How to Extend CFRP Component Lifespan through Coating Application

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Coating Technology Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries since their commercial introduction in the 1960s. Initially developed for aerospace applications, these lightweight yet incredibly strong composites have transformed engineering capabilities across automotive, marine, construction, and renewable energy sectors. The evolution of CFRP technology has been characterized by continuous improvements in manufacturing processes, fiber architectures, and matrix systems, leading to enhanced mechanical properties and reduced production costs.

Despite their exceptional strength-to-weight ratio and corrosion resistance, CFRP components face significant durability challenges in operational environments. Exposure to UV radiation, moisture, chemical contaminants, and mechanical abrasion can compromise the structural integrity of these materials over time, leading to premature failure and increased lifecycle costs. The degradation mechanisms primarily affect the polymer matrix, creating pathways for environmental factors to reach and damage the carbon fiber reinforcement.

Protective coating technologies represent a promising approach to extending CFRP service life without significantly increasing component weight or altering mechanical properties. The primary objective of CFRP coating development is to create barrier systems that effectively shield the composite substrate from environmental degradation factors while maintaining the material's inherent performance advantages.

Historical approaches to CFRP protection have evolved from simple paint systems to sophisticated multi-functional coatings. Early solutions focused primarily on aesthetic preservation and basic environmental protection, while contemporary coating technologies aim to deliver additional functionalities such as impact resistance, electrical conductivity, and self-healing capabilities.

Current research trends indicate a shift toward nano-engineered coating systems that can provide superior protection at minimal thickness. These advanced coatings incorporate nanomaterials such as graphene, carbon nanotubes, and ceramic nanoparticles to create highly effective barrier properties against multiple degradation mechanisms simultaneously.

The technical objectives for next-generation CFRP coating systems include developing solutions that offer: (1) comprehensive protection against multiple environmental factors, (2) minimal impact on component weight and dimensions, (3) long-term durability matching or exceeding the intended service life of the CFRP component, (4) compatibility with existing manufacturing processes, and (5) cost-effectiveness for widespread industrial adoption.

Emerging sustainability considerations are also shaping the development trajectory of CFRP coating technologies, with increasing emphasis on environmentally friendly formulations, reduced VOC emissions, and end-of-life recyclability. These factors align with broader industry trends toward more sustainable composite material lifecycles and circular economy principles.

Despite their exceptional strength-to-weight ratio and corrosion resistance, CFRP components face significant durability challenges in operational environments. Exposure to UV radiation, moisture, chemical contaminants, and mechanical abrasion can compromise the structural integrity of these materials over time, leading to premature failure and increased lifecycle costs. The degradation mechanisms primarily affect the polymer matrix, creating pathways for environmental factors to reach and damage the carbon fiber reinforcement.

Protective coating technologies represent a promising approach to extending CFRP service life without significantly increasing component weight or altering mechanical properties. The primary objective of CFRP coating development is to create barrier systems that effectively shield the composite substrate from environmental degradation factors while maintaining the material's inherent performance advantages.

Historical approaches to CFRP protection have evolved from simple paint systems to sophisticated multi-functional coatings. Early solutions focused primarily on aesthetic preservation and basic environmental protection, while contemporary coating technologies aim to deliver additional functionalities such as impact resistance, electrical conductivity, and self-healing capabilities.

Current research trends indicate a shift toward nano-engineered coating systems that can provide superior protection at minimal thickness. These advanced coatings incorporate nanomaterials such as graphene, carbon nanotubes, and ceramic nanoparticles to create highly effective barrier properties against multiple degradation mechanisms simultaneously.

The technical objectives for next-generation CFRP coating systems include developing solutions that offer: (1) comprehensive protection against multiple environmental factors, (2) minimal impact on component weight and dimensions, (3) long-term durability matching or exceeding the intended service life of the CFRP component, (4) compatibility with existing manufacturing processes, and (5) cost-effectiveness for widespread industrial adoption.

