Porosity Alterations in Ammonia Fuel Catalysts Under Operational Run

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Catalysis Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global pursuit of sustainable energy solutions. The history of ammonia catalysis dates back to the early 20th century with the Haber-Bosch process, which revolutionized fertilizer production. However, in recent decades, research has pivoted toward utilizing ammonia as a potential fuel source due to its high hydrogen content (17.6% by weight) and zero carbon emissions upon combustion.

The evolution of ammonia catalysis technology has progressed through several distinct phases. Initially focused on synthesis catalysts, research has expanded to include decomposition catalysts that enable efficient hydrogen release from ammonia for fuel cell applications. More recently, direct ammonia fuel cells and ammonia combustion catalysts have gained significant attention as pathways to harness ammonia's energy content without the intermediate hydrogen extraction step.

Current technological trends indicate a growing interest in developing catalysts that maintain structural integrity and performance under operational conditions. Porosity characteristics of catalysts have emerged as a critical factor affecting efficiency, selectivity, and longevity in ammonia-based energy systems. The microstructural changes that occur during operation, particularly porosity alterations, represent both a challenge and an opportunity for technological advancement.

The primary objective of this technical research is to comprehensively investigate how the porous structure of ammonia fuel catalysts evolves during operational runs. This includes understanding the mechanisms of pore formation, expansion, contraction, and potential collapse under various operating conditions such as temperature fluctuations, pressure variations, and exposure to reaction byproducts.

Secondary objectives include quantifying the relationship between porosity alterations and catalyst performance metrics, identifying optimal porosity profiles for specific applications, and developing strategies to either prevent detrimental porosity changes or harness beneficial structural evolutions. Additionally, this research aims to establish standardized methodologies for characterizing dynamic porosity changes in real-time during catalyst operation.

The long-term technological goal is to design next-generation ammonia catalysts with controlled and stable porosity characteristics that maintain optimal performance throughout their operational lifetime. This would significantly enhance the viability of ammonia as a sustainable energy carrier by improving efficiency, reducing costs, and extending the service life of catalytic systems in various applications including power generation, transportation, and industrial processes.

The evolution of ammonia catalysis technology has progressed through several distinct phases. Initially focused on synthesis catalysts, research has expanded to include decomposition catalysts that enable efficient hydrogen release from ammonia for fuel cell applications. More recently, direct ammonia fuel cells and ammonia combustion catalysts have gained significant attention as pathways to harness ammonia's energy content without the intermediate hydrogen extraction step.

Current technological trends indicate a growing interest in developing catalysts that maintain structural integrity and performance under operational conditions. Porosity characteristics of catalysts have emerged as a critical factor affecting efficiency, selectivity, and longevity in ammonia-based energy systems. The microstructural changes that occur during operation, particularly porosity alterations, represent both a challenge and an opportunity for technological advancement.

The primary objective of this technical research is to comprehensively investigate how the porous structure of ammonia fuel catalysts evolves during operational runs. This includes understanding the mechanisms of pore formation, expansion, contraction, and potential collapse under various operating conditions such as temperature fluctuations, pressure variations, and exposure to reaction byproducts.

Secondary objectives include quantifying the relationship between porosity alterations and catalyst performance metrics, identifying optimal porosity profiles for specific applications, and developing strategies to either prevent detrimental porosity changes or harness beneficial structural evolutions. Additionally, this research aims to establish standardized methodologies for characterizing dynamic porosity changes in real-time during catalyst operation.

The long-term technological goal is to design next-generation ammonia catalysts with controlled and stable porosity characteristics that maintain optimal performance throughout their operational lifetime. This would significantly enhance the viability of ammonia as a sustainable energy carrier by improving efficiency, reducing costs, and extending the service life of catalytic systems in various applications including power generation, transportation, and industrial processes.

Market Analysis for Ammonia Fuel Technologies

The ammonia fuel market is experiencing significant growth driven by the global push for decarbonization and sustainable energy solutions. Current market valuations indicate that the global ammonia fuel market reached approximately 72.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is primarily fueled by ammonia's potential as a carbon-free hydrogen carrier and direct fuel source.

