Ammonia Fuel's Compatibility with Low-Temperature Combustion Concepts

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global pursuit of sustainable energy solutions. First synthesized in the early 20th century through the Haber-Bosch process, ammonia (NH3) has primarily served as a fertilizer for decades. However, its potential as an alternative fuel has gained significant attention in recent years due to its zero-carbon combustion characteristics and established production and distribution infrastructure.

The evolution of ammonia as a fuel source has accelerated in response to increasingly stringent environmental regulations and the urgent need to reduce greenhouse gas emissions across all sectors. Unlike hydrogen, ammonia offers higher energy density by volume and can be liquefied at relatively moderate pressures (8.6 bar at 20°C), making it more practical for storage and transportation. This advantage positions ammonia as a potentially viable solution for hard-to-decarbonize sectors such as maritime shipping, heavy industry, and long-duration energy storage.

Current technological developments are focused on overcoming ammonia's inherent combustion challenges, particularly its high ignition energy requirements and relatively slow flame propagation speed compared to conventional hydrocarbon fuels. These characteristics have historically limited ammonia's widespread adoption as a direct fuel source despite its attractive zero-carbon credentials.

The primary technical objective in ammonia fuel research is to develop efficient, reliable, and clean combustion systems that can effectively utilize ammonia's energy content while minimizing harmful emissions, particularly nitrogen oxides (NOx). This includes exploring various combustion strategies, catalyst technologies, and engine modifications to enhance ammonia's combustion properties.

Low-temperature combustion (LTC) concepts represent a particularly promising approach for ammonia utilization. These advanced combustion strategies operate at lower peak temperatures than conventional combustion, potentially addressing ammonia's ignition difficulties while simultaneously reducing NOx formation. The compatibility between ammonia and LTC technologies could potentially unlock significant efficiency improvements and emissions reductions.

The convergence of ammonia fuel systems with LTC concepts aims to achieve several critical objectives: developing combustion systems with thermal efficiencies comparable to conventional fuels, minimizing unburned ammonia and NOx emissions, ensuring reliable ignition and combustion stability across various operating conditions, and creating practical retrofit solutions for existing infrastructure.

As global decarbonization efforts intensify, understanding and optimizing ammonia's compatibility with advanced combustion concepts has become increasingly urgent. This technological pathway could potentially enable a significant reduction in carbon emissions while leveraging existing ammonia production capabilities and infrastructure, representing a pragmatic transition strategy toward a more sustainable energy future.

The evolution of ammonia as a fuel source has accelerated in response to increasingly stringent environmental regulations and the urgent need to reduce greenhouse gas emissions across all sectors. Unlike hydrogen, ammonia offers higher energy density by volume and can be liquefied at relatively moderate pressures (8.6 bar at 20°C), making it more practical for storage and transportation. This advantage positions ammonia as a potentially viable solution for hard-to-decarbonize sectors such as maritime shipping, heavy industry, and long-duration energy storage.

Current technological developments are focused on overcoming ammonia's inherent combustion challenges, particularly its high ignition energy requirements and relatively slow flame propagation speed compared to conventional hydrocarbon fuels. These characteristics have historically limited ammonia's widespread adoption as a direct fuel source despite its attractive zero-carbon credentials.

The primary technical objective in ammonia fuel research is to develop efficient, reliable, and clean combustion systems that can effectively utilize ammonia's energy content while minimizing harmful emissions, particularly nitrogen oxides (NOx). This includes exploring various combustion strategies, catalyst technologies, and engine modifications to enhance ammonia's combustion properties.

Low-temperature combustion (LTC) concepts represent a particularly promising approach for ammonia utilization. These advanced combustion strategies operate at lower peak temperatures than conventional combustion, potentially addressing ammonia's ignition difficulties while simultaneously reducing NOx formation. The compatibility between ammonia and LTC technologies could potentially unlock significant efficiency improvements and emissions reductions.

The convergence of ammonia fuel systems with LTC concepts aims to achieve several critical objectives: developing combustion systems with thermal efficiencies comparable to conventional fuels, minimizing unburned ammonia and NOx emissions, ensuring reliable ignition and combustion stability across various operating conditions, and creating practical retrofit solutions for existing infrastructure.

