Exploring Catalytic Converters for Ammonia Fuel Efficiency Boost

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Catalysis Background and Objectives

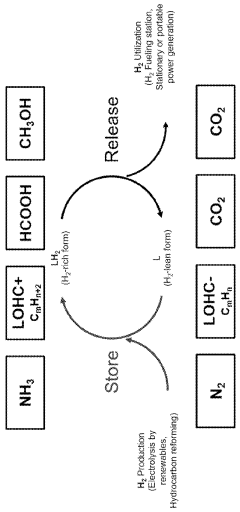

Ammonia has emerged as a promising carbon-free energy carrier in the global pursuit of sustainable energy solutions. The history of ammonia utilization dates back to the early 20th century with the development of the Haber-Bosch process, which revolutionized fertilizer production. However, its potential as an energy carrier has only gained significant attention in recent decades as the world seeks alternatives to fossil fuels.

The evolution of ammonia technology has progressed through several distinct phases. Initially viewed primarily as a chemical feedstock, ammonia's potential as a hydrogen carrier became recognized in the 1960s and 1970s. The 2000s marked a turning point when researchers began seriously investigating ammonia as a direct fuel source, leading to the current phase where catalytic technologies are being developed to enhance its combustion efficiency and reduce harmful emissions.

Current technological trends indicate a growing focus on developing specialized catalytic systems that can effectively break the strong N-H bonds in ammonia molecules at lower temperatures, thereby improving energy efficiency and reducing the activation energy required for combustion. This trend aligns with the broader movement toward green hydrogen and ammonia production using renewable electricity sources.

The primary technical objective of exploring catalytic converters for ammonia fuel efficiency is to overcome the fundamental challenges associated with ammonia combustion. These include its high ignition temperature, low flame speed, and narrow flammability limits compared to conventional fuels. Effective catalysts aim to accelerate the decomposition of ammonia into nitrogen and hydrogen, facilitating more complete combustion and higher energy conversion efficiency.

Secondary objectives include minimizing the formation of nitrogen oxides (NOx) during combustion, reducing catalyst degradation rates to ensure longevity, and developing systems that can operate effectively across varying load conditions. Additionally, there is a focus on creating catalysts from abundant, non-precious materials to ensure economic viability for widespread adoption.

The long-term vision encompasses the development of a comprehensive ammonia fuel ecosystem where catalytic technologies play a central role in enabling efficient energy extraction from ammonia in various applications, including power generation, maritime transport, and potentially even aviation. This vision aligns with global decarbonization goals and represents a pathway to leverage existing ammonia production and distribution infrastructure for energy applications.

Success in this field would significantly contribute to the viability of the "hydrogen economy" by addressing one of its key challenges: the efficient storage and transport of hydrogen energy through chemical carriers like ammonia.

The evolution of ammonia technology has progressed through several distinct phases. Initially viewed primarily as a chemical feedstock, ammonia's potential as a hydrogen carrier became recognized in the 1960s and 1970s. The 2000s marked a turning point when researchers began seriously investigating ammonia as a direct fuel source, leading to the current phase where catalytic technologies are being developed to enhance its combustion efficiency and reduce harmful emissions.

Current technological trends indicate a growing focus on developing specialized catalytic systems that can effectively break the strong N-H bonds in ammonia molecules at lower temperatures, thereby improving energy efficiency and reducing the activation energy required for combustion. This trend aligns with the broader movement toward green hydrogen and ammonia production using renewable electricity sources.

The primary technical objective of exploring catalytic converters for ammonia fuel efficiency is to overcome the fundamental challenges associated with ammonia combustion. These include its high ignition temperature, low flame speed, and narrow flammability limits compared to conventional fuels. Effective catalysts aim to accelerate the decomposition of ammonia into nitrogen and hydrogen, facilitating more complete combustion and higher energy conversion efficiency.

Secondary objectives include minimizing the formation of nitrogen oxides (NOx) during combustion, reducing catalyst degradation rates to ensure longevity, and developing systems that can operate effectively across varying load conditions. Additionally, there is a focus on creating catalysts from abundant, non-precious materials to ensure economic viability for widespread adoption.

