How to Assess CFRP Microstructural Integrity via X-ray Imaging

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP X-ray Imaging Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries over the past four decades. Initially developed for aerospace applications in the 1970s, these lightweight yet incredibly strong composite materials have transformed engineering capabilities across multiple sectors including automotive, wind energy, sporting goods, and civil infrastructure. The evolution of CFRP technology has been characterized by continuous improvements in manufacturing processes, fiber architectures, and matrix systems, leading to enhanced mechanical properties and reduced production costs.

The fundamental structure of CFRP consists of carbon fibers embedded within a polymer matrix, creating a heterogeneous material with complex microstructural features. This microstructure directly influences the mechanical behavior, durability, and failure mechanisms of CFRP components. As industries increasingly rely on these materials for critical applications, the need for reliable non-destructive evaluation methods has become paramount.

X-ray imaging techniques have progressively developed as powerful tools for inspecting CFRP materials. Beginning with conventional radiography and evolving to advanced methods such as computed tomography (CT), phase-contrast imaging, and synchrotron radiation techniques, X-ray technologies offer unique capabilities to visualize internal structures without damaging the specimen. The historical trajectory shows a clear trend toward higher resolution, faster acquisition times, and more sophisticated data analysis methods.

The primary objective of CFRP microstructural integrity assessment via X-ray imaging is to develop reliable, accurate, and efficient methodologies for detecting, characterizing, and quantifying defects and damage within composite structures. These defects may include fiber misalignment, matrix cracking, delamination, porosity, and foreign object inclusions—all of which can significantly compromise structural performance.

Secondary objectives include establishing standardized protocols for image acquisition and analysis, developing automated defect recognition algorithms, correlating imaging data with mechanical properties, and creating predictive models for component lifetime estimation. The ultimate goal is to implement these techniques in real-world quality control processes and in-service inspection routines.

Current technological trends point toward multi-modal imaging approaches that combine X-ray techniques with complementary methods such as ultrasonic testing and infrared thermography. Additionally, there is growing interest in in-situ testing, where X-ray imaging is performed while the specimen undergoes mechanical loading, providing valuable insights into damage initiation and propagation mechanisms.

As CFRP applications continue to expand into more critical and demanding environments, the importance of robust microstructural integrity assessment methods becomes increasingly vital. The development of accessible, reliable X-ray imaging techniques represents a key enabling technology for the next generation of composite materials and structures.

The fundamental structure of CFRP consists of carbon fibers embedded within a polymer matrix, creating a heterogeneous material with complex microstructural features. This microstructure directly influences the mechanical behavior, durability, and failure mechanisms of CFRP components. As industries increasingly rely on these materials for critical applications, the need for reliable non-destructive evaluation methods has become paramount.

X-ray imaging techniques have progressively developed as powerful tools for inspecting CFRP materials. Beginning with conventional radiography and evolving to advanced methods such as computed tomography (CT), phase-contrast imaging, and synchrotron radiation techniques, X-ray technologies offer unique capabilities to visualize internal structures without damaging the specimen. The historical trajectory shows a clear trend toward higher resolution, faster acquisition times, and more sophisticated data analysis methods.

The primary objective of CFRP microstructural integrity assessment via X-ray imaging is to develop reliable, accurate, and efficient methodologies for detecting, characterizing, and quantifying defects and damage within composite structures. These defects may include fiber misalignment, matrix cracking, delamination, porosity, and foreign object inclusions—all of which can significantly compromise structural performance.

Secondary objectives include establishing standardized protocols for image acquisition and analysis, developing automated defect recognition algorithms, correlating imaging data with mechanical properties, and creating predictive models for component lifetime estimation. The ultimate goal is to implement these techniques in real-world quality control processes and in-service inspection routines.

Current technological trends point toward multi-modal imaging approaches that combine X-ray techniques with complementary methods such as ultrasonic testing and infrared thermography. Additionally, there is growing interest in in-situ testing, where X-ray imaging is performed while the specimen undergoes mechanical loading, providing valuable insights into damage initiation and propagation mechanisms.

