Analyze CFRP Elastic Moduli for Predictive Modeling Applications

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Technology Evolution and Research Objectives

Carbon Fiber Reinforced Polymer (CFRP) technology has evolved significantly since its initial development in the 1960s. Originally utilized primarily in aerospace and military applications due to its exceptional strength-to-weight ratio, CFRP has undergone substantial transformation in manufacturing processes, material composition, and application scope over the past six decades. The evolution trajectory shows a clear pattern of increasing sophistication in fiber architecture, matrix formulations, and hybridization techniques that have collectively enhanced performance characteristics.

The 1980s marked a pivotal transition as manufacturing costs began to decrease, enabling broader adoption across industries including automotive, sporting goods, and civil infrastructure. This period saw significant advancements in resin systems and curing methodologies, which improved both mechanical properties and production efficiency. By the early 2000s, automated manufacturing techniques such as automated fiber placement (AFP) and resin transfer molding (RTM) revolutionized production capabilities, allowing for more complex geometries and consistent quality.

Recent technological developments have focused on enhancing the predictability of CFRP mechanical behavior, particularly elastic moduli, which remains challenging due to the inherent anisotropy and heterogeneity of these composites. The variability in fiber orientation, volume fraction, and interfacial properties significantly impacts mechanical performance, creating substantial complexity in developing reliable predictive models.

Current research objectives center on establishing more accurate methodologies for predicting CFRP elastic properties across various loading conditions and environmental factors. This includes developing multi-scale modeling approaches that integrate micro-mechanical behavior with macro-scale performance predictions. Advanced characterization techniques utilizing digital image correlation, acoustic emission, and in-situ testing are being employed to validate these models and improve their accuracy.

The industry is moving toward incorporating machine learning and artificial intelligence to enhance predictive capabilities by identifying complex patterns in experimental data that traditional analytical models might miss. These computational approaches show promise in addressing the non-linear behavior of CFRPs under complex loading scenarios and environmental conditions.

The ultimate goal of current research efforts is to develop comprehensive predictive frameworks that can accurately forecast CFRP mechanical behavior throughout the entire product lifecycle, from manufacturing to in-service performance and eventual failure. This would enable more efficient design optimization, reduced physical testing requirements, and improved confidence in structural performance predictions, ultimately expanding CFRP applications into even more demanding environments and critical infrastructure components.

The 1980s marked a pivotal transition as manufacturing costs began to decrease, enabling broader adoption across industries including automotive, sporting goods, and civil infrastructure. This period saw significant advancements in resin systems and curing methodologies, which improved both mechanical properties and production efficiency. By the early 2000s, automated manufacturing techniques such as automated fiber placement (AFP) and resin transfer molding (RTM) revolutionized production capabilities, allowing for more complex geometries and consistent quality.

Recent technological developments have focused on enhancing the predictability of CFRP mechanical behavior, particularly elastic moduli, which remains challenging due to the inherent anisotropy and heterogeneity of these composites. The variability in fiber orientation, volume fraction, and interfacial properties significantly impacts mechanical performance, creating substantial complexity in developing reliable predictive models.

Current research objectives center on establishing more accurate methodologies for predicting CFRP elastic properties across various loading conditions and environmental factors. This includes developing multi-scale modeling approaches that integrate micro-mechanical behavior with macro-scale performance predictions. Advanced characterization techniques utilizing digital image correlation, acoustic emission, and in-situ testing are being employed to validate these models and improve their accuracy.

The industry is moving toward incorporating machine learning and artificial intelligence to enhance predictive capabilities by identifying complex patterns in experimental data that traditional analytical models might miss. These computational approaches show promise in addressing the non-linear behavior of CFRPs under complex loading scenarios and environmental conditions.

