's potential as a hydrogen carrier for fuel cells represents another significant application pathway.

The primary technical objectives in ammonia fuel research include enhancing combustion efficiency, reducing NOx emissions, developing effective catalytic systems for cracking and partial oxidation, and optimizing fuel delivery systems. These objectives must be achieved while maintaining safety standards appropriate for ammonia's toxicity profile and addressing the energy intensity of current production methods.

Looking forward, the technology roadmap for ammonia fuel includes transitioning from co-firing applications to pure ammonia combustion systems, developing specialized materials resistant to ammonia's corrosive properties, and ultimately integrating with renewable energy sources for green ammonia production. The successful development of these technologies could position ammonia as a cornerstone of the future carbon-neutral energy landscape, particularly in hard-to-decarbonize sectors like heavy transport, shipping, and industrial heat.

The fundamental appeal of ammonia (NH₃) lies in its zero-carbon composition, high hydrogen density (17.8% by weight), and established global production and distribution infrastructure. Currently, over 180 million tons of ammonia are produced annually worldwide, primarily for fertilizer applications. This existing infrastructure provides a substantial foundation for its transition to energy applications.

The reactivity dynamics of ammonia as a fuel present unique challenges and opportunities. Unlike conventional hydrocarbon fuels, ammonia exhibits lower flame speed, higher ignition energy requirements, and narrower flammability limits. These characteristics necessitate specialized combustion strategies and catalyst systems to efficiently release its energy content. Understanding these dynamics under varying conditions of temperature, pressure, catalyst presence, and mixture composition is crucial for practical implementation.

Recent technological advancements have accelerated ammonia fuel development across multiple sectors. In power generation, ammonia-fired gas turbines and dual-fuel boilers are being developed by major manufacturers. The maritime industry has identified ammonia as a leading candidate for decarbonizing shipping, with several major classification societies approving ammonia-powered vessel designs. Additionally, ammonia's potential as a hydrogen carrier for fuel cells represents another significant application pathway.

The primary technical objectives in ammonia fuel research include enhancing combustion efficiency, reducing NOx emissions, developing effective catalytic systems for cracking and partial oxidation, and optimizing fuel delivery systems. These objectives must be achieved while maintaining safety standards appropriate for ammonia's toxicity profile and addressing the energy intensity of current production methods.

Looking forward, the technology roadmap for ammonia fuel includes transitioning from co-firing applications to pure ammonia combustion systems, developing specialized materials resistant to ammonia's corrosive properties, and ultimately integrating with renewable energy sources for green ammonia production. The successful development of these technologies could position ammonia as a cornerstone of the future carbon-neutral energy landscape, particularly in hard-to-decarbonize sectors like heavy transport, shipping, and industrial heat.

Market Analysis for Ammonia as Alternative Fuel

The global market for alternative fuels has experienced significant growth in recent years, driven by increasing environmental concerns, energy security issues, and the push for decarbonization across various sectors. Within this landscape, ammonia is emerging as a promising carbon-free energy carrier with substantial market potential, particularly in hard-to-abate sectors.

The current global ammonia market, valued at approximately $70 billion, is predominantly focused on fertilizer production. However, the potential market for ammonia as a fuel is projected to grow substantially, potentially reaching $150 billion by 2050 according to the International Energy Agency's sustainable development scenarios.

Maritime shipping represents one of the most promising immediate markets for ammonia fuel adoption. With the International Maritime Organization's targets to reduce greenhouse gas emissions by at least 50% by 2050, ammonia offers a viable zero-carbon alternative to conventional marine fuels. The global shipping industry consumes roughly 300 million tons of fuel annually, presenting a massive potential market for conversion.

Power generation constitutes another significant market opportunity, particularly for regions with limited renewable energy resources or inadequate energy storage capabilities. Ammonia can serve as both a hydrogen carrier and a direct fuel for modified gas turbines and fuel cells, enabling flexible power generation with minimal carbon emissions.

