Developing Ammonia Fuel Standards for Consistent Energy Output

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Development Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. The history of ammonia as a fuel dates back to the early 20th century, with intermittent interest during fuel shortages, but recent climate change concerns have catalyzed renewed attention. Since 2015, research into ammonia as a fuel has accelerated significantly, driven by its potential to serve as a hydrogen carrier without carbon emissions when combusted.

The fundamental advantage of ammonia lies in its chemical composition (NH₃), containing 17.8% hydrogen by weight while being much easier to transport and store than pure hydrogen. Unlike hydrogen, ammonia can be liquefied at moderate pressure (10 bar) or at -33°C at atmospheric pressure, achieving an energy density of 12.7 MJ/L. This characteristic makes it particularly attractive for long-duration energy storage and long-distance transport applications.

Current technological development focuses on three primary pathways: direct ammonia combustion in modified engines and turbines, cracking ammonia to hydrogen for use in fuel cells, and direct ammonia fuel cells. Each pathway presents unique technical challenges, particularly regarding combustion stability, NOx emissions control, and catalyst development. The evolution of these technologies has been marked by significant breakthroughs in catalyst efficiency and combustion chamber design since 2018.

The primary objective of developing ammonia fuel standards is to establish consistent specifications that ensure predictable energy output across various applications. This standardization is crucial for the commercial viability of ammonia as an alternative fuel. Specific technical goals include defining acceptable impurity levels, establishing storage and handling protocols, and creating performance benchmarks for various combustion systems.

International collaboration has become increasingly important in this field, with research consortia forming across Japan, Australia, Europe, and North America. The Green Ammonia Consortium in Japan and the Ammonia Energy Association have been particularly influential in coordinating global research efforts since their formation in 2017 and 2018, respectively.

The technology roadmap for ammonia fuel standardization anticipates commercial marine applications by 2025, power generation by 2030, and potentially wider transportation applications by 2035. This timeline is contingent upon overcoming key technical barriers, particularly in combustion efficiency and emissions control. The ultimate goal is to position ammonia as a key component in a diversified, carbon-neutral energy landscape, complementing other renewable technologies while leveraging existing infrastructure for distribution and storage.

The fundamental advantage of ammonia lies in its chemical composition (NH₃), containing 17.8% hydrogen by weight while being much easier to transport and store than pure hydrogen. Unlike hydrogen, ammonia can be liquefied at moderate pressure (10 bar) or at -33°C at atmospheric pressure, achieving an energy density of 12.7 MJ/L. This characteristic makes it particularly attractive for long-duration energy storage and long-distance transport applications.

Current technological development focuses on three primary pathways: direct ammonia combustion in modified engines and turbines, cracking ammonia to hydrogen for use in fuel cells, and direct ammonia fuel cells. Each pathway presents unique technical challenges, particularly regarding combustion stability, NOx emissions control, and catalyst development. The evolution of these technologies has been marked by significant breakthroughs in catalyst efficiency and combustion chamber design since 2018.

The primary objective of developing ammonia fuel standards is to establish consistent specifications that ensure predictable energy output across various applications. This standardization is crucial for the commercial viability of ammonia as an alternative fuel. Specific technical goals include defining acceptable impurity levels, establishing storage and handling protocols, and creating performance benchmarks for various combustion systems.

International collaboration has become increasingly important in this field, with research consortia forming across Japan, Australia, Europe, and North America. The Green Ammonia Consortium in Japan and the Ammonia Energy Association have been particularly influential in coordinating global research efforts since their formation in 2017 and 2018, respectively.

The technology roadmap for ammonia fuel standardization anticipates commercial marine applications by 2025, power generation by 2030, and potentially wider transportation applications by 2035. This timeline is contingent upon overcoming key technical barriers, particularly in combustion efficiency and emissions control. The ultimate goal is to position ammonia as a key component in a diversified, carbon-neutral energy landscape, complementing other renewable technologies while leveraging existing infrastructure for distribution and storage.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth, driven by the increasing demand for carbon-neutral energy solutions. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to expand at a compound annual growth rate of 5.3% through 2030, potentially reaching $120 billion by that time. This growth trajectory is supported by ammonia's high energy density of 18.6 MJ/kg and its established global production infrastructure, which produces over 180 million tonnes annually.