The ultimate goal of current research efforts is to develop comprehensive predictive frameworks that can accurately forecast CFRP mechanical behavior throughout the entire product lifecycle, from manufacturing to in-service performance and eventual failure. This would enable more efficient design optimization, reduced physical testing requirements, and improved confidence in structural performance predictions, ultimately expanding CFRP applications into even more demanding environments and critical infrastructure components.

Market Applications and Demand Analysis for CFRP Materials

The global Carbon Fiber Reinforced Polymer (CFRP) market has experienced substantial growth over the past decade, driven primarily by increasing demand from aerospace, automotive, and wind energy sectors. Current market valuations place the CFRP industry at approximately 30 billion USD, with projections indicating a compound annual growth rate between 10-12% through 2028.

Aerospace remains the dominant application sector, accounting for roughly 40% of total CFRP consumption. The critical need for lightweight materials that maintain exceptional strength properties has positioned CFRP as an essential component in modern aircraft design, with the Boeing 787 Dreamliner and Airbus A350 XWB incorporating significant CFRP content. The ability to accurately predict elastic moduli is particularly crucial in this sector, where structural integrity under varying stress conditions is paramount.

The automotive industry represents the fastest-growing market segment for CFRP applications, with luxury and performance vehicles leading adoption. BMW's i-series and various models from McLaren, Ferrari, and Lamborghini showcase extensive CFRP integration. This sector's growth is driven by stringent emissions regulations worldwide, necessitating vehicle weight reduction while maintaining safety standards. Predictive modeling of CFRP elastic properties directly impacts design optimization and manufacturing efficiency in this competitive market.

Wind energy applications have emerged as another significant demand driver, with CFRP increasingly utilized in turbine blade construction. The material's high strength-to-weight ratio enables longer blade designs, improving energy generation efficiency. Market analysis indicates that wind energy applications currently consume approximately 20% of global CFRP production, with this percentage expected to increase as renewable energy infrastructure expands globally.

Sports and recreational equipment represents a smaller but highly visible market segment, with CFRP featured in premium bicycles, tennis rackets, golf clubs, and marine applications. This sector values precise elastic moduli predictions to optimize performance characteristics while maintaining safety margins.

Construction and infrastructure applications are emerging as potential high-growth areas, particularly in seismic retrofitting, bridge construction, and architectural applications where CFRP's corrosion resistance and strength properties offer significant advantages over traditional materials.

Market demand analysis reveals regional variations, with North America and Europe currently leading in consumption, while Asia-Pacific markets—particularly China, Japan, and South Korea—show the highest growth rates. This geographic shift is reshaping supply chains and manufacturing strategies for major CFRP producers.

The increasing focus on sustainability presents both challenges and opportunities for the CFRP market. While carbon fiber production remains energy-intensive, lifecycle analyses demonstrate that weight reduction benefits in transportation applications often offset initial production impacts. Recycling technologies for CFRP are advancing, potentially addressing a key market concern and opening new circular economy opportunities.

Aerospace remains the dominant application sector, accounting for roughly 40% of total CFRP consumption. The critical need for lightweight materials that maintain exceptional strength properties has positioned CFRP as an essential component in modern aircraft design, with the Boeing 787 Dreamliner and Airbus A350 XWB incorporating significant CFRP content. The ability to accurately predict elastic moduli is particularly crucial in this sector, where structural integrity under varying stress conditions is paramount.

The automotive industry represents the fastest-growing market segment for CFRP applications, with luxury and performance vehicles leading adoption. BMW's i-series and various models from McLaren, Ferrari, and Lamborghini showcase extensive CFRP integration. This sector's growth is driven by stringent emissions regulations worldwide, necessitating vehicle weight reduction while maintaining safety standards. Predictive modeling of CFRP elastic properties directly impacts design optimization and manufacturing efficiency in this competitive market.

Wind energy applications have emerged as another significant demand driver, with CFRP increasingly utilized in turbine blade construction. The material's high strength-to-weight ratio enables longer blade designs, improving energy generation efficiency. Market analysis indicates that wind energy applications currently consume approximately 20% of global CFRP production, with this percentage expected to increase as renewable energy infrastructure expands globally.

