Thermodynamic Properties of Ammonia Fuel in Energy Optimization

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Evolution and Research Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global pursuit of sustainable energy solutions. The evolution of ammonia as a fuel can be traced back to the early 20th century, with its first significant application during World War II when it was used as a substitute for petroleum in European countries facing fuel shortages. However, interest in ammonia fuel waned with the post-war abundance of fossil fuels, only to resurface in recent decades amid growing climate concerns.

The thermodynamic properties of ammonia present both unique advantages and challenges for energy applications. With an energy density of 18.6 MJ/kg, ammonia contains approximately half the energy of conventional hydrocarbon fuels but significantly more than hydrogen per unit volume under ambient conditions. Its relatively high hydrogen content (17.8% by weight) coupled with established global production infrastructure makes ammonia an attractive hydrogen carrier.

Recent technological advancements have accelerated research into ammonia's potential as a sustainable fuel. The Haber-Bosch process, traditionally energy-intensive and carbon-emitting, is being reimagined through green ammonia production pathways utilizing renewable electricity. This evolution represents a critical shift from ammonia as merely an industrial chemical to a versatile energy vector capable of addressing decarbonization challenges across multiple sectors.

The current research landscape focuses on optimizing ammonia's thermodynamic behavior in various energy conversion systems. Key areas include combustion kinetics in internal combustion engines, flame stability in gas turbines, and catalytic decomposition for fuel cell applications. Each application presents distinct thermodynamic challenges requiring tailored solutions to maximize efficiency while minimizing harmful emissions such as NOx.

Our research objectives center on developing comprehensive thermodynamic models that accurately predict ammonia's behavior under various operating conditions relevant to energy optimization. These include high-pressure combustion environments, low-temperature catalytic reactions, and mixed-fuel scenarios where ammonia is blended with conventional fuels to enhance performance characteristics.

Additionally, we aim to investigate novel thermodynamic cycles specifically designed to leverage ammonia's unique properties, potentially achieving higher system efficiencies than conventional approaches. This includes exploring direct ammonia fuel cells, advanced combustion strategies, and innovative heat recovery systems that capitalize on ammonia's favorable phase-change characteristics.

The ultimate goal is to establish ammonia as a viable, efficient, and environmentally benign energy carrier that can facilitate the transition to a carbon-neutral energy ecosystem while maintaining the reliability and performance standards expected in modern energy applications.

The thermodynamic properties of ammonia present both unique advantages and challenges for energy applications. With an energy density of 18.6 MJ/kg, ammonia contains approximately half the energy of conventional hydrocarbon fuels but significantly more than hydrogen per unit volume under ambient conditions. Its relatively high hydrogen content (17.8% by weight) coupled with established global production infrastructure makes ammonia an attractive hydrogen carrier.

Recent technological advancements have accelerated research into ammonia's potential as a sustainable fuel. The Haber-Bosch process, traditionally energy-intensive and carbon-emitting, is being reimagined through green ammonia production pathways utilizing renewable electricity. This evolution represents a critical shift from ammonia as merely an industrial chemical to a versatile energy vector capable of addressing decarbonization challenges across multiple sectors.

The current research landscape focuses on optimizing ammonia's thermodynamic behavior in various energy conversion systems. Key areas include combustion kinetics in internal combustion engines, flame stability in gas turbines, and catalytic decomposition for fuel cell applications. Each application presents distinct thermodynamic challenges requiring tailored solutions to maximize efficiency while minimizing harmful emissions such as NOx.

Our research objectives center on developing comprehensive thermodynamic models that accurately predict ammonia's behavior under various operating conditions relevant to energy optimization. These include high-pressure combustion environments, low-temperature catalytic reactions, and mixed-fuel scenarios where ammonia is blended with conventional fuels to enhance performance characteristics.

Additionally, we aim to investigate novel thermodynamic cycles specifically designed to leverage ammonia's unique properties, potentially achieving higher system efficiencies than conventional approaches. This includes exploring direct ammonia fuel cells, advanced combustion strategies, and innovative heat recovery systems that capitalize on ammonia's favorable phase-change characteristics.

The ultimate goal is to establish ammonia as a viable, efficient, and environmentally benign energy carrier that can facilitate the transition to a carbon-neutral energy ecosystem while maintaining the reliability and performance standards expected in modern energy applications.

