Enhancing CFRP Curing Techniques for Optimized Performance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Curing Evolution and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have evolved significantly since their initial development in the 1960s. Originally limited to aerospace and military applications due to prohibitive costs, these advanced composite materials have gradually expanded into automotive, sporting goods, and infrastructure sectors. The evolution of CFRP curing techniques has been a critical factor in this expansion, transforming from basic autoclave processes to more sophisticated and efficient methodologies.

Traditional autoclave curing, while effective in producing high-quality composites, has presented significant limitations in terms of energy consumption, production rate, and scalability. These constraints have driven continuous innovation in the field, leading to the development of out-of-autoclave (OOA) techniques, microwave curing, electron beam curing, and more recently, advanced hybrid curing systems that combine multiple energy sources.

The primary objective in enhancing CFRP curing techniques is to optimize the balance between processing efficiency and final performance properties. This involves reducing cure cycle times while maintaining or improving mechanical properties, dimensional stability, and durability of the composite structures. Additionally, there is a growing emphasis on developing more sustainable curing processes that minimize energy consumption and environmental impact.

Another crucial objective is to overcome the inherent challenges in CFRP curing, such as managing residual stresses, preventing void formation, and ensuring uniform cure throughout complex geometries. These factors significantly influence the final performance characteristics of CFRP components, including fatigue resistance, impact tolerance, and long-term durability.

Recent technological advancements have focused on intelligent curing systems that incorporate real-time monitoring and adaptive control. These systems utilize embedded sensors and sophisticated algorithms to optimize cure parameters dynamically, responding to variations in material behavior and environmental conditions during the curing process.

Looking forward, the trajectory of CFRP curing technology is moving toward more integrated and automated manufacturing systems. The industry aims to develop curing techniques that can be seamlessly incorporated into high-volume production environments while maintaining the exceptional performance properties that make CFRP materials so valuable across various applications.

The ultimate goal is to establish curing methodologies that enable broader adoption of CFRP materials by reducing production costs, increasing manufacturing flexibility, and enhancing overall performance. This would facilitate the replacement of traditional materials in more applications, contributing to lighter, stronger, and more efficient products across multiple industries.

Traditional autoclave curing, while effective in producing high-quality composites, has presented significant limitations in terms of energy consumption, production rate, and scalability. These constraints have driven continuous innovation in the field, leading to the development of out-of-autoclave (OOA) techniques, microwave curing, electron beam curing, and more recently, advanced hybrid curing systems that combine multiple energy sources.

The primary objective in enhancing CFRP curing techniques is to optimize the balance between processing efficiency and final performance properties. This involves reducing cure cycle times while maintaining or improving mechanical properties, dimensional stability, and durability of the composite structures. Additionally, there is a growing emphasis on developing more sustainable curing processes that minimize energy consumption and environmental impact.

Another crucial objective is to overcome the inherent challenges in CFRP curing, such as managing residual stresses, preventing void formation, and ensuring uniform cure throughout complex geometries. These factors significantly influence the final performance characteristics of CFRP components, including fatigue resistance, impact tolerance, and long-term durability.

Recent technological advancements have focused on intelligent curing systems that incorporate real-time monitoring and adaptive control. These systems utilize embedded sensors and sophisticated algorithms to optimize cure parameters dynamically, responding to variations in material behavior and environmental conditions during the curing process.

Looking forward, the trajectory of CFRP curing technology is moving toward more integrated and automated manufacturing systems. The industry aims to develop curing techniques that can be seamlessly incorporated into high-volume production environments while maintaining the exceptional performance properties that make CFRP materials so valuable across various applications.

The ultimate goal is to establish curing methodologies that enable broader adoption of CFRP materials by reducing production costs, increasing manufacturing flexibility, and enhancing overall performance. This would facilitate the replacement of traditional materials in more applications, contributing to lighter, stronger, and more efficient products across multiple industries.