Emerging sustainability considerations are also shaping the development trajectory of CFRP coating technologies, with increasing emphasis on environmentally friendly formulations, reduced VOC emissions, and end-of-life recyclability. These factors align with broader industry trends toward more sustainable composite material lifecycles and circular economy principles.

Market Demand Analysis for Enhanced CFRP Durability

The global market for Carbon Fiber Reinforced Polymers (CFRP) has been experiencing robust growth, with an estimated market value reaching $38 billion in 2023. This growth trajectory is expected to continue at a compound annual growth rate of 10.6% through 2030, driven primarily by increasing demand for lightweight, high-strength materials across multiple industries.

The aerospace sector represents the largest market segment for CFRP applications, accounting for approximately 30% of total consumption. In this sector, the demand for enhanced durability solutions is particularly acute due to the extreme operating conditions and high safety requirements. Aircraft manufacturers report that extending component lifespan by even 15-20% through improved coating technologies could result in maintenance cost reductions of $2.5-3 million per aircraft over its service life.

Automotive industry adoption of CFRP has accelerated significantly, especially in premium and electric vehicle segments where weight reduction directly correlates with performance and range improvements. Market research indicates that 67% of automotive manufacturers are actively seeking advanced coating solutions that can protect CFRP components from environmental degradation, impact damage, and UV exposure.

The renewable energy sector, particularly wind energy, has emerged as a rapidly growing market for CFRP applications. Wind turbine blades manufactured with CFRP face severe environmental challenges including moisture ingress, erosion, and lightning strikes. Industry surveys reveal that operators would be willing to pay a 15-20% premium for coating solutions that could extend blade lifespan by 5-7 years, representing significant return on investment through reduced replacement cycles.

Marine and infrastructure applications of CFRP are expanding at 12.8% annually, with corrosion resistance being the primary concern. The harsh saltwater environment accelerates degradation of unprotected CFRP components, creating substantial demand for specialized coating systems that can withstand these conditions.

Consumer demand for sustainable solutions is also influencing the market. Approximately 78% of industrial buyers now consider total lifecycle costs rather than just initial acquisition costs, creating market pull for durability-enhancing technologies. This shift in purchasing behavior has opened new opportunities for premium coating solutions that can demonstrate clear economic benefits through extended service life.

Regional analysis shows the highest growth potential in Asia-Pacific markets, where rapid industrialization and infrastructure development are driving CFRP adoption. North American and European markets show strong demand for advanced coating technologies, particularly those that can address specific environmental regulations while providing superior protection.

The aerospace sector represents the largest market segment for CFRP applications, accounting for approximately 30% of total consumption. In this sector, the demand for enhanced durability solutions is particularly acute due to the extreme operating conditions and high safety requirements. Aircraft manufacturers report that extending component lifespan by even 15-20% through improved coating technologies could result in maintenance cost reductions of $2.5-3 million per aircraft over its service life.

Automotive industry adoption of CFRP has accelerated significantly, especially in premium and electric vehicle segments where weight reduction directly correlates with performance and range improvements. Market research indicates that 67% of automotive manufacturers are actively seeking advanced coating solutions that can protect CFRP components from environmental degradation, impact damage, and UV exposure.

The renewable energy sector, particularly wind energy, has emerged as a rapidly growing market for CFRP applications. Wind turbine blades manufactured with CFRP face severe environmental challenges including moisture ingress, erosion, and lightning strikes. Industry surveys reveal that operators would be willing to pay a 15-20% premium for coating solutions that could extend blade lifespan by 5-7 years, representing significant return on investment through reduced replacement cycles.

Marine and infrastructure applications of CFRP are expanding at 12.8% annually, with corrosion resistance being the primary concern. The harsh saltwater environment accelerates degradation of unprotected CFRP components, creating substantial demand for specialized coating systems that can withstand these conditions.