Market Analysis for Ammonia as Alternative Energy Carrier

The global market for ammonia as an alternative energy carrier is experiencing significant growth, driven by increasing focus on decarbonization and sustainable energy solutions. Currently valued at approximately $70 billion, the ammonia market is projected to expand at a compound annual growth rate of 5.3% through 2030, with the energy carrier segment showing particularly strong momentum.

The demand landscape for ammonia as an energy carrier spans multiple sectors. The maritime industry represents one of the most promising markets, with major shipping companies actively exploring ammonia as a carbon-neutral fuel option to meet International Maritime Organization emissions targets. Several pilot projects for ammonia-powered vessels are already underway in Japan, Norway, and Singapore, indicating strong commercial interest.

Power generation constitutes another substantial market segment, particularly for grid balancing and energy storage applications. Countries with ambitious renewable energy targets, including Australia, Japan, and several European nations, are investing in ammonia-based power generation infrastructure. The ability of ammonia to store and transport hydrogen energy efficiently makes it particularly valuable in regions with limited renewable energy resources but strong decarbonization commitments.

Industrial applications represent the third major market segment, with ammonia showing potential as a carbon-free fuel for high-temperature industrial processes. Steel manufacturing, cement production, and other energy-intensive industries are exploring ammonia co-firing and dedicated ammonia combustion systems to reduce their carbon footprint while maintaining production efficiency.

Regional market analysis reveals distinct patterns of adoption. Asia-Pacific leads in market development, with Japan's Strategic Roadmap for Hydrogen and Ammonia explicitly positioning ammonia as a key energy carrier. Australia has positioned itself as a potential major exporter, leveraging its abundant renewable resources for green ammonia production. Europe follows closely, with significant investments in both production technology and end-use applications, particularly in the Nordic countries and Germany.

Market barriers include the current cost premium of green ammonia compared to conventional fuels, infrastructure limitations for large-scale distribution, and technical challenges related to efficient combustion and energy conversion. However, these barriers are being addressed through targeted research initiatives and policy support mechanisms, including carbon pricing, subsidies for low-carbon fuels, and regulatory frameworks that incentivize alternative energy carriers.

The competitive landscape features traditional ammonia producers expanding into energy applications, energy majors diversifying their portfolios, and specialized technology startups focusing on specific aspects of the ammonia energy value chain. Strategic partnerships between technology providers, energy companies, and end-users are becoming increasingly common as the market matures.

The demand landscape for ammonia as an energy carrier spans multiple sectors. The maritime industry represents one of the most promising markets, with major shipping companies actively exploring ammonia as a carbon-neutral fuel option to meet International Maritime Organization emissions targets. Several pilot projects for ammonia-powered vessels are already underway in Japan, Norway, and Singapore, indicating strong commercial interest.

Power generation constitutes another substantial market segment, particularly for grid balancing and energy storage applications. Countries with ambitious renewable energy targets, including Australia, Japan, and several European nations, are investing in ammonia-based power generation infrastructure. The ability of ammonia to store and transport hydrogen energy efficiently makes it particularly valuable in regions with limited renewable energy resources but strong decarbonization commitments.

Industrial applications represent the third major market segment, with ammonia showing potential as a carbon-free fuel for high-temperature industrial processes. Steel manufacturing, cement production, and other energy-intensive industries are exploring ammonia co-firing and dedicated ammonia combustion systems to reduce their carbon footprint while maintaining production efficiency.

Regional market analysis reveals distinct patterns of adoption. Asia-Pacific leads in market development, with Japan's Strategic Roadmap for Hydrogen and Ammonia explicitly positioning ammonia as a key energy carrier. Australia has positioned itself as a potential major exporter, leveraging its abundant renewable resources for green ammonia production. Europe follows closely, with significant investments in both production technology and end-use applications, particularly in the Nordic countries and Germany.

Market barriers include the current cost premium of green ammonia compared to conventional fuels, infrastructure limitations for large-scale distribution, and technical challenges related to efficient combustion and energy conversion. However, these barriers are being addressed through targeted research initiatives and policy support mechanisms, including carbon pricing, subsidies for low-carbon fuels, and regulatory frameworks that incentivize alternative energy carriers.