Market Demand Analysis for Advanced CFRP Applications

The global Carbon Fiber Reinforced Polymer (CFRP) market is experiencing robust growth, driven primarily by increasing demand across aerospace, automotive, wind energy, and construction sectors. Market research indicates the global CFRP market is projected to reach $38.7 billion by 2027, growing at a CAGR of 11.2% from 2022. This significant growth trajectory underscores the expanding applications and market penetration of advanced composite materials.

In the aerospace industry, which accounts for approximately 30% of the total CFRP consumption, manufacturers are increasingly seeking optimized curing techniques to enhance production efficiency while maintaining or improving mechanical properties. Boeing and Airbus have both committed to increasing the composite content in their aircraft designs, with the latest models containing up to 50% composite materials by weight.

The automotive sector represents the fastest-growing market segment for CFRP applications, with a growth rate exceeding 13% annually. This surge is primarily driven by stringent emission regulations and the push toward vehicle lightweighting. Premium automotive manufacturers are particularly interested in advanced curing technologies that can reduce production cycle times from hours to minutes, enabling higher volume production capabilities.

Wind energy, another significant market for CFRP, is demanding larger turbine blades to increase energy generation efficiency. These larger structures require enhanced curing techniques to ensure uniform properties throughout the components and minimize internal stresses. The sector's demand for CFRP is expected to grow by 9.8% annually through 2027.

Regional analysis reveals that North America and Europe currently dominate the CFRP market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market with annual growth rates exceeding 14%, driven by expanding industrial applications and government initiatives supporting advanced materials development.

Customer requirements across these industries consistently highlight several key demands: reduced curing times to improve production throughput, enhanced uniformity in material properties, decreased energy consumption during the curing process, and improved overall part quality with fewer defects. Additionally, there is growing interest in curing technologies compatible with automation and Industry 4.0 integration.

Environmental considerations are also shaping market demands, with increasing pressure for more sustainable manufacturing processes. This has led to growing interest in alternative curing methods that reduce energy consumption and emissions compared to traditional autoclave curing. Out-of-autoclave techniques, microwave curing, and UV-assisted processes are gaining traction as potential solutions to these environmental challenges while potentially offering cost advantages.

In the aerospace industry, which accounts for approximately 30% of the total CFRP consumption, manufacturers are increasingly seeking optimized curing techniques to enhance production efficiency while maintaining or improving mechanical properties. Boeing and Airbus have both committed to increasing the composite content in their aircraft designs, with the latest models containing up to 50% composite materials by weight.

The automotive sector represents the fastest-growing market segment for CFRP applications, with a growth rate exceeding 13% annually. This surge is primarily driven by stringent emission regulations and the push toward vehicle lightweighting. Premium automotive manufacturers are particularly interested in advanced curing technologies that can reduce production cycle times from hours to minutes, enabling higher volume production capabilities.

Wind energy, another significant market for CFRP, is demanding larger turbine blades to increase energy generation efficiency. These larger structures require enhanced curing techniques to ensure uniform properties throughout the components and minimize internal stresses. The sector's demand for CFRP is expected to grow by 9.8% annually through 2027.

Regional analysis reveals that North America and Europe currently dominate the CFRP market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market with annual growth rates exceeding 14%, driven by expanding industrial applications and government initiatives supporting advanced materials development.

Customer requirements across these industries consistently highlight several key demands: reduced curing times to improve production throughput, enhanced uniformity in material properties, decreased energy consumption during the curing process, and improved overall part quality with fewer defects. Additionally, there is growing interest in curing technologies compatible with automation and Industry 4.0 integration.

Environmental considerations are also shaping market demands, with increasing pressure for more sustainable manufacturing processes. This has led to growing interest in alternative curing methods that reduce energy consumption and emissions compared to traditional autoclave curing. Out-of-autoclave techniques, microwave curing, and UV-assisted processes are gaining traction as potential solutions to these environmental challenges while potentially offering cost advantages.