The long-term vision encompasses the development of a comprehensive ammonia fuel ecosystem where catalytic technologies play a central role in enabling efficient energy extraction from ammonia in various applications, including power generation, maritime transport, and potentially even aviation. This vision aligns with global decarbonization goals and represents a pathway to leverage existing ammonia production and distribution infrastructure for energy applications.

Success in this field would significantly contribute to the viability of the "hydrogen economy" by addressing one of its key challenges: the efficient storage and transport of hydrogen energy through chemical carriers like ammonia.

Market Analysis for Ammonia Fuel Applications

The global ammonia fuel market is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards decarbonization. Current market valuations indicate that the ammonia fuel sector is projected to reach $5.5 billion by 2030, with a compound annual growth rate of 8.7% from 2023 to 2030. This growth trajectory is primarily fueled by stringent environmental regulations and the global commitment to reduce carbon emissions across various industries.

The maritime industry represents one of the most promising markets for ammonia fuel applications, as international shipping faces mounting pressure to reduce its environmental footprint. The International Maritime Organization's target to cut greenhouse gas emissions by at least 50% by 2050 has positioned ammonia as a leading alternative fuel candidate. Currently, approximately 120 ammonia-powered vessel projects are in development worldwide, signaling strong market adoption potential.

Power generation constitutes another substantial market segment, with ammonia co-firing in conventional power plants gaining traction as a transitional solution. Several pilot projects in Japan, Australia, and Europe have demonstrated the technical feasibility of using ammonia in existing infrastructure with minimal modifications, opening a market estimated at $1.2 billion by 2028.

The transportation sector beyond maritime applications shows emerging interest, particularly in heavy-duty vehicles and long-haul transportation where battery electric solutions face range and weight limitations. However, this segment remains in early development stages, with market penetration expected to accelerate post-2025 as infrastructure develops.

Regional analysis reveals Asia-Pacific as the dominant market for ammonia fuel applications, accounting for approximately 42% of global demand. Japan leads with its strategic "Green Ammonia Consortium" and substantial investments in ammonia fuel infrastructure. Europe follows closely at 35% market share, driven by aggressive carbon neutrality targets and supportive policy frameworks, particularly in Germany, the Netherlands, and Scandinavian countries.

Customer segmentation indicates three primary adopter categories: early industrial adopters seeking carbon reduction solutions, government-backed demonstration projects, and forward-thinking transportation companies. The willingness to pay premium prices for green ammonia varies significantly across these segments, with price sensitivity decreasing as carbon pricing mechanisms become more widespread.

Market barriers include the current cost differential between conventional fuels and ammonia, infrastructure limitations, and safety concerns regarding ammonia handling. However, technological advancements in catalytic converters specifically designed for ammonia combustion are expected to address efficiency and emission challenges, potentially accelerating market adoption by improving the economic proposition of ammonia as a fuel.

The maritime industry represents one of the most promising markets for ammonia fuel applications, as international shipping faces mounting pressure to reduce its environmental footprint. The International Maritime Organization's target to cut greenhouse gas emissions by at least 50% by 2050 has positioned ammonia as a leading alternative fuel candidate. Currently, approximately 120 ammonia-powered vessel projects are in development worldwide, signaling strong market adoption potential.

Power generation constitutes another substantial market segment, with ammonia co-firing in conventional power plants gaining traction as a transitional solution. Several pilot projects in Japan, Australia, and Europe have demonstrated the technical feasibility of using ammonia in existing infrastructure with minimal modifications, opening a market estimated at $1.2 billion by 2028.

The transportation sector beyond maritime applications shows emerging interest, particularly in heavy-duty vehicles and long-haul transportation where battery electric solutions face range and weight limitations. However, this segment remains in early development stages, with market penetration expected to accelerate post-2025 as infrastructure develops.

Regional analysis reveals Asia-Pacific as the dominant market for ammonia fuel applications, accounting for approximately 42% of global demand. Japan leads with its strategic "Green Ammonia Consortium" and substantial investments in ammonia fuel infrastructure. Europe follows closely at 35% market share, driven by aggressive carbon neutrality targets and supportive policy frameworks, particularly in Germany, the Netherlands, and Scandinavian countries.