Consumer demand for sustainable solutions is also influencing the market. Approximately 78% of industrial buyers now consider total lifecycle costs rather than just initial acquisition costs, creating market pull for durability-enhancing technologies. This shift in purchasing behavior has opened new opportunities for premium coating solutions that can demonstrate clear economic benefits through extended service life.

Regional analysis shows the highest growth potential in Asia-Pacific markets, where rapid industrialization and infrastructure development are driving CFRP adoption. North American and European markets show strong demand for advanced coating technologies, particularly those that can address specific environmental regulations while providing superior protection.

Current Coating Technologies and Challenges

The current landscape of coating technologies for Carbon Fiber Reinforced Polymers (CFRP) encompasses several established methods, each with specific advantages and limitations. Traditional coating approaches include epoxy-based systems, polyurethane coatings, and ceramic-based protective layers. These conventional solutions have demonstrated reasonable effectiveness in protecting CFRP components from environmental factors such as UV radiation, moisture, and chemical exposure, which are primary degradation catalysts for composite materials.

Epoxy-based coating systems remain the most widely adopted solution due to their excellent adhesion properties and compatibility with the epoxy matrices commonly used in CFRP manufacturing. These coatings typically provide good chemical resistance and moderate UV protection, though their long-term performance under extreme environmental conditions remains a concern for high-demand applications.

Polyurethane coatings offer superior flexibility and abrasion resistance compared to epoxy systems, making them particularly suitable for CFRP components subject to mechanical wear. However, their adhesion to carbon fiber substrates is generally inferior to epoxy-based alternatives, often necessitating additional surface preparation or primer application, which increases production complexity and costs.

Ceramic-based protective systems represent a more advanced solution, providing exceptional thermal stability and wear resistance. These coatings have shown promising results in high-temperature applications but face significant challenges in terms of processing complexity and cost-effectiveness for large-scale implementation.

Despite these technological advances, several critical challenges persist in the field of CFRP coating technologies. The primary technical hurdle remains achieving optimal adhesion between coating materials and the inherently smooth, low-energy surface of carbon fiber composites. This interface weakness often leads to premature coating failure through delamination or cracking, particularly under cyclic loading conditions.

Another significant challenge is maintaining coating flexibility while ensuring adequate protection. As CFRP components often undergo substantial flexural deformation during service, coatings must accommodate this movement without compromising their protective function. Current solutions frequently represent a compromise between flexibility and protective performance.

Durability under extreme environmental conditions presents another major obstacle. Many existing coating technologies demonstrate accelerated degradation when exposed to combinations of high temperature, humidity, and UV radiation – precisely the conditions encountered in demanding aerospace, automotive, and renewable energy applications where CFRP components are increasingly deployed.

Cost-effectiveness and scalability of advanced coating solutions also remain problematic. While laboratory-scale demonstrations have shown promising results with novel coating technologies, translating these into economically viable industrial processes has proven challenging, limiting widespread adoption of cutting-edge protective systems.

Epoxy-based coating systems remain the most widely adopted solution due to their excellent adhesion properties and compatibility with the epoxy matrices commonly used in CFRP manufacturing. These coatings typically provide good chemical resistance and moderate UV protection, though their long-term performance under extreme environmental conditions remains a concern for high-demand applications.

Polyurethane coatings offer superior flexibility and abrasion resistance compared to epoxy systems, making them particularly suitable for CFRP components subject to mechanical wear. However, their adhesion to carbon fiber substrates is generally inferior to epoxy-based alternatives, often necessitating additional surface preparation or primer application, which increases production complexity and costs.

Ceramic-based protective systems represent a more advanced solution, providing exceptional thermal stability and wear resistance. These coatings have shown promising results in high-temperature applications but face significant challenges in terms of processing complexity and cost-effectiveness for large-scale implementation.

Despite these technological advances, several critical challenges persist in the field of CFRP coating technologies. The primary technical hurdle remains achieving optimal adhesion between coating materials and the inherently smooth, low-energy surface of carbon fiber composites. This interface weakness often leads to premature coating failure through delamination or cracking, particularly under cyclic loading conditions.