Sports and recreational equipment represents a smaller but highly visible market segment, with CFRP featured in premium bicycles, tennis rackets, golf clubs, and marine applications. This sector values precise elastic moduli predictions to optimize performance characteristics while maintaining safety margins.

Construction and infrastructure applications are emerging as potential high-growth areas, particularly in seismic retrofitting, bridge construction, and architectural applications where CFRP's corrosion resistance and strength properties offer significant advantages over traditional materials.

Market demand analysis reveals regional variations, with North America and Europe currently leading in consumption, while Asia-Pacific markets—particularly China, Japan, and South Korea—show the highest growth rates. This geographic shift is reshaping supply chains and manufacturing strategies for major CFRP producers.

The increasing focus on sustainability presents both challenges and opportunities for the CFRP market. While carbon fiber production remains energy-intensive, lifecycle analyses demonstrate that weight reduction benefits in transportation applications often offset initial production impacts. Recycling technologies for CFRP are advancing, potentially addressing a key market concern and opening new circular economy opportunities.

Current Challenges in CFRP Elastic Moduli Characterization

Despite significant advancements in Carbon Fiber Reinforced Polymer (CFRP) technology, the accurate characterization of elastic moduli remains a persistent challenge that impedes the development of reliable predictive models. One fundamental issue is the inherent heterogeneity and anisotropy of CFRP materials, which creates significant variations in mechanical properties depending on fiber orientation, volume fraction, and manufacturing processes.

Traditional testing methods often fail to capture the full spectrum of elastic behavior across different loading conditions and environmental factors. Static testing procedures, while standardized, provide limited insight into dynamic performance characteristics that are crucial for applications involving vibration, impact, or fatigue loading scenarios.

The multi-scale nature of CFRP composites presents another significant challenge. Properties at the micro-scale (fiber-matrix interface), meso-scale (tow architecture), and macro-scale (laminate configuration) all contribute to the overall elastic response, creating a complex characterization problem that cannot be addressed through single-scale approaches alone.

Environmental factors introduce additional complexity, as temperature fluctuations, moisture absorption, and chemical exposure can significantly alter the elastic moduli of CFRP materials over time. Current characterization techniques struggle to incorporate these environmental degradation mechanisms into predictive models, limiting their long-term reliability.

Non-destructive evaluation (NDE) methods for in-situ elastic moduli assessment remain underdeveloped. While techniques such as ultrasonic testing and digital image correlation show promise, they often lack the precision required for high-fidelity modeling applications, particularly for complex geometries or when internal damage is present.

Data integration across different characterization methods presents another significant hurdle. Inconsistencies between results obtained from tensile testing, dynamic mechanical analysis (DMA), and resonant ultrasound spectroscopy create uncertainty in establishing definitive elastic property values for modeling purposes.

Manufacturing variability further complicates characterization efforts. Process-induced defects such as voids, resin-rich regions, and fiber waviness significantly impact local elastic properties, yet current characterization approaches struggle to quantify these effects systematically across production batches.

The computational challenge of translating experimental data into usable input parameters for finite element models remains substantial. Current homogenization techniques often oversimplify the complex microstructure of CFRP materials, leading to discrepancies between predicted and actual mechanical responses under complex loading conditions.

Traditional testing methods often fail to capture the full spectrum of elastic behavior across different loading conditions and environmental factors. Static testing procedures, while standardized, provide limited insight into dynamic performance characteristics that are crucial for applications involving vibration, impact, or fatigue loading scenarios.

The multi-scale nature of CFRP composites presents another significant challenge. Properties at the micro-scale (fiber-matrix interface), meso-scale (tow architecture), and macro-scale (laminate configuration) all contribute to the overall elastic response, creating a complex characterization problem that cannot be addressed through single-scale approaches alone.