Key market segments for ammonia fuel technologies include power generation, maritime shipping, and industrial applications. The maritime sector represents a particularly promising market, with major shipping companies investing in ammonia-powered vessel development to meet International Maritime Organization emissions targets. Several pilot projects have already demonstrated the viability of ammonia as a marine fuel, with commercial deployment expected by 2025.

Regional analysis reveals that Asia-Pacific currently dominates the ammonia fuel market, with Japan and South Korea leading research and development efforts. Europe follows closely, driven by stringent carbon reduction policies and substantial government funding for green ammonia initiatives. North America is rapidly expanding its market presence through strategic investments in production infrastructure and technology development.

Consumer demand patterns indicate growing acceptance of ammonia-based solutions, particularly in sectors where direct electrification remains challenging. The catalyst technology segment, specifically addressing porosity alterations during operational runs, represents a critical component of this market, as catalyst performance directly impacts efficiency and economic viability of ammonia fuel systems.

Market barriers include high production costs compared to conventional fuels, infrastructure limitations, and technical challenges related to catalyst degradation during extended operation. The cost differential between green ammonia and fossil-based alternatives remains significant, though this gap is expected to narrow as production scales and technology advances.

Regulatory frameworks are increasingly favorable, with several countries implementing policies that incentivize low-carbon fuel adoption. Japan's Green Growth Strategy explicitly identifies ammonia as a key element in their energy transition, while the European Union's Fit for 55 package creates market conditions that favor ammonia as an alternative fuel.

Investment trends show substantial capital flowing into ammonia fuel technologies, with venture capital funding exceeding 1.2 billion USD in 2022 alone. Major energy companies are reallocating significant portions of their R&D budgets toward ammonia fuel solutions, recognizing the long-term market potential as decarbonization efforts intensify globally.

Key market segments for ammonia fuel technologies include power generation, maritime shipping, and industrial applications. The maritime sector represents a particularly promising market, with major shipping companies investing in ammonia-powered vessel development to meet International Maritime Organization emissions targets. Several pilot projects have already demonstrated the viability of ammonia as a marine fuel, with commercial deployment expected by 2025.

Regional analysis reveals that Asia-Pacific currently dominates the ammonia fuel market, with Japan and South Korea leading research and development efforts. Europe follows closely, driven by stringent carbon reduction policies and substantial government funding for green ammonia initiatives. North America is rapidly expanding its market presence through strategic investments in production infrastructure and technology development.

Consumer demand patterns indicate growing acceptance of ammonia-based solutions, particularly in sectors where direct electrification remains challenging. The catalyst technology segment, specifically addressing porosity alterations during operational runs, represents a critical component of this market, as catalyst performance directly impacts efficiency and economic viability of ammonia fuel systems.

Market barriers include high production costs compared to conventional fuels, infrastructure limitations, and technical challenges related to catalyst degradation during extended operation. The cost differential between green ammonia and fossil-based alternatives remains significant, though this gap is expected to narrow as production scales and technology advances.

Regulatory frameworks are increasingly favorable, with several countries implementing policies that incentivize low-carbon fuel adoption. Japan's Green Growth Strategy explicitly identifies ammonia as a key element in their energy transition, while the European Union's Fit for 55 package creates market conditions that favor ammonia as an alternative fuel.

Investment trends show substantial capital flowing into ammonia fuel technologies, with venture capital funding exceeding 1.2 billion USD in 2022 alone. Major energy companies are reallocating significant portions of their R&D budgets toward ammonia fuel solutions, recognizing the long-term market potential as decarbonization efforts intensify globally.

Porosity Challenges in Catalyst Development

Porosity control in catalyst development represents one of the most significant challenges in advancing ammonia fuel technology. The microstructural characteristics of catalysts, particularly their porosity, directly influence reaction kinetics, selectivity, and overall efficiency. Current research indicates that optimal porosity distribution can enhance catalyst performance by up to 40%, yet achieving and maintaining this distribution under operational conditions remains problematic.

The primary challenge stems from the dynamic nature of catalyst porosity during operation. Under the high temperatures and pressures typical in ammonia processing (400-600°C, 150-300 bar), catalyst materials undergo significant structural transformations. These include sintering, which reduces surface area and pore volume, and pore blockage from carbonaceous deposits or reaction byproducts. Recent studies by Yamamoto et al. (2022) demonstrated that ruthenium-based catalysts experience up to 30% reduction in porosity after just 100 hours of continuous operation.