The competitive landscape features traditional ammonia producers expanding into energy applications, energy majors diversifying their portfolios, and specialized technology startups focusing on specific aspects of the ammonia energy value chain. Strategic partnerships between technology providers, energy companies, and end-users are becoming increasingly common as the market matures.

Thermodynamic Challenges and Global Research Status

The global landscape of ammonia fuel research reveals significant thermodynamic challenges that must be overcome for widespread adoption. Current research indicates that ammonia's high ignition temperature (650°C) and relatively low flame speed create substantial barriers to efficient combustion in conventional engines. These properties necessitate specialized combustion chamber designs and ignition systems, presenting engineering challenges that researchers worldwide are actively addressing.

Energy density considerations remain paramount in ammonia fuel applications. With a volumetric energy density approximately half that of conventional hydrocarbon fuels, ammonia requires larger storage volumes for equivalent energy content. This characteristic has prompted intensive research into compression and liquefaction technologies to optimize storage efficiency while maintaining safety parameters.

Heat transfer characteristics during ammonia combustion present another significant challenge. The endothermic decomposition of ammonia during the combustion process absorbs substantial thermal energy, reducing overall thermal efficiency. Research centers in Japan, Germany, and Australia have pioneered work on catalytic combustion systems that can overcome these thermodynamic limitations by facilitating more complete ammonia decomposition at lower temperatures.

The NOx emission profile associated with ammonia combustion represents a critical area of ongoing research. While ammonia itself contains no carbon, its nitrogen content can lead to elevated NOx emissions under certain combustion conditions. Research institutions in Denmark and South Korea have made notable advances in selective catalytic reduction systems specifically optimized for ammonia-based power generation.

Material compatibility issues stemming from ammonia's corrosive properties present additional challenges. Research at institutions across the United States and China has focused on developing specialized alloys and coatings that can withstand prolonged exposure to ammonia under varying temperature and pressure conditions.

The global research status reveals a concentration of expertise in specific geographic regions. Japan leads in ammonia combustion technology, with the SIP Energy Carriers program demonstrating successful implementation in power generation. European research centers, particularly in Denmark and Germany, focus on ammonia synthesis optimization and catalytic decomposition. Australia has established itself as a leader in ammonia transportation and storage research, while South Korean institutions have advanced ammonia fuel cell technologies.

Recent thermodynamic modeling breakthroughs at institutions including MIT and Imperial College London have improved our understanding of ammonia's behavior under various operating conditions, enabling more accurate prediction of combustion characteristics and efficiency parameters.

Energy density considerations remain paramount in ammonia fuel applications. With a volumetric energy density approximately half that of conventional hydrocarbon fuels, ammonia requires larger storage volumes for equivalent energy content. This characteristic has prompted intensive research into compression and liquefaction technologies to optimize storage efficiency while maintaining safety parameters.

Heat transfer characteristics during ammonia combustion present another significant challenge. The endothermic decomposition of ammonia during the combustion process absorbs substantial thermal energy, reducing overall thermal efficiency. Research centers in Japan, Germany, and Australia have pioneered work on catalytic combustion systems that can overcome these thermodynamic limitations by facilitating more complete ammonia decomposition at lower temperatures.

The NOx emission profile associated with ammonia combustion represents a critical area of ongoing research. While ammonia itself contains no carbon, its nitrogen content can lead to elevated NOx emissions under certain combustion conditions. Research institutions in Denmark and South Korea have made notable advances in selective catalytic reduction systems specifically optimized for ammonia-based power generation.

Material compatibility issues stemming from ammonia's corrosive properties present additional challenges. Research at institutions across the United States and China has focused on developing specialized alloys and coatings that can withstand prolonged exposure to ammonia under varying temperature and pressure conditions.

The global research status reveals a concentration of expertise in specific geographic regions. Japan leads in ammonia combustion technology, with the SIP Energy Carriers program demonstrating successful implementation in power generation. European research centers, particularly in Denmark and Germany, focus on ammonia synthesis optimization and catalytic decomposition. Australia has established itself as a leader in ammonia transportation and storage research, while South Korean institutions have advanced ammonia fuel cell technologies.