As global decarbonization efforts intensify, understanding and optimizing ammonia's compatibility with advanced combustion concepts has become increasingly urgent. This technological pathway could potentially enable a significant reduction in carbon emissions while leveraging existing ammonia production capabilities and infrastructure, representing a pragmatic transition strategy toward a more sustainable energy future.

Market Analysis for Low-Carbon Fuel Alternatives

The global market for low-carbon fuel alternatives is experiencing unprecedented growth driven by stringent environmental regulations, corporate sustainability commitments, and increasing consumer awareness. Ammonia as a carbon-free fuel carrier represents a significant opportunity within this evolving landscape, particularly when integrated with low-temperature combustion (LTC) concepts.

Current market projections indicate the global green ammonia market is poised for substantial expansion, with growth rates exceeding traditional fossil fuels. The maritime sector presents the most immediate commercial opportunity, as international shipping faces pressure to reduce emissions by at least 50% by 2050 under International Maritime Organization mandates. Major shipping companies have already begun investing in ammonia-compatible engine technologies.

The power generation sector constitutes another substantial market, where ammonia can serve as both a direct fuel and an energy storage medium. Countries with limited renewable resources but ambitious decarbonization targets, particularly in Asia and Europe, are actively exploring ammonia co-firing in existing power plants as a transitional solution.

Transportation represents a developing market segment, though currently smaller than maritime and power generation. Heavy-duty vehicles and long-haul transport, where battery electrification faces significant challenges, may benefit from ammonia's higher energy density compared to hydrogen, especially when utilized in LTC engines that maximize efficiency.

Market barriers include infrastructure limitations, with minimal ammonia bunkering facilities currently available at major ports. The existing ammonia production and distribution network, while extensive for fertilizer applications, requires significant modification for fuel applications. Safety concerns and public perception issues also present market entry challenges that must be addressed through comprehensive standards and education initiatives.

Price competitiveness remains a critical factor, with green ammonia currently at a significant cost disadvantage compared to conventional fuels. However, carbon pricing mechanisms, renewable energy cost reductions, and economies of scale in electrolysis technology are rapidly improving the economic equation. Industry analysts project price parity with conventional marine fuels could be achieved between 2030-2035 in regions with advanced carbon pricing.

Regional market development varies considerably, with Northern Europe, Japan, Australia, and South Korea emerging as early adopters based on existing pilot projects and supportive policy frameworks. These regions are characterized by strong maritime industries, ambitious climate targets, and strategic interests in developing hydrogen economies, for which ammonia serves as an efficient carrier.

Current market projections indicate the global green ammonia market is poised for substantial expansion, with growth rates exceeding traditional fossil fuels. The maritime sector presents the most immediate commercial opportunity, as international shipping faces pressure to reduce emissions by at least 50% by 2050 under International Maritime Organization mandates. Major shipping companies have already begun investing in ammonia-compatible engine technologies.

The power generation sector constitutes another substantial market, where ammonia can serve as both a direct fuel and an energy storage medium. Countries with limited renewable resources but ambitious decarbonization targets, particularly in Asia and Europe, are actively exploring ammonia co-firing in existing power plants as a transitional solution.

Transportation represents a developing market segment, though currently smaller than maritime and power generation. Heavy-duty vehicles and long-haul transport, where battery electrification faces significant challenges, may benefit from ammonia's higher energy density compared to hydrogen, especially when utilized in LTC engines that maximize efficiency.

Market barriers include infrastructure limitations, with minimal ammonia bunkering facilities currently available at major ports. The existing ammonia production and distribution network, while extensive for fertilizer applications, requires significant modification for fuel applications. Safety concerns and public perception issues also present market entry challenges that must be addressed through comprehensive standards and education initiatives.

Price competitiveness remains a critical factor, with green ammonia currently at a significant cost disadvantage compared to conventional fuels. However, carbon pricing mechanisms, renewable energy cost reductions, and economies of scale in electrolysis technology are rapidly improving the economic equation. Industry analysts project price parity with conventional marine fuels could be achieved between 2030-2035 in regions with advanced carbon pricing.

Regional market development varies considerably, with Northern Europe, Japan, Australia, and South Korea emerging as early adopters based on existing pilot projects and supportive policy frameworks. These regions are characterized by strong maritime industries, ambitious climate targets, and strategic interests in developing hydrogen economies, for which ammonia serves as an efficient carrier.