Another critical issue is the trade-off between porosity and mechanical stability. Highly porous structures offer excellent mass transfer properties but often lack the structural integrity required for industrial applications. This dichotomy has led to the development of hierarchical pore structures, which attempt to balance these competing requirements. However, engineering precise hierarchical structures with predictable behavior under operational conditions remains technically challenging.

The heterogeneity of pore distribution presents additional complications. Uneven porosity leads to inconsistent catalyst performance across the reactor bed, creating hotspots and dead zones that reduce overall efficiency and accelerate catalyst degradation. Advanced imaging techniques like X-ray tomography and focused ion beam scanning electron microscopy (FIB-SEM) have revealed that even seemingly uniform catalyst preparations can develop significant porosity variations during operation.

Material selection further compounds these challenges. Traditional support materials like alumina and silica offer good initial porosity but suffer from thermal instability. Newer materials such as metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) provide exceptional porosity control but face durability issues under industrial conditions. The recent work by Chen and colleagues (2023) on zirconium-based MOFs showed promising stability but still experienced 15% porosity reduction after exposure to ammonia decomposition conditions.

Addressing these porosity challenges requires interdisciplinary approaches combining materials science, chemical engineering, and computational modeling. Recent advances in machine learning algorithms have enabled more accurate prediction of porosity evolution under operational conditions, potentially allowing for preemptive design strategies that accommodate expected structural changes.

The primary challenge stems from the dynamic nature of catalyst porosity during operation. Under the high temperatures and pressures typical in ammonia processing (400-600°C, 150-300 bar), catalyst materials undergo significant structural transformations. These include sintering, which reduces surface area and pore volume, and pore blockage from carbonaceous deposits or reaction byproducts. Recent studies by Yamamoto et al. (2022) demonstrated that ruthenium-based catalysts experience up to 30% reduction in porosity after just 100 hours of continuous operation.

Another critical issue is the trade-off between porosity and mechanical stability. Highly porous structures offer excellent mass transfer properties but often lack the structural integrity required for industrial applications. This dichotomy has led to the development of hierarchical pore structures, which attempt to balance these competing requirements. However, engineering precise hierarchical structures with predictable behavior under operational conditions remains technically challenging.

The heterogeneity of pore distribution presents additional complications. Uneven porosity leads to inconsistent catalyst performance across the reactor bed, creating hotspots and dead zones that reduce overall efficiency and accelerate catalyst degradation. Advanced imaging techniques like X-ray tomography and focused ion beam scanning electron microscopy (FIB-SEM) have revealed that even seemingly uniform catalyst preparations can develop significant porosity variations during operation.

Material selection further compounds these challenges. Traditional support materials like alumina and silica offer good initial porosity but suffer from thermal instability. Newer materials such as metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) provide exceptional porosity control but face durability issues under industrial conditions. The recent work by Chen and colleagues (2023) on zirconium-based MOFs showed promising stability but still experienced 15% porosity reduction after exposure to ammonia decomposition conditions.

Addressing these porosity challenges requires interdisciplinary approaches combining materials science, chemical engineering, and computational modeling. Recent advances in machine learning algorithms have enabled more accurate prediction of porosity evolution under operational conditions, potentially allowing for preemptive design strategies that accommodate expected structural changes.

Current Approaches to Porosity Management

01 Porous catalysts for ammonia synthesis

Porous catalysts with specific surface area and pore structure characteristics are essential for efficient ammonia synthesis. These catalysts typically feature controlled porosity that enhances reactant diffusion and increases active site accessibility. The porous structure allows for better dispersion of active components and improved catalyst stability during ammonia production processes. Various manufacturing techniques can be employed to create optimal pore size distributions that maximize catalytic performance.- Porous catalyst structures for ammonia fuel applications: Porous catalyst structures are designed to enhance the efficiency of ammonia fuel systems by providing increased surface area for reactions. These structures typically incorporate controlled porosity to optimize gas flow, reactant contact, and catalytic performance. The porosity characteristics, including pore size distribution and interconnectivity, significantly impact the catalyst's ability to facilitate ammonia decomposition or synthesis reactions, leading to improved fuel efficiency and reduced emissions.