Current CFRP Curing Technologies and Limitations

Carbon Fiber Reinforced Polymers (CFRP) curing technologies have evolved significantly over the past decades, yet several limitations persist that affect performance optimization. The conventional autoclave curing process remains the industry standard for high-performance applications, offering excellent consolidation and void reduction through the application of high pressure (typically 6-8 bar) and controlled temperature cycles. This method produces components with superior mechanical properties but comes with substantial drawbacks including high energy consumption, lengthy processing times (often 2-8 hours), and significant capital investment requirements.

Out-of-autoclave (OOA) technologies have emerged as alternatives, with vacuum bag only (VBO) processing gaining traction in medium-performance applications. VBO methods utilize atmospheric pressure (approximately 1 bar) for consolidation, significantly reducing equipment costs but often resulting in higher void content (1-3% compared to <1% in autoclave curing) and consequently lower mechanical properties, particularly interlaminar shear strength.

Quickstep technology represents an innovative approach utilizing fluid-based heat transfer to achieve rapid, uniform heating rates of up to 15°C/minute. While this technology reduces cycle times by 30-50% compared to autoclave processing, it faces challenges in pressure application and scaling for larger components, limiting its widespread adoption despite its efficiency advantages.

Electron beam curing has demonstrated potential for room-temperature curing with significantly reduced cycle times (minutes rather than hours). However, this technology requires specialized resin systems compatible with radiation curing, which often exhibit lower thermal stability than traditional thermoset systems. Additionally, the penetration depth limitations restrict its application to thinner components.

Microwave curing offers volumetric heating capabilities that can reduce cure times by 70-80% and energy consumption by up to 90% compared to conventional methods. The primary limitations include uneven heating distribution, particularly for complex geometries, and the requirement for specialized tooling materials transparent to microwave energy.

Induction curing, utilizing electromagnetic fields to generate heat directly within carbon fibers, provides rapid heating rates but struggles with uniform temperature distribution across varying thicknesses. This non-uniformity can lead to residual stresses and potential warpage in the final components.

The current technological landscape also faces challenges in real-time cure monitoring and control systems. While dielectric analysis and fiber optic sensors offer promising approaches for in-situ monitoring, their integration into production environments remains limited by cost considerations and data interpretation complexities. This gap in process monitoring capability often results in conservative curing cycles that prioritize quality assurance over processing efficiency.

Out-of-autoclave (OOA) technologies have emerged as alternatives, with vacuum bag only (VBO) processing gaining traction in medium-performance applications. VBO methods utilize atmospheric pressure (approximately 1 bar) for consolidation, significantly reducing equipment costs but often resulting in higher void content (1-3% compared to <1% in autoclave curing) and consequently lower mechanical properties, particularly interlaminar shear strength.

Quickstep technology represents an innovative approach utilizing fluid-based heat transfer to achieve rapid, uniform heating rates of up to 15°C/minute. While this technology reduces cycle times by 30-50% compared to autoclave processing, it faces challenges in pressure application and scaling for larger components, limiting its widespread adoption despite its efficiency advantages.

Electron beam curing has demonstrated potential for room-temperature curing with significantly reduced cycle times (minutes rather than hours). However, this technology requires specialized resin systems compatible with radiation curing, which often exhibit lower thermal stability than traditional thermoset systems. Additionally, the penetration depth limitations restrict its application to thinner components.

Microwave curing offers volumetric heating capabilities that can reduce cure times by 70-80% and energy consumption by up to 90% compared to conventional methods. The primary limitations include uneven heating distribution, particularly for complex geometries, and the requirement for specialized tooling materials transparent to microwave energy.

Induction curing, utilizing electromagnetic fields to generate heat directly within carbon fibers, provides rapid heating rates but struggles with uniform temperature distribution across varying thicknesses. This non-uniformity can lead to residual stresses and potential warpage in the final components.

