The Interaction of Ammonia Fuel with Non-conventional energy Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Technology Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition toward sustainable energy systems. The history of ammonia as a fuel dates back to the early 20th century, but recent environmental concerns and technological advancements have revitalized interest in this compound. With a hydrogen content of 17.8% by weight and an energy density of 18.6 MJ/kg, ammonia offers significant potential as an alternative fuel while addressing the storage and transportation challenges associated with pure hydrogen.

The evolution of ammonia fuel technology has accelerated dramatically over the past decade. Initially viewed primarily as a fertilizer component, ammonia is now recognized as a versatile energy vector capable of integrating with various non-conventional energy systems. This paradigm shift has been driven by the urgent need to decarbonize energy-intensive sectors and the recognition that ammonia can be produced using renewable electricity, making it a viable pathway for green energy storage and distribution.

Current technological trends indicate a convergence of ammonia fuel applications with renewable energy systems, particularly in sectors where direct electrification remains challenging. The integration of ammonia with solar, wind, and other non-conventional energy sources represents a frontier in energy system design, enabling more flexible and resilient power networks. This synergy allows for effective energy storage during peak renewable production periods and subsequent utilization during demand spikes.

The primary technical objectives in this field include developing more efficient catalysts for ammonia synthesis and decomposition, enhancing combustion technologies for direct ammonia utilization, and optimizing system integration between ammonia infrastructure and renewable energy sources. Particular emphasis is placed on reducing the energy intensity of ammonia production through advanced electrolysis techniques and improving the efficiency of ammonia-based power generation systems.

Looking forward, the ammonia fuel technology roadmap aims to achieve cost parity with conventional fuels by 2030, while simultaneously reducing the carbon footprint of ammonia production by leveraging renewable energy inputs. Research priorities include addressing the technical challenges of ammonia's relatively low flame speed and high ignition energy, which currently limit its direct application in certain combustion systems.

The intersection of ammonia fuel with non-conventional energy systems represents a critical pathway toward achieving global decarbonization goals. By serving as both an energy carrier and storage medium, ammonia creates new possibilities for sector coupling and energy system flexibility, potentially revolutionizing how renewable energy is integrated into existing infrastructure and enabling deeper penetration of intermittent renewable sources into the global energy mix.

The evolution of ammonia fuel technology has accelerated dramatically over the past decade. Initially viewed primarily as a fertilizer component, ammonia is now recognized as a versatile energy vector capable of integrating with various non-conventional energy systems. This paradigm shift has been driven by the urgent need to decarbonize energy-intensive sectors and the recognition that ammonia can be produced using renewable electricity, making it a viable pathway for green energy storage and distribution.

Current technological trends indicate a convergence of ammonia fuel applications with renewable energy systems, particularly in sectors where direct electrification remains challenging. The integration of ammonia with solar, wind, and other non-conventional energy sources represents a frontier in energy system design, enabling more flexible and resilient power networks. This synergy allows for effective energy storage during peak renewable production periods and subsequent utilization during demand spikes.

The primary technical objectives in this field include developing more efficient catalysts for ammonia synthesis and decomposition, enhancing combustion technologies for direct ammonia utilization, and optimizing system integration between ammonia infrastructure and renewable energy sources. Particular emphasis is placed on reducing the energy intensity of ammonia production through advanced electrolysis techniques and improving the efficiency of ammonia-based power generation systems.

Looking forward, the ammonia fuel technology roadmap aims to achieve cost parity with conventional fuels by 2030, while simultaneously reducing the carbon footprint of ammonia production by leveraging renewable energy inputs. Research priorities include addressing the technical challenges of ammonia's relatively low flame speed and high ignition energy, which currently limit its direct application in certain combustion systems.

The intersection of ammonia fuel with non-conventional energy systems represents a critical pathway toward achieving global decarbonization goals. By serving as both an energy carrier and storage medium, ammonia creates new possibilities for sector coupling and energy system flexibility, potentially revolutionizing how renewable energy is integrated into existing infrastructure and enabling deeper penetration of intermittent renewable sources into the global energy mix.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth, driven by increasing environmental concerns and the push for decarbonization across various industries. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to grow at a compound annual growth rate of 5.3% through 2030, potentially reaching $103.8 billion by the end of the decade.

