How to Improve CFRP Efficiency in Motorized Racing Sports

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Technology Evolution and Performance Targets

Carbon Fiber Reinforced Polymers (CFRP) have revolutionized motorized racing sports since their introduction in the 1980s. Initially limited to Formula 1, CFRP technology has progressively expanded across various racing categories including MotoGP, NASCAR, and endurance racing. The evolution trajectory shows a clear pattern of increasing performance capabilities alongside decreasing production costs and manufacturing complexity.

The first generation of CFRP components in racing utilized basic layup techniques with limited fiber orientations, achieving weight reductions of approximately 30% compared to aluminum alternatives. By the early 2000s, advanced computational modeling enabled optimized fiber orientation and thickness distribution, pushing weight savings to 40-45% while maintaining structural integrity under extreme racing conditions.

Current CFRP technology in motorsports employs sophisticated hybrid composites, incorporating materials such as aramid fibers, titanium inserts, and specialized resins to address specific performance requirements. These modern composites deliver weight reductions approaching 50% compared to metallic alternatives while offering superior energy absorption characteristics during impacts—a critical safety consideration.

Performance targets for next-generation CFRP applications in racing focus on several key metrics. Primary among these is the strength-to-weight ratio, with industry benchmarks targeting 15-20% improvements over current standards. This would enable further vehicle weight reduction while maintaining or enhancing structural performance under the extreme g-forces experienced during competition.

Manufacturing efficiency represents another crucial target, with objectives to reduce production cycle times by 30-40% through automated fiber placement technologies and rapid-cure resin systems. Such advancements would significantly impact both cost structures and the ability to iterate designs more quickly during development phases.

Thermal management capabilities constitute an emerging performance target, as racing vehicles face increasingly challenging thermal environments. Next-generation CFRP systems aim to incorporate thermal conductivity pathways while maintaining structural properties, potentially eliminating the need for separate heat management systems in certain applications.

Sustainability metrics have also entered performance considerations, with targets focusing on recyclability and reduced environmental impact. Racing teams and manufacturers are exploring bio-based resins and recycling technologies that could recover up to 80% of carbon fibers from end-of-life components, aligning with broader industry sustainability initiatives while maintaining the performance advantages that make CFRP essential to competitive racing.

The first generation of CFRP components in racing utilized basic layup techniques with limited fiber orientations, achieving weight reductions of approximately 30% compared to aluminum alternatives. By the early 2000s, advanced computational modeling enabled optimized fiber orientation and thickness distribution, pushing weight savings to 40-45% while maintaining structural integrity under extreme racing conditions.

Current CFRP technology in motorsports employs sophisticated hybrid composites, incorporating materials such as aramid fibers, titanium inserts, and specialized resins to address specific performance requirements. These modern composites deliver weight reductions approaching 50% compared to metallic alternatives while offering superior energy absorption characteristics during impacts—a critical safety consideration.

Performance targets for next-generation CFRP applications in racing focus on several key metrics. Primary among these is the strength-to-weight ratio, with industry benchmarks targeting 15-20% improvements over current standards. This would enable further vehicle weight reduction while maintaining or enhancing structural performance under the extreme g-forces experienced during competition.

Manufacturing efficiency represents another crucial target, with objectives to reduce production cycle times by 30-40% through automated fiber placement technologies and rapid-cure resin systems. Such advancements would significantly impact both cost structures and the ability to iterate designs more quickly during development phases.

Thermal management capabilities constitute an emerging performance target, as racing vehicles face increasingly challenging thermal environments. Next-generation CFRP systems aim to incorporate thermal conductivity pathways while maintaining structural properties, potentially eliminating the need for separate heat management systems in certain applications.

Sustainability metrics have also entered performance considerations, with targets focusing on recyclability and reduced environmental impact. Racing teams and manufacturers are exploring bio-based resins and recycling technologies that could recover up to 80% of carbon fibers from end-of-life components, aligning with broader industry sustainability initiatives while maintaining the performance advantages that make CFRP essential to competitive racing.