As CFRP applications continue to expand into more critical and demanding environments, the importance of robust microstructural integrity assessment methods becomes increasingly vital. The development of accessible, reliable X-ray imaging techniques represents a key enabling technology for the next generation of composite materials and structures.

Market Demand for CFRP Integrity Assessment

The global market for Carbon Fiber Reinforced Polymers (CFRP) integrity assessment has witnessed substantial growth in recent years, driven primarily by the increasing adoption of these advanced materials across multiple industries. The aerospace sector remains the largest consumer of CFRP, accounting for approximately 30% of the total market share, followed closely by automotive and wind energy sectors.

The demand for reliable CFRP integrity assessment methods, particularly X-ray imaging techniques, has been growing at a compound annual growth rate of 8.7% since 2018. This growth trajectory is expected to continue as industries push for lighter, stronger materials to improve fuel efficiency and reduce carbon emissions. Market research indicates that the global CFRP testing and inspection market reached $1.2 billion in 2022, with X-ray-based assessment methods representing about 22% of this value.

A significant market driver is the increasing safety regulations across industries, particularly in aerospace and automotive sectors. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented stringent requirements for composite material inspection, creating a substantial demand for advanced non-destructive testing methods like X-ray imaging. Similarly, automotive safety standards are evolving to address the unique characteristics of composite materials in structural components.

The wind energy sector presents another rapidly expanding market for CFRP integrity assessment. With wind turbine blades growing larger to capture more energy, the structural integrity of CFRP components becomes increasingly critical. Market analysis shows that inspection costs represent approximately 4-7% of the total maintenance expenses for wind farms, creating a substantial market opportunity for efficient assessment technologies.

Healthcare and sporting goods industries are emerging as new market segments for CFRP applications, with corresponding needs for integrity assessment. Medical devices utilizing carbon fiber components require high-precision inspection methods, while high-performance sporting equipment manufacturers seek cost-effective quality control solutions.

Regional analysis reveals that North America and Europe currently dominate the market for CFRP integrity assessment technologies, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China and Japan, is experiencing the fastest growth rate at 12.3% annually, driven by rapid industrialization and increasing adoption of composite materials in manufacturing.

The market increasingly demands real-time, in-situ assessment capabilities that can be integrated into production lines, reducing inspection time and costs while improving detection accuracy. This trend is pushing technology providers to develop faster, more portable X-ray imaging solutions with advanced image processing capabilities.

The demand for reliable CFRP integrity assessment methods, particularly X-ray imaging techniques, has been growing at a compound annual growth rate of 8.7% since 2018. This growth trajectory is expected to continue as industries push for lighter, stronger materials to improve fuel efficiency and reduce carbon emissions. Market research indicates that the global CFRP testing and inspection market reached $1.2 billion in 2022, with X-ray-based assessment methods representing about 22% of this value.

A significant market driver is the increasing safety regulations across industries, particularly in aerospace and automotive sectors. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented stringent requirements for composite material inspection, creating a substantial demand for advanced non-destructive testing methods like X-ray imaging. Similarly, automotive safety standards are evolving to address the unique characteristics of composite materials in structural components.

The wind energy sector presents another rapidly expanding market for CFRP integrity assessment. With wind turbine blades growing larger to capture more energy, the structural integrity of CFRP components becomes increasingly critical. Market analysis shows that inspection costs represent approximately 4-7% of the total maintenance expenses for wind farms, creating a substantial market opportunity for efficient assessment technologies.

Healthcare and sporting goods industries are emerging as new market segments for CFRP applications, with corresponding needs for integrity assessment. Medical devices utilizing carbon fiber components require high-precision inspection methods, while high-performance sporting equipment manufacturers seek cost-effective quality control solutions.

Regional analysis reveals that North America and Europe currently dominate the market for CFRP integrity assessment technologies, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China and Japan, is experiencing the fastest growth rate at 12.3% annually, driven by rapid industrialization and increasing adoption of composite materials in manufacturing.