Industrial applications, especially in steel manufacturing, cement production, and other high-temperature processes, represent additional market segments where ammonia could replace fossil fuels. These industries collectively account for approximately 20% of global CO2 emissions, highlighting the substantial decarbonization potential.

Regional market analysis indicates varying levels of interest and investment. Japan and South Korea have established ambitious targets for ammonia fuel adoption, with Japan planning to use 3 million tons annually by 2030 in its power sector. The European Union, through its Hydrogen Strategy, has identified ammonia as a key hydrogen carrier, while Australia is positioning itself as a potential major exporter of green ammonia.

Market barriers include the current cost differential between conventional fuels and green ammonia, infrastructure requirements for storage and transportation, and regulatory frameworks that have yet to fully account for ammonia's potential role in decarbonization pathways.

Consumer acceptance and safety concerns also influence market development, with public perception regarding ammonia's toxicity requiring careful management through robust safety protocols and educational initiatives.

The competitive landscape features traditional ammonia producers like CF Industries and Yara International expanding into green ammonia production, alongside new entrants such as renewable energy developers and technology providers focusing specifically on ammonia fuel applications.

The current global ammonia market, valued at approximately $70 billion, is predominantly focused on fertilizer production. However, the potential market for ammonia as a fuel is projected to grow substantially, potentially reaching $150 billion by 2050 according to the International Energy Agency's sustainable development scenarios.

Maritime shipping represents one of the most promising immediate markets for ammonia fuel adoption. With the International Maritime Organization's targets to reduce greenhouse gas emissions by at least 50% by 2050, ammonia offers a viable zero-carbon alternative to conventional marine fuels. The global shipping industry consumes roughly 300 million tons of fuel annually, presenting a massive potential market for conversion.

Power generation constitutes another significant market opportunity, particularly for regions with limited renewable energy resources or inadequate energy storage capabilities. Ammonia can serve as both a hydrogen carrier and a direct fuel for modified gas turbines and fuel cells, enabling flexible power generation with minimal carbon emissions.

Industrial applications, especially in steel manufacturing, cement production, and other high-temperature processes, represent additional market segments where ammonia could replace fossil fuels. These industries collectively account for approximately 20% of global CO2 emissions, highlighting the substantial decarbonization potential.

Regional market analysis indicates varying levels of interest and investment. Japan and South Korea have established ambitious targets for ammonia fuel adoption, with Japan planning to use 3 million tons annually by 2030 in its power sector. The European Union, through its Hydrogen Strategy, has identified ammonia as a key hydrogen carrier, while Australia is positioning itself as a potential major exporter of green ammonia.

Market barriers include the current cost differential between conventional fuels and green ammonia, infrastructure requirements for storage and transportation, and regulatory frameworks that have yet to fully account for ammonia's potential role in decarbonization pathways.

Consumer acceptance and safety concerns also influence market development, with public perception regarding ammonia's toxicity requiring careful management through robust safety protocols and educational initiatives.

The competitive landscape features traditional ammonia producers like CF Industries and Yara International expanding into green ammonia production, alongside new entrants such as renewable energy developers and technology providers focusing specifically on ammonia fuel applications.

Current Challenges in Ammonia Fuel Reactivity

Despite ammonia's promising potential as a carbon-free fuel, its reactivity dynamics present significant challenges that impede widespread adoption. The primary obstacle lies in ammonia's inherent low reactivity and high ignition energy requirements compared to conventional hydrocarbon fuels. This characteristic necessitates either high-temperature environments (>500°C) or effective catalysts to achieve practical combustion rates, creating substantial engineering challenges for real-world applications.

Ammonia's narrow flammability limits (16-25% by volume in air) further complicate combustion system design, requiring precise control mechanisms to maintain stable operation. This narrow operational window becomes particularly problematic under varying load conditions typical in transportation and power generation applications, where rapid adjustments to fuel-air ratios are necessary.