Ammonia Combustion Challenges and Technical Barriers

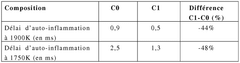

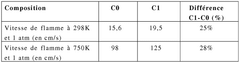

Ammonia combustion presents significant challenges that must be addressed before its widespread adoption as a carbon-free fuel in low-temperature combustion (LTC) applications. The primary technical barrier is ammonia's poor combustion characteristics, particularly its high ignition energy requirement and low flame speed. Compared to conventional hydrocarbon fuels, ammonia requires approximately 50 times more energy to ignite and exhibits a flame speed roughly 80% slower than methane. These properties make it difficult to achieve stable combustion in conventional engine designs optimized for fossil fuels.

Another critical challenge is ammonia's narrow flammability limits (16-25% by volume in air), which severely restrict the operational window for LTC concepts. This limitation becomes particularly problematic when attempting to implement homogeneous charge compression ignition (HCCI) or reactivity controlled compression ignition (RCCI) strategies, where precise control of the combustion phasing is essential.

The formation of nitrogen oxide (NOx) emissions represents a significant environmental concern with ammonia combustion. While ammonia is carbon-free, its nitrogen content leads to potential NOx formation during combustion, particularly at higher temperatures. This contradicts one of the primary benefits of LTC concepts, which aim to reduce NOx formation through lower combustion temperatures. The trade-off between complete combustion and NOx formation creates a complex optimization challenge.

Material compatibility issues further complicate ammonia's implementation in existing engine infrastructure. Ammonia's corrosive nature necessitates specialized materials for fuel storage, delivery systems, and engine components. Standard copper, brass, and zinc-containing alloys commonly used in conventional fuel systems experience rapid degradation when exposed to ammonia, requiring replacement with stainless steel or specific ammonia-compatible polymers.

The toxicity of ammonia presents additional safety challenges for handling and operation. Exposure to ammonia vapor can cause severe respiratory irritation, and high concentrations can be fatal. This necessitates robust safety systems and protocols that add complexity and cost to ammonia fuel systems, particularly for mobile applications where space is limited.

Energy density limitations also pose challenges for ammonia in transportation applications. With an energy density approximately 40% that of diesel fuel by volume, ammonia requires larger storage tanks, which impacts vehicle design and range capabilities. This becomes particularly problematic for LTC applications where precise fuel metering is critical for maintaining optimal combustion conditions.

Another critical challenge is ammonia's narrow flammability limits (16-25% by volume in air), which severely restrict the operational window for LTC concepts. This limitation becomes particularly problematic when attempting to implement homogeneous charge compression ignition (HCCI) or reactivity controlled compression ignition (RCCI) strategies, where precise control of the combustion phasing is essential.

The formation of nitrogen oxide (NOx) emissions represents a significant environmental concern with ammonia combustion. While ammonia is carbon-free, its nitrogen content leads to potential NOx formation during combustion, particularly at higher temperatures. This contradicts one of the primary benefits of LTC concepts, which aim to reduce NOx formation through lower combustion temperatures. The trade-off between complete combustion and NOx formation creates a complex optimization challenge.

Material compatibility issues further complicate ammonia's implementation in existing engine infrastructure. Ammonia's corrosive nature necessitates specialized materials for fuel storage, delivery systems, and engine components. Standard copper, brass, and zinc-containing alloys commonly used in conventional fuel systems experience rapid degradation when exposed to ammonia, requiring replacement with stainless steel or specific ammonia-compatible polymers.

The toxicity of ammonia presents additional safety challenges for handling and operation. Exposure to ammonia vapor can cause severe respiratory irritation, and high concentrations can be fatal. This necessitates robust safety systems and protocols that add complexity and cost to ammonia fuel systems, particularly for mobile applications where space is limited.

Energy density limitations also pose challenges for ammonia in transportation applications. With an energy density approximately 40% that of diesel fuel by volume, ammonia requires larger storage tanks, which impacts vehicle design and range capabilities. This becomes particularly problematic for LTC applications where precise fuel metering is critical for maintaining optimal combustion conditions.