The market increasingly demands real-time, in-situ assessment capabilities that can be integrated into production lines, reducing inspection time and costs while improving detection accuracy. This trend is pushing technology providers to develop faster, more portable X-ray imaging solutions with advanced image processing capabilities.

X-ray Imaging Technology Status and Challenges

X-ray imaging technology for assessing Carbon Fiber Reinforced Polymer (CFRP) microstructural integrity has evolved significantly over the past decades, with major advancements in both hardware capabilities and image processing algorithms. Currently, the global landscape shows varying levels of technological maturity across different regions, with North America, Europe, and East Asia leading in research and implementation.

The state-of-the-art X-ray imaging techniques for CFRP inspection include micro-computed tomography (micro-CT), phase-contrast imaging, and synchrotron radiation imaging. Micro-CT has become increasingly accessible for industrial applications, offering resolution down to several micrometers, which enables detection of micro-cracks, voids, and fiber orientation anomalies in CFRP components. Phase-contrast imaging enhances visibility of interfaces between materials with similar attenuation coefficients, particularly valuable for composite materials where traditional absorption contrast may be insufficient.

Despite these advancements, significant technical challenges persist in the field. Resolution limitations remain a primary concern, as detecting nanoscale defects that can critically impact CFRP performance requires further technological breakthroughs. Current commercial systems typically achieve 1-5 μm resolution, which is insufficient for identifying certain early-stage damage mechanisms in aerospace-grade composites.

Another major challenge is the trade-off between scanning speed and image quality. High-resolution scans often require extended exposure times, making real-time or in-line inspection impractical for many manufacturing environments. This creates a bottleneck for quality control in high-volume production settings where rapid assessment is essential.

Data processing and interpretation present additional hurdles. The massive datasets generated by high-resolution 3D imaging require sophisticated algorithms and substantial computing resources. Current automated defect recognition systems still struggle with reliability when identifying complex defect patterns in heterogeneous CFRP structures.

Radiation dose considerations also limit certain applications, particularly for in-service inspection of components where repeated examinations may be necessary. Developing low-dose protocols that maintain diagnostic quality remains an active research area.

Geographically, technological development shows distinct patterns. European research institutions lead in algorithm development and theoretical advances, while North American companies dominate commercial system integration. Asian manufacturers, particularly in Japan and China, are rapidly advancing in cost-effective implementation and specialized applications for automotive and consumer electronics sectors.

The regulatory landscape adds complexity, with varying standards for qualification of non-destructive testing methods across industries and regions. This has led to fragmentation in adoption patterns and slowed standardization of best practices for CFRP inspection using X-ray technologies.

The state-of-the-art X-ray imaging techniques for CFRP inspection include micro-computed tomography (micro-CT), phase-contrast imaging, and synchrotron radiation imaging. Micro-CT has become increasingly accessible for industrial applications, offering resolution down to several micrometers, which enables detection of micro-cracks, voids, and fiber orientation anomalies in CFRP components. Phase-contrast imaging enhances visibility of interfaces between materials with similar attenuation coefficients, particularly valuable for composite materials where traditional absorption contrast may be insufficient.

Despite these advancements, significant technical challenges persist in the field. Resolution limitations remain a primary concern, as detecting nanoscale defects that can critically impact CFRP performance requires further technological breakthroughs. Current commercial systems typically achieve 1-5 μm resolution, which is insufficient for identifying certain early-stage damage mechanisms in aerospace-grade composites.

Another major challenge is the trade-off between scanning speed and image quality. High-resolution scans often require extended exposure times, making real-time or in-line inspection impractical for many manufacturing environments. This creates a bottleneck for quality control in high-volume production settings where rapid assessment is essential.

Data processing and interpretation present additional hurdles. The massive datasets generated by high-resolution 3D imaging require sophisticated algorithms and substantial computing resources. Current automated defect recognition systems still struggle with reliability when identifying complex defect patterns in heterogeneous CFRP structures.

Radiation dose considerations also limit certain applications, particularly for in-service inspection of components where repeated examinations may be necessary. Developing low-dose protocols that maintain diagnostic quality remains an active research area.