The transportation sector represents the most promising immediate market for ammonia fuel, particularly in maritime applications. Shipping accounts for nearly 3% of global greenhouse gas emissions, and ammonia offers a viable zero-carbon alternative to conventional marine fuels. Major shipping companies including Maersk and NYK Line have already announced pilot projects implementing ammonia-powered vessels, with the first commercial ships expected to enter service by 2025.

Power generation constitutes another substantial market segment, with ammonia showing potential as both a direct fuel for turbines and as a hydrogen carrier for fuel cells. Several utility companies in Japan, Australia, and Europe have initiated demonstration projects using ammonia in existing coal-fired plants through co-firing techniques, achieving carbon emission reductions of up to 20% in initial trials.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for ammonia fuel adoption, led by Japan's commitment to establish an international ammonia fuel supply chain by 2027. Europe follows closely, with countries like Germany and the Netherlands investing heavily in ammonia infrastructure as part of their hydrogen strategies. North America shows increasing interest, particularly in industrial applications and long-haul transportation.

Market barriers remain significant, including high production costs compared to conventional fuels. Current green ammonia production costs range between $600-900 per ton, approximately 2-3 times higher than conventional ammonia. However, technological advancements and economies of scale are expected to reduce this premium substantially by 2030.

Infrastructure development represents another critical market challenge. The current global ammonia infrastructure, while extensive for fertilizer applications, requires significant modification for energy applications. Industry analysts estimate global investment requirements of $30-40 billion over the next decade to develop adequate ammonia fuel infrastructure.

Consumer acceptance and safety concerns also influence market dynamics, with public perception regarding ammonia's toxicity potentially limiting adoption in certain applications. However, the established safety protocols from the chemical industry provide a foundation for addressing these concerns in new applications.

The transportation sector represents the most promising immediate market for ammonia fuel, particularly in maritime applications. Shipping accounts for nearly 3% of global greenhouse gas emissions, and ammonia offers a viable zero-carbon alternative to conventional marine fuels. Major shipping companies including Maersk and NYK Line have already announced pilot projects implementing ammonia-powered vessels, with the first commercial ships expected to enter service by 2025.

Power generation constitutes another substantial market segment, with ammonia showing potential as both a direct fuel for turbines and as a hydrogen carrier for fuel cells. Several utility companies in Japan, Australia, and Europe have initiated demonstration projects using ammonia in existing coal-fired plants through co-firing techniques, achieving carbon emission reductions of up to 20% in initial trials.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for ammonia fuel adoption, led by Japan's commitment to establish an international ammonia fuel supply chain by 2027. Europe follows closely, with countries like Germany and the Netherlands investing heavily in ammonia infrastructure as part of their hydrogen strategies. North America shows increasing interest, particularly in industrial applications and long-haul transportation.

Market barriers remain significant, including high production costs compared to conventional fuels. Current green ammonia production costs range between $600-900 per ton, approximately 2-3 times higher than conventional ammonia. However, technological advancements and economies of scale are expected to reduce this premium substantially by 2030.

Infrastructure development represents another critical market challenge. The current global ammonia infrastructure, while extensive for fertilizer applications, requires significant modification for energy applications. Industry analysts estimate global investment requirements of $30-40 billion over the next decade to develop adequate ammonia fuel infrastructure.

Consumer acceptance and safety concerns also influence market dynamics, with public perception regarding ammonia's toxicity potentially limiting adoption in certain applications. However, the established safety protocols from the chemical industry provide a foundation for addressing these concerns in new applications.

Current Challenges in Ammonia-Energy Integration

The integration of ammonia fuel with non-conventional energy systems faces several significant technical and operational challenges that currently impede widespread adoption. One primary obstacle is the energy-intensive nature of ammonia production, which traditionally relies on the Haber-Bosch process requiring high temperatures (400-500°C) and pressures (150-300 bar). This process consumes approximately 1-2% of global energy production, making the overall energy efficiency questionable unless powered by renewable sources.