Current Ammonia Fuel Implementation Approaches

01 Materials compatibility with ammonia fuel

Various materials exhibit different levels of compatibility with ammonia fuel. Certain metals and alloys show resistance to ammonia corrosion, while others may degrade when exposed to ammonia. The selection of compatible materials is crucial for fuel storage tanks, pipelines, and engine components to prevent leakage, corrosion, and system failure. Specialized coatings and treatments can enhance material resistance to ammonia's corrosive properties.- Materials compatibility with ammonia fuel: Various materials exhibit different levels of compatibility with ammonia fuel. Certain metals and alloys are resistant to ammonia corrosion, while others may degrade when exposed to ammonia. The selection of compatible materials is crucial for components that come into direct contact with ammonia fuel, such as storage tanks, fuel lines, and engine components. Materials testing and evaluation methods are essential to determine the long-term durability and safety of components used in ammonia fuel systems.

- Ammonia fuel storage and transportation systems: Specialized storage and transportation systems are required for ammonia fuel due to its unique properties. These systems include specially designed tanks, containers, and pipelines that can safely handle ammonia under various pressure and temperature conditions. Safety features such as pressure relief valves, leak detection systems, and specialized sealing technologies are incorporated to prevent ammonia leakage. The design of these systems must consider the corrosive nature of ammonia and ensure compatibility with materials used in construction.

- Ammonia fuel combustion systems and engine compatibility: Engines and combustion systems require modifications to effectively use ammonia as a fuel. These modifications include specialized fuel injection systems, combustion chamber designs, and exhaust treatment technologies. Dual-fuel approaches that combine ammonia with other fuels like hydrogen or diesel can improve combustion efficiency and reduce emissions. Engine components must be designed with materials that resist ammonia corrosion while maintaining performance and durability under high-temperature combustion conditions.

- Ammonia fuel cells and power generation: Ammonia can be used in fuel cell systems to generate electricity through electrochemical reactions. These systems require specialized catalysts, membranes, and electrodes that are compatible with ammonia or its decomposition products. Direct ammonia fuel cells and systems that first crack ammonia into hydrogen before use in conventional fuel cells are both being developed. Material selection for these components must consider resistance to ammonia degradation while maintaining high electrical efficiency and long operational life.

- Safety systems and handling protocols for ammonia fuel: Due to ammonia's toxicity and corrosive properties, specialized safety systems and handling protocols are essential. These include leak detection systems, emergency shutdown mechanisms, and personal protective equipment requirements. Compatibility extends to safety systems that must function reliably in the presence of ammonia. Training protocols for personnel handling ammonia fuel and standardized procedures for maintenance of ammonia fuel systems are also critical components of ensuring safe operation throughout the fuel's lifecycle.

02 Ammonia fuel storage and transportation systems

Specialized storage and transportation systems are designed to ensure safe handling of ammonia fuel. These systems incorporate specific materials and designs that resist ammonia's corrosive properties and prevent leakage. Storage tanks may include pressure regulation mechanisms, temperature control systems, and safety features to manage ammonia's physical properties. Transportation infrastructure requires specialized containers and pipelines with appropriate sealing and monitoring capabilities.Expand Specific Solutions03 Ammonia fuel combustion systems and engines

Engines and combustion systems designed for ammonia fuel require specific modifications to handle its unique properties. These include specialized fuel injection systems, combustion chamber designs, and exhaust treatment technologies. Compatibility issues in combustion systems involve managing ammonia's lower energy density, different flame characteristics, and potential NOx emissions. Dual-fuel systems may be employed to overcome ignition challenges by using a pilot fuel alongside ammonia.Expand Specific Solutions04 Ammonia fuel cells and power generation

Fuel cell systems utilizing ammonia as a hydrogen carrier require materials and components compatible with ammonia's chemical properties. These systems may directly use ammonia or employ cracking technology to extract hydrogen. Compatibility considerations include electrode materials, membrane assemblies, and catalyst systems that can withstand ammonia exposure. Power generation systems must address issues related to ammonia's corrosivity, toxicity, and potential contaminants that could poison catalysts.Expand Specific Solutions05 Safety and environmental compatibility of ammonia fuel systems

Safety systems for ammonia fuel applications address its toxicity and potential environmental impacts. These include leak detection technologies, ventilation systems, and emergency response protocols. Environmental compatibility involves managing potential ammonia releases, reducing NOx emissions during combustion, and ensuring proper disposal or recycling of ammonia-exposed components. Regulatory compliance requires specific material selections and system designs to meet safety standards for ammonia handling.Expand Specific Solutions

