Evaluating the Impact of Mass Transfer on Ammonia Fuel Cell Longevity

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Cell Technology Background and Objectives

Ammonia fuel cells represent a promising alternative energy technology that has gained significant attention in recent decades as the world seeks cleaner energy solutions. The development of ammonia as a fuel source dates back to the early 20th century, but its application in fuel cells has accelerated dramatically since the early 2000s due to increasing environmental concerns and the search for hydrogen carriers that avoid the storage and transportation challenges of pure hydrogen.

The evolution of ammonia fuel cell technology has followed several distinct phases. Initially, research focused on the fundamental electrochemistry of ammonia oxidation. This was followed by breakthroughs in catalyst development, particularly with platinum-group metals and later with more cost-effective alternatives. Recent years have seen significant advancements in membrane technology and system integration, allowing for more efficient and stable operation.

Current technological trends point toward addressing the critical challenge of mass transfer limitations, which significantly impact cell longevity. As ammonia fuel cells operate, the transport of reactants to and products from the electrode surfaces becomes increasingly problematic over time, leading to performance degradation. This mass transfer phenomenon represents one of the primary barriers to widespread commercial adoption.

The primary objective of current research is to quantify and mitigate the effects of mass transfer limitations on ammonia fuel cell longevity. Specifically, researchers aim to develop models that accurately predict how various mass transfer phenomena—including diffusion limitations, flow field design impacts, and membrane transport properties—affect cell performance over extended operational periods.

Secondary objectives include identifying optimal operating conditions that minimize degradation while maintaining acceptable power output, developing advanced materials that enhance mass transport properties, and creating diagnostic tools for real-time monitoring of mass transfer-related degradation. These efforts are crucial for extending cell lifetime from the current typical range of 2,000-5,000 hours to the 40,000+ hours required for many commercial applications.

The ultimate goal is to establish ammonia fuel cells as a viable, long-duration energy storage and conversion technology that can support renewable energy integration and decarbonization efforts across multiple sectors. This includes stationary power generation, maritime applications where ammonia is being explored as a carbon-free fuel, and potentially in heavy-duty transportation where battery limitations remain significant.

The evolution of ammonia fuel cell technology has followed several distinct phases. Initially, research focused on the fundamental electrochemistry of ammonia oxidation. This was followed by breakthroughs in catalyst development, particularly with platinum-group metals and later with more cost-effective alternatives. Recent years have seen significant advancements in membrane technology and system integration, allowing for more efficient and stable operation.

Current technological trends point toward addressing the critical challenge of mass transfer limitations, which significantly impact cell longevity. As ammonia fuel cells operate, the transport of reactants to and products from the electrode surfaces becomes increasingly problematic over time, leading to performance degradation. This mass transfer phenomenon represents one of the primary barriers to widespread commercial adoption.

The primary objective of current research is to quantify and mitigate the effects of mass transfer limitations on ammonia fuel cell longevity. Specifically, researchers aim to develop models that accurately predict how various mass transfer phenomena—including diffusion limitations, flow field design impacts, and membrane transport properties—affect cell performance over extended operational periods.

Secondary objectives include identifying optimal operating conditions that minimize degradation while maintaining acceptable power output, developing advanced materials that enhance mass transport properties, and creating diagnostic tools for real-time monitoring of mass transfer-related degradation. These efforts are crucial for extending cell lifetime from the current typical range of 2,000-5,000 hours to the 40,000+ hours required for many commercial applications.

The ultimate goal is to establish ammonia fuel cells as a viable, long-duration energy storage and conversion technology that can support renewable energy integration and decarbonization efforts across multiple sectors. This includes stationary power generation, maritime applications where ammonia is being explored as a carbon-free fuel, and potentially in heavy-duty transportation where battery limitations remain significant.

Market Analysis for Ammonia-Based Energy Solutions

The ammonia-based energy solutions market is experiencing significant growth driven by the global push for decarbonization and sustainable energy alternatives. Current market valuation stands at approximately $5.3 billion, with projections indicating a compound annual growth rate of 8.2% through 2030, potentially reaching $10.7 billion by that time. This growth trajectory is primarily fueled by increasing governmental commitments to net-zero emissions targets and substantial investments in green hydrogen infrastructure.