The current technological landscape also faces challenges in real-time cure monitoring and control systems. While dielectric analysis and fiber optic sensors offer promising approaches for in-situ monitoring, their integration into production environments remains limited by cost considerations and data interpretation complexities. This gap in process monitoring capability often results in conservative curing cycles that prioritize quality assurance over processing efficiency.

State-of-the-Art CFRP Curing Methodologies

01 Autoclave curing techniques for CFRP

Autoclave curing is a high-performance technique for CFRP manufacturing that uses controlled heat and pressure to achieve optimal composite properties. This method ensures uniform consolidation, reduces void content, and enhances the mechanical properties of the final product. The process typically involves placing the layup in a vacuum bag and subjecting it to elevated temperatures and pressures in an autoclave chamber, resulting in superior fiber-matrix adhesion and structural integrity.- Autoclave curing techniques for CFRP: Autoclave curing is a high-performance technique for CFRP manufacturing that uses controlled pressure and temperature to produce composites with superior mechanical properties. This process minimizes void content and ensures uniform consolidation of the carbon fiber reinforcement and polymer matrix. The controlled environment of an autoclave allows for precise management of cure cycles, resulting in components with excellent structural integrity and performance characteristics.

- Out-of-autoclave curing methods: Out-of-autoclave curing techniques provide cost-effective alternatives to traditional autoclave processing for CFRP. These methods include vacuum bag only (VBO) processing, resin transfer molding (RTM), and vacuum-assisted resin transfer molding (VARTM). These approaches reduce energy consumption and capital equipment costs while still producing high-quality CFRP components. Recent advancements in resin chemistry and process control have significantly improved the performance of parts manufactured using these techniques.

- Microwave and rapid curing technologies: Advanced rapid curing technologies such as microwave, induction, and infrared heating offer significant reductions in CFRP processing time while maintaining or enhancing performance properties. These methods provide more localized and efficient energy transfer to the composite material, resulting in faster cure cycles and reduced energy consumption. The controlled application of these technologies can lead to improved cross-linking density in the polymer matrix and enhanced interfacial bonding between fiber and resin.

- Optimization of cure cycles for enhanced mechanical properties: Precise control and optimization of cure cycles significantly impact the final mechanical properties of CFRP components. Parameters such as heating rate, dwell temperature, pressure application timing, and cooling rate can be tailored to achieve specific performance characteristics. Advanced monitoring systems using embedded sensors allow for real-time adjustments during the curing process, resulting in composites with improved strength, stiffness, and fatigue resistance. Optimized cure cycles also minimize residual stresses and prevent warpage in complex geometries.

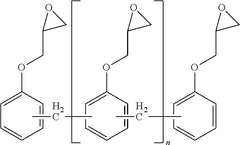

- Novel resin systems and additives for improved curing performance: Innovative resin formulations and additives are being developed to enhance the curing performance and resulting properties of CFRP materials. These include toughened epoxy systems, thermoplastic-modified thermosets, and nano-enhanced matrices. Such advanced resin systems offer benefits like reduced cure times, lower curing temperatures, improved damage tolerance, and enhanced environmental resistance. The incorporation of specific catalysts and hardeners can provide better control over the curing reaction kinetics, resulting in more consistent and predictable material properties.

02 Out-of-autoclave (OOA) curing methods

Out-of-autoclave curing methods offer cost-effective alternatives to traditional autoclave processing for CFRP components. These techniques include vacuum-assisted resin transfer molding (VARTM), resin infusion, and oven curing with vacuum bagging. OOA methods reduce energy consumption and capital investment while still producing high-quality composites with good mechanical properties. These approaches are particularly valuable for large structures or when autoclave access is limited, enabling broader adoption of CFRP technology across various industries.Expand Specific Solutions03 Microwave and rapid curing technologies