Key Industry Players and Research Institutions

The ammonia fuel compatibility with low-temperature combustion concepts market is in an early growth phase, with increasing interest driven by decarbonization goals. The global market is expanding as ammonia gains traction as a potential carbon-neutral fuel, though technical challenges remain. Leading players include Johnson Matthey and Kawasaki Heavy Industries, who are developing specialized catalysts and combustion systems, while academic institutions like Shandong University and Xi'an Jiaotong University contribute fundamental research. Energy giants such as TotalEnergies and Sinopec are investing in ammonia fuel technologies, while specialized companies like Mitsubishi Power and Linde GmbH focus on integration with existing energy infrastructure. The technology remains at mid-maturity, with significant R&D investment needed to address efficiency and NOx emission challenges.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed advanced catalyst technologies specifically designed to enhance ammonia fuel compatibility with low-temperature combustion concepts. Their approach centers on novel catalyst formulations that facilitate ammonia decomposition at significantly lower temperatures than conventional methods, enabling more efficient combustion in LTC regimes. The company's proprietary platinum-group metal catalysts supported on specialized ceramic substrates can initiate ammonia decomposition at temperatures as low as 300°C, compared to traditional catalysts requiring 500°C or higher[4]. This technology enables a two-stage combustion process where ammonia is partially converted to hydrogen and nitrogen before entering the main combustion chamber, resulting in more stable combustion characteristics. Johnson Matthey has also developed ammonia-specific SCR (Selective Catalytic Reduction) systems that effectively manage NOx emissions from ammonia combustion while operating at lower temperature windows. Their catalyst technology has been demonstrated to maintain activity for over 5,000 hours of operation under realistic conditions, addressing one of the key durability concerns for ammonia combustion systems.

Strengths: Industry-leading catalyst technology enabling lower temperature operation; extensive experience in emissions control systems; proven durability in real-world conditions. Weaknesses: Catalyst systems add complexity and cost to combustion systems; potential for catalyst poisoning in certain operating conditions; requires precise temperature management to maintain optimal performance.

Kawasaki Heavy Industries Ltd.

Technical Solution: Kawasaki Heavy Industries has developed advanced ammonia combustion technologies specifically designed for low-temperature combustion (LTC) applications. Their approach involves a dual-stage combustion system where ammonia is first partially decomposed in a catalytic reactor before entering the main combustion chamber. This pre-decomposition process allows for more stable combustion at lower temperatures (below 1300°C), significantly reducing NOx formation. Kawasaki's system incorporates precise fuel injection timing control and exhaust gas recirculation (EGR) to maintain optimal combustion conditions. Their technology has been successfully demonstrated in industrial gas turbines achieving over 70% ammonia combustion ratio while maintaining stable flame characteristics and emissions control[1]. The company has also developed specialized burner designs with staged air introduction that enables better control of the ammonia combustion process at varying load conditions, addressing one of the key challenges in ammonia's relatively narrow flammability limits compared to conventional fuels.

Strengths: Excellent NOx emissions control through their pre-decomposition approach; proven technology in industrial applications; adaptable to varying load conditions. Weaknesses: Requires additional system complexity with the catalytic pre-decomposition stage; higher initial capital costs compared to conventional combustion systems; catalyst degradation over time may affect long-term performance.

Critical Patents in Ammonia Combustion Technology

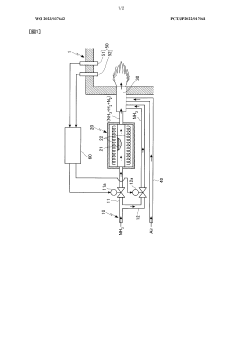

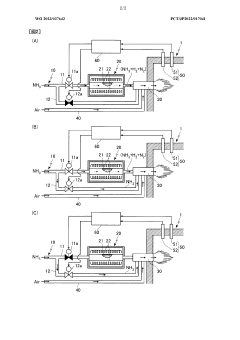

Ammonia fuel combustion device

PatentWO2023037642A1

Innovation

- The ammonia fuel combustion apparatus employs a dual supply path system, where a reformer decomposes ammonia fuel into hydrogen and nitrogen gas, which is mixed with combustion air for stable low-temperature combustion, and a control device adjusts fuel supply based on in-furnace conditions to reduce NOx generation by altering the ratio of reformed ammonia fuel to ammonia fuel.