Another significant challenge is maintaining coating flexibility while ensuring adequate protection. As CFRP components often undergo substantial flexural deformation during service, coatings must accommodate this movement without compromising their protective function. Current solutions frequently represent a compromise between flexibility and protective performance.

Durability under extreme environmental conditions presents another major obstacle. Many existing coating technologies demonstrate accelerated degradation when exposed to combinations of high temperature, humidity, and UV radiation – precisely the conditions encountered in demanding aerospace, automotive, and renewable energy applications where CFRP components are increasingly deployed.

Cost-effectiveness and scalability of advanced coating solutions also remain problematic. While laboratory-scale demonstrations have shown promising results with novel coating technologies, translating these into economically viable industrial processes has proven challenging, limiting widespread adoption of cutting-edge protective systems.

Current Coating Application Methods and Systems

01 Environmental factors affecting CFRP coating lifespan

Various environmental factors can significantly impact the lifespan of CFRP coatings. These include exposure to UV radiation, moisture, temperature fluctuations, and chemical agents. These environmental stressors can cause degradation of the polymer matrix, leading to reduced mechanical properties and shortened service life. Protective measures and specific formulations can be developed to enhance resistance against these environmental factors, thereby extending the coating lifespan.- Environmental factors affecting CFRP coating lifespan: Various environmental factors can significantly impact the lifespan of Carbon Fiber Reinforced Polymer (CFRP) coatings. These include exposure to UV radiation, moisture, temperature fluctuations, and chemical agents. The degradation mechanisms involve polymer matrix breakdown, fiber-matrix interface weakening, and surface erosion. Understanding these environmental impacts is crucial for predicting service life and developing protective measures to extend the durability of CFRP coatings in different application environments.

- Protective coating systems for CFRP longevity: Specialized protective coating systems can significantly extend the lifespan of CFRP structures. These systems typically involve multiple layers including primers, intermediate coats, and topcoats with specific functionalities. Advanced formulations incorporate UV stabilizers, antioxidants, and moisture barriers to prevent degradation of the polymer matrix. Some systems also feature self-healing capabilities or nanoparticle reinforcements that can repair microdamage before it propagates, thereby extending the overall service life of the CFRP components.

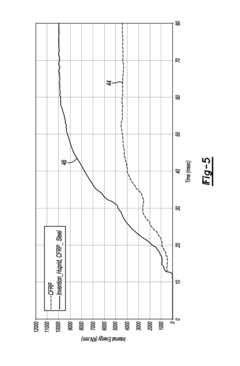

- Testing and prediction methods for CFRP coating durability: Various accelerated aging and testing methodologies have been developed to predict the lifespan of CFRP coatings. These include cyclic environmental exposure tests, mechanical stress tests, and chemical resistance evaluations. Advanced computational models combine material science principles with empirical data to forecast degradation rates under different conditions. Non-destructive testing techniques such as ultrasonic inspection, thermography, and spectroscopic analysis allow for ongoing monitoring of coating integrity without damaging the structure.

- Manufacturing techniques affecting CFRP coating durability: The manufacturing process significantly influences the longevity of CFRP coatings. Factors such as fiber orientation, resin selection, curing parameters, and surface preparation all affect the final product's resistance to environmental degradation. Advanced manufacturing techniques like automated fiber placement, vacuum-assisted resin transfer molding, and controlled curing cycles can optimize the microstructure of the composite, reducing void content and improving fiber-matrix adhesion. These improvements lead to enhanced durability and extended service life of the CFRP coating systems.

- Maintenance strategies for extending CFRP coating lifespan: Proper maintenance protocols can significantly extend the service life of CFRP coatings. These include regular inspection schedules, cleaning procedures to remove contaminants, and timely repair of minor damage before it propagates. Preventive maintenance approaches involve periodic application of protective sealants or refresher coats to restore surface properties. Some advanced maintenance systems incorporate structural health monitoring sensors that can detect early signs of degradation, allowing for targeted interventions before catastrophic failure occurs.