Customer segmentation indicates three primary adopter categories: early industrial adopters seeking carbon reduction solutions, government-backed demonstration projects, and forward-thinking transportation companies. The willingness to pay premium prices for green ammonia varies significantly across these segments, with price sensitivity decreasing as carbon pricing mechanisms become more widespread.

Market barriers include the current cost differential between conventional fuels and ammonia, infrastructure limitations, and safety concerns regarding ammonia handling. However, technological advancements in catalytic converters specifically designed for ammonia combustion are expected to address efficiency and emission challenges, potentially accelerating market adoption by improving the economic proposition of ammonia as a fuel.

Current Catalytic Converter Technologies and Barriers

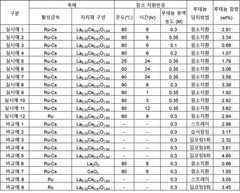

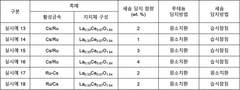

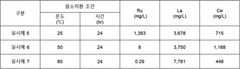

Current catalytic converter technologies for ammonia fuel systems primarily focus on enhancing the efficiency of ammonia combustion while minimizing harmful emissions. Traditional catalytic converters designed for hydrocarbon fuels prove inadequate for ammonia's unique chemical properties, necessitating specialized solutions. The predominant technologies include ruthenium-based catalysts, which demonstrate exceptional activity for ammonia decomposition at relatively low temperatures (300-400°C), achieving conversion rates of up to 99% under optimal conditions.

Platinum group metals (PGMs) catalysts represent another significant technology segment, with platinum, palladium, and rhodium combinations showing promising results for both ammonia decomposition and NOx reduction. These catalysts typically operate at temperature ranges of 350-550°C and can achieve conversion efficiencies of 85-95%, though at considerably higher costs than alternatives.

Transition metal nitrides, particularly those based on molybdenum and nickel, have emerged as cost-effective alternatives to PGMs. These catalysts demonstrate reasonable activity at temperatures above 450°C, with conversion rates of 70-85%, making them attractive for commercial applications despite their lower efficiency compared to noble metal catalysts.

Despite these advancements, significant barriers impede widespread implementation. Temperature management presents a critical challenge, as ammonia catalytic converters require precise thermal conditions to function optimally. Cold-start performance remains particularly problematic, with conversion efficiencies dropping below 30% at temperatures under 250°C, resulting in substantial emissions during vehicle warm-up phases.

Catalyst poisoning represents another major barrier, with sulfur compounds and water vapor significantly degrading catalyst performance over time. Studies indicate performance losses of 15-25% after 1,000 hours of operation in real-world conditions, necessitating more frequent replacement compared to conventional catalytic converters.

Cost factors also limit adoption, particularly for PGM-based solutions. Current ruthenium and platinum-based catalysts add approximately $800-1,200 to vehicle production costs, representing a 3-5x premium over conventional catalytic converters. This cost differential significantly impacts the economic viability of ammonia fuel systems, especially in price-sensitive market segments.

Durability concerns further complicate implementation, with thermal cycling and mechanical stress causing structural degradation of catalyst substrates. Current technologies typically demonstrate lifespans of 80,000-120,000 kilometers before requiring replacement, substantially below the 160,000+ kilometer standard for conventional catalytic converters.

Manufacturing scalability presents additional challenges, with current production methods for specialized ammonia catalysts limited to small-batch processes that are difficult to scale for mass production. This manufacturing constraint creates a significant bottleneck for potential widespread adoption of ammonia fuel technologies in transportation applications.

Platinum group metals (PGMs) catalysts represent another significant technology segment, with platinum, palladium, and rhodium combinations showing promising results for both ammonia decomposition and NOx reduction. These catalysts typically operate at temperature ranges of 350-550°C and can achieve conversion efficiencies of 85-95%, though at considerably higher costs than alternatives.

Transition metal nitrides, particularly those based on molybdenum and nickel, have emerged as cost-effective alternatives to PGMs. These catalysts demonstrate reasonable activity at temperatures above 450°C, with conversion rates of 70-85%, making them attractive for commercial applications despite their lower efficiency compared to noble metal catalysts.