Market Analysis for CFRP in Motorsport Applications

The Carbon Fiber Reinforced Polymer (CFRP) market in motorsport applications has experienced substantial growth over the past decade, driven primarily by the increasing demand for lightweight yet high-strength materials that enhance vehicle performance. The global CFRP market specifically for motorsport was valued at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 8.7% through 2028.

Formula 1 remains the largest consumer of CFRP in motorsport, accounting for roughly 35% of the total market share. This dominance stems from F1's continuous pursuit of performance optimization and the sport's substantial financial resources. Following closely are other high-tier racing categories including MotoGP, WRC (World Rally Championship), and NASCAR, which collectively represent another 40% of market consumption.

Market research indicates that chassis components constitute the largest application segment (42%), followed by aerodynamic elements (28%), powertrain components (18%), and interior elements (12%). The trend toward increased electrification in racing series has created new demand vectors for CFRP, particularly in battery enclosure systems where the material's lightweight properties and structural integrity provide significant advantages.

Regional analysis reveals Europe as the dominant market for motorsport CFRP applications, holding approximately 58% of global market share. This concentration aligns with the region's strong motorsport heritage and the presence of major racing teams and manufacturers. North America follows at 24%, with Asia-Pacific showing the fastest growth rate at 12.3% annually, driven by increasing motorsport popularity in countries like Japan, China, and Australia.

Customer demand patterns indicate a growing emphasis on sustainability alongside performance. Racing teams and manufacturers are increasingly seeking CFRP solutions that maintain performance characteristics while reducing environmental impact. This has spurred innovation in recycling technologies and bio-based carbon fiber precursors, creating a nascent but rapidly expanding sub-segment within the market.

Price sensitivity varies significantly across racing categories. While premium series like Formula 1 prioritize performance over cost, emerging electric racing series and lower-tier competitions demonstrate higher price elasticity. This market stratification has created opportunities for tiered CFRP product offerings, with manufacturers developing cost-optimized solutions for budget-conscious segments while maintaining premium offerings for elite competitions.

Supply chain analysis reveals potential vulnerabilities, with 68% of carbon fiber precursors sourced from just three countries. Recent global disruptions have highlighted the need for supply diversification, creating market opportunities for new entrants in previously underrepresented regions.

Formula 1 remains the largest consumer of CFRP in motorsport, accounting for roughly 35% of the total market share. This dominance stems from F1's continuous pursuit of performance optimization and the sport's substantial financial resources. Following closely are other high-tier racing categories including MotoGP, WRC (World Rally Championship), and NASCAR, which collectively represent another 40% of market consumption.

Market research indicates that chassis components constitute the largest application segment (42%), followed by aerodynamic elements (28%), powertrain components (18%), and interior elements (12%). The trend toward increased electrification in racing series has created new demand vectors for CFRP, particularly in battery enclosure systems where the material's lightweight properties and structural integrity provide significant advantages.

Regional analysis reveals Europe as the dominant market for motorsport CFRP applications, holding approximately 58% of global market share. This concentration aligns with the region's strong motorsport heritage and the presence of major racing teams and manufacturers. North America follows at 24%, with Asia-Pacific showing the fastest growth rate at 12.3% annually, driven by increasing motorsport popularity in countries like Japan, China, and Australia.

Customer demand patterns indicate a growing emphasis on sustainability alongside performance. Racing teams and manufacturers are increasingly seeking CFRP solutions that maintain performance characteristics while reducing environmental impact. This has spurred innovation in recycling technologies and bio-based carbon fiber precursors, creating a nascent but rapidly expanding sub-segment within the market.

Price sensitivity varies significantly across racing categories. While premium series like Formula 1 prioritize performance over cost, emerging electric racing series and lower-tier competitions demonstrate higher price elasticity. This market stratification has created opportunities for tiered CFRP product offerings, with manufacturers developing cost-optimized solutions for budget-conscious segments while maintaining premium offerings for elite competitions.