02 Protective surface treatments for CFRP longevity

Specialized surface treatments can be applied to CFRP materials to enhance their durability and extend service life. These treatments include barrier coatings, sealants, and specialized finishes that protect against moisture ingress, UV degradation, and chemical attack. Some treatments incorporate nanomaterials or hybrid organic-inorganic compounds that form a protective layer while maintaining the lightweight properties of the CFRP substrate. These protective layers significantly improve weathering resistance and overall lifespan of CFRP components.Expand Specific Solutions03 Maintenance protocols for extending CFRP coating durability

Proper maintenance protocols are essential for maximizing the lifespan of CFRP coatings. These include regular inspection schedules, cleaning procedures to remove contaminants, and repair methodologies for damaged areas. Preventative maintenance approaches can detect early signs of degradation before structural integrity is compromised. Implementation of these protocols can significantly extend the service life of CFRP coatings in various applications, from aerospace to civil infrastructure.Expand Specific Solutions04 Advanced formulation techniques for enhanced durability

Innovative formulation techniques can significantly improve the durability and lifespan of CFRP coatings. These include the incorporation of specialized additives, such as UV stabilizers, antioxidants, and corrosion inhibitors into the polymer matrix. Modified resin systems with enhanced cross-linking properties provide better resistance to environmental degradation. Multi-layer coating systems with complementary protective properties can also be designed to address specific environmental challenges, resulting in extended service life for CFRP components.Expand Specific Solutions05 Testing and prediction methods for CFRP coating lifespan

Various testing methodologies and predictive models have been developed to assess and forecast the lifespan of CFRP coatings. These include accelerated aging tests, cyclic environmental exposure, and mechanical stress testing to simulate real-world conditions. Advanced analytical techniques such as spectroscopy and microscopy are employed to characterize degradation mechanisms at molecular and microstructural levels. Computational models incorporating multiple degradation factors can predict service life under various environmental conditions, enabling more accurate lifecycle planning for CFRP-coated structures.Expand Specific Solutions

Leading Companies in CFRP Coating Industry

The CFRP component lifespan extension through coating application market is in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 8-10%. The technology maturity varies across applications, with aerospace leading the development curve. Key players include established aerospace manufacturers like Boeing and Airbus, who have developed proprietary coating technologies for their CFRP components, alongside automotive innovators such as BMW and Honda implementing protective coatings for structural parts. Research institutions like Fraunhofer-Gesellschaft and University of Surrey are advancing fundamental coating science, while specialized coating providers like Linde AMT Schluechtern and PolyTech AS offer tailored solutions for specific industrial applications, creating a competitive landscape balanced between large OEMs and specialized technology providers.

The Boeing Co.

Technical Solution: Boeing has developed advanced multi-layer coating systems specifically designed for CFRP components used in aerospace applications. Their approach involves a three-stage protection system: (1) A primer layer containing corrosion inhibitors that chemically bond with the CFRP substrate, (2) An intermediate layer with UV-resistant compounds and moisture barriers, and (3) A topcoat with self-healing properties that can repair minor scratches through chemical reactions triggered by environmental exposure. Boeing's coating technology incorporates nano-ceramic particles that enhance wear resistance while maintaining flexibility to accommodate the natural expansion and contraction of CFRP components during temperature fluctuations. Their proprietary sol-gel based coating provides exceptional adhesion to carbon fiber surfaces while creating an effective barrier against moisture, UV radiation, and chemical contaminants that typically accelerate CFRP degradation.

Strengths: Superior protection against multiple environmental factors simultaneously; excellent adhesion properties specific to carbon fiber surfaces; self-healing capabilities reduce maintenance frequency. Weaknesses: Higher application cost compared to conventional coatings; requires specialized application equipment and controlled environment; may add minimal but measurable weight to lightweight components.