Despite these advancements, significant barriers impede widespread implementation. Temperature management presents a critical challenge, as ammonia catalytic converters require precise thermal conditions to function optimally. Cold-start performance remains particularly problematic, with conversion efficiencies dropping below 30% at temperatures under 250°C, resulting in substantial emissions during vehicle warm-up phases.

Catalyst poisoning represents another major barrier, with sulfur compounds and water vapor significantly degrading catalyst performance over time. Studies indicate performance losses of 15-25% after 1,000 hours of operation in real-world conditions, necessitating more frequent replacement compared to conventional catalytic converters.

Cost factors also limit adoption, particularly for PGM-based solutions. Current ruthenium and platinum-based catalysts add approximately $800-1,200 to vehicle production costs, representing a 3-5x premium over conventional catalytic converters. This cost differential significantly impacts the economic viability of ammonia fuel systems, especially in price-sensitive market segments.

Durability concerns further complicate implementation, with thermal cycling and mechanical stress causing structural degradation of catalyst substrates. Current technologies typically demonstrate lifespans of 80,000-120,000 kilometers before requiring replacement, substantially below the 160,000+ kilometer standard for conventional catalytic converters.

Manufacturing scalability presents additional challenges, with current production methods for specialized ammonia catalysts limited to small-batch processes that are difficult to scale for mass production. This manufacturing constraint creates a significant bottleneck for potential widespread adoption of ammonia fuel technologies in transportation applications.

Existing Catalytic Solutions for Ammonia Fuel Efficiency

01 Catalytic converter design optimization for fuel efficiency

Optimizing the design of catalytic converters can significantly improve fuel efficiency in vehicles. This includes modifications to the converter's structure, substrate material, and flow patterns to reduce backpressure and improve exhaust gas flow. Advanced designs incorporate features like variable cell density, optimized channel geometry, and improved thermal management to enhance conversion efficiency while minimizing the negative impact on engine performance and fuel consumption.- Catalytic converter design optimization for fuel efficiency: Optimizing the design of catalytic converters can significantly improve fuel efficiency in vehicles. This includes modifications to the converter's structure, substrate material, and coating technology to reduce backpressure while maintaining emission control performance. Advanced designs incorporate improved flow dynamics and heat management to ensure faster light-off times and more efficient conversion of pollutants, which reduces the engine load and improves overall fuel economy.

- Sensor-based control systems for catalytic converters: Integration of advanced sensor technologies with catalytic converter systems enables real-time monitoring and adjustment of engine parameters to optimize fuel efficiency. These systems use oxygen sensors, temperature sensors, and pressure sensors to provide feedback to the engine control unit, allowing for precise fuel-air mixture control and timing adjustments. This dynamic control helps maintain optimal catalytic converter performance while minimizing fuel consumption under various operating conditions.

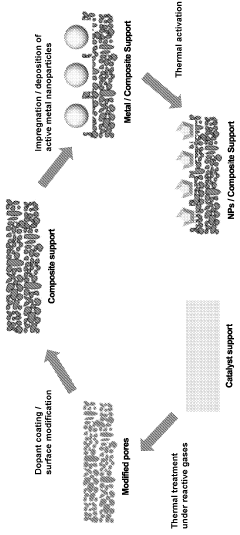

- Novel catalyst materials and formulations: Development of innovative catalyst materials and formulations enhances the performance of catalytic converters while improving fuel efficiency. These include rare earth metals, advanced metal alloys, and nano-structured materials that provide higher catalytic activity at lower temperatures. By enabling more complete combustion of exhaust gases with less precious metal content, these materials reduce the energy penalty associated with emission control systems and contribute to better fuel economy.

- Thermal management systems for catalytic converters: Effective thermal management systems for catalytic converters help optimize their operation and improve fuel efficiency. These systems include insulation techniques, heat recovery mechanisms, and strategic placement of converters to maintain optimal operating temperatures. By reducing the time needed to reach light-off temperature and preventing heat loss, these systems ensure that catalytic converters operate in their most efficient temperature range, reducing the need for fuel-rich operation and improving overall fuel economy.