The maritime sector represents the most promising immediate market for ammonia fuel, with major shipping companies like Maersk and NYK Line already investing in ammonia-powered vessel development. Industry analysts estimate that ammonia could capture up to 25% of the marine fuel market by 2040, representing a value of $30 billion annually. This transition is accelerated by the International Maritime Organization's stringent emissions regulations, which mandate a 40% reduction in carbon intensity by 2030.

Power generation constitutes another substantial market segment, particularly in regions with limited renewable energy resources. Japan's commitment to ammonia co-firing in coal plants aims to utilize 3 million tonnes of ammonia annually by 2030, creating a market worth approximately $1.5 billion in that country alone. Similar initiatives in South Korea, Australia, and parts of Europe could expand this market segment to $15 billion globally within the decade.

The transportation sector beyond maritime applications presents a longer-term opportunity, with heavy-duty vehicles and long-haul transport being the most viable applications. While currently limited by infrastructure constraints, this segment could reach $5 billion by 2035 as fueling networks expand and engine technologies mature.

Regional market distribution shows Asia-Pacific leading with 42% of the potential market share, followed by Europe (28%), North America (18%), and other regions (12%). Japan, Australia, and Norway have emerged as early adopters, implementing supportive policy frameworks and investing in infrastructure development.

Market barriers include competition from other alternative fuels such as hydrogen and advanced biofuels, which currently enjoy more established standards and infrastructure. Additionally, the current cost premium of green ammonia at $600-800 per tonne compared to conventional fuels remains a significant adoption hurdle, though this gap is expected to narrow as production scales and carbon pricing mechanisms become more widespread.

Consumer acceptance and safety concerns represent additional market challenges, with public perception of ammonia's toxicity requiring comprehensive education and stringent safety protocols to overcome resistance in certain applications.

The maritime sector represents the most promising immediate market for ammonia fuel, with major shipping companies like Maersk and NYK Line already investing in ammonia-powered vessel development. Industry analysts estimate that ammonia could capture up to 25% of the marine fuel market by 2040, representing a value of $30 billion annually. This transition is accelerated by the International Maritime Organization's stringent emissions regulations, which mandate a 40% reduction in carbon intensity by 2030.

Power generation constitutes another substantial market segment, particularly in regions with limited renewable energy resources. Japan's commitment to ammonia co-firing in coal plants aims to utilize 3 million tonnes of ammonia annually by 2030, creating a market worth approximately $1.5 billion in that country alone. Similar initiatives in South Korea, Australia, and parts of Europe could expand this market segment to $15 billion globally within the decade.

The transportation sector beyond maritime applications presents a longer-term opportunity, with heavy-duty vehicles and long-haul transport being the most viable applications. While currently limited by infrastructure constraints, this segment could reach $5 billion by 2035 as fueling networks expand and engine technologies mature.

Regional market distribution shows Asia-Pacific leading with 42% of the potential market share, followed by Europe (28%), North America (18%), and other regions (12%). Japan, Australia, and Norway have emerged as early adopters, implementing supportive policy frameworks and investing in infrastructure development.

Market barriers include competition from other alternative fuels such as hydrogen and advanced biofuels, which currently enjoy more established standards and infrastructure. Additionally, the current cost premium of green ammonia at $600-800 per tonne compared to conventional fuels remains a significant adoption hurdle, though this gap is expected to narrow as production scales and carbon pricing mechanisms become more widespread.

Consumer acceptance and safety concerns represent additional market challenges, with public perception of ammonia's toxicity requiring comprehensive education and stringent safety protocols to overcome resistance in certain applications.

Current Technical Barriers in Ammonia Fuel Standardization

The standardization of ammonia as a fuel faces several significant technical barriers that impede its widespread adoption and consistent energy output. One of the primary challenges is the variability in ammonia composition from different production methods. Green ammonia produced via renewable electricity, blue ammonia from natural gas with carbon capture, and traditional Haber-Bosch ammonia all possess slightly different impurity profiles, which can affect combustion characteristics and emissions.