Supply chain analysis reveals potential vulnerabilities, with 68% of carbon fiber precursors sourced from just three countries. Recent global disruptions have highlighted the need for supply diversification, creating market opportunities for new entrants in previously underrepresented regions.

Current CFRP Limitations and Technical Challenges

Carbon Fiber Reinforced Polymers (CFRP) face several significant limitations and technical challenges in motorized racing sports despite their widespread adoption. The primary constraint remains the high manufacturing cost, which can be 5-10 times higher than traditional materials. This cost factor stems from expensive raw materials, particularly carbon fibers (approximately $20-30 per kilogram for standard modulus fibers), and complex manufacturing processes requiring specialized equipment and skilled labor.

Production efficiency presents another major challenge, with CFRP components typically requiring longer manufacturing cycles compared to metal alternatives. The labor-intensive layup process, extended curing times (often 2-4 hours in autoclaves), and limited automation capabilities contribute to reduced production throughput, creating bottlenecks in racing team supply chains.

Quality consistency across manufactured parts remains problematic. The manual nature of many CFRP manufacturing processes introduces variability, with studies showing up to 15% performance variation between supposedly identical components. This inconsistency can significantly impact racing performance where millisecond advantages are crucial.

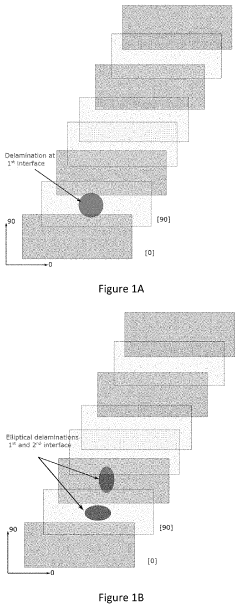

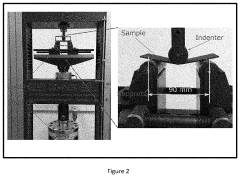

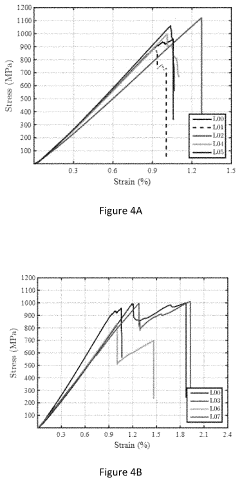

Damage detection and assessment pose unique challenges for CFRP structures. Unlike metals that show visible deformation, carbon fiber composites can experience internal delamination or matrix cracking without apparent surface damage. This "barely visible impact damage" (BVID) phenomenon complicates inspection protocols and can lead to catastrophic failures if undetected.

Repairability limitations further constrain CFRP efficiency in racing environments. While metal components can often be welded or reshaped, damaged CFRP parts typically require complete replacement, increasing operational costs and waste. Current repair techniques often result in performance degradation of 10-30% compared to original specifications.

Environmental factors also impact CFRP performance in racing conditions. These materials can experience property degradation under extreme temperature cycling, with some epoxy systems showing up to 25% strength reduction at temperatures exceeding 120°C—temperatures commonly reached in braking systems and engine compartments.

Recycling and sustainability present growing challenges as regulatory pressures increase. Current end-of-life options for CFRP waste remain limited, with most racing components ending up in landfills. Mechanical recycling methods typically yield materials with 40-60% reduced mechanical properties compared to virgin materials.

Weight optimization paradoxically becomes more challenging as designs approach theoretical limits. Engineers face diminishing returns when further reducing weight while maintaining structural integrity, often requiring sophisticated multi-physics simulation capabilities and extensive physical testing to validate increasingly complex designs.

Production efficiency presents another major challenge, with CFRP components typically requiring longer manufacturing cycles compared to metal alternatives. The labor-intensive layup process, extended curing times (often 2-4 hours in autoclaves), and limited automation capabilities contribute to reduced production throughput, creating bottlenecks in racing team supply chains.