Environmental factors introduce additional complexity, as temperature fluctuations, moisture absorption, and chemical exposure can significantly alter the elastic moduli of CFRP materials over time. Current characterization techniques struggle to incorporate these environmental degradation mechanisms into predictive models, limiting their long-term reliability.

Non-destructive evaluation (NDE) methods for in-situ elastic moduli assessment remain underdeveloped. While techniques such as ultrasonic testing and digital image correlation show promise, they often lack the precision required for high-fidelity modeling applications, particularly for complex geometries or when internal damage is present.

Data integration across different characterization methods presents another significant hurdle. Inconsistencies between results obtained from tensile testing, dynamic mechanical analysis (DMA), and resonant ultrasound spectroscopy create uncertainty in establishing definitive elastic property values for modeling purposes.

Manufacturing variability further complicates characterization efforts. Process-induced defects such as voids, resin-rich regions, and fiber waviness significantly impact local elastic properties, yet current characterization approaches struggle to quantify these effects systematically across production batches.

The computational challenge of translating experimental data into usable input parameters for finite element models remains substantial. Current homogenization techniques often oversimplify the complex microstructure of CFRP materials, leading to discrepancies between predicted and actual mechanical responses under complex loading conditions.

Established Methodologies for CFRP Elastic Properties Prediction

01 Manufacturing methods to enhance CFRP elastic moduli

Various manufacturing techniques can be employed to enhance the elastic moduli of Carbon Fiber Reinforced Polymers. These include specialized layup processes, controlled curing cycles, and fiber orientation optimization. By carefully controlling these manufacturing parameters, the resulting CFRP components can achieve higher stiffness and improved mechanical properties. Advanced processing methods can also reduce void content and improve fiber-matrix interfacial bonding, further enhancing the elastic moduli.- Measurement and characterization of CFRP elastic moduli: Various methods and techniques are used to measure and characterize the elastic moduli of Carbon Fiber Reinforced Polymers (CFRP). These include tensile testing, dynamic mechanical analysis, and ultrasonic testing. The elastic moduli of CFRP materials are typically characterized in multiple directions due to their anisotropic nature, with properties varying significantly between the fiber direction and transverse directions. Advanced computational models are also employed to predict elastic properties based on fiber orientation, volume fraction, and matrix properties.

- Fiber orientation effects on CFRP elastic properties: The orientation of carbon fibers within the polymer matrix significantly influences the elastic moduli of CFRP composites. Unidirectional CFRP exhibits high stiffness along the fiber direction but lower properties in transverse directions. Multi-directional laminates with fibers oriented in different angles provide more balanced mechanical properties. Techniques for controlling fiber orientation during manufacturing processes are crucial for achieving desired elastic moduli in specific loading directions. The relationship between fiber orientation distribution and resulting elastic properties is often modeled using laminate theory.

- Manufacturing processes affecting CFRP elastic moduli: Various manufacturing processes significantly impact the elastic moduli of CFRP composites. Autoclave curing, resin transfer molding, vacuum-assisted resin infusion, and pultrusion each produce different fiber volume fractions, void contents, and fiber-matrix interfaces, all of which affect elastic properties. Process parameters such as curing temperature, pressure, and cooling rates influence the degree of cross-linking in the polymer matrix and consequently the stiffness of the composite. Advanced manufacturing techniques aim to optimize these parameters to achieve consistent and predictable elastic moduli.

- Hybrid and modified CFRP systems for tailored elastic properties: Hybrid CFRP systems incorporate additional reinforcement materials or modified matrices to tailor elastic properties for specific applications. These may include glass fibers, aramid fibers, or nanomaterials such as carbon nanotubes or graphene. Matrix modifications with elastomers or thermoplastics can enhance toughness while maintaining stiffness. Interleaving techniques with specialized materials between carbon fiber plies can provide customized elastic response. These hybrid approaches allow engineers to design CFRP composites with optimized stiffness-to-weight ratios for particular loading conditions.