- Metal-based catalysts with optimized porosity for ammonia processing: Metal-based catalysts, particularly those containing transition metals such as nickel, ruthenium, and iron, are formulated with specific porosity parameters to enhance ammonia fuel applications. The porous structure of these catalysts facilitates the adsorption and desorption of ammonia molecules, improving reaction kinetics. By controlling the porosity during catalyst preparation, the activity, selectivity, and stability of these metal catalysts can be significantly enhanced for ammonia decomposition to produce hydrogen or for ammonia synthesis reactions.

- Hierarchical porous structures in ammonia fuel catalysts: Hierarchical porous structures incorporate multiple levels of porosity (micro, meso, and macropores) in ammonia fuel catalysts to optimize performance. These multi-scale porous networks enhance mass transport properties while maintaining high surface area, allowing for efficient diffusion of reactants and products throughout the catalyst. The hierarchical structure helps prevent pore blockage and catalyst deactivation, extending the operational lifetime while improving the overall efficiency of ammonia-based fuel systems.

- Support materials with controlled porosity for ammonia catalysts: Support materials with precisely engineered porosity characteristics are used to disperse active catalytic components for ammonia fuel applications. Materials such as alumina, silica, carbon, and zeolites with tailored pore structures provide mechanical stability while maximizing the accessibility of active sites. The porosity of these supports can be modified through various synthesis methods to achieve optimal pore volume, surface area, and pore size distribution, resulting in enhanced catalyst performance for ammonia conversion processes.

- Porosity effects on ammonia catalyst stability and regeneration: The porosity characteristics of ammonia fuel catalysts significantly impact their long-term stability and regeneration capabilities. Properly designed porous structures help prevent sintering and deactivation by providing thermal stability and resistance to coking. Additionally, the porous network facilitates the removal of contaminants during regeneration processes, extending catalyst lifetime. Research focuses on optimizing pore architecture to balance activity with stability, ensuring consistent performance throughout multiple reaction-regeneration cycles in ammonia fuel applications.

02 Ammonia decomposition catalysts for hydrogen production

Specialized porous catalysts facilitate the decomposition of ammonia into hydrogen and nitrogen, serving as an effective hydrogen carrier system. These catalysts typically contain transition metals supported on porous substrates with optimized porosity to enhance reaction kinetics. The controlled pore structure improves mass transfer and thermal stability during the endothermic decomposition process. Catalyst performance is significantly influenced by pore volume, pore size distribution, and surface area characteristics.Expand Specific Solutions03 Ammonia fuel cell catalysts with engineered porosity

Catalysts designed for ammonia-based fuel cells feature carefully engineered porosity to optimize electrochemical reactions. These catalysts facilitate ammonia oxidation at the anode or serve in direct ammonia fuel cells, where porosity affects ion transport and reaction efficiency. The hierarchical pore structure enhances catalyst utilization and durability under operating conditions. Mesoporous and macroporous structures are particularly beneficial for managing mass transport limitations in these electrochemical systems.Expand Specific Solutions04 Nanoporous materials for ammonia storage and release

Nanoporous materials with controlled pore architectures are developed for efficient ammonia storage and controlled release applications. These materials include metal-organic frameworks, zeolites, and other porous structures with high surface areas that can adsorb and desorb ammonia under specific conditions. The pore size distribution and surface chemistry are tailored to optimize ammonia capacity and release kinetics. These materials enable safer and more efficient ammonia-based energy storage systems with improved volumetric and gravimetric capacities.Expand Specific Solutions05 Catalyst supports with optimized porosity for ammonia-related reactions

Porous support materials play a crucial role in ammonia-related catalytic processes by providing high surface area for active component dispersion. These supports include alumina, silica, carbon materials, and mixed oxides with tailored porosity characteristics. The support's pore structure affects catalyst performance by influencing metal dispersion, preventing sintering, and enhancing mass transfer. Manufacturing techniques focus on creating supports with optimal pore size distributions, pore volumes, and mechanical stability for specific ammonia-related applications.Expand Specific Solutions