Ammonia's low energy density compared to conventional fuels presents another substantial barrier. With approximately 18.6 MJ/kg compared to diesel's 45.5 MJ/kg, ammonia requires larger storage volumes and more frequent refueling, complicating standardization efforts across different applications and industries. This physical limitation necessitates careful consideration in developing consistent performance metrics.

The corrosive nature of ammonia poses significant materials compatibility challenges. Current fuel handling infrastructure components—including seals, gaskets, and certain metal alloys—can degrade when exposed to ammonia, leading to safety risks and performance inconsistencies. Standardization must address these material compatibility issues to ensure reliable long-term operation.

Combustion stability represents another critical technical barrier. Ammonia's narrow flammability range (16-25% by volume in air) and high ignition energy requirements make it difficult to achieve stable combustion across varying operating conditions. This instability complicates the development of universal performance standards that would apply across different engine types and load conditions.

Emissions control presents further standardization challenges. While ammonia combustion produces no carbon dioxide, it can generate significant NOx emissions if combustion parameters are not precisely controlled. The trade-off between combustion efficiency and NOx formation varies with different combustion technologies, making it difficult to establish universal emissions standards.

Measurement and quality control methodologies for ammonia fuel remain underdeveloped compared to conventional fuels. The industry lacks standardized testing protocols for key parameters such as water content, lubricant additives compatibility, and trace contaminants that affect performance. This absence of uniform testing methods hampers the development of consistent quality standards.

Safety considerations also present significant standardization barriers. Ammonia's toxicity and potential for accidental release require robust safety protocols that may vary based on application context, further complicating the development of universal handling standards that ensure both safety and performance consistency.

Ammonia's low energy density compared to conventional fuels presents another substantial barrier. With approximately 18.6 MJ/kg compared to diesel's 45.5 MJ/kg, ammonia requires larger storage volumes and more frequent refueling, complicating standardization efforts across different applications and industries. This physical limitation necessitates careful consideration in developing consistent performance metrics.

The corrosive nature of ammonia poses significant materials compatibility challenges. Current fuel handling infrastructure components—including seals, gaskets, and certain metal alloys—can degrade when exposed to ammonia, leading to safety risks and performance inconsistencies. Standardization must address these material compatibility issues to ensure reliable long-term operation.

Combustion stability represents another critical technical barrier. Ammonia's narrow flammability range (16-25% by volume in air) and high ignition energy requirements make it difficult to achieve stable combustion across varying operating conditions. This instability complicates the development of universal performance standards that would apply across different engine types and load conditions.

Emissions control presents further standardization challenges. While ammonia combustion produces no carbon dioxide, it can generate significant NOx emissions if combustion parameters are not precisely controlled. The trade-off between combustion efficiency and NOx formation varies with different combustion technologies, making it difficult to establish universal emissions standards.

Measurement and quality control methodologies for ammonia fuel remain underdeveloped compared to conventional fuels. The industry lacks standardized testing protocols for key parameters such as water content, lubricant additives compatibility, and trace contaminants that affect performance. This absence of uniform testing methods hampers the development of consistent quality standards.

Safety considerations also present significant standardization barriers. Ammonia's toxicity and potential for accidental release require robust safety protocols that may vary based on application context, further complicating the development of universal handling standards that ensure both safety and performance consistency.

Current Ammonia Fuel Standardization Approaches

01 Ammonia fuel composition standards for consistent energy output

Standardized ammonia fuel compositions are essential for achieving consistent energy output in various applications. These standards specify the purity levels, allowable contaminants, and optimal chemical formulations to ensure reliable performance. Properly formulated ammonia fuels can deliver predictable energy density and combustion characteristics, which is crucial for industrial and transportation applications where consistent power output is required.- Ammonia fuel composition standards for consistent energy output: Standardized ammonia fuel compositions are essential for achieving consistent energy output in various applications. These standards specify the purity levels, allowable contaminants, and optimal chemical formulations to ensure reliable performance. By controlling the composition of ammonia fuel, energy output consistency can be maintained across different operating conditions, which is crucial for industrial applications and power generation systems.