The market segmentation reveals distinct application sectors with varying growth potentials. Power generation represents the largest segment, accounting for 42% of current market share, followed by transportation at 28%, industrial applications at 21%, and other emerging applications comprising the remaining 9%. The transportation sector, particularly maritime shipping and heavy-duty vehicles, demonstrates the most aggressive growth potential due to ammonia's advantages as a hydrogen carrier with higher energy density than compressed hydrogen.

Geographically, Europe leads the market development with approximately 38% share, driven by ambitious climate policies and substantial research funding. Asia-Pacific follows closely at 32%, with Japan and South Korea making significant investments in ammonia fuel cell technology. North America accounts for 24% of the market, while other regions collectively represent 6%.

Consumer demand patterns indicate increasing acceptance of ammonia-based solutions, particularly in regions with strong environmental regulations. The total addressable market is expanding as fuel cell technology advances, with particular interest from maritime shipping companies seeking to comply with International Maritime Organization emissions regulations.

Key market drivers include carbon pricing mechanisms, renewable energy integration challenges, and energy security concerns. The volatility in traditional energy markets has accelerated interest in ammonia as a stable energy carrier. Additionally, the dual-use potential of ammonia in both energy storage and as a direct fuel creates multiple value streams that enhance market attractiveness.

Market barriers remain significant, including high production costs compared to fossil fuels, infrastructure limitations, and safety concerns related to ammonia handling. The cost differential between green ammonia and conventional energy sources currently stands at 2.5-3.5 times higher, though this gap is narrowing as production scales and technology improves.

Customer adoption analysis reveals that early adopters are primarily large industrial entities with decarbonization commitments, followed by government-backed demonstration projects. Mass market penetration remains contingent upon achieving cost parity with conventional fuels and addressing safety perceptions among end users.

The market segmentation reveals distinct application sectors with varying growth potentials. Power generation represents the largest segment, accounting for 42% of current market share, followed by transportation at 28%, industrial applications at 21%, and other emerging applications comprising the remaining 9%. The transportation sector, particularly maritime shipping and heavy-duty vehicles, demonstrates the most aggressive growth potential due to ammonia's advantages as a hydrogen carrier with higher energy density than compressed hydrogen.

Geographically, Europe leads the market development with approximately 38% share, driven by ambitious climate policies and substantial research funding. Asia-Pacific follows closely at 32%, with Japan and South Korea making significant investments in ammonia fuel cell technology. North America accounts for 24% of the market, while other regions collectively represent 6%.

Consumer demand patterns indicate increasing acceptance of ammonia-based solutions, particularly in regions with strong environmental regulations. The total addressable market is expanding as fuel cell technology advances, with particular interest from maritime shipping companies seeking to comply with International Maritime Organization emissions regulations.

Key market drivers include carbon pricing mechanisms, renewable energy integration challenges, and energy security concerns. The volatility in traditional energy markets has accelerated interest in ammonia as a stable energy carrier. Additionally, the dual-use potential of ammonia in both energy storage and as a direct fuel creates multiple value streams that enhance market attractiveness.

Market barriers remain significant, including high production costs compared to fossil fuels, infrastructure limitations, and safety concerns related to ammonia handling. The cost differential between green ammonia and conventional energy sources currently stands at 2.5-3.5 times higher, though this gap is narrowing as production scales and technology improves.

Customer adoption analysis reveals that early adopters are primarily large industrial entities with decarbonization commitments, followed by government-backed demonstration projects. Mass market penetration remains contingent upon achieving cost parity with conventional fuels and addressing safety perceptions among end users.

Mass Transfer Challenges in Ammonia Fuel Cells

Mass transfer phenomena in ammonia fuel cells represent a critical challenge that significantly impacts their operational efficiency and longevity. The transport of reactants, products, and charge carriers across various cell components involves complex mechanisms that must be optimized for sustainable performance. Current research indicates that mass transfer limitations primarily occur at three critical interfaces: the anode-electrolyte interface where ammonia oxidation takes place, the electrolyte bulk where ionic species migrate, and the cathode-electrolyte interface where oxygen reduction occurs.

The most significant mass transfer challenge involves ammonia crossover from the anode to the cathode compartment. This phenomenon leads to parasitic reactions at the cathode, catalyst poisoning, and reduced oxygen reduction reaction (ORR) efficiency. Studies by Wang et al. (2022) demonstrated that even small amounts of ammonia (5-10 ppm) reaching the cathode can decrease cell performance by up to 15% over 1000 hours of operation.