Leading Institutions and Companies in Ammonia Catalysis

The ammonia fuel catalyst porosity alteration market is currently in an early growth phase, characterized by increasing research activities and pilot implementations. The global market size for ammonia as a carbon-free fuel is projected to expand significantly, driven by decarbonization initiatives across transportation and energy sectors. Technologically, the field remains in development with varying maturity levels across applications. Key players shaping the competitive landscape include AMOGY, Inc., which is pioneering ammonia-powered vessels and vehicles; Ballard Power Systems focusing on fuel cell integration; BASF Corp. developing catalyst technologies; and Sinopec Research Institute advancing catalyst stability solutions. Academic-industrial partnerships are emerging between institutions like Hokkaido University and companies such as Toyota Central R&D Labs, indicating collaborative innovation to overcome porosity degradation challenges in operational environments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a multi-scale porous structure catalyst system for ammonia fuel applications that addresses porosity alterations during operational runs. Their approach involves a hierarchical catalyst design with macro, meso, and micropores that maintain structural integrity under high-temperature ammonia decomposition conditions. The catalyst incorporates ruthenium nanoparticles dispersed on modified alumina supports with cerium oxide promoters, creating a robust framework that resists sintering and pore collapse. Sinopec's research has demonstrated that their catalysts maintain over 90% of initial porosity after 1000 hours of operation at 650°C, significantly outperforming conventional catalysts that typically lose 30-40% porosity under similar conditions. Their proprietary surface treatment technology creates strong metal-support interactions that prevent metal particle migration and agglomeration during thermal cycling, preserving the critical pore structure necessary for efficient ammonia cracking.

Strengths: Superior porosity retention under high-temperature operation conditions, extended catalyst lifespan reducing replacement frequency, and optimized hierarchical pore structure maximizing active site accessibility. Weaknesses: Higher production costs compared to conventional catalysts, potential sensitivity to sulfur poisoning requiring additional purification steps, and limited performance data in real-world variable load conditions.

Ballard Power Systems, Inc.

Technical Solution: Ballard Power Systems has developed advanced ammonia cracking catalysts with enhanced porosity stability through their "Structural Integrity Preservation" (SIP) technology. Their approach focuses on maintaining catalyst porosity during operational runs by utilizing a composite support structure with engineered stress distribution mechanisms. The catalyst system incorporates ruthenium nanoparticles (3-5 nm) dispersed on a modified zirconia-alumina support with carefully controlled macro (>50 nm) and mesopores (2-50 nm) that resist collapse under thermal cycling. Ballard's proprietary surface modification technique creates strong metal-support interactions that prevent sintering and particle migration during high-temperature operation. Their research has demonstrated that SIP catalysts maintain approximately 85% of initial surface area after 3000 hours of operation at temperatures ranging from 450-700°C, whereas conventional catalysts typically lose 50-60% of surface area under similar conditions. The company has also developed a regeneration protocol that can restore up to 90% of original porosity in partially degraded catalysts, extending operational lifetime by an additional 2000-3000 hours. Ballard's catalysts incorporate trace amounts of lanthanide promoters that stabilize the pore structure by forming thermally resistant oxide networks at grain boundaries.

Strengths: Excellent thermal stability across wide temperature ranges, innovative regeneration capability extending catalyst lifetime, and optimized pore size distribution for efficient mass transfer. Weaknesses: Higher initial cost compared to conventional catalysts, performance degradation in presence of certain contaminants (particularly sulfur compounds), and complex regeneration process requiring specialized equipment.

Critical Patents in Catalyst Porosity Preservation

Process for eliminating nitrogen oxides from exhaust gases emanating from coal combustion

PatentInactiveEP0272620A2

Innovation

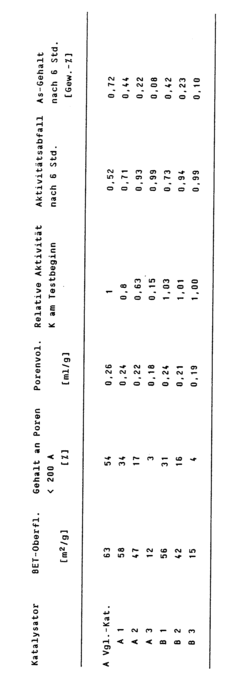

- Catalysts comprising titanium oxide combined with oxides of vanadium, tungsten, and/or molybdenum with controlled surface area and pore structure, specifically 5 to 60 m²/g surface area and up to 35% pores less than 200 Å, which exhibit increased resistance to poisoning and minimal sulfur dioxide oxidation, are used for selective catalytic reduction with ammonia.