The formation of nitrogen oxides (NOx) during ammonia combustion represents another significant challenge. While ammonia is carbon-free, incomplete combustion can lead to substantial NOx emissions, potentially negating its environmental benefits. Current NOx reduction technologies add complexity, cost, and efficiency penalties to ammonia fuel systems.

Heat transfer characteristics during ammonia combustion differ substantially from conventional fuels, with lower flame temperatures and different radiation properties. These differences necessitate redesigned combustion chambers and heat exchange systems, complicating the adaptation of existing infrastructure for ammonia use.

Material compatibility issues further complicate ammonia fuel implementation. Ammonia's corrosive nature affects many conventional materials used in fuel systems, requiring specialized alloys and components that increase system costs and maintenance requirements. This corrosivity varies significantly with temperature and pressure conditions, creating additional engineering challenges.

Ignition stability across varying operational conditions remains problematic, particularly in applications requiring rapid load changes. Current ignition systems struggle to provide reliable combustion initiation across the full range of operating conditions, leading to potential misfires, incomplete combustion, and system inefficiencies.

The dual-fuel approach, blending ammonia with more reactive fuels like hydrogen or methane, introduces additional complexity in fuel delivery systems and combustion control. While this approach improves reactivity, it complicates system design and potentially reduces the carbon-neutral benefits of pure ammonia systems.

Sensor technology for real-time monitoring of ammonia combustion parameters remains underdeveloped compared to conventional fuel systems. This limitation hampers the implementation of advanced control systems necessary for optimizing combustion efficiency and minimizing emissions across varying operational conditions.

Ammonia's narrow flammability limits (16-25% by volume in air) further complicate combustion system design, requiring precise control mechanisms to maintain stable operation. This narrow operational window becomes particularly problematic under varying load conditions typical in transportation and power generation applications, where rapid adjustments to fuel-air ratios are necessary.

The formation of nitrogen oxides (NOx) during ammonia combustion represents another significant challenge. While ammonia is carbon-free, incomplete combustion can lead to substantial NOx emissions, potentially negating its environmental benefits. Current NOx reduction technologies add complexity, cost, and efficiency penalties to ammonia fuel systems.

Heat transfer characteristics during ammonia combustion differ substantially from conventional fuels, with lower flame temperatures and different radiation properties. These differences necessitate redesigned combustion chambers and heat exchange systems, complicating the adaptation of existing infrastructure for ammonia use.

Material compatibility issues further complicate ammonia fuel implementation. Ammonia's corrosive nature affects many conventional materials used in fuel systems, requiring specialized alloys and components that increase system costs and maintenance requirements. This corrosivity varies significantly with temperature and pressure conditions, creating additional engineering challenges.

Ignition stability across varying operational conditions remains problematic, particularly in applications requiring rapid load changes. Current ignition systems struggle to provide reliable combustion initiation across the full range of operating conditions, leading to potential misfires, incomplete combustion, and system inefficiencies.

The dual-fuel approach, blending ammonia with more reactive fuels like hydrogen or methane, introduces additional complexity in fuel delivery systems and combustion control. While this approach improves reactivity, it complicates system design and potentially reduces the carbon-neutral benefits of pure ammonia systems.

Sensor technology for real-time monitoring of ammonia combustion parameters remains underdeveloped compared to conventional fuel systems. This limitation hampers the implementation of advanced control systems necessary for optimizing combustion efficiency and minimizing emissions across varying operational conditions.

Current Ammonia Reactivity Enhancement Solutions

01 Ammonia combustion in engines

Ammonia can be used as a fuel in internal combustion engines, where its reactivity is controlled through various methods. These include adjusting the air-fuel ratio, using catalysts to enhance combustion efficiency, and implementing specialized injection systems. The combustion characteristics of ammonia in engines differ from traditional fuels due to its lower flame speed and higher ignition temperature, requiring specific engine modifications to optimize performance and reduce emissions.- Ammonia combustion reactivity enhancement: Various methods to enhance ammonia's combustion reactivity in fuel applications, including catalysts, additives, and optimized combustion conditions. These approaches address ammonia's inherently low flame speed and high ignition energy requirements, making it more viable as a carbon-free fuel. Enhanced reactivity leads to more complete combustion, reduced emissions, and improved energy efficiency in engines and power generation systems.