Water management presents another critical mass transfer challenge. In alkaline membrane ammonia fuel cells, insufficient water content leads to decreased ionic conductivity, while excessive water causes flooding that blocks gas diffusion pathways. This delicate balance directly affects cell longevity, with research showing that fluctuations in membrane hydration can accelerate degradation rates by 2-3 times compared to stable hydration conditions.

The diffusion of hydroxide ions through the electrolyte represents a third major mass transfer limitation. The mobility of these ions determines the internal resistance of the cell and consequently affects power density. Recent studies have shown that hydroxide conductivity decreases by approximately 30% over 2000 hours of operation due to carbonation effects and membrane degradation, directly impacting long-term cell performance.

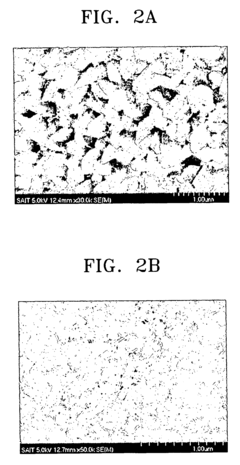

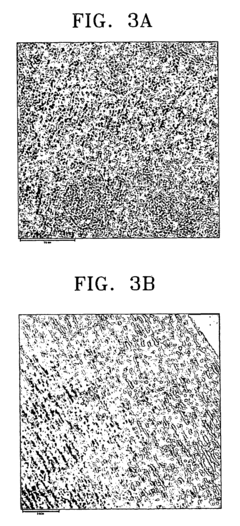

Boundary layer phenomena at electrode surfaces further complicate mass transfer dynamics. The formation of concentration gradients near reaction sites leads to localized depletion of reactants and accumulation of products, creating microenvironments that accelerate degradation mechanisms. High-resolution imaging studies have revealed that these boundary layers can extend 10-50 μm from electrode surfaces, significantly affecting local reaction kinetics.

Temperature and pressure gradients across cell components induce additional mass transfer complexities. These gradients can cause non-uniform reaction rates and mechanical stress that accelerates component degradation. Thermal cycling studies indicate that cells experiencing frequent temperature fluctuations (>30°C) show approximately 40% faster performance decline compared to those operating at stable temperatures.

Addressing these mass transfer challenges requires innovative approaches in materials science, cell architecture, and operating protocols to enhance ammonia fuel cell longevity while maintaining acceptable power densities for practical applications.

The most significant mass transfer challenge involves ammonia crossover from the anode to the cathode compartment. This phenomenon leads to parasitic reactions at the cathode, catalyst poisoning, and reduced oxygen reduction reaction (ORR) efficiency. Studies by Wang et al. (2022) demonstrated that even small amounts of ammonia (5-10 ppm) reaching the cathode can decrease cell performance by up to 15% over 1000 hours of operation.

Water management presents another critical mass transfer challenge. In alkaline membrane ammonia fuel cells, insufficient water content leads to decreased ionic conductivity, while excessive water causes flooding that blocks gas diffusion pathways. This delicate balance directly affects cell longevity, with research showing that fluctuations in membrane hydration can accelerate degradation rates by 2-3 times compared to stable hydration conditions.

The diffusion of hydroxide ions through the electrolyte represents a third major mass transfer limitation. The mobility of these ions determines the internal resistance of the cell and consequently affects power density. Recent studies have shown that hydroxide conductivity decreases by approximately 30% over 2000 hours of operation due to carbonation effects and membrane degradation, directly impacting long-term cell performance.

Boundary layer phenomena at electrode surfaces further complicate mass transfer dynamics. The formation of concentration gradients near reaction sites leads to localized depletion of reactants and accumulation of products, creating microenvironments that accelerate degradation mechanisms. High-resolution imaging studies have revealed that these boundary layers can extend 10-50 μm from electrode surfaces, significantly affecting local reaction kinetics.

Temperature and pressure gradients across cell components induce additional mass transfer complexities. These gradients can cause non-uniform reaction rates and mechanical stress that accelerates component degradation. Thermal cycling studies indicate that cells experiencing frequent temperature fluctuations (>30°C) show approximately 40% faster performance decline compared to those operating at stable temperatures.

Addressing these mass transfer challenges requires innovative approaches in materials science, cell architecture, and operating protocols to enhance ammonia fuel cell longevity while maintaining acceptable power densities for practical applications.