Advanced rapid curing technologies like microwave, induction, and infrared heating offer significant advantages for CFRP manufacturing. These methods dramatically reduce curing time while maintaining or improving mechanical properties. Microwave curing, in particular, provides volumetric heating that ensures uniform curing throughout the composite thickness. These technologies enable faster production cycles, lower energy consumption, and can result in improved cross-linking density in the polymer matrix, potentially enhancing the thermal and mechanical performance of the final composite.Expand Specific Solutions04 Optimization of cure cycles and parameters

Optimizing cure cycles and process parameters is critical for achieving maximum CFRP performance. This involves precise control of temperature ramps, dwell times, pressure profiles, and cooling rates tailored to specific resin systems. Advanced monitoring techniques using embedded sensors allow for real-time tracking of the curing process, enabling adaptive control systems. Properly optimized cure cycles minimize residual stresses, prevent thermal degradation, reduce cycle times, and ensure complete cross-linking of the polymer matrix, resulting in superior mechanical properties and dimensional stability.Expand Specific Solutions05 Tooling and mold design for CFRP curing

Specialized tooling and mold designs significantly impact CFRP curing performance. Innovative mold materials with tailored thermal conductivity, thermal expansion characteristics, and surface finishes ensure uniform heat distribution and dimensional accuracy. Integrated heating elements, cooling channels, and vacuum systems within the tooling enhance process control. Advanced mold designs also incorporate features to manage resin flow, fiber orientation, and part removal, minimizing defects and improving reproducibility. Proper tool design is essential for achieving high-quality CFRP components with consistent mechanical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CFRP Industry

The CFRP curing techniques market is in a growth phase, with increasing demand driven by aerospace, automotive, and renewable energy sectors. The market size is projected to expand significantly due to the superior properties of carbon fiber reinforced polymers. Technologically, the field is advancing rapidly with innovations in out-of-autoclave processes, microwave curing, and digital monitoring systems. Leading players include established industrial giants like Mitsubishi Electric, Toray Industries, and Airbus, who are investing heavily in R&D. Academic institutions such as Southeast University and Sichuan University are contributing fundamental research, while specialized manufacturers like FANUC and Tokyo Seimitsu are developing advanced automation solutions for CFRP processing, creating a competitive landscape balancing innovation with industrial scale.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a comprehensive CFRP curing solution centered around their proprietary resin systems optimized for rapid curing cycles. Their technology incorporates specially formulated toughened epoxy resins with controlled reactivity profiles that achieve complete cross-linking at lower temperatures than conventional systems[2]. Toray's approach includes a multi-zone curing process where different sections of composite parts are subjected to tailored temperature profiles based on thickness and geometry variations, ensuring uniform curing throughout complex structures[4]. The company has also pioneered hybrid curing methods combining conventional heating with targeted infrared radiation to accelerate curing in critical areas while minimizing residual stresses. Their advanced process monitoring system utilizes embedded fiber optic sensors that provide real-time data on resin flow, cure progression, and temperature distribution, enabling adaptive control of curing parameters[7]. Toray has demonstrated that their optimized curing techniques can reduce cycle times by up to 30% while improving interlaminar shear strength by approximately 15% compared to standard autoclave processes.

Strengths: Superior resin chemistry expertise allowing for faster curing cycles without compromising mechanical properties; comprehensive process monitoring capabilities enabling precise quality control; scalable solutions applicable to both small and large components. Weaknesses: Proprietary resin systems may limit compatibility with other manufacturers' materials; higher material costs compared to standard epoxy systems; requires specialized training for operators to fully utilize the advanced monitoring systems.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed an innovative CFRP curing approach called Accelerated Curing System (ACS) that combines multiple heating technologies to optimize the curing process. Their system integrates conventional convection heating with strategically positioned induction heating elements that target specific areas of complex composite structures, ensuring uniform temperature distribution and reducing thermal gradients[3]. MHI's technology incorporates a proprietary vacuum-assisted pressure application system that maintains consistent consolidation pressure throughout the curing cycle, minimizing void content to below 0.5% by volume[6]. The company has also implemented advanced cure monitoring using dielectric sensors embedded within the tooling that provide real-time feedback on resin viscosity and degree of cure, allowing for dynamic adjustment of process parameters. Their automated curing control system utilizes machine learning algorithms that analyze historical process data to continuously refine curing profiles for different component geometries and material combinations[8]. MHI has demonstrated that their ACS technology can reduce energy consumption by approximately 35% while decreasing overall cycle time by 25-30% compared to traditional autoclave curing methods.