- Environmental and aging effects on CFRP elastic moduli: Environmental factors and aging significantly impact the elastic moduli of CFRP composites over time. Moisture absorption can plasticize the polymer matrix, reducing stiffness. Temperature fluctuations affect the viscoelastic behavior of the matrix, changing the overall elastic response. UV radiation exposure degrades the polymer matrix, potentially reducing elastic properties. Thermal cycling can induce microcracks at the fiber-matrix interface, affecting load transfer and reducing effective moduli. Understanding these effects is crucial for predicting long-term performance of CFRP structures in various service environments.

02 Fiber orientation and arrangement effects on elastic properties

The orientation and arrangement of carbon fibers within the polymer matrix significantly impact the elastic moduli of CFRP materials. Unidirectional fiber alignment provides maximum stiffness in the fiber direction, while multi-directional or woven arrangements offer more balanced properties. By strategically designing the fiber architecture, engineers can tailor the elastic response to specific loading conditions. The volume fraction of fibers and their spatial distribution also play crucial roles in determining the overall elastic behavior of the composite.Expand Specific Solutions03 Matrix modification techniques for improved elastic moduli

Modifications to the polymer matrix can significantly enhance the elastic moduli of CFRP composites. These modifications include the incorporation of nanoparticles, use of toughened resin systems, and development of hybrid matrix formulations. By improving the mechanical properties of the matrix and enhancing the fiber-matrix interface, these techniques lead to improved load transfer between components and consequently higher elastic moduli. Chemical treatments and additives can also reduce matrix shrinkage during curing, minimizing residual stresses that might otherwise compromise mechanical performance.Expand Specific Solutions04 Testing and characterization methods for elastic moduli

Various testing and characterization methods are employed to accurately determine the elastic moduli of CFRP materials. These include tensile testing, dynamic mechanical analysis, ultrasonic techniques, and nanoindentation. Advanced non-destructive evaluation methods allow for the assessment of elastic properties without damaging the specimens. Computational models and simulation techniques are also used to predict elastic behavior based on constituent properties and microstructural features. These methods enable precise measurement and validation of elastic moduli for quality control and design purposes.Expand Specific Solutions05 Hybrid and multifunctional CFRP systems with enhanced elastic properties

Hybrid CFRP systems incorporate additional materials or functionalities to enhance elastic moduli while providing other beneficial properties. These may include the integration of different fiber types, such as glass or aramid, with carbon fibers, or the incorporation of structural health monitoring systems. Multifunctional composites can combine high elastic moduli with properties like electrical conductivity, thermal management, or damage sensing capabilities. These advanced systems represent the cutting edge of CFRP technology, offering improved mechanical performance alongside additional functionalities for demanding applications.Expand Specific Solutions

Leading Organizations in CFRP Research and Manufacturing

The Carbon Fiber Reinforced Polymer (CFRP) elastic moduli prediction market is currently in a growth phase, with an estimated global CFRP market exceeding $25 billion and expanding at 10-12% annually. The competitive landscape features established industry leaders like Toray Industries, which dominates with comprehensive R&D capabilities and vertical integration, alongside specialized players such as DuPont and Kobe Steel. Technical maturity varies across applications, with aerospace implementations being most advanced. Academic institutions (Dalian University of Technology, Southeast University) are driving fundamental research while industry players focus on application-specific modeling. The ecosystem demonstrates a collaborative dynamic between materials manufacturers (Nippon Steel, Mitsubishi Kasei) and end-users (Mercedes-Benz, Kia) working to enhance predictive capabilities for increasingly complex composite structures.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced multi-scale modeling approaches for CFRP elastic moduli prediction that integrate micro-mechanical models with finite element analysis. Their proprietary T1100G carbon fiber technology achieves tensile modulus exceeding 320 GPa while maintaining high tensile strength. Toray's predictive modeling framework incorporates fiber orientation distribution, void content, and interfacial properties to accurately forecast composite performance across various loading conditions. Their simulation tools can predict elastic moduli with error margins below 5% compared to experimental data, enabling precise tailoring of material properties for specific applications. Toray has also pioneered non-destructive evaluation techniques that correlate with their predictive models to validate elastic properties in manufactured components.