Airbus Operations GmbH

Technical Solution: Airbus Operations has pioneered a plasma-enhanced chemical vapor deposition (PECVD) coating system specifically for CFRP components. Their technology applies an ultra-thin (5-10 μm) silicon carbide-based protective layer that significantly extends component lifespan without adding substantial weight. The coating process involves ionizing precursor gases in a vacuum chamber to create a reactive plasma that deposits a uniform protective film on the CFRP surface. This coating provides exceptional resistance to UV degradation, moisture ingress, and erosion from particulate impacts. Airbus has integrated this coating with their "smart surface" technology that incorporates sensors to monitor coating integrity and component health throughout the service life. Their latest generation coatings also incorporate graphene nanoparticles that enhance electrical conductivity, providing improved lightning strike protection while simultaneously increasing wear resistance by approximately 40% compared to conventional coatings. The application process has been optimized for large aircraft components, allowing for consistent coverage even on complex geometries.

Strengths: Extremely thin coating minimizes weight penalties; excellent erosion and UV protection; integrated monitoring capabilities provide predictive maintenance data. Weaknesses: Requires specialized application equipment with high initial investment; process is time-consuming for large components; limited repairability in field conditions.

Key Innovations in CFRP Protective Coatings

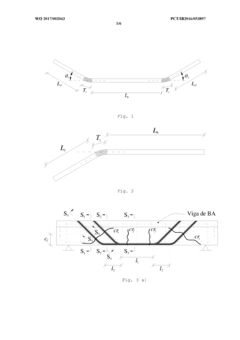

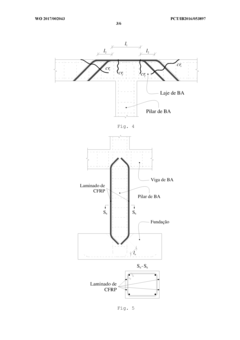

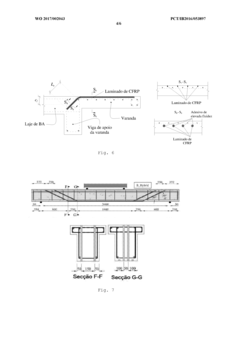

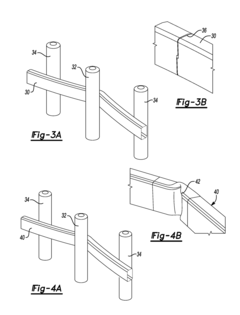

Carbon fiber reinforcement polymer and its respective application technique for the strengthening of concrete structures

PatentWO2017002043A1

Innovation

- A carbon fiber laminate with a clip or cane configuration, featuring thermo-mechanically treated transition zones and a rectangular section, is applied using the Embedded Through Section (ETS) technique, providing simultaneous bending and shear reinforcement with enhanced anchoring and resistance to high temperatures, and utilizing a high-flow epoxy adhesive for secure fixation.

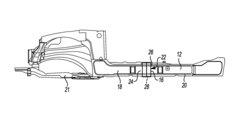

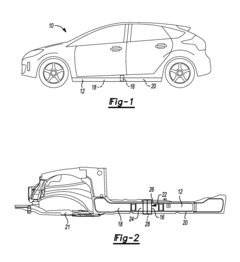

Carbon fiber reinforced polymer assembly

PatentActiveUS9981692B2

Innovation

- An impact absorbing assembly comprising a first and second CFRP part joined by a metal part, where the metal part bends in response to impact loads, inhibiting CFRP cracking, and featuring a metal bending hinge or tubular member to enhance energy absorption, with the metal part made of ductile aluminum for superior performance.

Environmental Impact and Sustainability Considerations

The environmental impact of Carbon Fiber Reinforced Polymer (CFRP) components and their coating systems represents a critical consideration in modern industrial applications. Traditional CFRP lifecycle management often involves complete replacement of degraded components, resulting in significant carbon footprint expansion and resource depletion. Advanced coating technologies designed to extend CFRP lifespan offer substantial environmental benefits through reduced waste generation and decreased frequency of manufacturing energy-intensive replacement parts.