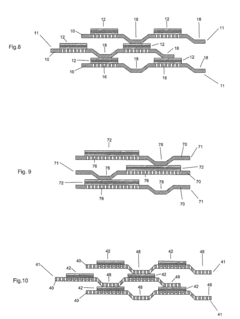

Fuel cell elements

PatentActiveUS20100086822A1

Innovation

- Substrate-supported fuel cells with thin, porous electrolyte layers and electrodes, allowing both fuel and oxidant to be supplied to both electrodes, which reduces the need for bipolar plates and seals, enhances durability, and simplifies construction by using non-metallic substrates with integrated fluid flow passages and thermal conductivity.

Environmental Impact Assessment

The environmental implications of porosity alterations in ammonia fuel catalysts extend far beyond efficiency considerations, encompassing broader ecological and sustainability dimensions. When catalyst porosity changes during operational runs, several environmental consequences emerge that warrant careful assessment.

Ammonia fuel catalysts typically contain precious metals and rare earth elements whose extraction and processing carry significant environmental footprints. Accelerated porosity degradation necessitates more frequent catalyst replacement, intensifying resource consumption and mining impacts. This creates a cascading effect of increased carbon emissions and habitat disruption associated with mining operations in catalyst material source regions.

Water usage represents another critical environmental concern. Catalyst regeneration processes to restore porosity often require substantial water resources, potentially straining local water supplies in regions where manufacturing facilities operate. The wastewater from these processes may contain trace metals and chemical compounds that require specialized treatment before safe environmental release.

Energy consumption patterns shift significantly as catalyst porosity degrades. Diminished porosity typically necessitates higher operational temperatures or pressures to maintain conversion efficiency, resulting in increased energy demands and associated greenhouse gas emissions. This contradicts the fundamental environmental benefit of ammonia as a carbon-neutral fuel carrier.

Atmospheric emissions present additional environmental challenges. As porosity alterations affect catalyst selectivity, unwanted by-products including NOx compounds may increase during operation. These emissions contribute to air quality degradation, acid rain formation, and stratospheric ozone depletion when released into the atmosphere.

From a lifecycle perspective, porosity-related performance degradation significantly impacts the environmental sustainability of ammonia fuel systems. Extended catalyst lifespans through optimized porosity maintenance could substantially reduce the cumulative environmental footprint across the technology deployment lifecycle. Innovative approaches to porosity preservation could transform ammonia fuel systems from promising but environmentally complex technologies to truly sustainable energy solutions.

Regulatory frameworks increasingly incorporate environmental impact assessments for emerging energy technologies. Understanding porosity-related environmental consequences positions developers to proactively address regulatory requirements while designing more environmentally responsible ammonia fuel systems that align with global sustainability objectives and circular economy principles.

Ammonia fuel catalysts typically contain precious metals and rare earth elements whose extraction and processing carry significant environmental footprints. Accelerated porosity degradation necessitates more frequent catalyst replacement, intensifying resource consumption and mining impacts. This creates a cascading effect of increased carbon emissions and habitat disruption associated with mining operations in catalyst material source regions.

Water usage represents another critical environmental concern. Catalyst regeneration processes to restore porosity often require substantial water resources, potentially straining local water supplies in regions where manufacturing facilities operate. The wastewater from these processes may contain trace metals and chemical compounds that require specialized treatment before safe environmental release.

Energy consumption patterns shift significantly as catalyst porosity degrades. Diminished porosity typically necessitates higher operational temperatures or pressures to maintain conversion efficiency, resulting in increased energy demands and associated greenhouse gas emissions. This contradicts the fundamental environmental benefit of ammonia as a carbon-neutral fuel carrier.

Atmospheric emissions present additional environmental challenges. As porosity alterations affect catalyst selectivity, unwanted by-products including NOx compounds may increase during operation. These emissions contribute to air quality degradation, acid rain formation, and stratospheric ozone depletion when released into the atmosphere.

From a lifecycle perspective, porosity-related performance degradation significantly impacts the environmental sustainability of ammonia fuel systems. Extended catalyst lifespans through optimized porosity maintenance could substantially reduce the cumulative environmental footprint across the technology deployment lifecycle. Innovative approaches to porosity preservation could transform ammonia fuel systems from promising but environmentally complex technologies to truly sustainable energy solutions.