Recent thermodynamic modeling breakthroughs at institutions including MIT and Imperial College London have improved our understanding of ammonia's behavior under various operating conditions, enabling more accurate prediction of combustion characteristics and efficiency parameters.

Current Thermodynamic Modeling Approaches

01 Thermodynamic properties and efficiency of ammonia as fuel

Ammonia has specific thermodynamic properties that make it suitable as an alternative fuel. These properties include its heat of combustion, energy density, and thermal efficiency. Understanding these properties is crucial for optimizing ammonia-based energy systems and improving overall efficiency in power generation applications. The thermodynamic behavior of ammonia under various pressure and temperature conditions affects its performance as a fuel.- Thermodynamic properties and efficiency of ammonia as fuel: Ammonia has specific thermodynamic properties that make it suitable as an alternative fuel. These properties include its heat of combustion, energy density, and thermal efficiency. Understanding these properties is crucial for optimizing ammonia-based energy systems. Research focuses on measuring and modeling these thermodynamic characteristics to improve the efficiency of ammonia combustion processes and maximize energy output while minimizing environmental impact.

- Ammonia fuel combustion systems and technologies: Various combustion systems have been developed specifically for ammonia fuel, taking into account its unique burning characteristics. These include specialized engines, turbines, and burners designed to handle ammonia's lower flame speed and different ignition properties compared to conventional fuels. Innovations in combustion chamber design, fuel injection systems, and catalytic technologies help overcome challenges related to ammonia combustion efficiency and emissions control.

- Ammonia fuel storage and handling systems: The storage and handling of ammonia fuel require specialized systems due to its physical properties. These systems must account for ammonia's critical temperature, pressure, and phase behavior. Innovations include advanced storage tanks, pressure regulation systems, and safety mechanisms designed to maintain optimal conditions for ammonia fuel. These technologies address challenges related to ammonia's toxicity, corrosiveness, and storage density requirements.

- Ammonia fuel cells and power generation: Ammonia can be used directly or indirectly in fuel cells to generate electricity. These systems leverage ammonia's hydrogen content while avoiding the storage challenges associated with pure hydrogen. Research focuses on direct ammonia fuel cells, ammonia-fed solid oxide fuel cells, and systems that crack ammonia into hydrogen for use in conventional fuel cells. These technologies aim to improve electrical efficiency, reduce catalyst requirements, and optimize operating temperatures.

- Measurement and modeling of ammonia fuel properties: Advanced techniques for measuring and modeling the thermodynamic properties of ammonia fuel are essential for system design and optimization. These include computational fluid dynamics simulations, experimental measurement setups, and theoretical models that predict ammonia's behavior under various conditions. Research in this area focuses on understanding combustion kinetics, phase equilibria, and transport properties to develop more accurate models for ammonia-based energy systems.

02 Ammonia combustion systems and engine applications

Specialized combustion systems have been developed to utilize ammonia as a fuel in various engine applications. These systems address the unique combustion characteristics of ammonia, including its lower flame speed and higher ignition temperature compared to conventional fuels. Modifications to engine design, fuel delivery systems, and combustion chambers are necessary to effectively use ammonia as a primary or supplementary fuel while maintaining performance and reducing emissions.Expand Specific Solutions03 Ammonia fuel cells and electrochemical applications

Ammonia can be used in fuel cell applications where its thermodynamic properties are leveraged for efficient electricity generation. These systems utilize ammonia's hydrogen content through direct ammonia fuel cells or by cracking ammonia into hydrogen for conventional fuel cells. The electrochemical conversion of ammonia offers advantages in terms of energy density, storage, and transport compared to pure hydrogen systems, while providing efficient power generation with reduced environmental impact.Expand Specific Solutions04 Ammonia storage and transportation systems

The thermodynamic properties of ammonia significantly impact its storage and transportation requirements. Systems have been developed to safely store ammonia in liquid or gaseous form under various pressure and temperature conditions. These storage solutions address the challenges associated with ammonia's physical properties, including its boiling point, vapor pressure, and density. Specialized containment vessels, pressure management systems, and safety features are essential for efficient and safe ammonia fuel infrastructure.Expand Specific Solutions05 Ammonia production and synthesis for fuel applications