Sustainability metrics indicate that extending CFRP component lifespan through appropriate coating applications can reduce overall environmental impact by 30-45% compared to conventional replacement strategies. This reduction stems primarily from decreased carbon fiber production requirements, which typically involve energy-intensive manufacturing processes generating considerable greenhouse gas emissions. Additionally, the chemical processes involved in CFRP production often utilize potentially harmful substances that pose environmental risks when improperly managed.

Coating systems themselves present varying environmental profiles that must be carefully evaluated. Water-based coating systems generally demonstrate lower volatile organic compound (VOC) emissions compared to solvent-based alternatives, though they may require additional energy for curing processes. Recent innovations in bio-based coating materials derived from renewable resources show promising environmental performance metrics while maintaining necessary protective properties for CFRP applications.

Life Cycle Assessment (LCA) studies comparing coated versus uncoated CFRP components reveal significant sustainability advantages when appropriate coating technologies are implemented. These advantages include reduced raw material consumption, decreased energy requirements across the product lifecycle, and minimized end-of-life waste management challenges. The environmental payback period for implementing protective coating systems typically ranges from 6-18 months, depending on application conditions and coating composition.

Regulatory frameworks worldwide increasingly emphasize sustainable materials management, with particular focus on composite materials like CFRP. Coating technologies that extend component lifespan align with circular economy principles by maximizing resource efficiency and minimizing waste generation. Furthermore, emerging environmental regulations in key markets are establishing more stringent requirements for VOC emissions and chemical content in coating formulations, driving innovation toward more environmentally benign protection systems.

End-of-life considerations for coated CFRP components present both challenges and opportunities. While coating layers may complicate recycling processes, their contribution to extended service life generally outweighs these disadvantages from a holistic environmental perspective. Research into coating systems designed for easier separation during recycling processes represents a promising frontier for further enhancing the sustainability profile of protected CFRP components.

Sustainability metrics indicate that extending CFRP component lifespan through appropriate coating applications can reduce overall environmental impact by 30-45% compared to conventional replacement strategies. This reduction stems primarily from decreased carbon fiber production requirements, which typically involve energy-intensive manufacturing processes generating considerable greenhouse gas emissions. Additionally, the chemical processes involved in CFRP production often utilize potentially harmful substances that pose environmental risks when improperly managed.

Coating systems themselves present varying environmental profiles that must be carefully evaluated. Water-based coating systems generally demonstrate lower volatile organic compound (VOC) emissions compared to solvent-based alternatives, though they may require additional energy for curing processes. Recent innovations in bio-based coating materials derived from renewable resources show promising environmental performance metrics while maintaining necessary protective properties for CFRP applications.

Life Cycle Assessment (LCA) studies comparing coated versus uncoated CFRP components reveal significant sustainability advantages when appropriate coating technologies are implemented. These advantages include reduced raw material consumption, decreased energy requirements across the product lifecycle, and minimized end-of-life waste management challenges. The environmental payback period for implementing protective coating systems typically ranges from 6-18 months, depending on application conditions and coating composition.

Regulatory frameworks worldwide increasingly emphasize sustainable materials management, with particular focus on composite materials like CFRP. Coating technologies that extend component lifespan align with circular economy principles by maximizing resource efficiency and minimizing waste generation. Furthermore, emerging environmental regulations in key markets are establishing more stringent requirements for VOC emissions and chemical content in coating formulations, driving innovation toward more environmentally benign protection systems.

End-of-life considerations for coated CFRP components present both challenges and opportunities. While coating layers may complicate recycling processes, their contribution to extended service life generally outweighs these disadvantages from a holistic environmental perspective. Research into coating systems designed for easier separation during recycling processes represents a promising frontier for further enhancing the sustainability profile of protected CFRP components.