- Integration with hybrid and alternative fuel systems: Specialized catalytic converter designs for hybrid vehicles and alternative fuel systems address unique emission profiles while maximizing fuel efficiency. These systems are tailored to handle the intermittent operation of internal combustion engines in hybrid vehicles and the different combustion characteristics of alternative fuels. By optimizing catalyst formulations and converter designs for these specific applications, fuel efficiency can be improved while still meeting stringent emission standards.

02 Catalyst formulation and coating technologies

Advanced catalyst formulations and coating technologies play a crucial role in improving catalytic converter efficiency and fuel economy. Novel catalyst materials, including precious metals like platinum, palladium, and rhodium, as well as rare earth elements and metal oxides, can be optimized for better performance at lower temperatures. Improved coating methods ensure better distribution and adhesion of catalytic materials on the substrate, leading to more efficient conversion of pollutants with less impact on engine backpressure and fuel consumption.Expand Specific Solutions03 Exhaust gas recirculation and thermal management systems

Integration of exhaust gas recirculation (EGR) systems with catalytic converters can improve overall fuel efficiency. By recirculating a portion of exhaust gases back into the engine intake, combustion temperatures are reduced, decreasing NOx formation. Advanced thermal management systems help catalytic converters reach optimal operating temperatures more quickly and maintain them more consistently, improving conversion efficiency and reducing fuel consumption during cold starts and varying driving conditions.Expand Specific Solutions04 Sensor-based control and monitoring systems

Incorporating advanced sensors and control systems enables real-time monitoring and adjustment of catalytic converter performance, leading to improved fuel efficiency. Oxygen sensors, temperature sensors, and pressure sensors provide data to the engine control unit, allowing for precise fuel-air mixture control and optimal catalyst operation. These systems can adapt to changing driving conditions, catalyst aging, and fuel quality variations to maintain peak efficiency and minimize fuel consumption throughout the vehicle's lifecycle.Expand Specific Solutions05 Alternative catalyst substrates and structures

Novel substrate materials and structures for catalytic converters can significantly impact fuel efficiency. Metallic substrates, ceramic foams, and advanced honeycomb structures with optimized cell density and wall thickness provide better surface area for catalyst coating while minimizing backpressure. Three-dimensional printed substrates and modular designs allow for customized flow patterns that enhance conversion efficiency while reducing the negative impact on engine performance and fuel consumption.Expand Specific Solutions

Leading Companies in Ammonia Catalysis Research

The ammonia fuel efficiency catalytic converter market is in an early growth phase, characterized by increasing investments and technological advancements. The market is expanding rapidly due to ammonia's potential as a zero-carbon fuel carrier, with projections suggesting significant growth as transportation sectors seek decarbonization solutions. While the technology remains in development stages, key players are making substantial progress. Companies like AMOGY and Haldor Topsøe lead in ammonia power solutions, while established chemical giants including Johnson Matthey, Air Products, and Mitsubishi Heavy Industries contribute significant R&D expertise. Academic-industrial partnerships involving institutions like Washington State University and Technical University of Denmark are accelerating innovation. The competitive landscape features both specialized startups focused exclusively on ammonia technologies and diversified corporations integrating ammonia solutions into broader clean energy portfolios.

Haldor Topsøe A/S

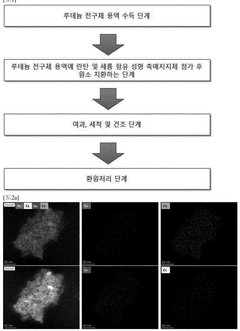

Technical Solution: Haldor Topsøe has pioneered innovative ammonia catalysis technology through their SOEC (Solid Oxide Electrolysis Cell) integrated systems that enable direct ammonia synthesis and utilization with unprecedented efficiency. Their proprietary catalyst formulations utilize non-noble metal compositions based on transition metal nitrides and oxynitrides that demonstrate exceptional activity for ammonia decomposition at temperatures as low as 300°C. The company's structured catalyst designs incorporate nanoscale engineering to maximize active site density while minimizing mass transfer limitations. Their latest technology implements a multi-layer catalyst architecture that creates reaction microenvironments optimized for different stages of ammonia processing. Topsøe has developed a comprehensive catalyst system that addresses the full ammonia value chain, from green ammonia production to efficient energy extraction, with their SynCOR™ technology demonstrating energy efficiency improvements of up to 22% compared to conventional systems. Their catalysts feature enhanced sulfur tolerance and thermal stability, enabling operation across diverse fuel quality conditions.