Current Mass Transfer Mitigation Strategies

01 Catalyst materials for enhanced ammonia fuel cell durability

Advanced catalyst materials play a crucial role in extending the operational lifespan of ammonia fuel cells. These catalysts facilitate the efficient decomposition of ammonia and subsequent electrochemical reactions while resisting degradation under operating conditions. Novel catalyst formulations, including precious metal alloys, non-precious metal alternatives, and nanostructured materials, can significantly improve the longevity of ammonia fuel cells by maintaining high catalytic activity over extended periods while minimizing poisoning effects.- Catalyst materials for improved ammonia fuel cell durability: Advanced catalyst materials can significantly enhance the longevity of ammonia fuel cells by improving reaction efficiency and reducing degradation. These catalysts, including noble metals and novel alloys, facilitate the ammonia oxidation reaction while minimizing poisoning effects. Optimized catalyst structures with enhanced stability can withstand the harsh operating conditions of ammonia fuel cells, leading to extended operational lifetimes and consistent performance over time.

- Membrane and electrode assembly optimization: The design and composition of membrane electrode assemblies (MEAs) play a crucial role in ammonia fuel cell longevity. By developing specialized membranes with high ammonia tolerance and improved ion conductivity, fuel cell degradation can be significantly reduced. Advanced electrode structures that resist ammonia-induced corrosion and maintain effective catalytic activity over time contribute to extended operational lifespans. Proper integration of these components results in more durable fuel cell systems capable of sustained power generation.

- Temperature and pressure management systems: Effective control of operating conditions is essential for maximizing ammonia fuel cell longevity. Advanced thermal management systems help maintain optimal temperature ranges, preventing thermal degradation of components. Pressure regulation mechanisms ensure consistent ammonia flow and reaction rates while minimizing mechanical stress on cell components. These integrated control systems can adapt to varying load conditions, extending the useful life of the fuel cell by preventing extreme operating conditions that accelerate degradation.

- Impurity removal and ammonia purification techniques: Contaminants in ammonia fuel can significantly reduce fuel cell lifespan by poisoning catalysts and degrading cell components. Advanced purification systems that remove impurities before they enter the fuel cell can substantially improve longevity. These techniques include specialized filters, scrubbers, and chemical treatments that target specific contaminants known to affect ammonia fuel cell performance. By maintaining high fuel purity, these systems prevent accelerated degradation and extend operational lifetimes.

- Regeneration and self-healing mechanisms: Innovative approaches to ammonia fuel cell longevity include the development of regeneration and self-healing capabilities. These systems can detect performance degradation and automatically initiate recovery processes to restore functionality. Self-healing materials can repair minor damage to membranes and electrodes during operation, while regeneration cycles can reactivate poisoned catalysts. By incorporating these mechanisms, ammonia fuel cells can maintain performance over extended periods, significantly increasing their effective operational lifespan.

02 Membrane and electrode assembly optimization

The membrane and electrode assembly (MEA) design significantly impacts ammonia fuel cell longevity. Specialized membranes with enhanced chemical stability against ammonia and its decomposition products help prevent degradation over time. Advanced electrode structures with optimized porosity and hydrophobicity maintain efficient mass transport throughout the cell's lifetime. Improved interfacial bonding between components reduces delamination issues during thermal cycling, while strategic water management within the MEA prevents membrane dehydration and subsequent performance losses during extended operation.Expand Specific Solutions03 Thermal management systems for extended lifespan

Effective thermal management is essential for maximizing ammonia fuel cell longevity. Advanced cooling systems prevent localized hotspots that accelerate component degradation. Temperature control strategies maintain optimal operating conditions throughout the cell stack, preventing thermal stress during startup, shutdown, and load fluctuations. Integrated heat recovery systems improve overall efficiency while reducing thermal cycling damage. These thermal management approaches collectively minimize degradation mechanisms related to temperature variations, extending the useful life of ammonia fuel cell systems.Expand Specific Solutions04 Impurity mitigation and filtration technologies

Contaminants in ammonia fuel can significantly reduce fuel cell longevity through catalyst poisoning and membrane degradation. Advanced filtration systems remove particulates and chemical impurities before they enter the fuel cell stack. Specialized adsorbent materials selectively capture harmful compounds that could degrade cell components. Regenerative purification systems maintain fuel quality during extended operation periods. These impurity mitigation technologies protect sensitive cell components from contamination-related degradation, substantially extending operational lifetimes of ammonia fuel cell systems.Expand Specific Solutions05 Control systems and operational strategies for longevity