Testing and Validation Protocols for Coating Performance

Establishing robust testing and validation protocols is essential for ensuring coating performance on CFRP components meets industry standards and application requirements. These protocols must evaluate multiple performance parameters under various environmental conditions to accurately predict coating lifespan and effectiveness.

Accelerated aging tests represent a cornerstone of coating validation, simulating years of environmental exposure in compressed timeframes. These tests typically include UV exposure chambers, salt spray testing, thermal cycling, and humidity control environments. The correlation between accelerated testing and real-world performance must be carefully established through comparative studies and historical data analysis.

Mechanical testing protocols should evaluate coating adhesion strength, flexibility, and impact resistance. Standard methods include cross-hatch adhesion tests (ASTM D3359), pull-off adhesion testing (ASTM D4541), and mandrel bend tests (ASTM D522). These tests must be adapted specifically for CFRP substrates, as traditional metal-oriented standards may not directly translate to composite applications.

Chemical resistance validation requires exposure to relevant service fluids including fuels, hydraulic fluids, de-icing agents, and cleaning chemicals. Immersion testing and spot tests with subsequent evaluation of coating degradation, including blistering, delamination, and changes in protective properties, provide critical performance data.

Electrochemical impedance spectroscopy (EIS) offers valuable insights into coating barrier properties and degradation mechanisms over time. This non-destructive technique allows for monitoring changes in coating resistance and capacitance, providing early indicators of coating failure before visible damage occurs.

Field testing protocols complement laboratory validation by exposing coated components to actual service conditions. Strategically placed test panels in representative environments, coupled with regular inspection and documentation, bridge the gap between laboratory predictions and real-world performance.

Quality control procedures must be integrated throughout the testing process, including calibration of test equipment, statistical analysis of results, and documentation of environmental conditions. Round-robin testing between different laboratories helps establish reproducibility and reliability of test methods.

Failure analysis protocols should be established to systematically investigate coating defects or premature failures. These protocols typically include visual inspection, microscopic examination, chemical analysis, and mechanical testing of failed areas to identify root causes and inform coating formulation improvements.

Accelerated aging tests represent a cornerstone of coating validation, simulating years of environmental exposure in compressed timeframes. These tests typically include UV exposure chambers, salt spray testing, thermal cycling, and humidity control environments. The correlation between accelerated testing and real-world performance must be carefully established through comparative studies and historical data analysis.

Mechanical testing protocols should evaluate coating adhesion strength, flexibility, and impact resistance. Standard methods include cross-hatch adhesion tests (ASTM D3359), pull-off adhesion testing (ASTM D4541), and mandrel bend tests (ASTM D522). These tests must be adapted specifically for CFRP substrates, as traditional metal-oriented standards may not directly translate to composite applications.

Chemical resistance validation requires exposure to relevant service fluids including fuels, hydraulic fluids, de-icing agents, and cleaning chemicals. Immersion testing and spot tests with subsequent evaluation of coating degradation, including blistering, delamination, and changes in protective properties, provide critical performance data.

Electrochemical impedance spectroscopy (EIS) offers valuable insights into coating barrier properties and degradation mechanisms over time. This non-destructive technique allows for monitoring changes in coating resistance and capacitance, providing early indicators of coating failure before visible damage occurs.

Field testing protocols complement laboratory validation by exposing coated components to actual service conditions. Strategically placed test panels in representative environments, coupled with regular inspection and documentation, bridge the gap between laboratory predictions and real-world performance.

Quality control procedures must be integrated throughout the testing process, including calibration of test equipment, statistical analysis of results, and documentation of environmental conditions. Round-robin testing between different laboratories helps establish reproducibility and reliability of test methods.

Failure analysis protocols should be established to systematically investigate coating defects or premature failures. These protocols typically include visual inspection, microscopic examination, chemical analysis, and mechanical testing of failed areas to identify root causes and inform coating formulation improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!