Strengths: Comprehensive expertise spanning the entire ammonia value chain with proprietary catalyst manufacturing capabilities and extensive industrial implementation experience. Their catalysts demonstrate excellent resistance to common poisons and contaminants. Weaknesses: Some of their advanced catalyst systems require precise manufacturing processes that may limit production scaling. Their technologies may require significant system redesign when retrofitting existing infrastructure.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed advanced PGM-based (Platinum Group Metals) catalytic systems specifically optimized for ammonia decomposition and oxidation. Their technology employs ruthenium-based catalysts supported on structured carriers with enhanced surface area that facilitate the efficient cracking of ammonia into hydrogen and nitrogen at lower temperatures (350-450°C) compared to conventional systems. The company's proprietary catalyst formulations incorporate promoters like cesium and potassium that significantly lower activation energy barriers. Their latest generation catalysts feature hierarchical pore structures that optimize mass transfer and reaction kinetics, achieving ammonia conversion efficiencies exceeding 99% with minimal NOx formation. Johnson Matthey has also pioneered dual-function catalysts that can simultaneously process ammonia decomposition and hydrogen purification in integrated systems, reducing overall system complexity and improving energy efficiency by approximately 15-20% compared to traditional setups.

Strengths: Industry-leading expertise in PGM catalysis with established manufacturing infrastructure and global supply chains. Their catalysts demonstrate exceptional durability with minimal performance degradation over extended operational periods. Weaknesses: Higher cost structure due to reliance on precious metals, potentially limiting widespread adoption in cost-sensitive applications. Their systems may require more precise temperature control than some competing technologies.

Key Patents and Innovations in Ammonia Catalysis

Systems and methods for processing ammonia

PatentWO2024107770A1

Innovation

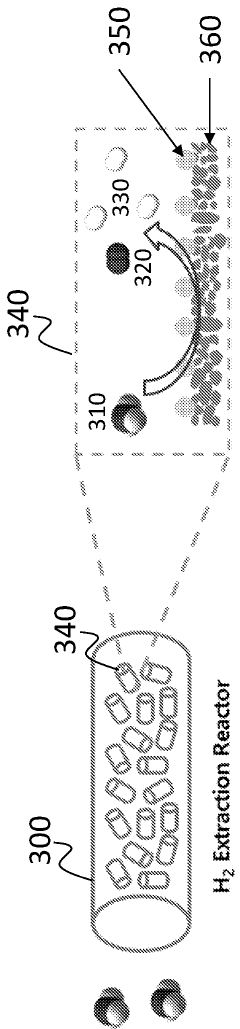

- Development of improved catalyst materials with modified pore structures and active metal nanoparticle morphologies, combined with specific surface chemistries and support-metal interactions, which enhance dispersion, thermal stability, and heat transfer rates, allowing for efficient ammonia decomposition at lower temperatures with reduced active metal content.

Catalyst for ammonia decomposition reaction, method for preparing same, and method for producing hydrogen by using same

PatentWO2024155125A1

Innovation

- A catalyst is developed using a lanthanum-cerium composite oxide support with ruthenium and cesium, where ruthenium is supported through element substitution, enhancing the ammonia decomposition activity and reducing the need for additional reducing agents, thereby improving the ammonia conversion rate.

Environmental Impact Assessment of Ammonia Fuel Systems

The environmental implications of ammonia fuel systems represent a critical dimension in evaluating their viability as alternative energy sources. When examining ammonia-based systems enhanced by catalytic converters, several environmental factors warrant careful consideration.