Material compatibility presents another substantial hurdle, as ammonia's corrosive properties necessitate specialized storage and handling infrastructure. Conventional metals like copper, brass, and certain alloys experience accelerated degradation when exposed to ammonia, requiring the development and implementation of resistant materials such as stainless steel or specific polymers, which increases system costs significantly.

Combustion inefficiencies further complicate ammonia's integration with energy systems. Ammonia has a relatively low flame speed and narrow flammability limits (16-25% by volume in air), resulting in poor combustion characteristics compared to conventional fuels. This necessitates either catalytic decomposition to hydrogen before combustion or sophisticated combustion chamber designs with precise control systems.

Safety concerns represent a critical challenge, as ammonia is toxic at concentrations above 25-50 ppm and can cause severe respiratory issues or death at higher concentrations. Implementing robust detection systems, ventilation protocols, and emergency response mechanisms adds complexity and cost to ammonia-based energy systems.

The intermittent nature of many non-conventional energy sources (solar, wind) creates synchronization challenges with ammonia production and utilization cycles. Current electrolysis technologies for green ammonia production lack the flexibility to efficiently ramp up or down in response to fluctuating renewable energy availability, necessitating either substantial energy storage solutions or hybrid systems.

Regulatory frameworks worldwide remain underdeveloped for ammonia as an energy carrier, creating uncertainty for investors and technology developers. The absence of standardized safety protocols, emissions standards, and certification processes specifically tailored to ammonia energy systems impedes commercial deployment and scaling.

Economic viability remains questionable under current market conditions, with green ammonia production costs estimated at $600-1,200 per ton compared to $200-400 per ton for conventional ammonia. This price differential, coupled with the need for specialized infrastructure, creates significant market entry barriers without supportive policy mechanisms or carbon pricing.

Material compatibility presents another substantial hurdle, as ammonia's corrosive properties necessitate specialized storage and handling infrastructure. Conventional metals like copper, brass, and certain alloys experience accelerated degradation when exposed to ammonia, requiring the development and implementation of resistant materials such as stainless steel or specific polymers, which increases system costs significantly.

Combustion inefficiencies further complicate ammonia's integration with energy systems. Ammonia has a relatively low flame speed and narrow flammability limits (16-25% by volume in air), resulting in poor combustion characteristics compared to conventional fuels. This necessitates either catalytic decomposition to hydrogen before combustion or sophisticated combustion chamber designs with precise control systems.

Safety concerns represent a critical challenge, as ammonia is toxic at concentrations above 25-50 ppm and can cause severe respiratory issues or death at higher concentrations. Implementing robust detection systems, ventilation protocols, and emergency response mechanisms adds complexity and cost to ammonia-based energy systems.

The intermittent nature of many non-conventional energy sources (solar, wind) creates synchronization challenges with ammonia production and utilization cycles. Current electrolysis technologies for green ammonia production lack the flexibility to efficiently ramp up or down in response to fluctuating renewable energy availability, necessitating either substantial energy storage solutions or hybrid systems.

Regulatory frameworks worldwide remain underdeveloped for ammonia as an energy carrier, creating uncertainty for investors and technology developers. The absence of standardized safety protocols, emissions standards, and certification processes specifically tailored to ammonia energy systems impedes commercial deployment and scaling.

Economic viability remains questionable under current market conditions, with green ammonia production costs estimated at $600-1,200 per ton compared to $200-400 per ton for conventional ammonia. This price differential, coupled with the need for specialized infrastructure, creates significant market entry barriers without supportive policy mechanisms or carbon pricing.

Current Ammonia-Energy System Integration Solutions

01 Ammonia fuel production methods

Various methods for producing ammonia fuel are disclosed, including catalytic processes, renewable energy integration, and sustainable synthesis approaches. These methods aim to create ammonia in a more environmentally friendly manner by reducing carbon emissions during production. Some techniques involve novel catalysts to improve efficiency, while others focus on using green hydrogen and nitrogen sources to create carbon-neutral ammonia fuel.- Ammonia fuel production methods: Various methods for producing ammonia fuel are disclosed, including processes that utilize renewable energy sources. These methods aim to create sustainable ammonia production pathways that reduce carbon emissions compared to traditional production methods. The processes may involve electrolysis of water to produce hydrogen, which is then combined with nitrogen from air separation to synthesize ammonia through modified Haber-Bosch or alternative processes.