- Ammonia-hydrogen fuel blends: Blending ammonia with hydrogen to improve combustion characteristics and reactivity. Hydrogen acts as a combustion promoter, lowering ignition energy requirements and increasing flame propagation speed. These blends maintain ammonia's advantages as a carbon-free fuel carrier while addressing its reactivity limitations. The optimal ratio between ammonia and hydrogen depends on the specific application and combustion system design.

- Ammonia fuel cell applications: Utilizing ammonia's reactivity in fuel cell systems for efficient electricity generation. These systems may directly use ammonia or decompose it to produce hydrogen for conventional fuel cells. Specialized catalysts and membranes are employed to enhance ammonia's electrochemical reactivity at various operating temperatures. This approach offers advantages in energy density, storage, and transportation compared to pure hydrogen systems.

- Ammonia decomposition catalysts: Development of catalysts to enhance ammonia decomposition into hydrogen and nitrogen, improving its reactivity for various applications. These catalysts typically contain transition metals or rare earth elements supported on various substrates. The catalytic decomposition can occur at lower temperatures than thermal decomposition, making ammonia more practical as a hydrogen carrier. Catalyst design focuses on efficiency, durability, and cost-effectiveness.

- Ammonia combustion control systems: Advanced control systems designed to manage ammonia's unique reactivity characteristics in combustion applications. These systems monitor and adjust parameters such as air-fuel ratio, temperature, pressure, and residence time to optimize combustion efficiency and minimize harmful emissions. Specialized injection systems, flame stabilization techniques, and combustion chamber designs are employed to address ammonia's lower reactivity compared to conventional fuels.

02 Ammonia as hydrogen carrier for fuel cells

Ammonia serves as an efficient hydrogen carrier for fuel cell applications due to its high hydrogen content and relatively easy storage and transport properties. The reactivity of ammonia in fuel cell systems involves its decomposition or cracking to release hydrogen, which then participates in electrochemical reactions to generate electricity. Various catalysts and reactor designs are employed to enhance the efficiency of ammonia decomposition and improve the overall performance of ammonia-based fuel cell systems.Expand Specific Solutions03 Catalytic decomposition of ammonia

The catalytic decomposition of ammonia is a critical process for utilizing ammonia as a fuel or hydrogen source. Various catalysts, including transition metals and their compounds, are used to lower the activation energy required for ammonia decomposition, enhancing its reactivity at lower temperatures. The efficiency of this process depends on catalyst composition, structure, and operating conditions such as temperature and pressure, which significantly influence the rate of hydrogen production from ammonia.Expand Specific Solutions04 Ammonia-based dual fuel systems

Dual fuel systems that combine ammonia with conventional fuels like diesel or gasoline can overcome the inherent limitations of ammonia's reactivity. These systems typically use a small amount of conventional fuel as a pilot ignition source or reactivity enhancer for the ammonia. The combination allows for better combustion control, improved efficiency, and reduced emissions compared to using either fuel alone. Various injection strategies and timing mechanisms are employed to optimize the reactivity of the ammonia-conventional fuel mixture.Expand Specific Solutions05 Ammonia reactivity in power generation

Ammonia's reactivity characteristics make it suitable for various power generation applications, including gas turbines and industrial burners. The controlled combustion of ammonia for power generation requires specialized burner designs, flame stabilization techniques, and combustion chamber configurations to accommodate its unique combustion properties. Advanced monitoring and control systems are implemented to manage the combustion process, optimize energy output, and minimize the formation of nitrogen oxides and other emissions.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Development