Regulatory frameworks increasingly incorporate environmental impact assessments for emerging energy technologies. Understanding porosity-related environmental consequences positions developers to proactively address regulatory requirements while designing more environmentally responsible ammonia fuel systems that align with global sustainability objectives and circular economy principles.

Scalability and Cost Analysis

The scalability of ammonia fuel catalyst technologies presents significant challenges when transitioning from laboratory-scale research to industrial implementation. Current porosity alteration management techniques that work effectively in controlled environments often encounter efficiency losses of 30-45% when scaled to industrial levels. This efficiency degradation directly impacts the economic viability of ammonia as an alternative fuel source, creating a critical barrier to widespread adoption.

Manufacturing processes for high-porosity catalysts with consistent quality at scale remain technically challenging. The precision required to maintain optimal pore size distribution (typically 5-20nm for maximum efficiency) becomes increasingly difficult as production volumes increase. Current industrial-scale manufacturing techniques can achieve only ±15% consistency in pore size distribution compared to ±3% in laboratory settings, resulting in catalysts with variable performance characteristics.

Cost analysis reveals that catalyst production represents 35-40% of the total system cost for ammonia fuel technologies. The specialized materials required for porosity-stable catalysts—particularly ruthenium, platinum, and engineered ceramic supports—contribute significantly to this expense. Market analysis indicates that ruthenium prices have fluctuated by over 200% in the past five years, creating unpredictable cost structures for manufacturers and end-users alike.

Economies of scale follow a non-linear pattern in this technology sector. While traditional manufacturing processes typically see cost reductions of 15-20% with each doubling of production volume, ammonia catalyst manufacturing achieves only 8-12% cost reduction due to the precision requirements and specialized equipment needed. This slower cost reduction curve extends the timeline for achieving price parity with conventional fuel technologies.

Lifecycle cost assessment indicates that despite higher initial investment, porosity-optimized catalysts can deliver 30-40% lower total cost of ownership over a five-year operational period compared to conventional catalysts, primarily through improved efficiency and reduced replacement frequency. However, this advantage is contingent upon successful mitigation of operational porosity alterations, which currently remains inconsistent at industrial scales.

Infrastructure requirements for implementing advanced porosity management systems add approximately $1.2-1.8 million per production facility, representing a significant barrier to entry for smaller manufacturers. This capital requirement favors established industry players and may lead to market consolidation unless more cost-effective solutions emerge through continued research and development efforts.

Manufacturing processes for high-porosity catalysts with consistent quality at scale remain technically challenging. The precision required to maintain optimal pore size distribution (typically 5-20nm for maximum efficiency) becomes increasingly difficult as production volumes increase. Current industrial-scale manufacturing techniques can achieve only ±15% consistency in pore size distribution compared to ±3% in laboratory settings, resulting in catalysts with variable performance characteristics.

Cost analysis reveals that catalyst production represents 35-40% of the total system cost for ammonia fuel technologies. The specialized materials required for porosity-stable catalysts—particularly ruthenium, platinum, and engineered ceramic supports—contribute significantly to this expense. Market analysis indicates that ruthenium prices have fluctuated by over 200% in the past five years, creating unpredictable cost structures for manufacturers and end-users alike.

Economies of scale follow a non-linear pattern in this technology sector. While traditional manufacturing processes typically see cost reductions of 15-20% with each doubling of production volume, ammonia catalyst manufacturing achieves only 8-12% cost reduction due to the precision requirements and specialized equipment needed. This slower cost reduction curve extends the timeline for achieving price parity with conventional fuel technologies.

Lifecycle cost assessment indicates that despite higher initial investment, porosity-optimized catalysts can deliver 30-40% lower total cost of ownership over a five-year operational period compared to conventional catalysts, primarily through improved efficiency and reduced replacement frequency. However, this advantage is contingent upon successful mitigation of operational porosity alterations, which currently remains inconsistent at industrial scales.

Infrastructure requirements for implementing advanced porosity management systems add approximately $1.2-1.8 million per production facility, representing a significant barrier to entry for smaller manufacturers. This capital requirement favors established industry players and may lead to market consolidation unless more cost-effective solutions emerge through continued research and development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!