- Ammonia fuel storage and transportation systems: Specialized systems for storing and transporting ammonia fuel are described, addressing the challenges of ammonia's physical properties. These systems include specialized tanks, containers, and infrastructure designed to safely handle ammonia under various pressure and temperature conditions. The technologies focus on preventing leakage, minimizing safety risks, and optimizing the logistics chain for ammonia as an energy carrier.

- Ammonia combustion engines and power generation: Innovations in ammonia combustion for internal combustion engines and power generation systems are presented. These technologies address the challenges of ammonia's lower energy density and different combustion characteristics compared to conventional fuels. Modifications to engine design, combustion chambers, fuel delivery systems, and ignition mechanisms enable efficient ammonia combustion while minimizing NOx emissions and other pollutants.

- Ammonia fuel cells and hydrogen extraction: Technologies for utilizing ammonia in fuel cells or as a hydrogen carrier are detailed. These include systems for extracting hydrogen from ammonia through catalytic decomposition or cracking processes, as well as direct ammonia fuel cells that can generate electricity without the hydrogen extraction step. The innovations focus on catalyst development, reaction efficiency, and system integration to make ammonia a practical energy carrier for fuel cell applications.

- Ammonia blending with conventional fuels: Methods and systems for blending ammonia with conventional fuels to create dual-fuel or mixed-fuel solutions are described. These approaches allow for gradual transition to ammonia-based energy systems while leveraging existing infrastructure. The technologies address challenges in fuel mixing ratios, combustion stability, emissions control, and engine performance when using ammonia-blended fuels in various applications including maritime engines, power generation, and industrial heating.

02 Ammonia fuel storage and transportation systems

Specialized systems for the safe storage and transportation of ammonia fuel are described. These include advanced containment vessels, pressure management systems, and safety mechanisms to address ammonia's toxicity and corrosive properties. The technologies focus on preventing leakage, managing thermal conditions, and ensuring compatibility with existing infrastructure while enabling efficient distribution of ammonia as an energy carrier.Expand Specific Solutions03 Ammonia combustion engines and power generation

Innovations in engine design and combustion systems specifically adapted for ammonia fuel use in power generation and transportation. These technologies address ammonia's lower energy density and different combustion characteristics compared to conventional fuels. Modifications include specialized injection systems, combustion chamber designs, and ignition mechanisms to improve efficiency and reduce nitrogen oxide emissions when burning ammonia as a primary fuel or in dual-fuel configurations.Expand Specific Solutions04 Ammonia fuel cells and electricity generation

Fuel cell technologies that utilize ammonia directly or indirectly to generate electricity. These systems may involve direct ammonia fuel cells or systems that first crack ammonia into hydrogen before use in conventional fuel cells. The technologies focus on catalyst development, membrane improvements, and system integration to enable efficient electricity generation from ammonia while managing issues such as catalyst poisoning and operating temperature requirements.Expand Specific Solutions05 Ammonia fuel blending and co-firing systems

Technologies for blending ammonia with other fuels or using it in co-firing applications to reduce carbon emissions while leveraging existing infrastructure. These systems enable the gradual transition to ammonia fuel by allowing its use in combination with conventional fuels like natural gas, diesel, or hydrogen. The innovations include specialized mixing equipment, combustion control systems, and emissions management technologies to optimize performance while reducing environmental impact.Expand Specific Solutions

Key Industry Players in Ammonia Energy Sector

The ammonia fuel interaction with non-conventional energy systems market is in an early growth phase, characterized by increasing research activities and pilot implementations. The global market is projected to expand significantly as ammonia gains traction as a carbon-free energy carrier, particularly in transportation and power generation sectors. Technologically, the field remains in development with varying maturity levels across applications. Leading players include AMOGY, which is pioneering ammonia-powered transportation solutions with successful demonstrations in vehicles and vessels; Siemens AG, leveraging its extensive energy infrastructure expertise; and IHI Corp, advancing ammonia combustion technologies. Academic institutions like Tianjin University and University of Strathclyde are contributing fundamental research, while industrial players such as Toyota Motor Corp and TotalEnergies OneTech are exploring integration with existing energy systems, indicating a collaborative ecosystem developing across research and commercial applications.