Quality consistency across manufactured parts remains problematic. The manual nature of many CFRP manufacturing processes introduces variability, with studies showing up to 15% performance variation between supposedly identical components. This inconsistency can significantly impact racing performance where millisecond advantages are crucial.

Damage detection and assessment pose unique challenges for CFRP structures. Unlike metals that show visible deformation, carbon fiber composites can experience internal delamination or matrix cracking without apparent surface damage. This "barely visible impact damage" (BVID) phenomenon complicates inspection protocols and can lead to catastrophic failures if undetected.

Repairability limitations further constrain CFRP efficiency in racing environments. While metal components can often be welded or reshaped, damaged CFRP parts typically require complete replacement, increasing operational costs and waste. Current repair techniques often result in performance degradation of 10-30% compared to original specifications.

Environmental factors also impact CFRP performance in racing conditions. These materials can experience property degradation under extreme temperature cycling, with some epoxy systems showing up to 25% strength reduction at temperatures exceeding 120°C—temperatures commonly reached in braking systems and engine compartments.

Recycling and sustainability present growing challenges as regulatory pressures increase. Current end-of-life options for CFRP waste remain limited, with most racing components ending up in landfills. Mechanical recycling methods typically yield materials with 40-60% reduced mechanical properties compared to virgin materials.

Weight optimization paradoxically becomes more challenging as designs approach theoretical limits. Engineers face diminishing returns when further reducing weight while maintaining structural integrity, often requiring sophisticated multi-physics simulation capabilities and extensive physical testing to validate increasingly complex designs.

Current CFRP Manufacturing and Implementation Methods

01 Manufacturing techniques for CFRP efficiency

Various manufacturing techniques can enhance the efficiency of Carbon Fiber Reinforced Polymer (CFRP) components. These include specialized molding processes, automated layup methods, and precision fabrication techniques that optimize fiber orientation and resin distribution. These manufacturing approaches reduce material waste, decrease production time, and improve the structural integrity of the final CFRP components, leading to higher overall efficiency in both production and performance.- Manufacturing techniques for CFRP efficiency: Various manufacturing techniques can enhance the efficiency of Carbon Fiber Reinforced Polymer (CFRP) components. These include optimized molding processes, automated layup methods, and precision cutting technologies that minimize material waste. Advanced manufacturing approaches help achieve consistent quality, reduce production time, and lower costs while maintaining the high strength-to-weight ratio that makes CFRP desirable for industrial applications.

- Structural design optimization for CFRP components: Optimizing the structural design of CFRP components significantly improves their efficiency. This includes strategic fiber orientation, variable thickness distribution, and topology optimization to maximize strength while minimizing weight. Innovative joint designs and integration of load-bearing elements further enhance structural performance. Computer-aided design and finite element analysis help engineers develop CFRP structures that achieve optimal mechanical properties with minimal material usage.

- Hybrid material systems with CFRP: Combining CFRP with other materials creates hybrid systems that maximize efficiency for specific applications. These hybrid approaches include metal-CFRP combinations, multi-material structures, and gradient material transitions that optimize performance characteristics. By strategically integrating CFRP with complementary materials, engineers can achieve enhanced mechanical properties, improved impact resistance, better thermal management, and cost efficiency while maintaining lightweight advantages.

- CFRP recycling and sustainability improvements: Enhancing the sustainability of CFRP involves developing efficient recycling methods and environmentally friendly production processes. Techniques include solvolysis, pyrolysis, and mechanical recycling to recover carbon fibers from end-of-life components. Using bio-based polymers as matrix materials and implementing closed-loop manufacturing systems further improves the environmental profile of CFRP. These approaches address the traditionally high energy intensity and waste challenges associated with CFRP production and disposal.