Strengths: Exceptional void reduction capabilities resulting in superior mechanical properties; significant energy and time savings through optimized heating strategies; adaptable system suitable for various component sizes and geometries. Weaknesses: Complex integration of multiple heating technologies requires sophisticated control systems; higher initial capital investment compared to conventional curing equipment; limited track record for very large aerospace structures.

Critical Patents and Research in CFRP Curing Optimization

Recyclable enhanced performance carbon fiber-reinforced polymer

PatentActiveJP2021133685A

Innovation

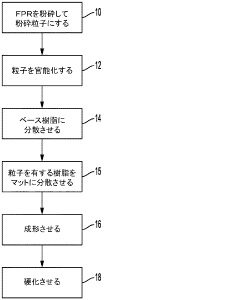

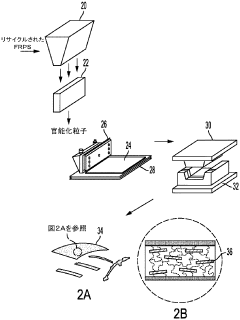

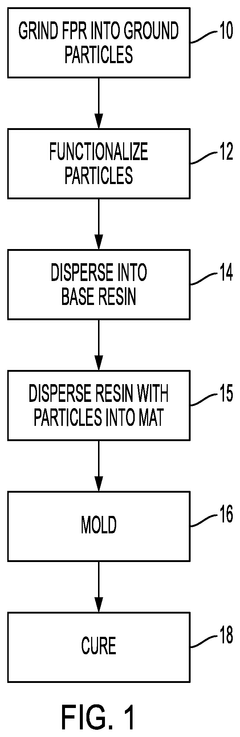

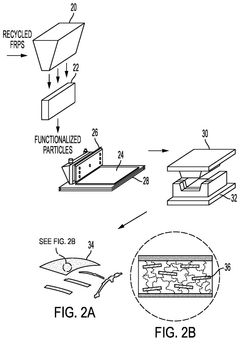

- A method involving the recycling of CFRPs through grinding, functionalizing, and dispersing functionalized particles into a base resin, followed by shaping and curing to produce parts, using high glass transition temperature epoxy resins and chemically bonded particle networks for improved mechanical properties and recyclability.

Recyclable enhanced performance carbon fiber reinforced polymers

PatentActiveUS12115701B2

Innovation

- A method involving grinding used CFRPs to produce ground particles, functionalizing them, and dispersing these particles into a base resin with high glass transition temperature epoxy, which are then molded and cured to create recyclable CFRP parts with enhanced mechanical properties and dimensional stability, enabling cost-effective and efficient recycling.

Environmental Impact and Sustainability Considerations

The environmental impact of Carbon Fiber Reinforced Polymer (CFRP) manufacturing processes, particularly curing techniques, represents a critical consideration in the industry's sustainable development. Traditional curing methods often involve energy-intensive processes that contribute significantly to carbon emissions. Autoclave curing, while effective for quality, requires substantial energy consumption with temperatures typically ranging from 120°C to 180°C maintained for extended periods, resulting in considerable environmental footprints.

Recent advancements in out-of-autoclave (OOA) curing techniques have demonstrated potential for reducing energy consumption by up to 40-60% compared to conventional methods. These approaches not only minimize direct energy inputs but also reduce the associated carbon emissions, aligning with global sustainability targets. Microwave and electron beam curing technologies further enhance this efficiency by enabling more targeted energy application, reducing waste heat and overall process duration.