The ammonia fuel reactivity dynamics market is in an early growth phase, characterized by increasing research intensity across academic and industrial sectors. The global market is expanding rapidly, driven by decarbonization initiatives and hydrogen economy development, with projections suggesting significant growth in the next decade. Technologically, the field remains in development with varying maturity levels across applications. Leading institutions like Tianjin University, Harbin Engineering University, and University of Strathclyde are advancing fundamental research, while companies including AMOGY, Toyota Motor Corp., and thyssenkrupp AG are focusing on commercial applications. Notably, AMOGY has demonstrated ammonia power in various transport applications, while established energy players like Equinor and Sinopec are investing in ammonia fuel infrastructure development, indicating growing industrial commitment to this technology.

AMOGY, Inc.

Technical Solution: AMOGY has developed a proprietary ammonia cracking technology that efficiently converts ammonia to hydrogen for fuel cell applications. Their system operates at optimized temperatures (650-700°C) with novel catalysts that enhance ammonia decomposition kinetics while minimizing energy requirements. The technology incorporates a compact reactor design with integrated heat management that captures and recycles thermal energy from the cracking process, improving overall system efficiency. AMOGY's approach addresses ammonia's reactivity challenges through precise control of reaction parameters and catalyst formulations that maintain stability under varying load conditions. Their system can adapt to fluctuating power demands by modulating ammonia flow rates and reaction conditions in real-time, maintaining optimal conversion efficiency across different operational scenarios.

Strengths: Highly efficient ammonia cracking with proprietary catalyst technology; compact system design suitable for mobile applications; rapid response to varying power demands. Weaknesses: Relatively new technology with limited long-term durability data; higher initial cost compared to conventional systems; requires precise thermal management.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to ammonia fuel utilization focusing on both direct combustion and cracking technologies. Their research includes advanced internal combustion engine modifications with specialized injection systems that optimize ammonia spray patterns and timing to enhance combustion stability. Toyota's technology incorporates dual-fuel strategies that blend ammonia with hydrogen or conventional fuels to overcome ammonia's low flame speed and ignition challenges. Their systems feature adaptive control algorithms that continuously adjust combustion parameters based on real-time monitoring of exhaust composition and engine performance metrics. Toyota has also pioneered novel catalyst formulations that enhance ammonia decomposition at lower temperatures, improving cold-start performance and transient response. Their approach includes innovative thermal management systems that recover waste heat to maintain optimal catalyst temperatures, ensuring consistent ammonia reactivity across varying operational conditions.

Strengths: Extensive R&D resources and testing capabilities; integrated approach combining combustion and fuel cell applications; advanced control systems for optimizing performance. Weaknesses: Technology still in development phase for many applications; requires significant modifications to existing engine designs; higher complexity compared to conventional fuel systems.

Critical Patents in Ammonia Combustion Technology

Generation of ammonia/hydrogen mixtures and/or hydrogen-enriched fuel mixtures

PatentWO2023137197A2

Innovation

- A membrane reactor system utilizing a sweep gas as a secondary fuel to enhance hydrogen recovery, allowing for complete decomposition of ammonia and mixing with hydrogen to form enriched fuel blends, operating at lower temperatures and pressures with reduced membrane selectivity requirements.

Method and apparatus for producting liquid hydrocarbon fuels

PatentInactiveUS20140066526A1

Innovation

- A simple, one-step, continuous process using a microwave-powered reactor to convert a blend of coal and water, or carbon dioxide and water, with a catalyst like magnetite, to produce petroleum-like products, reducing capital and operating costs and minimizing carbon dioxide emissions by utilizing carbon dioxide from various sources.

Environmental Impact Assessment

The environmental implications of ammonia as a fuel source represent a critical dimension in evaluating its viability as an alternative energy carrier. When comparing ammonia to conventional fossil fuels, significant reductions in carbon dioxide emissions can be achieved, as ammonia combustion primarily produces nitrogen and water vapor. However, the environmental assessment must consider the complete lifecycle, from production to end-use.