Geographically, technological development shows distinct patterns. European research institutions lead in algorithm development and theoretical advances, while North American companies dominate commercial system integration. Asian manufacturers, particularly in Japan and China, are rapidly advancing in cost-effective implementation and specialized applications for automotive and consumer electronics sectors.

The regulatory landscape adds complexity, with varying standards for qualification of non-destructive testing methods across industries and regions. This has led to fragmentation in adoption patterns and slowed standardization of best practices for CFRP inspection using X-ray technologies.

Current X-ray Methods for CFRP Microstructure Analysis

01 Manufacturing techniques for CFRP microstructural integrity

Various manufacturing techniques are employed to enhance the microstructural integrity of Carbon Fiber Reinforced Polymers. These include specialized layup methods, curing processes, and molding techniques that minimize defects and ensure proper fiber alignment. Advanced manufacturing processes help to reduce void content, improve fiber-matrix adhesion, and create more uniform microstructures, resulting in CFRP components with superior mechanical properties and durability.- Manufacturing techniques for CFRP microstructural integrity: Various manufacturing techniques are employed to enhance the microstructural integrity of Carbon Fiber Reinforced Polymers. These include specialized layup methods, curing processes, and molding techniques that minimize defects and ensure proper fiber alignment. Advanced manufacturing processes help to reduce void content, improve fiber-matrix adhesion, and create more uniform microstructures, resulting in superior mechanical properties and durability of the final CFRP components.

- Testing and evaluation methods for CFRP microstructure: Non-destructive testing and evaluation methods are critical for assessing the microstructural integrity of CFRP components. These include ultrasonic inspection, X-ray tomography, thermography, and acoustic emission techniques that can detect internal defects, delaminations, and matrix cracks without damaging the material. These methods allow for quality control during manufacturing and in-service inspection to ensure the continued structural integrity of CFRP components under various loading conditions.

- Fiber-matrix interface optimization: The interface between carbon fibers and the polymer matrix is crucial for CFRP microstructural integrity. Surface treatments of carbon fibers, such as sizing, oxidation, or plasma treatment, can improve adhesion to the polymer matrix. Additionally, the selection of compatible sizing agents and coupling agents can enhance the interfacial bond strength. Optimizing this interface prevents microcracking, improves load transfer between fibers and matrix, and enhances the overall durability and performance of CFRP composites.

- Environmental degradation resistance: CFRP microstructural integrity can be compromised by environmental factors such as moisture, temperature fluctuations, UV radiation, and chemical exposure. Protective coatings, additives, and matrix modifications can be incorporated to enhance resistance to these degradation mechanisms. Specialized formulations that minimize water absorption, prevent thermal degradation, and resist chemical attack help maintain the microstructural integrity of CFRP components throughout their service life in challenging environments.

- Damage detection and self-healing mechanisms: Advanced systems for detecting and mitigating damage in CFRP microstructures include embedded sensors, smart materials, and self-healing mechanisms. These technologies can identify microstructural damage in real-time and, in some cases, initiate repair processes. Self-healing approaches include microcapsules containing healing agents, vascular networks that deliver repair chemicals, and reversible polymer systems that can restore mechanical properties after damage, thereby extending the service life and reliability of CFRP components.

02 Inspection and testing methods for CFRP microstructure

Non-destructive testing and inspection methods are crucial for evaluating the microstructural integrity of CFRP components. Techniques such as ultrasonic testing, X-ray computed tomography, and thermography can detect internal defects, delaminations, and fiber misalignments that may compromise structural integrity. These methods allow for quality control during manufacturing and in-service inspection to ensure the continued performance and safety of CFRP structures.Expand Specific Solutions03 Fiber-matrix interface optimization

The interface between carbon fibers and the polymer matrix is critical for CFRP microstructural integrity. Surface treatments of carbon fibers, such as sizing, oxidation, or plasma treatment, can improve adhesion to the matrix. Additionally, the selection of compatible matrix materials and the use of coupling agents can enhance load transfer between fibers and matrix. These optimizations result in stronger interfaces that resist delamination and microcracking, thereby improving the overall durability and performance of CFRP components.Expand Specific Solutions04 Environmental degradation resistance