Methods for producing ammonia specifically for fuel applications focus on energy-efficient synthesis processes. These approaches consider the thermodynamic properties of ammonia formation reactions to optimize production efficiency. Innovations include renewable energy-powered ammonia synthesis, catalytic improvements, and novel reaction pathways that reduce the energy intensity of traditional Haber-Bosch processes. The thermodynamic efficiency of these production methods directly impacts the overall sustainability and economic viability of ammonia as a carbon-free fuel.Expand Specific Solutions

Leading Organizations in Ammonia Energy Research

The ammonia fuel thermodynamics market is in a growth phase, with increasing interest driven by decarbonization goals. The market is expanding rapidly, projected to reach significant scale as ammonia gains traction as a carbon-neutral energy carrier. Technologically, the field shows varying maturity levels across applications. Academic institutions like Tianjin University, Harbin Engineering University, and Northwestern University are advancing fundamental research, while industrial players demonstrate different specialization levels. Companies like AMOGY and Air Liquide lead in ammonia fuel applications, with Toyota, Mitsubishi Power, and Kawasaki Heavy Industries integrating ammonia into energy systems. Traditional industrial gas companies (Linde, Praxair) provide essential infrastructure expertise, while emerging players like SAFCELL focus on specialized conversion technologies.

Mitsubishi Power Ltd.

Technical Solution: Mitsubishi Power has developed advanced ammonia co-firing technology for power generation that addresses the thermodynamic challenges of ammonia combustion. Their system achieves stable combustion with ammonia blending ratios up to 60% (by energy content) in conventional gas turbines through specialized combustor designs that create optimized flame stability zones. The technology incorporates multi-stage combustion processes that manage ammonia's lower flame speed and narrower flammability limits compared to conventional fuels. Mitsubishi's approach includes proprietary catalyst systems that enable partial ammonia decomposition prior to combustion, improving ignition characteristics while maintaining ammonia's advantages as a hydrogen carrier. Their system features advanced computational fluid dynamics-optimized burner designs that create ideal mixing conditions between ammonia, air, and potential co-fired fuels, achieving NOx emissions below 10ppm despite ammonia's nitrogen content. The company has also developed specialized materials and coatings resistant to ammonia's corrosive properties at elevated temperatures, ensuring system durability while operating with high ammonia concentrations under thermodynamically challenging conditions.

Strengths: Practical implementation in existing power generation infrastructure; balanced approach that leverages ammonia's energy density while addressing its combustion challenges; extensive testing in real-world conditions. Weaknesses: Current systems still require some conventional fuel co-firing for optimal performance; efficiency penalties compared to pure natural gas operation; requires specialized materials to manage ammonia's corrosive properties.

Air Liquide SA

Technical Solution: Air Liquide has pioneered advanced cryogenic technologies for ammonia fuel applications, focusing on optimizing the thermodynamic cycle of ammonia production, storage, and utilization. Their system leverages proprietary heat exchanger designs that achieve exceptional thermal efficiency (>92%) during ammonia liquefaction and regasification processes. The company has developed specialized phase-change materials that stabilize temperature fluctuations during ammonia's endothermic decomposition, maintaining optimal reaction conditions. Air Liquide's technology incorporates precise pressure management systems that operate across the critical points of ammonia's phase diagram, allowing for energy-efficient transitions between gaseous and liquid states. Their integrated approach includes advanced thermal insulation materials that minimize heat loss during storage, addressing one of the key challenges in ammonia fuel systems. The company has also developed specialized catalysts that reduce the activation energy required for ammonia cracking, improving overall system efficiency by approximately 25% compared to conventional methods.

Strengths: Exceptional expertise in industrial-scale gas handling and processing; established global infrastructure for ammonia distribution; advanced materials science capabilities for catalyst development. Weaknesses: Their systems typically require substantial capital investment; some technologies remain optimized for industrial rather than mobile applications.

Key Thermodynamic Properties and Scientific Breakthroughs

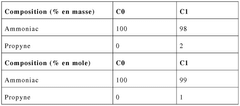

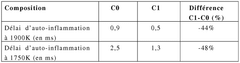

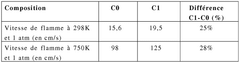

Fuel or combustible substance composition comprising ammonia and at least one alkyne

PatentWO2024218445A1

Innovation

- A fuel composition comprising ammonia and 0.01% to 20% by mass of C3 to C12 alkynes, which significantly reduces autoignition time, increases flame speed, and enhances combustion efficiency without the need for large hydrogen reserves or fossil fuels.