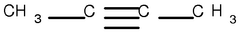

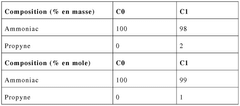

Fuel or combustible substance composition comprising ammonia and at least one alkyne

PatentWO2024218445A1

Innovation

- A fuel composition comprising ammonia and 0.01% to 20% by mass of C3 to C12 alkynes, which significantly reduces autoignition time, increases flame speed, and enhances combustion efficiency without the need for large hydrogen reserves or fossil fuels.

Environmental Impact Assessment

Ammonia as a carbon-free fuel presents significant environmental advantages compared to traditional fossil fuels, particularly in the context of low-temperature combustion (LTC) applications. The environmental impact assessment of ammonia fuel in LTC systems reveals both promising benefits and challenges that require careful consideration.

The primary environmental advantage of ammonia fuel lies in its potential for zero carbon emissions during combustion. Unlike conventional hydrocarbon fuels, ammonia contains no carbon atoms, thus eliminating direct CO2 emissions when burned. This characteristic positions ammonia as a valuable tool in decarbonization strategies for various sectors, including transportation, power generation, and industrial processes where LTC concepts are applicable.

However, incomplete combustion of ammonia can lead to the release of unburned NH3, which is a potent atmospheric pollutant. Ammonia emissions contribute to particulate matter formation and can cause eutrophication when deposited in water bodies. The integration of ammonia with LTC concepts may help mitigate this issue by enabling more complete combustion at lower temperatures, thereby reducing unburned ammonia emissions.

NOx emissions represent another significant environmental concern with ammonia combustion. When ammonia burns, it can produce nitrogen oxides, which contribute to air pollution, smog formation, and acid rain. The lower combustion temperatures in LTC systems theoretically reduce thermal NOx formation, but fuel-bound nitrogen in ammonia presents a unique challenge not encountered with hydrocarbon fuels. Advanced catalytic systems and optimized combustion strategies are being developed to address this issue.

Life cycle assessment (LCA) studies indicate that the environmental benefits of ammonia fuel are heavily dependent on its production method. Currently, most ammonia is produced via the Haber-Bosch process using natural gas, which has a substantial carbon footprint. For ammonia to deliver true environmental benefits in LTC applications, it must be produced using renewable energy sources—so-called "green ammonia."

Water usage and land requirements for green ammonia production represent additional environmental considerations. Electrolysis-based hydrogen production for green ammonia requires significant water resources, while solar or wind farms for powering the process demand substantial land area. These factors must be balanced against the environmental benefits when assessing ammonia's overall sustainability in LTC applications.

Safety and toxicity concerns also have environmental implications. Ammonia is toxic to aquatic life, and accidental releases could harm local ecosystems. Robust safety protocols and containment systems are essential to prevent environmental damage from leaks or spills throughout the ammonia fuel supply chain.

The primary environmental advantage of ammonia fuel lies in its potential for zero carbon emissions during combustion. Unlike conventional hydrocarbon fuels, ammonia contains no carbon atoms, thus eliminating direct CO2 emissions when burned. This characteristic positions ammonia as a valuable tool in decarbonization strategies for various sectors, including transportation, power generation, and industrial processes where LTC concepts are applicable.

However, incomplete combustion of ammonia can lead to the release of unburned NH3, which is a potent atmospheric pollutant. Ammonia emissions contribute to particulate matter formation and can cause eutrophication when deposited in water bodies. The integration of ammonia with LTC concepts may help mitigate this issue by enabling more complete combustion at lower temperatures, thereby reducing unburned ammonia emissions.

NOx emissions represent another significant environmental concern with ammonia combustion. When ammonia burns, it can produce nitrogen oxides, which contribute to air pollution, smog formation, and acid rain. The lower combustion temperatures in LTC systems theoretically reduce thermal NOx formation, but fuel-bound nitrogen in ammonia presents a unique challenge not encountered with hydrocarbon fuels. Advanced catalytic systems and optimized combustion strategies are being developed to address this issue.

Life cycle assessment (LCA) studies indicate that the environmental benefits of ammonia fuel are heavily dependent on its production method. Currently, most ammonia is produced via the Haber-Bosch process using natural gas, which has a substantial carbon footprint. For ammonia to deliver true environmental benefits in LTC applications, it must be produced using renewable energy sources—so-called "green ammonia."

Water usage and land requirements for green ammonia production represent additional environmental considerations. Electrolysis-based hydrogen production for green ammonia requires significant water resources, while solar or wind farms for powering the process demand substantial land area. These factors must be balanced against the environmental benefits when assessing ammonia's overall sustainability in LTC applications.