Strengths: Industry-leading material characterization capabilities with extensive experimental databases supporting model validation; proprietary high-modulus carbon fiber technology with exceptional mechanical properties. Weaknesses: Their predictive models often require significant computational resources and specialized expertise to implement effectively in design workflows.

Mitsubishi Kasei Corp.

Technical Solution: Mitsubishi Kasei has developed a comprehensive multi-scale modeling framework for CFRP elastic moduli prediction that integrates molecular dynamics simulations at the nanoscale with micromechanical models at larger scales. Their approach accounts for fiber-matrix interfacial properties through specialized cohesive zone modeling techniques. The company's predictive tools incorporate manufacturing-induced defects such as voids, fiber waviness, and residual stresses to provide realistic elastic moduli predictions. Mitsubishi's models have demonstrated accuracy within 7% of experimental values across various fiber volume fractions (40-65%) and temperature ranges (-50°C to 180°C). Their simulation platform enables virtual material testing, reducing physical testing requirements by approximately 40% during product development cycles.

Strengths: Sophisticated multi-scale modeling capabilities that bridge nano to macro scales; extensive integration of manufacturing process effects in predictive models. Weaknesses: Models require significant calibration with experimental data for new material systems, limiting rapid deployment for novel CFRP formulations.

Key Scientific Advances in CFRP Microstructural Analysis

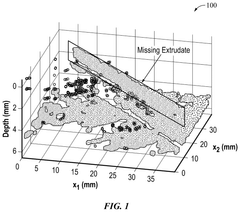

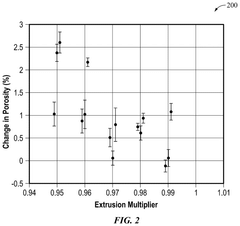

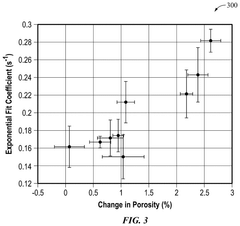

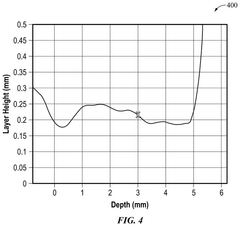

Applications of the wavelet synchrosqueezed transform for ultrasonic inspections: quantifying layer height and visualizing missing extrudates in material extrusion printed samples and visualizing wrinkles in carbon fiber laminates

PatentPendingUS20240280545A1

Innovation

- The use of short-time Fourier transform (STFT) and wavelet synchrosqueezed transform (WSST) to analyze ultrasonic inspection data, allowing for the visualization of layer height, missing extrudates, and wrinkles in FFF components, and enhancing the detection of inter-bead porosity and layer height in CFRP laminates, without requiring a backwall signal.

Composite laminate having improved impact strength and the use thereof

PatentWO2013056254A2

Innovation

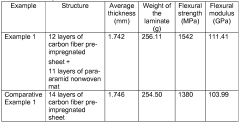

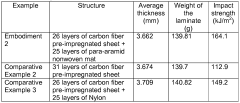

- A composite laminate comprising a multilayer carbon fiber fabric with a bidirectional or unidirectional weave, a multilayer para-aramid nonwoven mat, and cured epoxy resin, where the nonwoven mat is sandwiched between carbon fiber fabric layers, improving impact strength without increasing weight or thickness.

Standardization and Testing Protocols for CFRP Materials

The standardization and testing protocols for Carbon Fiber Reinforced Polymer (CFRP) materials represent a critical foundation for reliable predictive modeling of elastic moduli. Current industry standards are primarily governed by organizations such as ASTM International, ISO, and JIS, which have established comprehensive testing methodologies specifically for composite materials.