AMOGY, Inc.

Technical Solution: AMOGY has developed an innovative ammonia-to-power system that efficiently converts ammonia to hydrogen for fuel cell applications. Their technology employs a compact cracking reactor that operates at lower temperatures (around 650°C compared to traditional 850°C) using proprietary catalysts to decompose ammonia into hydrogen and nitrogen. The system integrates with PEM fuel cells to generate electricity with zero carbon emissions. AMOGY's solution includes a comprehensive ammonia handling system with advanced safety features and has been successfully demonstrated in transportation applications including a drone, tractor, and semi-truck, proving scalability from kilowatts to megawatts of power. Their approach addresses the energy density limitations of hydrogen by using ammonia as a hydrogen carrier, enabling longer operational ranges for vehicles and vessels.

Strengths: High energy density solution (3X the energy density of compressed hydrogen); eliminates need for high-pressure hydrogen storage; uses existing ammonia infrastructure; demonstrated scalability across multiple applications. Weaknesses: Still requires high temperatures for ammonia cracking; potential ammonia toxicity concerns; system complexity compared to battery electric solutions; dependence on green ammonia production for true carbon neutrality.

Siemens AG

Technical Solution: Siemens has developed a comprehensive ammonia-energy integration platform called "NH3 Energy Solutions" that combines their expertise in power generation, industrial automation, and renewable energy systems. Their approach centers on a hybrid energy system that uses renewable electricity to produce green ammonia through water electrolysis and nitrogen separation, then utilizes this ammonia in modified gas turbines and fuel cells. Siemens' SGT-series gas turbines have been adapted to co-fire ammonia with natural gas, achieving up to 30% ammonia in the fuel mix without significant modifications. Their proprietary digital twin technology enables real-time optimization of the entire system, balancing production and consumption based on energy availability and demand. For grid stabilization, Siemens has engineered ammonia-based energy storage solutions that can provide long-duration storage capabilities (weeks to months) compared to batteries (hours to days), addressing renewable energy intermittency challenges. The system incorporates advanced safety protocols and monitoring systems to manage ammonia's toxicity risks.

Strengths: Comprehensive end-to-end solution from production to utilization; leverages existing gas turbine technology; advanced digital control systems for optimization; global service network for implementation and maintenance. Weaknesses: Limited experience with pure ammonia combustion (currently focused on co-firing); high capital costs for full system implementation; efficiency losses in the energy conversion chain; requires significant modifications to existing power infrastructure.

Critical Patents and Research in Ammonia Fuel Technology

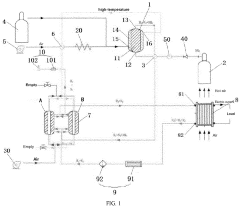

Thermal decomposition and high-pressure direct injection type ammonia-fuelled engine

PatentWO2023151121A1

Innovation

- 设计了一种热分解高压直喷型氨燃料发动机,包括氨罐、氨增压泵、氨预热及分解装置、高压喷射阀、喷嘴、发动机、尾气处理装置,通过氨增压和热解产生氢氮混合气体,利用高压喷射和催化分解技术提高发动机效率,降低排气中的氮氧化物含量。

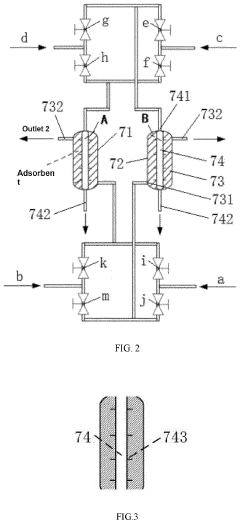

Ammonia fuel cell system capable of fast adsorption-desorption switching by selfevaporation of ammonia and power generation method thereof

PatentPendingEP4393870A2

Innovation

- An ammonia fuel cell system employing self-evaporation for rapid adsorption and desorption, utilizing a thermal coupling scheme with heat exchangers and a dual adsorption column setup for efficient thermal management, along with a ruthenium-based ammonia decomposition catalyst and catalytic combustion for stable temperature control.