- Performance enhancement additives for CFRP: Various additives can be incorporated into CFRP formulations to enhance specific performance characteristics. These include nanomaterials for improved mechanical properties, flame retardants for better fire resistance, and conductive additives for electrical functionality. Surface treatments and coupling agents improve fiber-matrix adhesion, while toughening agents enhance impact resistance. These additives allow CFRP to be tailored for specific applications while maintaining its fundamental lightweight and high-strength advantages.

02 Structural design optimization for CFRP applications

Optimizing the structural design of CFRP components significantly improves their efficiency. This includes strategic fiber orientation, variable thickness designs, and topology optimization techniques that maximize strength-to-weight ratios. Advanced computational modeling helps identify optimal geometries that distribute loads effectively while minimizing material usage. These design approaches enable CFRP structures to achieve superior performance with reduced weight, which is particularly valuable in aerospace, automotive, and construction applications.Expand Specific Solutions03 Hybrid CFRP systems for enhanced efficiency

Hybrid CFRP systems combine carbon fiber reinforced polymers with other materials to achieve enhanced efficiency. These systems may integrate metals, alternative fiber types, or specialized core materials to create structures with optimized properties. By strategically combining materials, these hybrid approaches can overcome limitations of pure CFRP, such as impact resistance or cost constraints, while maintaining lightweight characteristics. This results in more efficient components that balance performance requirements with practical considerations.Expand Specific Solutions04 CFRP joining and assembly techniques

Specialized joining and assembly techniques for CFRP components significantly impact overall system efficiency. These include advanced adhesive bonding methods, mechanical fastening systems designed specifically for composite materials, and hybrid joining approaches. Effective joining techniques preserve the integrity of the carbon fiber structure while creating strong connections between components. These methods minimize weight penalties associated with traditional joining approaches and maintain the performance advantages of CFRP throughout assembled structures.Expand Specific Solutions05 CFRP recycling and sustainability improvements

Innovations in CFRP recycling and sustainability enhance the lifecycle efficiency of carbon fiber components. These include methods for reclaiming carbon fibers from end-of-life products, techniques for reprocessing recovered materials, and approaches for incorporating recycled carbon fiber into new applications. Sustainable manufacturing processes reduce energy consumption and environmental impact while maintaining material performance. These advancements improve the overall efficiency of CFRP by addressing economic and environmental considerations throughout the material lifecycle.Expand Specific Solutions

Leading Manufacturers and Racing Teams in CFRP Innovation

The carbon fiber reinforced polymer (CFRP) efficiency market in motorized racing sports is in a growth phase, with increasing adoption driven by performance demands. The market is expanding as racing teams seek lightweight, high-strength materials to enhance speed and fuel efficiency. Technologically, industry leaders like Toray Industries and Nippon Steel have developed advanced manufacturing processes, while automotive companies including Toyota, Honda, Porsche, and Hyundai are integrating CFRP into racing applications. Academic institutions such as Jiangsu University and research organizations like Japan Aerospace Exploration Agency are advancing fundamental research. The competitive landscape features collaboration between material suppliers and automotive manufacturers, with emerging players from specialized composite manufacturers challenging established companies through innovative production techniques and cost-effective solutions.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced T1100G carbon fiber prepreg systems specifically optimized for motorsport applications, featuring ultra-high tensile strength (7 GPa) and modulus (324 GPa). Their proprietary resin systems enable faster curing cycles (reduced by 30%) while maintaining mechanical properties. Toray's manufacturing process incorporates automated fiber placement (AFP) technology with precise fiber orientation control, allowing for tailored reinforcement in high-stress areas of racing components. Their recent innovation includes nano-modified matrix systems that improve interlaminar shear strength by approximately 15%, addressing a common failure mode in high-performance racing applications. Toray has also developed specialized surface treatments that enhance fiber-matrix adhesion, resulting in improved impact resistance crucial for motorsport safety requirements.