Material waste represents another significant environmental concern in CFRP manufacturing. Current industry standards indicate that approximately 15-30% of prepreg materials become waste during production processes. Advanced curing techniques incorporating precise temperature control and monitoring systems have demonstrated capability to reduce this waste by improving first-time-right rates and minimizing rejected components.

Chemical emissions during curing processes pose additional environmental challenges. Traditional thermoset resins release volatile organic compounds (VOCs) during cure cycles, contributing to air pollution and potential health hazards. Newer resin systems designed specifically for low-temperature curing have shown reduced VOC emissions by up to 70%, while maintaining comparable mechanical properties in the final composite structure.

Water consumption in CFRP manufacturing, though less discussed, remains significant in certain processes. Cooling systems for tooling and equipment in traditional curing setups can consume substantial water resources. Optimized curing cycles with improved thermal management have demonstrated water usage reductions of 25-35% in industrial applications.

End-of-life considerations increasingly influence curing technique development, with recyclability becoming a key performance indicator. Thermoplastic CFRP systems, which can be processed using specialized curing approaches, offer improved recyclability compared to traditional thermoset systems. Recent research indicates that properly cured thermoplastic CFRPs can maintain up to 80% of their mechanical properties after recycling, significantly extending the material lifecycle and reducing environmental impact.

Recent advancements in out-of-autoclave (OOA) curing techniques have demonstrated potential for reducing energy consumption by up to 40-60% compared to conventional methods. These approaches not only minimize direct energy inputs but also reduce the associated carbon emissions, aligning with global sustainability targets. Microwave and electron beam curing technologies further enhance this efficiency by enabling more targeted energy application, reducing waste heat and overall process duration.

Material waste represents another significant environmental concern in CFRP manufacturing. Current industry standards indicate that approximately 15-30% of prepreg materials become waste during production processes. Advanced curing techniques incorporating precise temperature control and monitoring systems have demonstrated capability to reduce this waste by improving first-time-right rates and minimizing rejected components.

Chemical emissions during curing processes pose additional environmental challenges. Traditional thermoset resins release volatile organic compounds (VOCs) during cure cycles, contributing to air pollution and potential health hazards. Newer resin systems designed specifically for low-temperature curing have shown reduced VOC emissions by up to 70%, while maintaining comparable mechanical properties in the final composite structure.

Water consumption in CFRP manufacturing, though less discussed, remains significant in certain processes. Cooling systems for tooling and equipment in traditional curing setups can consume substantial water resources. Optimized curing cycles with improved thermal management have demonstrated water usage reductions of 25-35% in industrial applications.

End-of-life considerations increasingly influence curing technique development, with recyclability becoming a key performance indicator. Thermoplastic CFRP systems, which can be processed using specialized curing approaches, offer improved recyclability compared to traditional thermoset systems. Recent research indicates that properly cured thermoplastic CFRPs can maintain up to 80% of their mechanical properties after recycling, significantly extending the material lifecycle and reducing environmental impact.

Quality Control and Testing Protocols for Cured CFRP Components

Quality control and testing protocols are fundamental to ensuring the reliability and performance of cured CFRP components. The implementation of comprehensive testing methodologies has evolved significantly with advancements in CFRP curing techniques, necessitating standardized approaches to validate material integrity and structural performance.

Non-destructive testing (NDT) methods have become increasingly sophisticated for CFRP quality assessment. Ultrasonic inspection techniques, including through-transmission ultrasonics (TTU) and phased array ultrasonic testing (PAUT), enable detection of internal defects such as delaminations, voids, and porosity without compromising component integrity. These methods provide critical data on cure uniformity and internal structure consistency.