- Combustion control systems for ammonia fuel efficiency: Advanced combustion control systems are developed to optimize ammonia fuel utilization and ensure consistent energy output. These systems monitor and adjust combustion parameters in real-time, including air-fuel ratios, temperature, and pressure conditions. By implementing precise control mechanisms, these technologies can compensate for variations in ammonia fuel quality, environmental conditions, and load demands, thereby maintaining stable energy output and improving overall system efficiency.

- Ammonia fuel storage and delivery standardization: Standardized storage and delivery systems for ammonia fuel are critical for maintaining energy output consistency. These standards address storage tank specifications, pressure management, temperature control, and delivery system requirements. Proper storage and delivery systems prevent fuel degradation, contamination, and ensure that the ammonia fuel maintains its energy content from production through to the point of use, resulting in predictable and consistent energy output.

- Ammonia fuel quality monitoring and testing methods: Standardized testing and monitoring methods are essential for verifying ammonia fuel quality and predicting energy output consistency. These methods include analytical techniques for measuring purity, detecting contaminants, and assessing energy content. Real-time monitoring systems can be integrated into fuel handling and combustion systems to provide continuous quality assurance, allowing for adjustments to maintain consistent energy output despite variations in fuel quality.

- Catalyst and additive technologies for ammonia fuel performance: Specialized catalysts and additives are developed to enhance ammonia fuel combustion stability and energy output consistency. These technologies can lower the activation energy required for ammonia combustion, reduce emissions, and improve flame stability. By incorporating appropriate catalysts and additives according to standardized formulations, ammonia fuel systems can achieve more consistent energy output across varying operating conditions and load requirements.

02 Combustion systems optimized for ammonia fuel consistency

Specialized combustion systems designed specifically for ammonia fuel can help maintain consistent energy output. These systems incorporate advanced control mechanisms, optimized injectors, and combustion chamber designs that accommodate ammonia's unique burning properties. By precisely controlling the combustion process, these systems can compensate for variations in fuel quality and environmental conditions, ensuring stable energy production across different operating scenarios.Expand Specific Solutions03 Monitoring and control systems for ammonia fuel performance

Advanced monitoring and control systems play a critical role in maintaining consistent energy output from ammonia fuels. These systems continuously analyze combustion parameters, fuel quality, and energy production metrics in real-time. Using sensors, data analytics, and feedback mechanisms, they can make automatic adjustments to optimize performance and ensure energy output remains within standardized parameters despite variations in operating conditions.Expand Specific Solutions04 Ammonia fuel blending techniques for energy consistency

Blending ammonia with other fuels or additives can enhance energy output consistency. These techniques involve precise mixing ratios and formulations to create fuel blends that compensate for ammonia's inherent combustion characteristics. By incorporating hydrogen, hydrocarbons, or specific catalysts, these blends can achieve more stable ignition properties and consistent energy release patterns, making them suitable for applications requiring reliable power delivery.Expand Specific Solutions05 Testing and certification protocols for ammonia fuel standards

Standardized testing and certification protocols are essential for verifying ammonia fuel quality and energy output consistency. These protocols include specific methodologies for measuring energy content, combustion efficiency, emissions profiles, and performance under various conditions. By establishing uniform testing procedures and certification requirements, these standards ensure that ammonia fuels meet predetermined specifications for reliable energy output across different applications and equipment types.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Ecosystem

The ammonia fuel standards market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global ammonia as fuel market is projected to expand significantly as industries seek carbon-neutral alternatives, with current estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field remains in development with varying maturity levels across applications. Leading academic institutions (Harbin Engineering University, Tianjin University, University of Strathclyde) are advancing fundamental research, while energy corporations (Sinopec, TotalEnergies, Chugoku Electric) focus on practical implementation. Maritime applications show particular promise, with companies like Samsung Heavy Industries and HD Hyundai developing ammonia-powered vessels. AMOGY has demonstrated ammonia power in various transport applications, while established industrial gas companies like Linde provide essential infrastructure expertise.