Safety and toxicity concerns also have environmental implications. Ammonia is toxic to aquatic life, and accidental releases could harm local ecosystems. Robust safety protocols and containment systems are essential to prevent environmental damage from leaks or spills throughout the ammonia fuel supply chain.

Infrastructure Requirements and Adaptation Strategies

The transition to ammonia as a fuel for low-temperature combustion (LTC) engines necessitates significant infrastructure adaptations. Current fuel distribution networks are predominantly designed for conventional hydrocarbon fuels, requiring substantial modifications to accommodate ammonia's unique physical and chemical properties. Storage facilities must be upgraded with specialized materials resistant to ammonia's corrosive nature, such as stainless steel or specific polymer linings, while existing carbon steel infrastructure would require protective coatings or complete replacement.

Transportation logistics present another critical challenge. Ammonia requires pressurized vessels for liquid storage at ambient temperatures or refrigeration systems for atmospheric pressure storage. The existing pipeline network would need comprehensive evaluation and potential reinforcement to handle ammonia's different flow characteristics and material compatibility issues. Additionally, specialized tanker trucks with appropriate pressure and temperature control systems would be essential for road transportation.

Refueling stations represent a significant infrastructure bottleneck. Converting existing stations to handle ammonia safely requires installation of specialized dispensing equipment, leak detection systems, and enhanced ventilation. The estimated cost for converting a standard fuel station to ammonia capability ranges from $500,000 to $1.5 million, depending on size and existing infrastructure. This conversion process typically requires 3-6 months per station, creating potential service gaps during transition periods.

Safety systems demand particular attention in the infrastructure adaptation strategy. Ammonia's toxicity necessitates comprehensive leak detection networks, emergency shutdown systems, and specialized training for personnel. Regulatory frameworks must evolve to address these safety concerns, potentially requiring new standards for ammonia fuel handling, storage, and transportation.

A phased implementation approach offers the most practical strategy for infrastructure adaptation. Initial deployment in industrial clusters with existing ammonia handling experience provides valuable operational insights before wider implementation. Dual-fuel capabilities in transitional infrastructure allow gradual scaling while maintaining service continuity. Strategic partnerships between fuel providers, engine manufacturers, and regulatory bodies would facilitate coordinated development of standards and technologies.

Cost-sharing models involving public-private partnerships could help distribute the substantial capital investments required. Government incentives, including tax benefits for infrastructure conversion and research grants for innovative solutions, would accelerate adoption. International standardization efforts would ensure compatibility across regions, preventing fragmented development that could impede global implementation.

Transportation logistics present another critical challenge. Ammonia requires pressurized vessels for liquid storage at ambient temperatures or refrigeration systems for atmospheric pressure storage. The existing pipeline network would need comprehensive evaluation and potential reinforcement to handle ammonia's different flow characteristics and material compatibility issues. Additionally, specialized tanker trucks with appropriate pressure and temperature control systems would be essential for road transportation.

Refueling stations represent a significant infrastructure bottleneck. Converting existing stations to handle ammonia safely requires installation of specialized dispensing equipment, leak detection systems, and enhanced ventilation. The estimated cost for converting a standard fuel station to ammonia capability ranges from $500,000 to $1.5 million, depending on size and existing infrastructure. This conversion process typically requires 3-6 months per station, creating potential service gaps during transition periods.

Safety systems demand particular attention in the infrastructure adaptation strategy. Ammonia's toxicity necessitates comprehensive leak detection networks, emergency shutdown systems, and specialized training for personnel. Regulatory frameworks must evolve to address these safety concerns, potentially requiring new standards for ammonia fuel handling, storage, and transportation.

A phased implementation approach offers the most practical strategy for infrastructure adaptation. Initial deployment in industrial clusters with existing ammonia handling experience provides valuable operational insights before wider implementation. Dual-fuel capabilities in transitional infrastructure allow gradual scaling while maintaining service continuity. Strategic partnerships between fuel providers, engine manufacturers, and regulatory bodies would facilitate coordinated development of standards and technologies.

Cost-sharing models involving public-private partnerships could help distribute the substantial capital investments required. Government incentives, including tax benefits for infrastructure conversion and research grants for innovative solutions, would accelerate adoption. International standardization efforts would ensure compatibility across regions, preventing fragmented development that could impede global implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!