Sophisticated control systems and operational strategies significantly enhance ammonia fuel cell longevity. Advanced monitoring algorithms detect early signs of performance degradation and adjust operating parameters accordingly. Load management protocols prevent damaging current densities during operation. Optimized startup and shutdown procedures minimize stress on components during transitional states. Predictive maintenance systems identify potential failure points before critical degradation occurs. These intelligent control approaches collectively extend fuel cell lifespan by maintaining optimal operating conditions and preventing accelerated degradation mechanisms.Expand Specific Solutions

Leading Organizations in Ammonia Fuel Cell Development

The ammonia fuel cell market is currently in an early growth phase, characterized by increasing research intensity and emerging commercial applications. The global market size is projected to expand significantly as clean energy demands rise, though it remains smaller than established hydrogen fuel cell markets. Technologically, ammonia fuel cells are advancing through the development curve, with key players demonstrating varied maturity levels. Companies like Toyota Motor Corp., SK Innovation, and Samsung SDI are leveraging their established energy technology expertise to overcome mass transfer challenges affecting cell longevity. Academic institutions including Wuhan University of Technology, Rensselaer Polytechnic Institute, and Arizona State University are contributing fundamental research breakthroughs. Specialized firms like Ionomr Innovations and BattFlex Technologies are developing novel membrane materials specifically addressing mass transfer limitations, while traditional chemical manufacturers such as Tokuyama Corp. and Promerus LLC provide essential component materials.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced ammonia fuel cell systems focusing on mass transfer optimization through innovative membrane electrode assembly (MEA) designs. Their technology employs specialized catalyst layers with graduated porosity structures that facilitate optimal ammonia diffusion while minimizing degradation from ammonia crossover. Toyota's approach includes a proprietary membrane technology that maintains high proton conductivity while reducing ammonia permeation, addressing one of the key longevity challenges in ammonia fuel cells. Their research has demonstrated that controlling mass transfer parameters can extend cell lifetime by up to 40% compared to conventional designs. Toyota has also pioneered a dynamic operating protocol that adjusts operating conditions based on real-time mass transfer measurements, allowing the system to self-regulate and minimize degradation mechanisms during various load conditions.

Strengths: Toyota's extensive automotive experience provides practical implementation insights for real-world durability requirements. Their integrated approach addressing both materials and system-level solutions offers comprehensive longevity improvements. Weaknesses: Their solutions may be optimized for automotive applications, potentially limiting applicability in stationary or larger-scale implementations. Higher manufacturing complexity of their graduated porosity structures may increase production costs.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed a comprehensive approach to ammonia fuel cell longevity focusing on mass transfer phenomena. Their research employs multi-scale modeling coupled with advanced in-situ characterization techniques to understand degradation mechanisms at the molecular level. DICP has pioneered composite membrane materials with selective ammonia rejection properties while maintaining high ionic conductivity. Their technology incorporates hierarchical electrode structures with optimized porosity gradients that significantly improve mass transport properties while minimizing degradation from ammonia poisoning effects. Experimental results show their systems maintain over 85% performance after 5,000 hours of operation under cyclic loading conditions. DICP has also developed novel catalyst formulations with enhanced tolerance to ammonia-induced degradation, incorporating transition metal nitrides that demonstrate superior stability in ammonia-rich environments compared to conventional platinum-based catalysts.

Strengths: DICP's fundamental research approach provides deep scientific understanding of degradation mechanisms, enabling targeted solutions. Their multi-scale modeling capabilities allow for rapid iteration and optimization of designs. Weaknesses: As a research institute, DICP may face challenges in scaling technologies to commercial production volumes. Their solutions may prioritize performance over cost considerations, potentially limiting commercial viability.