Thermographic inspection represents another valuable NDT approach, utilizing infrared imaging to identify subsurface anomalies through thermal conductivity variations. Active thermography, where external heat sources are applied, has proven particularly effective for detecting cure-related defects in complex CFRP geometries where traditional methods may be limited.

Mechanical testing protocols serve as the definitive validation of cured CFRP performance characteristics. Standardized tests including interlaminar shear strength (ILSS), short beam shear (SBS), and dynamic mechanical analysis (DMA) provide quantitative measurements of cure quality. Glass transition temperature (Tg) determination through DMA has emerged as a critical parameter for assessing cure completeness and predicting high-temperature performance.

Digital image correlation (DIC) techniques have revolutionized strain measurement capabilities for cured components, allowing full-field strain mapping during mechanical testing. This technology enables precise identification of localized weaknesses related to cure inconsistencies that might otherwise remain undetected through conventional testing methods.

In-process monitoring systems represent the frontier of quality control for CFRP curing. Dielectric analysis (DEA) sensors embedded within tooling provide real-time cure progression data, while fiber optic sensors enable distributed temperature and strain monitoring throughout the cure cycle. These technologies facilitate adaptive process control and documentation of cure parameters for regulatory compliance.

Statistical process control (SPC) methodologies have been adapted specifically for CFRP manufacturing, establishing control limits for critical cure parameters and enabling trend analysis to identify process drift before defects occur. Advanced data analytics approaches now correlate multiple quality indicators to develop predictive models for component performance based on cure characteristics.

Standardization efforts by organizations including ASTM, ISO, and NADCAP have established industry-wide testing protocols specific to cured CFRP components. These standards ensure consistency in quality assessment across the supply chain while providing benchmark requirements for emerging curing technologies to demonstrate equivalence or improvement over established methods.

Non-destructive testing (NDT) methods have become increasingly sophisticated for CFRP quality assessment. Ultrasonic inspection techniques, including through-transmission ultrasonics (TTU) and phased array ultrasonic testing (PAUT), enable detection of internal defects such as delaminations, voids, and porosity without compromising component integrity. These methods provide critical data on cure uniformity and internal structure consistency.

Thermographic inspection represents another valuable NDT approach, utilizing infrared imaging to identify subsurface anomalies through thermal conductivity variations. Active thermography, where external heat sources are applied, has proven particularly effective for detecting cure-related defects in complex CFRP geometries where traditional methods may be limited.

Mechanical testing protocols serve as the definitive validation of cured CFRP performance characteristics. Standardized tests including interlaminar shear strength (ILSS), short beam shear (SBS), and dynamic mechanical analysis (DMA) provide quantitative measurements of cure quality. Glass transition temperature (Tg) determination through DMA has emerged as a critical parameter for assessing cure completeness and predicting high-temperature performance.

Digital image correlation (DIC) techniques have revolutionized strain measurement capabilities for cured components, allowing full-field strain mapping during mechanical testing. This technology enables precise identification of localized weaknesses related to cure inconsistencies that might otherwise remain undetected through conventional testing methods.

In-process monitoring systems represent the frontier of quality control for CFRP curing. Dielectric analysis (DEA) sensors embedded within tooling provide real-time cure progression data, while fiber optic sensors enable distributed temperature and strain monitoring throughout the cure cycle. These technologies facilitate adaptive process control and documentation of cure parameters for regulatory compliance.

Statistical process control (SPC) methodologies have been adapted specifically for CFRP manufacturing, establishing control limits for critical cure parameters and enabling trend analysis to identify process drift before defects occur. Advanced data analytics approaches now correlate multiple quality indicators to develop predictive models for component performance based on cure characteristics.

Standardization efforts by organizations including ASTM, ISO, and NADCAP have established industry-wide testing protocols specific to cured CFRP components. These standards ensure consistency in quality assessment across the supply chain while providing benchmark requirements for emerging curing technologies to demonstrate equivalence or improvement over established methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!