Strengths: Industry-leading carbon fiber mechanical properties; extensive motorsport experience with Formula 1 partnerships; advanced manufacturing capabilities. Weaknesses: Higher cost compared to competitors; longer lead times for specialized materials; requires sophisticated processing equipment for optimal results.

Toyota Motor Corp.

Technical Solution: Toyota Racing Development has pioneered a comprehensive CFRP efficiency program focused on their WRC and endurance racing platforms. Their approach centers on a multi-scale optimization methodology that analyzes fiber orientation at the microscale, laminate design at the mesoscale, and structural performance at the macroscale. Toyota has developed proprietary high-speed manufacturing techniques that reduce production time by approximately 40% compared to conventional autoclave processes. Their recent innovation includes variable stiffness composites (VSC) where fiber orientations are continuously varied across components to optimize load paths, resulting in 15-20% weight reduction while maintaining structural performance. Toyota has also implemented advanced recycling protocols for manufacturing waste and end-of-life components, addressing sustainability concerns in motorsport. Their CFRP components undergo rigorous testing in simulated race conditions, including thermal cycling and vibration analysis to ensure durability.

Strengths: Integrated approach from design to manufacturing; significant weight reduction achievements; advanced simulation capabilities. Weaknesses: Higher initial tooling costs; complex manufacturing processes requiring specialized expertise; challenges in rapid iteration during race season development.

Breakthrough CFRP Patents and Research Developments

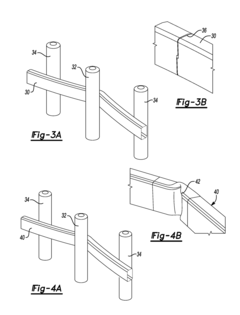

Bio-inspired composite laminate design with high out-of-plane strength and ductility

PatentActiveUS11207867B1

Innovation

- Bio-inspired CFRP composite laminates are designed with intentionally introduced delaminations at specific positions and sizes during the lamination process to control crack propagation and enhance ductility, featuring a pseudo-ductile response with increased failure strain and energy absorption.

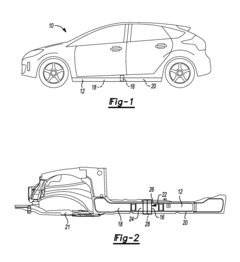

Carbon fiber reinforced polymer assembly

PatentActiveUS9981692B2

Innovation

- An impact absorbing assembly comprising a first and second CFRP part joined by a metal part, where the metal part bends in response to impact loads, inhibiting CFRP cracking, and featuring a metal bending hinge or tubular member to enhance energy absorption, with the metal part made of ductile aluminum for superior performance.

Sustainability and Recycling Considerations for Racing CFRP

The environmental impact of Carbon Fiber Reinforced Polymers (CFRP) in racing sports has become increasingly significant as sustainability concerns grow across all industries. Racing teams and manufacturers now face mounting pressure to address the lifecycle environmental footprint of these high-performance materials. Traditional CFRP production and disposal methods present substantial ecological challenges, with carbon fiber requiring energy-intensive manufacturing processes and thermoset matrices that resist conventional recycling methods.

Current recycling rates for racing CFRP components remain alarmingly low, with estimates suggesting less than 15% of carbon fiber composites are effectively recovered across the motorsport industry. This inefficiency stems from both technical limitations and economic barriers. The cross-linked structure of thermoset resins makes material separation particularly challenging, while the high costs associated with recycling processes often outweigh the perceived value of recovered materials.

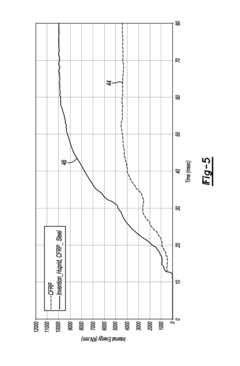

Several promising recycling technologies are emerging to address these challenges. Pyrolysis processes, which thermally decompose the polymer matrix while preserving carbon fiber integrity, have shown potential for recovering fibers with up to 90% retention of mechanical properties. Solvolysis techniques using supercritical fluids offer more environmentally friendly alternatives by chemically dissolving resin systems at lower temperatures. Additionally, mechanical recycling methods provide options for converting end-of-life components into valuable fillers and reinforcements for secondary applications.