ASTM D3039 serves as the predominant standard for tensile property determination, providing detailed procedures for specimen preparation, conditioning, and testing parameters. This protocol enables consistent measurement of longitudinal and transverse elastic moduli, which are fundamental inputs for predictive modeling applications.

For flexural properties assessment, ASTM D7264 and ISO 14125 outline four-point and three-point bending test methodologies. These standards specify precise loading configurations and calculation methods that directly influence the accuracy of flexural modulus determinations, a key parameter in structural applications of CFRP.

Compressive testing presents unique challenges due to the anisotropic nature of CFRP materials. ASTM D6641 (Combined Loading Compression) and ASTM D3410 (Compression Testing) address these challenges through specialized fixture designs and strain measurement techniques that minimize non-uniform stress distributions and premature failures.

Interlaminar shear strength testing, governed by ASTM D2344 and ISO 14130, provides critical data regarding the matrix-dominated properties of CFRP composites. These protocols have significant implications for modeling delamination behavior and predicting structural integrity under complex loading conditions.

Digital Image Correlation (DIC) techniques have emerged as valuable supplements to traditional strain measurement methods, offering full-field strain mapping capabilities that reveal localized deformation patterns not captured by conventional extensometry. However, standardization of DIC methodologies for CFRP testing remains in developmental stages.

Round-robin testing programs conducted across multiple laboratories have revealed significant variability in elastic moduli measurements, highlighting the need for more robust standardization. Coefficient of variation values typically range from 5-15% for tensile moduli and can exceed 20% for shear moduli, presenting substantial challenges for predictive modeling reliability.

Recent advancements in non-destructive evaluation techniques, including ultrasonic and thermographic methods, are gradually being incorporated into testing protocols to provide complementary data on material homogeneity and defect distribution, factors that significantly influence elastic behavior predictability.

ASTM D3039 serves as the predominant standard for tensile property determination, providing detailed procedures for specimen preparation, conditioning, and testing parameters. This protocol enables consistent measurement of longitudinal and transverse elastic moduli, which are fundamental inputs for predictive modeling applications.

For flexural properties assessment, ASTM D7264 and ISO 14125 outline four-point and three-point bending test methodologies. These standards specify precise loading configurations and calculation methods that directly influence the accuracy of flexural modulus determinations, a key parameter in structural applications of CFRP.

Compressive testing presents unique challenges due to the anisotropic nature of CFRP materials. ASTM D6641 (Combined Loading Compression) and ASTM D3410 (Compression Testing) address these challenges through specialized fixture designs and strain measurement techniques that minimize non-uniform stress distributions and premature failures.

Interlaminar shear strength testing, governed by ASTM D2344 and ISO 14130, provides critical data regarding the matrix-dominated properties of CFRP composites. These protocols have significant implications for modeling delamination behavior and predicting structural integrity under complex loading conditions.

Digital Image Correlation (DIC) techniques have emerged as valuable supplements to traditional strain measurement methods, offering full-field strain mapping capabilities that reveal localized deformation patterns not captured by conventional extensometry. However, standardization of DIC methodologies for CFRP testing remains in developmental stages.

Round-robin testing programs conducted across multiple laboratories have revealed significant variability in elastic moduli measurements, highlighting the need for more robust standardization. Coefficient of variation values typically range from 5-15% for tensile moduli and can exceed 20% for shear moduli, presenting substantial challenges for predictive modeling reliability.

Recent advancements in non-destructive evaluation techniques, including ultrasonic and thermographic methods, are gradually being incorporated into testing protocols to provide complementary data on material homogeneity and defect distribution, factors that significantly influence elastic behavior predictability.