Ammonia Casale SpA

Technical Solution: Ammonia Casale has developed advanced catalytic combustion systems specifically designed for ammonia fuel applications. Their technology focuses on optimizing ammonia combustion efficiency through proprietary catalyst formulations that reduce NOx emissions while maintaining consistent energy output. The company has pioneered a standardized ammonia fuel quality specification system that addresses impurity levels, water content, and storage stability parameters critical for reliable energy generation. Their approach includes integrated monitoring systems that continuously analyze ammonia composition during combustion, allowing real-time adjustments to maintain optimal performance[1]. Ammonia Casale has also developed specialized burner technologies that can accommodate varying ammonia fuel qualities while delivering predictable thermal output, essential for industrial applications requiring precise energy control[3].

Strengths: Extensive experience in ammonia processing technology with over 100 years in the industry; proprietary catalyst formulations that significantly reduce NOx emissions while maintaining combustion efficiency. Weaknesses: Their solutions often require substantial capital investment and may be less adaptable to smaller-scale applications or rapid deployment scenarios.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed a comprehensive ammonia fuel standardization framework focused on transportation and distributed power generation applications. Their approach combines experimental combustion analysis with advanced computational modeling to establish performance-based ammonia fuel standards. SwRI has created specialized test protocols that evaluate ammonia fuel quality impacts on combustion stability, energy output consistency, and emissions profiles across different engine types and operating conditions[7]. Their technology includes a modular ammonia fuel quality assessment system that can rapidly characterize key parameters including trace contaminants, water content, and energy density variations. SwRI has pioneered adaptive control strategies that compensate for ammonia fuel quality variations in real-time, ensuring consistent power output despite supply chain inconsistencies. Their research has established correlations between specific ammonia impurities and combustion performance metrics, allowing for targeted quality control measures that balance cost and performance[8]. Additionally, SwRI has developed specialized materials compatibility standards for ammonia fuel systems that address the unique corrosion and embrittlement challenges posed by ammonia.

Strengths: Extensive testing capabilities across multiple engine types and combustion systems; data-driven approach to standards development based on actual performance metrics; balanced consideration of both technical and economic factors. Weaknesses: Less focused on very large-scale power generation applications; standards development still evolving as technology matures.

Critical Patents and Research in Ammonia Fuel Standards

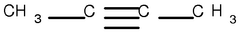

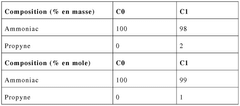

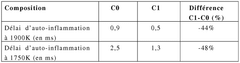

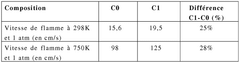

Fuel or combustible substance composition comprising ammonia and at least one alkyne

PatentWO2024218445A1

Innovation

- A fuel composition comprising ammonia and 0.01% to 20% by mass of C3 to C12 alkynes, which significantly reduces autoignition time, increases flame speed, and enhances combustion efficiency without the need for large hydrogen reserves or fossil fuels.

Ammonia-based fuel or fuel composition comprising a nitrate additive

PatentPendingFR3140091A1

Innovation

- A fuel composition comprising ammonia and a small amount (0.01-8% by mass) of ammonium nitrate or organo-nitrates, such as 2-ethyl-hexyl nitrate, improves combustion reactivity and reduces self-ignition time, minimizing CO emissions.

Environmental Impact Assessment of Ammonia Fuel Adoption

The environmental implications of ammonia fuel adoption represent a critical dimension in the development of sustainable energy alternatives. Ammonia (NH3) offers significant potential as a carbon-free energy carrier, but its widespread implementation necessitates comprehensive assessment of environmental impacts across its entire lifecycle.

When evaluating ammonia as a fuel, greenhouse gas emissions reduction stands as a primary environmental benefit. Unlike traditional fossil fuels, ammonia combustion produces nitrogen and water vapor without direct carbon dioxide emissions. Quantitative lifecycle analyses indicate potential emissions reductions of 75-90% compared to conventional fuels, depending on production pathways. However, these benefits are contingent upon using renewable energy sources for ammonia synthesis.