Critical Patents and Research on Mass Transfer Effects

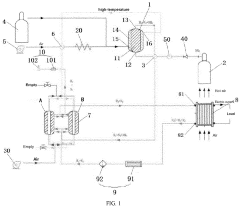

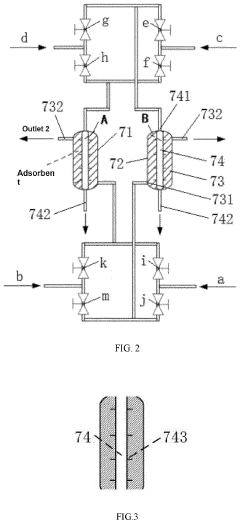

Ammonia fuel cell system capable of fast adsorption-desorption switching by selfevaporation of ammonia and power generation method thereof

PatentPendingEP4393870A2

Innovation

- An ammonia fuel cell system employing self-evaporation for rapid adsorption and desorption, utilizing a thermal coupling scheme with heat exchangers and a dual adsorption column setup for efficient thermal management, along with a ruthenium-based ammonia decomposition catalyst and catalytic combustion for stable temperature control.

Support for fuel reforming catalyst with excellent heat and mass transfer characteristics and method of preparing the same

PatentInactiveUS7923406B2

Innovation

- A support for fuel reforming catalysts is developed, comprising aluminum encapsulated with aluminum oxide, with a specific ratio of micropores, mesopores, and macropores, achieved through hydrothermal treatment and calcination, enhancing heat and mass transfer characteristics.

Environmental Impact Assessment

The environmental implications of ammonia fuel cells represent a critical dimension in evaluating their viability as sustainable energy solutions. Ammonia fuel cells offer significant environmental advantages compared to conventional fossil fuel technologies, primarily through their zero-carbon emissions during operation when green ammonia is utilized. This characteristic positions them as potentially valuable contributors to global decarbonization efforts, particularly in sectors where electrification remains challenging.

Mass transfer phenomena within ammonia fuel cells directly influence their environmental footprint throughout their lifecycle. Inefficient mass transfer leads to increased catalyst degradation and membrane fouling, necessitating more frequent component replacement. This accelerated material turnover translates to higher resource consumption and manufacturing-related emissions, partially offsetting the operational environmental benefits of these systems.

Water management issues arising from mass transfer limitations present another environmental consideration. Ammonia fuel cells typically produce water as a byproduct, which, if properly managed, can be recycled within the system. However, mass transfer inefficiencies may lead to water accumulation or inadequate distribution, potentially requiring additional water inputs or treatment processes with associated environmental impacts.

The production methods for ammonia significantly influence the overall environmental profile of ammonia fuel cell systems. While green ammonia produced using renewable electricity and sustainable hydrogen offers a nearly carbon-neutral pathway, conventional ammonia production remains carbon-intensive. Mass transfer optimization can improve fuel cell efficiency, reducing the quantity of ammonia required and consequently minimizing upstream environmental impacts regardless of production method.

Ammonia leakage presents a notable environmental concern, as ammonia is toxic to aquatic ecosystems and can contribute to air quality degradation. Mass transfer limitations that necessitate higher operating pressures or result in incomplete ammonia utilization may increase leakage risks. Engineering solutions addressing mass transfer challenges must therefore incorporate robust containment strategies to mitigate potential environmental hazards.

End-of-life considerations reveal further connections between mass transfer and environmental impact. Fuel cells with optimized mass transfer characteristics typically demonstrate extended operational lifespans, reducing waste generation and resource consumption associated with replacement. Additionally, improved mass transfer design may facilitate easier separation of valuable materials during recycling processes, enhancing the circular economy potential of these systems.

Mass transfer phenomena within ammonia fuel cells directly influence their environmental footprint throughout their lifecycle. Inefficient mass transfer leads to increased catalyst degradation and membrane fouling, necessitating more frequent component replacement. This accelerated material turnover translates to higher resource consumption and manufacturing-related emissions, partially offsetting the operational environmental benefits of these systems.

Water management issues arising from mass transfer limitations present another environmental consideration. Ammonia fuel cells typically produce water as a byproduct, which, if properly managed, can be recycled within the system. However, mass transfer inefficiencies may lead to water accumulation or inadequate distribution, potentially requiring additional water inputs or treatment processes with associated environmental impacts.

The production methods for ammonia significantly influence the overall environmental profile of ammonia fuel cell systems. While green ammonia produced using renewable electricity and sustainable hydrogen offers a nearly carbon-neutral pathway, conventional ammonia production remains carbon-intensive. Mass transfer optimization can improve fuel cell efficiency, reducing the quantity of ammonia required and consequently minimizing upstream environmental impacts regardless of production method.