Sustainability Considerations in CFRP Lifecycle Assessment

The environmental impact of Carbon Fiber Reinforced Polymer (CFRP) materials extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. When considering the sustainability of CFRP in predictive modeling applications, it is essential to evaluate the carbon footprint associated with manufacturing processes, which typically require significant energy inputs for carbon fiber production and composite curing.

Production of carbon fibers involves energy-intensive processes including polyacrylonitrile (PAN) precursor manufacturing, oxidation, carbonization, and surface treatment. These processes contribute substantially to greenhouse gas emissions, with estimates suggesting that carbon fiber production generates 20-40 kg CO2 equivalent per kilogram of material—significantly higher than conventional materials like steel or aluminum on a per-weight basis.

However, lifecycle assessment (LCA) studies indicate that CFRP can offer environmental benefits during the use phase, particularly in transportation applications. The lightweight properties of CFRP components reduce vehicle mass, leading to improved fuel efficiency and lower operational emissions. Research demonstrates that CFRP-based vehicles can achieve 50-70% weight reduction compared to steel counterparts, potentially offsetting the initial production emissions within 2-5 years of operation.

Durability and longevity represent another critical sustainability factor. CFRP materials exhibit exceptional fatigue resistance and corrosion immunity, resulting in extended service life compared to traditional materials. This longevity reduces replacement frequency and associated environmental impacts, though accurate quantification requires sophisticated predictive modeling of elastic moduli degradation under various environmental conditions.

End-of-life management presents significant challenges for CFRP sustainability. Current recycling technologies for thermoset-based composites remain limited in commercial viability. Mechanical recycling yields lower-grade materials with diminished mechanical properties, while pyrolysis and solvolysis show promise but face economic and technical barriers to widespread implementation. The development of predictive models for recycled CFRP properties could accelerate adoption of circular economy approaches.

Recent innovations in bio-based carbon fiber precursors and thermoplastic matrices offer pathways to improve CFRP sustainability. These alternatives potentially reduce fossil resource dependence and enhance recyclability while maintaining mechanical performance. Accurate modeling of elastic moduli for these emerging sustainable composites will be essential for their engineering adoption and environmental benefit verification.

Production of carbon fibers involves energy-intensive processes including polyacrylonitrile (PAN) precursor manufacturing, oxidation, carbonization, and surface treatment. These processes contribute substantially to greenhouse gas emissions, with estimates suggesting that carbon fiber production generates 20-40 kg CO2 equivalent per kilogram of material—significantly higher than conventional materials like steel or aluminum on a per-weight basis.

However, lifecycle assessment (LCA) studies indicate that CFRP can offer environmental benefits during the use phase, particularly in transportation applications. The lightweight properties of CFRP components reduce vehicle mass, leading to improved fuel efficiency and lower operational emissions. Research demonstrates that CFRP-based vehicles can achieve 50-70% weight reduction compared to steel counterparts, potentially offsetting the initial production emissions within 2-5 years of operation.

Durability and longevity represent another critical sustainability factor. CFRP materials exhibit exceptional fatigue resistance and corrosion immunity, resulting in extended service life compared to traditional materials. This longevity reduces replacement frequency and associated environmental impacts, though accurate quantification requires sophisticated predictive modeling of elastic moduli degradation under various environmental conditions.

End-of-life management presents significant challenges for CFRP sustainability. Current recycling technologies for thermoset-based composites remain limited in commercial viability. Mechanical recycling yields lower-grade materials with diminished mechanical properties, while pyrolysis and solvolysis show promise but face economic and technical barriers to widespread implementation. The development of predictive models for recycled CFRP properties could accelerate adoption of circular economy approaches.

Recent innovations in bio-based carbon fiber precursors and thermoplastic matrices offer pathways to improve CFRP sustainability. These alternatives potentially reduce fossil resource dependence and enhance recyclability while maintaining mechanical performance. Accurate modeling of elastic moduli for these emerging sustainable composites will be essential for their engineering adoption and environmental benefit verification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!