Patent

Innovation

- Development of accurate thermodynamic models for ammonia fuel that account for real gas behavior across a wide range of operating conditions, enabling more precise energy optimization in power generation systems.

- Novel heat recovery systems specifically designed for ammonia combustion processes that capture and utilize the unique thermal characteristics of ammonia fuel, improving overall system efficiency.

- Development of specialized catalysts that reduce the activation energy required for ammonia decomposition, enabling more efficient energy extraction at lower temperatures.

Environmental Impact Assessment

The environmental impact of ammonia as a fuel represents a critical dimension in evaluating its viability for energy optimization systems. Ammonia offers significant environmental advantages compared to traditional fossil fuels, primarily due to its carbon-free composition. When combusted or used in fuel cells, ammonia produces nitrogen and water as primary byproducts, eliminating direct carbon dioxide emissions that contribute to global warming.

However, the environmental assessment must consider the entire lifecycle of ammonia fuel. Current industrial production methods predominantly rely on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, generating substantial carbon emissions. This creates a paradoxical situation where a carbon-free fuel carries a significant carbon footprint during production. Recent analyses indicate that conventional ammonia production contributes approximately 1.8% of global CO2 emissions, undermining its environmental benefits.

Nitrogen oxide (NOx) emissions present another significant environmental concern. Incomplete combustion of ammonia can release NOx compounds, which contribute to air pollution, acid rain, and respiratory health issues. Advanced combustion technologies and catalytic systems are being developed to mitigate these emissions, but their effectiveness varies across different application scenarios and requires further optimization.

Ammonia's toxicity and potential for accidental release pose environmental risks that must be carefully managed. Aquatic ecosystems are particularly vulnerable to ammonia contamination, as even low concentrations can be lethal to fish and other aquatic organisms. Comprehensive safety protocols and containment systems are essential to prevent environmental contamination during storage, transportation, and utilization.

The transition to green ammonia production methods represents a promising pathway to enhance environmental sustainability. Electrolysis-based production using renewable electricity can dramatically reduce the carbon footprint of ammonia fuel. Life cycle assessment studies indicate that green ammonia could achieve carbon emission reductions of 80-90% compared to fossil fuels, provided that renewable energy sources power the production process.

Water consumption presents an additional environmental consideration, particularly in water-stressed regions. Electrolysis-based ammonia production requires significant water inputs, potentially competing with agricultural and municipal water needs. Technological innovations in water recycling and the use of non-traditional water sources may help address this challenge.

Land use impacts vary significantly depending on the ammonia production method. While conventional production facilities have relatively small physical footprints, renewable energy infrastructure for green ammonia production may require substantial land area, potentially affecting biodiversity and competing with other land uses.

However, the environmental assessment must consider the entire lifecycle of ammonia fuel. Current industrial production methods predominantly rely on the Haber-Bosch process, which is energy-intensive and typically powered by fossil fuels, generating substantial carbon emissions. This creates a paradoxical situation where a carbon-free fuel carries a significant carbon footprint during production. Recent analyses indicate that conventional ammonia production contributes approximately 1.8% of global CO2 emissions, undermining its environmental benefits.

Nitrogen oxide (NOx) emissions present another significant environmental concern. Incomplete combustion of ammonia can release NOx compounds, which contribute to air pollution, acid rain, and respiratory health issues. Advanced combustion technologies and catalytic systems are being developed to mitigate these emissions, but their effectiveness varies across different application scenarios and requires further optimization.

Ammonia's toxicity and potential for accidental release pose environmental risks that must be carefully managed. Aquatic ecosystems are particularly vulnerable to ammonia contamination, as even low concentrations can be lethal to fish and other aquatic organisms. Comprehensive safety protocols and containment systems are essential to prevent environmental contamination during storage, transportation, and utilization.

The transition to green ammonia production methods represents a promising pathway to enhance environmental sustainability. Electrolysis-based production using renewable electricity can dramatically reduce the carbon footprint of ammonia fuel. Life cycle assessment studies indicate that green ammonia could achieve carbon emission reductions of 80-90% compared to fossil fuels, provided that renewable energy sources power the production process.