Ammonia leakage presents a notable environmental concern, as ammonia is toxic to aquatic ecosystems and can contribute to air quality degradation. Mass transfer limitations that necessitate higher operating pressures or result in incomplete ammonia utilization may increase leakage risks. Engineering solutions addressing mass transfer challenges must therefore incorporate robust containment strategies to mitigate potential environmental hazards.

End-of-life considerations reveal further connections between mass transfer and environmental impact. Fuel cells with optimized mass transfer characteristics typically demonstrate extended operational lifespans, reducing waste generation and resource consumption associated with replacement. Additionally, improved mass transfer design may facilitate easier separation of valuable materials during recycling processes, enhancing the circular economy potential of these systems.

Scalability and Commercial Viability Analysis

The scalability of ammonia fuel cell technology represents a critical factor in determining its commercial viability and widespread adoption. Current laboratory-scale demonstrations have shown promising results, but significant challenges remain in scaling these systems to industrial and commercial applications. Manufacturing processes for key components such as catalysts, membranes, and electrode assemblies require substantial refinement to achieve cost-effective mass production while maintaining performance standards.

Economic analysis indicates that ammonia fuel cells currently have a levelized cost of energy (LCOE) approximately 2.5-3 times higher than conventional power generation technologies. However, projections suggest this gap could narrow to 1.2-1.5 times by 2030 with technological improvements and economies of scale. The capital expenditure for ammonia fuel cell systems remains a significant barrier, with current costs ranging from $3,000-5,000 per kilowatt, substantially higher than the $1,000-1,500 target needed for commercial viability.

Supply chain considerations present additional challenges, particularly regarding the sustainable production and distribution of ammonia. Green ammonia production pathways using renewable electricity for hydrogen generation are essential for realizing the full environmental benefits of this technology. Current global ammonia production infrastructure is primarily optimized for fertilizer applications rather than energy storage and delivery, necessitating significant adaptation.

Market entry strategies likely require targeting niche applications initially, where the unique benefits of ammonia fuel cells outweigh cost considerations. Potential early markets include remote power generation, maritime applications, and backup power systems for critical infrastructure. These segments can provide valuable operational data and manufacturing experience while allowing for iterative improvements in technology and production processes.

Regulatory frameworks and standards development will significantly impact commercialization timelines. Current regulations regarding ammonia handling and storage were developed primarily for industrial and agricultural applications, not for distributed energy systems. Harmonized international standards for ammonia fuel cell systems, including safety protocols and performance metrics, are still evolving and represent a potential bottleneck to market expansion.

Investment requirements for achieving commercial scale are substantial, estimated at $2-3 billion globally over the next decade to establish manufacturing capacity and supply chain infrastructure. This necessitates coordinated efforts between industry stakeholders, government entities, and financial institutions to distribute risk and accelerate development timelines.

Economic analysis indicates that ammonia fuel cells currently have a levelized cost of energy (LCOE) approximately 2.5-3 times higher than conventional power generation technologies. However, projections suggest this gap could narrow to 1.2-1.5 times by 2030 with technological improvements and economies of scale. The capital expenditure for ammonia fuel cell systems remains a significant barrier, with current costs ranging from $3,000-5,000 per kilowatt, substantially higher than the $1,000-1,500 target needed for commercial viability.

Supply chain considerations present additional challenges, particularly regarding the sustainable production and distribution of ammonia. Green ammonia production pathways using renewable electricity for hydrogen generation are essential for realizing the full environmental benefits of this technology. Current global ammonia production infrastructure is primarily optimized for fertilizer applications rather than energy storage and delivery, necessitating significant adaptation.

Market entry strategies likely require targeting niche applications initially, where the unique benefits of ammonia fuel cells outweigh cost considerations. Potential early markets include remote power generation, maritime applications, and backup power systems for critical infrastructure. These segments can provide valuable operational data and manufacturing experience while allowing for iterative improvements in technology and production processes.

Regulatory frameworks and standards development will significantly impact commercialization timelines. Current regulations regarding ammonia handling and storage were developed primarily for industrial and agricultural applications, not for distributed energy systems. Harmonized international standards for ammonia fuel cell systems, including safety protocols and performance metrics, are still evolving and represent a potential bottleneck to market expansion.

Investment requirements for achieving commercial scale are substantial, estimated at $2-3 billion globally over the next decade to establish manufacturing capacity and supply chain infrastructure. This necessitates coordinated efforts between industry stakeholders, government entities, and financial institutions to distribute risk and accelerate development timelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!