Forward-thinking racing teams are implementing closed-loop material systems where damaged or retired CFRP components are systematically collected, processed, and reincorporated into non-critical parts. Formula 1's sustainability initiatives have established ambitious targets to achieve net-zero carbon footprints, with material circularity playing a central role in these strategies. Some teams have partnered with specialized recycling facilities to develop proprietary recovery processes tailored to their specific composite formulations.

Design for recyclability represents another crucial frontier in sustainable racing CFRP. Innovations include thermoplastic matrix systems that can be melted and reformed multiple times, reversible chemical bonding agents that facilitate component disassembly, and modular designs that isolate high-wear components from more durable structures. These approaches not only improve end-of-life recovery but can enhance performance through weight optimization and more efficient material utilization.

The economic viability of CFRP recycling in racing is improving as regulatory pressures increase and technologies mature. Life cycle assessment studies indicate that incorporating recycled carbon fibers can reduce energy consumption by up to 60% compared to virgin fiber production. Furthermore, racing's high-profile platform offers valuable opportunities to demonstrate and accelerate sustainable composite technologies that may eventually transfer to mainstream automotive and aerospace applications.

Current recycling rates for racing CFRP components remain alarmingly low, with estimates suggesting less than 15% of carbon fiber composites are effectively recovered across the motorsport industry. This inefficiency stems from both technical limitations and economic barriers. The cross-linked structure of thermoset resins makes material separation particularly challenging, while the high costs associated with recycling processes often outweigh the perceived value of recovered materials.

Several promising recycling technologies are emerging to address these challenges. Pyrolysis processes, which thermally decompose the polymer matrix while preserving carbon fiber integrity, have shown potential for recovering fibers with up to 90% retention of mechanical properties. Solvolysis techniques using supercritical fluids offer more environmentally friendly alternatives by chemically dissolving resin systems at lower temperatures. Additionally, mechanical recycling methods provide options for converting end-of-life components into valuable fillers and reinforcements for secondary applications.

Forward-thinking racing teams are implementing closed-loop material systems where damaged or retired CFRP components are systematically collected, processed, and reincorporated into non-critical parts. Formula 1's sustainability initiatives have established ambitious targets to achieve net-zero carbon footprints, with material circularity playing a central role in these strategies. Some teams have partnered with specialized recycling facilities to develop proprietary recovery processes tailored to their specific composite formulations.

Design for recyclability represents another crucial frontier in sustainable racing CFRP. Innovations include thermoplastic matrix systems that can be melted and reformed multiple times, reversible chemical bonding agents that facilitate component disassembly, and modular designs that isolate high-wear components from more durable structures. These approaches not only improve end-of-life recovery but can enhance performance through weight optimization and more efficient material utilization.

The economic viability of CFRP recycling in racing is improving as regulatory pressures increase and technologies mature. Life cycle assessment studies indicate that incorporating recycled carbon fibers can reduce energy consumption by up to 60% compared to virgin fiber production. Furthermore, racing's high-profile platform offers valuable opportunities to demonstrate and accelerate sustainable composite technologies that may eventually transfer to mainstream automotive and aerospace applications.

Regulatory Framework and Safety Standards for CFRP in Motorsports

The regulatory landscape governing Carbon Fiber Reinforced Polymer (CFRP) usage in motorsports represents a complex framework balancing innovation with safety. The Fédération Internationale de l'Automobile (FIA) serves as the primary regulatory body establishing global standards for CFRP implementation across Formula 1, WRC, and other premier racing categories. These regulations undergo continuous evolution, with significant updates typically occurring in 3-5 year cycles to accommodate technological advancements while maintaining competitive balance.