CFRP microstructural integrity can be compromised by environmental factors such as moisture, temperature fluctuations, UV radiation, and chemical exposure. Protective coatings, matrix modifications, and specialized additives can be incorporated to enhance resistance to these degradation mechanisms. Techniques to improve the hydrophobicity of the matrix, reduce moisture absorption, and prevent oxidation help maintain the microstructural integrity of CFRP components throughout their service life in challenging environments.Expand Specific Solutions05 Damage detection and self-healing capabilities

Advanced CFRP systems incorporate damage detection and self-healing capabilities to maintain microstructural integrity. Embedded sensors, such as fiber optic or piezoelectric sensors, can monitor structural health and detect microstructural damage in real-time. Self-healing mechanisms, including microcapsules containing healing agents or vascular networks that deliver repair materials to damaged areas, can automatically restore microstructural integrity after damage occurs, extending the service life of CFRP components and improving safety.Expand Specific Solutions

Key Players in CFRP Imaging Industry

The X-ray imaging assessment of CFRP microstructural integrity is currently in a growth phase, with the market expanding due to increasing demand in aerospace, automotive, and energy sectors. The global market size for advanced composite testing is estimated at $2-3 billion annually, with X-ray techniques representing a significant segment. Technology maturity varies across different approaches, with companies demonstrating diverse capabilities. Rigaku Corp. and Carl Zeiss X-ray Microscopy lead in high-resolution imaging systems, while aerospace manufacturers like Safran SA and Airbus SAS have developed specialized applications for composite inspection. Research institutions including Nanjing University of Aeronautics & Astronautics and University of Southern California are advancing fundamental techniques. The competitive landscape shows a balance between established equipment manufacturers and emerging specialized solution providers focusing on AI-enhanced analysis methods.

Safran SA

Technical Solution: Safran SA has developed proprietary X-ray imaging technologies specifically tailored for CFRP components used in aerospace applications. Their approach combines high-energy industrial CT systems with specialized image processing algorithms designed to detect and characterize critical defects in complex composite structures. Safran's technology employs multi-energy X-ray sources (operating at 225-450kV) to penetrate thick CFRP sections while maintaining sufficient contrast to identify subtle variations in fiber architecture. Their proprietary CIVA simulation software allows for virtual inspection planning and defect response modeling, optimizing scan parameters before physical testing. Safran has implemented automated defect recognition systems that can identify and classify manufacturing anomalies including porosity clusters, resin-rich regions, foreign object debris, and fiber misalignment with high reliability. Their inspection protocol incorporates reference standards with engineered defects to establish probability of detection curves specific to each component geometry. The company has also developed in-situ loading fixtures that enable X-ray monitoring of damage progression under mechanical or thermal loading, providing critical data for validating structural integrity models and establishing damage tolerance criteria for safety-critical CFRP components.

Strengths: Deep aerospace industry expertise with specific focus on safety-critical applications; integrated approach combining simulation and physical testing; specialized algorithms for complex geometries typical in aerospace components. Weaknesses: Solutions primarily optimized for aerospace applications with less focus on other industries; high equipment costs; systems typically require significant floor space and radiation shielding infrastructure.

Rigaku Corp.

Technical Solution: Rigaku Corporation has developed specialized X-ray diffraction (XRD) and computed tomography (CT) systems for CFRP microstructural integrity assessment. Their nano3DX system utilizes a rotating anode X-ray source to generate high-brilliance X-rays, achieving resolutions down to 0.27μm for detailed fiber orientation analysis and void detection. The company's CT Lab GX series incorporates dual-energy CT capabilities, allowing simultaneous visualization of both carbon fibers and polymer matrix components through material decomposition algorithms. Rigaku's proprietary image reconstruction software employs iterative techniques to reduce artifacts common in composite materials with high aspect ratio features. Their systems integrate in-line inspection capabilities with automated defect recognition algorithms that can classify and quantify common CFRP manufacturing defects including porosity, fiber misalignment, and resin-rich regions. The company has also developed specialized sample holders and environmental chambers that enable in-situ mechanical testing while performing X-ray analysis, providing insights into damage initiation and propagation mechanisms under various loading conditions.