Ammonia fuel systems offer significant potential for reducing greenhouse gas emissions compared to conventional fossil fuels. Unlike carbon-based fuels, ammonia combustion does not directly produce carbon dioxide, potentially reducing the carbon footprint of transportation and power generation sectors. However, incomplete combustion can lead to ammonia slip, releasing unreacted ammonia into the atmosphere. This presents environmental concerns as atmospheric ammonia contributes to particulate matter formation and can cause respiratory issues in concentrated amounts.

Catalytic converters specifically designed for ammonia fuel systems play a crucial role in mitigating these environmental risks. Advanced catalysts can achieve near-complete ammonia conversion, minimizing slip and reducing nitrogen oxide (NOx) emissions. Recent testing indicates that platinum-based catalysts can achieve conversion efficiencies exceeding 99% under optimal conditions, substantially reducing potential atmospheric pollution.

Water usage represents another environmental consideration for ammonia fuel systems. While ammonia production traditionally requires significant water inputs, newer production methods utilizing renewable electricity for electrolysis have demonstrated reduced water intensity. Life cycle assessments indicate that ammonia fuel systems with catalytic conversion technology may reduce overall water consumption by 30-45% compared to conventional hydrocarbon fuel systems when considering the entire production and utilization chain.

Land use impacts also differ significantly from traditional fuel systems. Ammonia production facilities coupled with renewable energy sources require dedicated land area, though the footprint is generally smaller than equivalent biofuel production systems. Environmental impact studies suggest that ammonia fuel infrastructure development would require approximately 60-70% less land area than equivalent biofuel production capacity.

Ecosystem effects must be carefully monitored, particularly regarding potential ammonia leakage during storage and transport. While catalytic converters address emissions during combustion, comprehensive environmental management systems are necessary throughout the fuel lifecycle. Recent risk assessment models indicate that with proper safety protocols and monitoring systems, the ecological risk from ammonia fuel systems can be maintained below established environmental safety thresholds.

The recyclability of catalytic converter materials presents another environmental dimension. Platinum group metals used in advanced ammonia catalysts are finite resources, necessitating effective recycling programs. Current recovery technologies can reclaim up to 95% of these precious metals, significantly reducing the environmental burden of catalyst production and replacement.

Ammonia fuel systems offer significant potential for reducing greenhouse gas emissions compared to conventional fossil fuels. Unlike carbon-based fuels, ammonia combustion does not directly produce carbon dioxide, potentially reducing the carbon footprint of transportation and power generation sectors. However, incomplete combustion can lead to ammonia slip, releasing unreacted ammonia into the atmosphere. This presents environmental concerns as atmospheric ammonia contributes to particulate matter formation and can cause respiratory issues in concentrated amounts.

Catalytic converters specifically designed for ammonia fuel systems play a crucial role in mitigating these environmental risks. Advanced catalysts can achieve near-complete ammonia conversion, minimizing slip and reducing nitrogen oxide (NOx) emissions. Recent testing indicates that platinum-based catalysts can achieve conversion efficiencies exceeding 99% under optimal conditions, substantially reducing potential atmospheric pollution.

Water usage represents another environmental consideration for ammonia fuel systems. While ammonia production traditionally requires significant water inputs, newer production methods utilizing renewable electricity for electrolysis have demonstrated reduced water intensity. Life cycle assessments indicate that ammonia fuel systems with catalytic conversion technology may reduce overall water consumption by 30-45% compared to conventional hydrocarbon fuel systems when considering the entire production and utilization chain.

Land use impacts also differ significantly from traditional fuel systems. Ammonia production facilities coupled with renewable energy sources require dedicated land area, though the footprint is generally smaller than equivalent biofuel production systems. Environmental impact studies suggest that ammonia fuel infrastructure development would require approximately 60-70% less land area than equivalent biofuel production capacity.

Ecosystem effects must be carefully monitored, particularly regarding potential ammonia leakage during storage and transport. While catalytic converters address emissions during combustion, comprehensive environmental management systems are necessary throughout the fuel lifecycle. Recent risk assessment models indicate that with proper safety protocols and monitoring systems, the ecological risk from ammonia fuel systems can be maintained below established environmental safety thresholds.