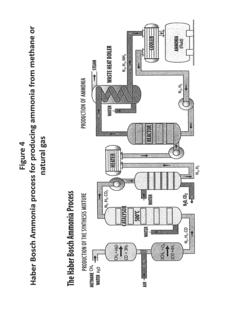

Current ammonia production predominantly relies on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, resulting in substantial carbon emissions. The environmental benefits of ammonia fuel are therefore contingent upon transitioning to green production methods utilizing renewable energy sources. Recent advancements in electrolysis-based ammonia synthesis show promising potential for reducing the carbon footprint of production.

Incomplete combustion of ammonia presents environmental challenges through the formation of nitrogen oxides (NOx), which contribute to air pollution, acid rain, and photochemical smog. The reactivity dynamics of ammonia under varying conditions directly influence these emission profiles. Research indicates that combustion temperature, pressure, and air-fuel ratios significantly affect NOx formation rates, with lower temperatures generally resulting in reduced emissions.

Water ecosystems face potential risks from ammonia fuel adoption due to its high solubility and toxicity to aquatic organisms. Accidental releases during transportation, storage, or utilization could lead to localized environmental damage. However, ammonia rapidly degrades in the environment and does not persist as long-term pollution, unlike many hydrocarbon fuels that can cause lasting contamination.

The land use implications of transitioning to ammonia fuel infrastructure must also be considered. While existing natural gas infrastructure can be partially repurposed for ammonia distribution, additional facilities for production, storage, and handling would be required. This expansion must be balanced against the environmental benefits of reduced greenhouse gas emissions.

Comparative lifecycle assessments between ammonia and conventional fuels demonstrate that the environmental advantages of ammonia are maximized when production utilizes renewable energy sources. Under these conditions, ammonia fuel systems can achieve up to 80-90% reduction in greenhouse gas emissions compared to fossil fuel alternatives, positioning ammonia as a potentially significant contributor to decarbonization efforts across various sectors, particularly in hard-to-abate industries like shipping and heavy transport.

Current ammonia production predominantly relies on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, resulting in substantial carbon emissions. The environmental benefits of ammonia fuel are therefore contingent upon transitioning to green production methods utilizing renewable energy sources. Recent advancements in electrolysis-based ammonia synthesis show promising potential for reducing the carbon footprint of production.

Incomplete combustion of ammonia presents environmental challenges through the formation of nitrogen oxides (NOx), which contribute to air pollution, acid rain, and photochemical smog. The reactivity dynamics of ammonia under varying conditions directly influence these emission profiles. Research indicates that combustion temperature, pressure, and air-fuel ratios significantly affect NOx formation rates, with lower temperatures generally resulting in reduced emissions.

Water ecosystems face potential risks from ammonia fuel adoption due to its high solubility and toxicity to aquatic organisms. Accidental releases during transportation, storage, or utilization could lead to localized environmental damage. However, ammonia rapidly degrades in the environment and does not persist as long-term pollution, unlike many hydrocarbon fuels that can cause lasting contamination.

The land use implications of transitioning to ammonia fuel infrastructure must also be considered. While existing natural gas infrastructure can be partially repurposed for ammonia distribution, additional facilities for production, storage, and handling would be required. This expansion must be balanced against the environmental benefits of reduced greenhouse gas emissions.

Comparative lifecycle assessments between ammonia and conventional fuels demonstrate that the environmental advantages of ammonia are maximized when production utilizes renewable energy sources. Under these conditions, ammonia fuel systems can achieve up to 80-90% reduction in greenhouse gas emissions compared to fossil fuel alternatives, positioning ammonia as a potentially significant contributor to decarbonization efforts across various sectors, particularly in hard-to-abate industries like shipping and heavy transport.