Strengths: High-resolution capabilities suitable for detecting microscale defects; specialized software for composite material analysis; dual-energy capabilities for enhanced material differentiation. Weaknesses: Systems typically require controlled laboratory environments; relatively slow scanning speeds limit production line integration; higher radiation doses compared to some competing technologies.

Advanced X-ray Techniques for CFRP Defect Detection

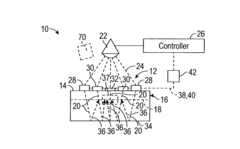

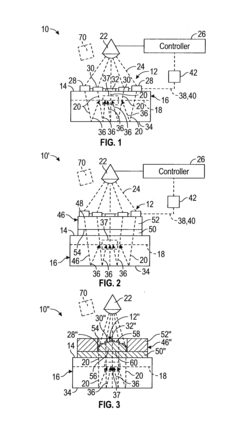

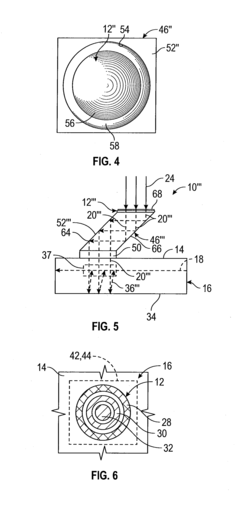

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

Standardization and Certification Requirements

The standardization and certification landscape for CFRP (Carbon Fiber Reinforced Polymer) microstructural integrity assessment using X-ray imaging is complex and evolving rapidly. Currently, several international standards organizations, including ASTM International, ISO, and ASME, have established guidelines that partially address this domain. ASTM E2580 provides standards for digital imaging and communication in nondestructive evaluation, while ISO 15708 focuses on non-destructive testing using X-ray computed tomography.

For CFRP specifically, certification requirements typically mandate quantifiable metrics for void content, fiber orientation, delamination detection, and inclusion identification. These requirements vary significantly across industries, with aerospace demanding the most stringent standards (typically allowing less than 1% void content), followed by automotive and renewable energy sectors. The certification process generally requires traceability of measurement methods, calibration procedures, and uncertainty quantification.

A significant challenge in standardization efforts is the lack of unified protocols for image acquisition parameters. Variables such as X-ray energy, detector resolution, exposure time, and reconstruction algorithms significantly impact the assessment results. This variability creates inconsistencies in quality assessment across different facilities and equipment manufacturers, complicating certification processes.

Recent developments include the emergence of digital reference materials and phantoms specifically designed for CFRP inspection. These reference materials enable calibration and validation of X-ray systems against known standards, facilitating more consistent certification processes. Organizations like the National Institute of Standards and Technology (NIST) are actively developing these reference materials to support industry-wide standardization.

Certification requirements also increasingly address the qualifications of personnel conducting and interpreting X-ray assessments of CFRP components. Standards such as EN 4179 and NAS 410 outline the training, experience, and examination requirements for nondestructive testing personnel, including those specializing in radiographic techniques for composite materials.

Looking forward, the integration of artificial intelligence in image analysis is creating new challenges for certification frameworks. Regulatory bodies are beginning to develop guidelines for validating AI-assisted inspection systems, requiring demonstration of reliability, reproducibility, and transparency in algorithmic decision-making processes. This emerging area will likely see significant standardization activity in the coming years as machine learning becomes more prevalent in CFRP quality assessment.

For CFRP specifically, certification requirements typically mandate quantifiable metrics for void content, fiber orientation, delamination detection, and inclusion identification. These requirements vary significantly across industries, with aerospace demanding the most stringent standards (typically allowing less than 1% void content), followed by automotive and renewable energy sectors. The certification process generally requires traceability of measurement methods, calibration procedures, and uncertainty quantification.

A significant challenge in standardization efforts is the lack of unified protocols for image acquisition parameters. Variables such as X-ray energy, detector resolution, exposure time, and reconstruction algorithms significantly impact the assessment results. This variability creates inconsistencies in quality assessment across different facilities and equipment manufacturers, complicating certification processes.