Environmental Impact Assessment of Ammonia Fuel

The environmental impact assessment of ammonia fuel reveals a complex profile of benefits and challenges when compared to conventional fossil fuels. Ammonia (NH3) offers significant advantages as a carbon-free energy carrier, producing zero carbon dioxide emissions during combustion. This characteristic positions ammonia as a potentially valuable tool in decarbonization strategies, particularly when integrated with non-conventional energy systems such as solar, wind, and other renewable sources.

When produced using renewable electricity through green hydrogen pathways, ammonia's lifecycle emissions can be dramatically lower than fossil fuel alternatives. Studies indicate potential greenhouse gas emission reductions of 80-95% compared to diesel or natural gas when the entire production and utilization chain employs renewable energy. This synergy between ammonia fuel and non-conventional energy systems creates a particularly promising pathway for sectors difficult to electrify directly.

However, ammonia presents several environmental concerns that require careful management. NOx emissions during combustion remain a significant challenge, as these compounds contribute to air pollution, acid rain, and photochemical smog formation. Current combustion technologies typically require sophisticated catalytic converters or selective catalytic reduction systems to mitigate these emissions to acceptable levels.

Ammonia toxicity poses another environmental risk, particularly in aquatic ecosystems where even low concentrations can be lethal to fish and other aquatic organisms. Rigorous safety protocols and containment systems are essential to prevent accidental releases during transportation, storage, and utilization phases. The potential for ammonia leakage necessitates comprehensive risk assessment and mitigation strategies in any implementation scenario.

Water usage represents an additional environmental consideration, particularly for green ammonia production pathways that rely on electrolysis. The water requirements for hydrogen production—a precursor to ammonia synthesis—can be substantial, potentially creating competition for water resources in water-stressed regions. This aspect requires careful regional assessment when planning ammonia fuel infrastructure.

Land use impacts vary significantly depending on production methods. While ammonia production facilities themselves have relatively modest footprints, the renewable energy infrastructure required for green ammonia production can require substantial land area, particularly for solar installations. This creates potential land-use conflicts that must be evaluated on a case-by-case basis.

The integration of ammonia with non-conventional energy systems offers unique environmental benefits through energy storage capabilities. Ammonia can effectively store surplus renewable energy during peak production periods, enabling greater penetration of intermittent renewable sources and potentially reducing the need for environmentally problematic battery storage solutions at grid scale.

When produced using renewable electricity through green hydrogen pathways, ammonia's lifecycle emissions can be dramatically lower than fossil fuel alternatives. Studies indicate potential greenhouse gas emission reductions of 80-95% compared to diesel or natural gas when the entire production and utilization chain employs renewable energy. This synergy between ammonia fuel and non-conventional energy systems creates a particularly promising pathway for sectors difficult to electrify directly.

However, ammonia presents several environmental concerns that require careful management. NOx emissions during combustion remain a significant challenge, as these compounds contribute to air pollution, acid rain, and photochemical smog formation. Current combustion technologies typically require sophisticated catalytic converters or selective catalytic reduction systems to mitigate these emissions to acceptable levels.

Ammonia toxicity poses another environmental risk, particularly in aquatic ecosystems where even low concentrations can be lethal to fish and other aquatic organisms. Rigorous safety protocols and containment systems are essential to prevent accidental releases during transportation, storage, and utilization phases. The potential for ammonia leakage necessitates comprehensive risk assessment and mitigation strategies in any implementation scenario.

Water usage represents an additional environmental consideration, particularly for green ammonia production pathways that rely on electrolysis. The water requirements for hydrogen production—a precursor to ammonia synthesis—can be substantial, potentially creating competition for water resources in water-stressed regions. This aspect requires careful regional assessment when planning ammonia fuel infrastructure.

Land use impacts vary significantly depending on production methods. While ammonia production facilities themselves have relatively modest footprints, the renewable energy infrastructure required for green ammonia production can require substantial land area, particularly for solar installations. This creates potential land-use conflicts that must be evaluated on a case-by-case basis.

The integration of ammonia with non-conventional energy systems offers unique environmental benefits through energy storage capabilities. Ammonia can effectively store surplus renewable energy during peak production periods, enabling greater penetration of intermittent renewable sources and potentially reducing the need for environmentally problematic battery storage solutions at grid scale.