Air quality considerations present a more complex picture. While ammonia combustion eliminates sulfur dioxide and particulate matter emissions associated with fossil fuels, it potentially increases nitrogen oxide (NOx) emissions without proper combustion management. Advanced catalytic systems and optimized combustion technologies can mitigate these concerns, reducing NOx formation by up to 85% compared to uncontrolled combustion.

Water resource impacts must be carefully managed in ammonia fuel systems. Production facilities require significant water inputs—approximately 4-9 gallons per kilogram of ammonia produced. Additionally, ammonia's high water solubility presents risks for aquatic ecosystems in case of spills or leaks, potentially causing eutrophication and toxicity to aquatic organisms at concentrations above 0.25 mg/L.

Land use changes associated with ammonia infrastructure development warrant consideration, particularly regarding renewable energy installations needed for green ammonia production. Solar and wind facilities for powering electrolysis may require substantial land area—approximately 10-15 acres per megawatt of capacity.

Biodiversity protection measures must be integrated into ammonia fuel standards, especially considering potential impacts from ammonia releases. Buffer zones around production and storage facilities, along with robust monitoring systems, can help protect sensitive ecosystems from exposure risks.

Circular economy principles offer promising approaches for minimizing environmental footprints. Waste heat recovery from ammonia synthesis can achieve energy efficiency improvements of 15-20%, while water recycling systems can reduce freshwater consumption by up to 40% in production facilities.

Standardized environmental impact metrics will be essential for consistent evaluation across different ammonia fuel applications and production pathways, enabling meaningful comparisons with alternative energy carriers and establishing clear environmental performance benchmarks.

When evaluating ammonia as a fuel, greenhouse gas emissions reduction stands as a primary environmental benefit. Unlike traditional fossil fuels, ammonia combustion produces nitrogen and water vapor without direct carbon dioxide emissions. Quantitative lifecycle analyses indicate potential emissions reductions of 75-90% compared to conventional fuels, depending on production pathways. However, these benefits are contingent upon using renewable energy sources for ammonia synthesis.

Air quality considerations present a more complex picture. While ammonia combustion eliminates sulfur dioxide and particulate matter emissions associated with fossil fuels, it potentially increases nitrogen oxide (NOx) emissions without proper combustion management. Advanced catalytic systems and optimized combustion technologies can mitigate these concerns, reducing NOx formation by up to 85% compared to uncontrolled combustion.

Water resource impacts must be carefully managed in ammonia fuel systems. Production facilities require significant water inputs—approximately 4-9 gallons per kilogram of ammonia produced. Additionally, ammonia's high water solubility presents risks for aquatic ecosystems in case of spills or leaks, potentially causing eutrophication and toxicity to aquatic organisms at concentrations above 0.25 mg/L.

Land use changes associated with ammonia infrastructure development warrant consideration, particularly regarding renewable energy installations needed for green ammonia production. Solar and wind facilities for powering electrolysis may require substantial land area—approximately 10-15 acres per megawatt of capacity.

Biodiversity protection measures must be integrated into ammonia fuel standards, especially considering potential impacts from ammonia releases. Buffer zones around production and storage facilities, along with robust monitoring systems, can help protect sensitive ecosystems from exposure risks.

Circular economy principles offer promising approaches for minimizing environmental footprints. Waste heat recovery from ammonia synthesis can achieve energy efficiency improvements of 15-20%, while water recycling systems can reduce freshwater consumption by up to 40% in production facilities.

Standardized environmental impact metrics will be essential for consistent evaluation across different ammonia fuel applications and production pathways, enabling meaningful comparisons with alternative energy carriers and establishing clear environmental performance benchmarks.

Safety Protocols and Risk Management for Ammonia Fuel

The implementation of ammonia as a fuel source necessitates comprehensive safety protocols and risk management strategies due to its toxic and potentially hazardous properties. Ammonia presents significant risks including toxicity when inhaled, potential for fire and explosion under specific conditions, and corrosive effects on certain materials. These characteristics demand rigorous safety standards to ensure consistent energy output while protecting personnel, equipment, and the environment.