Safety Standards and Regulatory Framework

The regulatory landscape for ammonia as a fuel is evolving rapidly as its potential for decarbonization gains recognition. Currently, ammonia falls under multiple regulatory frameworks, including hazardous materials handling regulations (such as OSHA in the US and REACH in Europe), maritime regulations through the International Maritime Organization (IMO), and various national energy policies. These frameworks were primarily designed for ammonia's traditional uses in fertilizer production and refrigeration, not as an energy carrier.

The International Organization for Standardization (ISO) is developing specific standards for ammonia fuel handling, with ISO/TC 197 focusing on hydrogen technologies that include ammonia as a hydrogen carrier. Similarly, the American Society for Testing and Materials (ASTM) is working on standards for ammonia fuel quality and handling procedures. These emerging standards aim to address the unique challenges posed by ammonia's toxicity and corrosivity when used as a fuel.

Safety thresholds for ammonia exposure remain stringent across jurisdictions. The US Environmental Protection Agency sets the immediately dangerous to life and health (IDLH) concentration at 300 ppm, while permissible exposure limits for an 8-hour workday range from 25-50 ppm depending on the regulatory body. These limits significantly impact facility design and operational protocols for ammonia fuel systems.

Maritime applications of ammonia fuel face particularly complex regulatory challenges. The IMO's International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) is being adapted to address ammonia as a fuel rather than just as cargo. Additionally, classification societies like DNV GL and Lloyd's Register have developed provisional guidelines for ammonia-fueled vessels while formal regulations are being established.

Risk assessment methodologies for ammonia fuel systems are being standardized to account for its reactivity under varying conditions. These include Hazard and Operability Studies (HAZOP), Layer of Protection Analysis (LOPA), and Quantitative Risk Assessment (QRA) approaches tailored to ammonia's specific properties. The reactivity dynamics of ammonia under different temperature, pressure, and catalyst conditions are central to these risk assessments.

Regulatory gaps remain in addressing the unique combustion characteristics of ammonia, particularly its narrow flammability range and high ignition energy compared to conventional fuels. Current standards inadequately address the potential for NOx formation during incomplete combustion and the safety implications of ammonia's reactivity with certain materials under varying operational conditions.

The International Organization for Standardization (ISO) is developing specific standards for ammonia fuel handling, with ISO/TC 197 focusing on hydrogen technologies that include ammonia as a hydrogen carrier. Similarly, the American Society for Testing and Materials (ASTM) is working on standards for ammonia fuel quality and handling procedures. These emerging standards aim to address the unique challenges posed by ammonia's toxicity and corrosivity when used as a fuel.

Safety thresholds for ammonia exposure remain stringent across jurisdictions. The US Environmental Protection Agency sets the immediately dangerous to life and health (IDLH) concentration at 300 ppm, while permissible exposure limits for an 8-hour workday range from 25-50 ppm depending on the regulatory body. These limits significantly impact facility design and operational protocols for ammonia fuel systems.

Maritime applications of ammonia fuel face particularly complex regulatory challenges. The IMO's International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) is being adapted to address ammonia as a fuel rather than just as cargo. Additionally, classification societies like DNV GL and Lloyd's Register have developed provisional guidelines for ammonia-fueled vessels while formal regulations are being established.

Risk assessment methodologies for ammonia fuel systems are being standardized to account for its reactivity under varying conditions. These include Hazard and Operability Studies (HAZOP), Layer of Protection Analysis (LOPA), and Quantitative Risk Assessment (QRA) approaches tailored to ammonia's specific properties. The reactivity dynamics of ammonia under different temperature, pressure, and catalyst conditions are central to these risk assessments.

Regulatory gaps remain in addressing the unique combustion characteristics of ammonia, particularly its narrow flammability range and high ignition energy compared to conventional fuels. Current standards inadequately address the potential for NOx formation during incomplete combustion and the safety implications of ammonia's reactivity with certain materials under varying operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!