Regulatory Framework for Ammonia as Energy Carrier

The regulatory landscape for ammonia as an energy carrier is evolving rapidly as governments worldwide recognize its potential in decarbonization strategies. Currently, most regulations governing ammonia focus on its traditional applications in fertilizer production and industrial processes, with limited frameworks specifically addressing its use as an energy carrier. This regulatory gap presents significant challenges for widespread adoption.

International maritime organizations have taken the lead in developing guidelines for ammonia as a marine fuel. The International Maritime Organization (IMO) has included ammonia in its alternative fuels framework, while classification societies such as DNV GL and Lloyd's Register have published provisional rules for ammonia-fueled vessels. These guidelines primarily address safety concerns, storage requirements, and emission standards.

National regulatory frameworks vary considerably across regions. Japan and South Korea have integrated ammonia into their hydrogen strategies, establishing clear pathways for certification and standardization. The European Union, through its Renewable Energy Directive II and the European Green Deal, has created mechanisms that could accommodate ammonia within its renewable energy framework, though specific provisions remain under development.

Safety regulations represent a critical component of the regulatory landscape. Ammonia's toxicity and corrosive properties necessitate stringent handling protocols. Organizations such as the U.S. Occupational Safety and Health Administration (OSHA) and the European Chemicals Agency have established exposure limits and safety guidelines, which must be adapted for energy applications. The development of specialized codes for ammonia fuel cells, turbines, and combustion systems remains in nascent stages.

Certification and standardization processes are emerging as key enablers for market development. The International Organization for Standardization (ISO) has initiated working groups focused on developing standards for ammonia production, storage, and utilization as an energy carrier. These standards will be crucial for ensuring interoperability across different systems and international borders.

Carbon accounting frameworks present another regulatory challenge. As ammonia can be produced through various pathways with significantly different carbon intensities, regulatory systems must develop robust methodologies to differentiate between "green," "blue," and "gray" ammonia. Several jurisdictions are exploring certification schemes similar to guarantees of origin used for renewable electricity.

Regulatory harmonization across international boundaries will be essential for establishing global ammonia value chains. Current disparities in safety standards, certification requirements, and emissions accounting create barriers to cross-border trade and technology transfer. International cooperation through forums such as the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is working to address these challenges.

International maritime organizations have taken the lead in developing guidelines for ammonia as a marine fuel. The International Maritime Organization (IMO) has included ammonia in its alternative fuels framework, while classification societies such as DNV GL and Lloyd's Register have published provisional rules for ammonia-fueled vessels. These guidelines primarily address safety concerns, storage requirements, and emission standards.

National regulatory frameworks vary considerably across regions. Japan and South Korea have integrated ammonia into their hydrogen strategies, establishing clear pathways for certification and standardization. The European Union, through its Renewable Energy Directive II and the European Green Deal, has created mechanisms that could accommodate ammonia within its renewable energy framework, though specific provisions remain under development.

Safety regulations represent a critical component of the regulatory landscape. Ammonia's toxicity and corrosive properties necessitate stringent handling protocols. Organizations such as the U.S. Occupational Safety and Health Administration (OSHA) and the European Chemicals Agency have established exposure limits and safety guidelines, which must be adapted for energy applications. The development of specialized codes for ammonia fuel cells, turbines, and combustion systems remains in nascent stages.

Certification and standardization processes are emerging as key enablers for market development. The International Organization for Standardization (ISO) has initiated working groups focused on developing standards for ammonia production, storage, and utilization as an energy carrier. These standards will be crucial for ensuring interoperability across different systems and international borders.

Carbon accounting frameworks present another regulatory challenge. As ammonia can be produced through various pathways with significantly different carbon intensities, regulatory systems must develop robust methodologies to differentiate between "green," "blue," and "gray" ammonia. Several jurisdictions are exploring certification schemes similar to guarantees of origin used for renewable electricity.

Regulatory harmonization across international boundaries will be essential for establishing global ammonia value chains. Current disparities in safety standards, certification requirements, and emissions accounting create barriers to cross-border trade and technology transfer. International cooperation through forums such as the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is working to address these challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!