Safety standards for CFRP components in motorsports focus on three critical areas: crash structure integrity, fire resistance, and failure mode predictability. Current FIA regulations mandate specific impact absorption capabilities for CFRP monocoques, requiring survival cell structures to withstand up to 40G of force in standardized crash tests. Additionally, all CFRP components must meet stringent fire resistance standards, maintaining structural integrity for a minimum of 15 seconds when exposed to direct flame at temperatures exceeding 800°C.

Material certification processes represent another crucial regulatory dimension, with teams required to submit comprehensive documentation on fiber types, resin systems, and manufacturing processes. The FIA Technical Working Group has recently implemented more stringent traceability requirements, mandating batch-level documentation for all structural CFRP components to enhance quality control and failure analysis capabilities.

Environmental considerations have gained prominence in recent regulatory updates, with sustainability metrics increasingly incorporated into technical regulations. The 2023 FIA Technical Directive introduced carbon footprint assessment requirements for CFRP manufacturing processes, signaling a shift toward lifecycle impact considerations alongside performance parameters.

Regional variations in CFRP regulations present challenges for international racing teams. While European motorsport bodies generally align with FIA standards, North American series like NASCAR and IndyCar maintain distinct regulatory frameworks with different emphasis on material qualification and testing methodologies. Japanese Super GT regulations feature unique provisions regarding hybrid CFRP structures incorporating aramid fibers for specific impact absorption characteristics.

Compliance verification mechanisms include pre-season homologation processes, random sampling during race weekends, and post-incident forensic analysis. Teams must maintain comprehensive material libraries and manufacturing documentation, with penalties for non-compliance ranging from fines to disqualification. The regulatory burden has driven significant investment in compliance management systems among top-tier racing organizations.

Future regulatory trends point toward increased emphasis on sustainable CFRP solutions, standardized recycling protocols, and more sophisticated simulation-based certification processes to reduce physical testing requirements while maintaining safety standards.

Safety standards for CFRP components in motorsports focus on three critical areas: crash structure integrity, fire resistance, and failure mode predictability. Current FIA regulations mandate specific impact absorption capabilities for CFRP monocoques, requiring survival cell structures to withstand up to 40G of force in standardized crash tests. Additionally, all CFRP components must meet stringent fire resistance standards, maintaining structural integrity for a minimum of 15 seconds when exposed to direct flame at temperatures exceeding 800°C.

Material certification processes represent another crucial regulatory dimension, with teams required to submit comprehensive documentation on fiber types, resin systems, and manufacturing processes. The FIA Technical Working Group has recently implemented more stringent traceability requirements, mandating batch-level documentation for all structural CFRP components to enhance quality control and failure analysis capabilities.

Environmental considerations have gained prominence in recent regulatory updates, with sustainability metrics increasingly incorporated into technical regulations. The 2023 FIA Technical Directive introduced carbon footprint assessment requirements for CFRP manufacturing processes, signaling a shift toward lifecycle impact considerations alongside performance parameters.

Regional variations in CFRP regulations present challenges for international racing teams. While European motorsport bodies generally align with FIA standards, North American series like NASCAR and IndyCar maintain distinct regulatory frameworks with different emphasis on material qualification and testing methodologies. Japanese Super GT regulations feature unique provisions regarding hybrid CFRP structures incorporating aramid fibers for specific impact absorption characteristics.

Compliance verification mechanisms include pre-season homologation processes, random sampling during race weekends, and post-incident forensic analysis. Teams must maintain comprehensive material libraries and manufacturing documentation, with penalties for non-compliance ranging from fines to disqualification. The regulatory burden has driven significant investment in compliance management systems among top-tier racing organizations.

Future regulatory trends point toward increased emphasis on sustainable CFRP solutions, standardized recycling protocols, and more sophisticated simulation-based certification processes to reduce physical testing requirements while maintaining safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!