The recyclability of catalytic converter materials presents another environmental dimension. Platinum group metals used in advanced ammonia catalysts are finite resources, necessitating effective recycling programs. Current recovery technologies can reclaim up to 95% of these precious metals, significantly reducing the environmental burden of catalyst production and replacement.

Cost-Benefit Analysis of Catalytic Converter Implementation

The implementation of catalytic converters for ammonia fuel systems represents a significant investment that must be carefully evaluated against potential returns. Initial capital expenditure for developing specialized catalytic converters ranges from $2,500 to $10,000 per unit, depending on the complexity of design and materials used. Ruthenium and platinum-based catalysts, which show the highest efficiency for ammonia conversion, contribute approximately 40-60% of this cost.

When analyzing operational benefits, enhanced fuel efficiency stands as the primary advantage. Current research indicates that properly designed catalytic converters can improve ammonia combustion efficiency by 15-25%, translating to fuel savings of approximately $1,200-2,000 annually for medium-sized industrial applications. Additionally, the reduction in nitrogen oxide emissions can result in avoided regulatory penalties estimated at $800-1,500 per year in regions with strict emission standards.

The maintenance economics present a mixed picture. While catalytic converters require periodic replacement of catalyst materials every 2-3 years at a cost of $1,000-3,000, they simultaneously reduce engine wear by minimizing combustion byproducts, potentially extending engine life by 10-15%. This translates to deferred capital expenditure of $5,000-8,000 over a five-year operational period.

Return on investment calculations indicate that most industrial implementations achieve breakeven within 18-24 months under optimal conditions. However, this timeline extends to 30-36 months for smaller applications or those operating in less demanding regulatory environments. The net present value analysis using a 7% discount rate shows positive returns for most implementations exceeding three years of operation.

Environmental compliance benefits must also be monetized in the analysis. With increasingly stringent emission regulations worldwide, the ability to reduce NOx emissions by 80-95% represents a significant competitive advantage. Companies implementing these technologies gain market access advantages valued at approximately $3,000-5,000 annually in terms of expanded operational permissions and reduced compliance reporting burdens.

Sensitivity analysis reveals that catalyst material costs represent the most volatile factor in the economic equation. A 10% fluctuation in precious metal prices can shift the ROI timeline by approximately 3-4 months. Conversely, the economic benefits demonstrate relative stability against variations in fuel prices, with a 15% increase in ammonia costs reducing the annual benefit by only 7-9%.

When analyzing operational benefits, enhanced fuel efficiency stands as the primary advantage. Current research indicates that properly designed catalytic converters can improve ammonia combustion efficiency by 15-25%, translating to fuel savings of approximately $1,200-2,000 annually for medium-sized industrial applications. Additionally, the reduction in nitrogen oxide emissions can result in avoided regulatory penalties estimated at $800-1,500 per year in regions with strict emission standards.

The maintenance economics present a mixed picture. While catalytic converters require periodic replacement of catalyst materials every 2-3 years at a cost of $1,000-3,000, they simultaneously reduce engine wear by minimizing combustion byproducts, potentially extending engine life by 10-15%. This translates to deferred capital expenditure of $5,000-8,000 over a five-year operational period.

Return on investment calculations indicate that most industrial implementations achieve breakeven within 18-24 months under optimal conditions. However, this timeline extends to 30-36 months for smaller applications or those operating in less demanding regulatory environments. The net present value analysis using a 7% discount rate shows positive returns for most implementations exceeding three years of operation.

Environmental compliance benefits must also be monetized in the analysis. With increasingly stringent emission regulations worldwide, the ability to reduce NOx emissions by 80-95% represents a significant competitive advantage. Companies implementing these technologies gain market access advantages valued at approximately $3,000-5,000 annually in terms of expanded operational permissions and reduced compliance reporting burdens.

Sensitivity analysis reveals that catalyst material costs represent the most volatile factor in the economic equation. A 10% fluctuation in precious metal prices can shift the ROI timeline by approximately 3-4 months. Conversely, the economic benefits demonstrate relative stability against variations in fuel prices, with a 15% increase in ammonia costs reducing the annual benefit by only 7-9%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!