Safety protocols for ammonia fuel systems must begin with proper storage infrastructure. Storage tanks require specialized design with appropriate pressure ratings, temperature controls, and corrosion-resistant materials. Facilities must implement robust ventilation systems capable of detecting and mitigating ammonia leaks before they reach dangerous concentrations. Regular inspection schedules and preventative maintenance protocols are essential to identify potential failure points before incidents occur.

Personnel safety represents another critical dimension of ammonia fuel management. All staff working with ammonia systems must receive specialized training covering handling procedures, emergency response protocols, and proper use of personal protective equipment (PPE). This training should be regularly refreshed and updated as standards evolve. Designated safety officers should oversee operations and ensure compliance with established protocols.

Emergency response planning constitutes a fundamental component of ammonia risk management. Facilities must develop detailed contingency plans addressing various potential scenarios including leaks, fires, and equipment failures. These plans should include evacuation procedures, emergency shutdown protocols, and coordination with local emergency services. Regular drills help ensure personnel can execute these procedures effectively under pressure.

Monitoring and detection systems provide the technological backbone for ammonia safety management. Modern facilities should implement multi-layered detection systems including ammonia sensors, pressure monitors, and temperature gauges with automated alarms. These systems should connect to emergency shutdown mechanisms that can automatically isolate compromised sections of the system to prevent escalation of incidents.

Regulatory compliance represents the final pillar of ammonia safety management. Organizations must navigate complex regulatory landscapes that vary by jurisdiction but typically include standards from agencies such as OSHA, EPA, and industry-specific regulatory bodies. Maintaining comprehensive documentation of safety procedures, incident reports, and compliance activities is essential for both regulatory purposes and continuous improvement of safety systems.

The development of standardized safety protocols specifically designed for ammonia as a fuel source remains an evolving field. As adoption increases, industry collaboration will be crucial to establish best practices that balance operational efficiency with rigorous safety standards, ultimately enabling ammonia to fulfill its potential as a viable alternative fuel while minimizing associated risks.

Safety protocols for ammonia fuel systems must begin with proper storage infrastructure. Storage tanks require specialized design with appropriate pressure ratings, temperature controls, and corrosion-resistant materials. Facilities must implement robust ventilation systems capable of detecting and mitigating ammonia leaks before they reach dangerous concentrations. Regular inspection schedules and preventative maintenance protocols are essential to identify potential failure points before incidents occur.

Personnel safety represents another critical dimension of ammonia fuel management. All staff working with ammonia systems must receive specialized training covering handling procedures, emergency response protocols, and proper use of personal protective equipment (PPE). This training should be regularly refreshed and updated as standards evolve. Designated safety officers should oversee operations and ensure compliance with established protocols.

Emergency response planning constitutes a fundamental component of ammonia risk management. Facilities must develop detailed contingency plans addressing various potential scenarios including leaks, fires, and equipment failures. These plans should include evacuation procedures, emergency shutdown protocols, and coordination with local emergency services. Regular drills help ensure personnel can execute these procedures effectively under pressure.

Monitoring and detection systems provide the technological backbone for ammonia safety management. Modern facilities should implement multi-layered detection systems including ammonia sensors, pressure monitors, and temperature gauges with automated alarms. These systems should connect to emergency shutdown mechanisms that can automatically isolate compromised sections of the system to prevent escalation of incidents.

Regulatory compliance represents the final pillar of ammonia safety management. Organizations must navigate complex regulatory landscapes that vary by jurisdiction but typically include standards from agencies such as OSHA, EPA, and industry-specific regulatory bodies. Maintaining comprehensive documentation of safety procedures, incident reports, and compliance activities is essential for both regulatory purposes and continuous improvement of safety systems.

The development of standardized safety protocols specifically designed for ammonia as a fuel source remains an evolving field. As adoption increases, industry collaboration will be crucial to establish best practices that balance operational efficiency with rigorous safety standards, ultimately enabling ammonia to fulfill its potential as a viable alternative fuel while minimizing associated risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!