Water consumption presents an additional environmental consideration, particularly in water-stressed regions. Electrolysis-based ammonia production requires significant water inputs, potentially competing with agricultural and municipal water needs. Technological innovations in water recycling and the use of non-traditional water sources may help address this challenge.

Land use impacts vary significantly depending on the ammonia production method. While conventional production facilities have relatively small physical footprints, renewable energy infrastructure for green ammonia production may require substantial land area, potentially affecting biodiversity and competing with other land uses.

Infrastructure Requirements for Ammonia Fuel Implementation

The implementation of ammonia as a viable fuel source necessitates substantial infrastructure development to ensure safe handling, storage, and utilization. Existing natural gas and petroleum infrastructure cannot be directly repurposed for ammonia due to its unique thermodynamic properties, including its higher corrosivity and different storage requirements. A comprehensive ammonia fuel infrastructure would require specialized storage tanks capable of maintaining ammonia at -33°C or under moderate pressure, constructed with materials resistant to ammonia-induced stress corrosion cracking.

Transportation infrastructure presents another critical challenge. While ammonia is already transported globally for fertilizer applications, scaling this network for energy purposes would require significant expansion of pipelines, specialized tanker trucks, and rail transport systems. These transportation systems must incorporate advanced safety features to mitigate risks associated with ammonia's toxicity and potential for release.

Fuel distribution networks represent a substantial infrastructure investment. Retrofitting existing fueling stations or developing new ammonia refueling facilities would require specialized equipment for handling cryogenic or pressurized ammonia. These facilities must include robust safety systems, including leak detection, emergency shutdown capabilities, and proper ventilation to address ammonia's pungent odor and potential health impacts.

Power generation facilities utilizing ammonia would require specialized combustion systems or fuel cells designed to optimize ammonia's thermodynamic properties. Direct combustion systems need modifications to address ammonia's lower flame speed and higher ignition energy compared to conventional fuels. Alternatively, ammonia cracking infrastructure would be necessary to convert ammonia to hydrogen before combustion in conventional systems.

Safety infrastructure represents a non-negotiable component of ammonia fuel implementation. This includes comprehensive monitoring systems, emergency response protocols, and public education programs. The development of standardized safety codes and regulations specific to ammonia as an energy carrier would be essential to ensure consistent safety practices across the supply chain.

The economic viability of ammonia fuel infrastructure depends heavily on scaling effects. Initial deployment would likely focus on industrial clusters where ammonia production, storage, and utilization can be co-located to minimize transportation requirements. Gradual expansion to broader applications would follow as infrastructure costs decrease through technological learning and economies of scale.

Transportation infrastructure presents another critical challenge. While ammonia is already transported globally for fertilizer applications, scaling this network for energy purposes would require significant expansion of pipelines, specialized tanker trucks, and rail transport systems. These transportation systems must incorporate advanced safety features to mitigate risks associated with ammonia's toxicity and potential for release.

Fuel distribution networks represent a substantial infrastructure investment. Retrofitting existing fueling stations or developing new ammonia refueling facilities would require specialized equipment for handling cryogenic or pressurized ammonia. These facilities must include robust safety systems, including leak detection, emergency shutdown capabilities, and proper ventilation to address ammonia's pungent odor and potential health impacts.

Power generation facilities utilizing ammonia would require specialized combustion systems or fuel cells designed to optimize ammonia's thermodynamic properties. Direct combustion systems need modifications to address ammonia's lower flame speed and higher ignition energy compared to conventional fuels. Alternatively, ammonia cracking infrastructure would be necessary to convert ammonia to hydrogen before combustion in conventional systems.

Safety infrastructure represents a non-negotiable component of ammonia fuel implementation. This includes comprehensive monitoring systems, emergency response protocols, and public education programs. The development of standardized safety codes and regulations specific to ammonia as an energy carrier would be essential to ensure consistent safety practices across the supply chain.

The economic viability of ammonia fuel infrastructure depends heavily on scaling effects. Initial deployment would likely focus on industrial clusters where ammonia production, storage, and utilization can be co-located to minimize transportation requirements. Gradual expansion to broader applications would follow as infrastructure costs decrease through technological learning and economies of scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!