Recent developments include the emergence of digital reference materials and phantoms specifically designed for CFRP inspection. These reference materials enable calibration and validation of X-ray systems against known standards, facilitating more consistent certification processes. Organizations like the National Institute of Standards and Technology (NIST) are actively developing these reference materials to support industry-wide standardization.

Certification requirements also increasingly address the qualifications of personnel conducting and interpreting X-ray assessments of CFRP components. Standards such as EN 4179 and NAS 410 outline the training, experience, and examination requirements for nondestructive testing personnel, including those specializing in radiographic techniques for composite materials.

Looking forward, the integration of artificial intelligence in image analysis is creating new challenges for certification frameworks. Regulatory bodies are beginning to develop guidelines for validating AI-assisted inspection systems, requiring demonstration of reliability, reproducibility, and transparency in algorithmic decision-making processes. This emerging area will likely see significant standardization activity in the coming years as machine learning becomes more prevalent in CFRP quality assessment.

Cost-Benefit Analysis of X-ray Inspection Systems

When evaluating the implementation of X-ray inspection systems for CFRP microstructural integrity assessment, organizations must conduct a thorough cost-benefit analysis to justify the investment. The initial capital expenditure for advanced X-ray imaging systems ranges from $150,000 for basic 2D radiography setups to over $1.5 million for high-resolution CT systems with automated inspection capabilities. These figures represent significant investments that require careful financial planning and return-on-investment calculations.

Operating costs present another substantial consideration, including maintenance contracts (typically 8-12% of the initial equipment cost annually), specialized operator training ($5,000-$15,000 per technician), and facility modifications to accommodate radiation shielding requirements ($50,000-$200,000 depending on system specifications). Energy consumption costs for continuous operation can add $10,000-$30,000 annually to operational expenses.

Against these costs, organizations must weigh quantifiable benefits such as defect detection improvements. Studies indicate that advanced X-ray inspection systems can increase defect detection rates by 30-45% compared to conventional methods, significantly reducing the probability of in-service failures. This translates to substantial savings in warranty claims and liability costs, which can exceed millions of dollars for critical aerospace or automotive components.

Production efficiency gains represent another significant benefit, with automated X-ray inspection reducing inspection time by 40-60% compared to manual ultrasonic testing methods. This acceleration of quality control processes can increase production throughput by 15-25% in high-volume manufacturing environments, creating measurable revenue opportunities.

Long-term strategic benefits include enhanced product reliability data collection, which enables predictive maintenance strategies and lifecycle cost reductions for end-users. Organizations implementing comprehensive X-ray inspection programs report 20-35% reductions in field failures over 5-year periods, strengthening brand reputation and customer confidence.

The payback period for X-ray inspection systems varies significantly by application, ranging from 12-18 months in high-volume aerospace manufacturing to 3-5 years in lower-volume specialty applications. Organizations should develop detailed ROI models incorporating both direct cost savings and indirect benefits such as improved design feedback loops and reduced time-to-market for new CFRP applications.

Operating costs present another substantial consideration, including maintenance contracts (typically 8-12% of the initial equipment cost annually), specialized operator training ($5,000-$15,000 per technician), and facility modifications to accommodate radiation shielding requirements ($50,000-$200,000 depending on system specifications). Energy consumption costs for continuous operation can add $10,000-$30,000 annually to operational expenses.

Against these costs, organizations must weigh quantifiable benefits such as defect detection improvements. Studies indicate that advanced X-ray inspection systems can increase defect detection rates by 30-45% compared to conventional methods, significantly reducing the probability of in-service failures. This translates to substantial savings in warranty claims and liability costs, which can exceed millions of dollars for critical aerospace or automotive components.

Production efficiency gains represent another significant benefit, with automated X-ray inspection reducing inspection time by 40-60% compared to manual ultrasonic testing methods. This acceleration of quality control processes can increase production throughput by 15-25% in high-volume manufacturing environments, creating measurable revenue opportunities.

Long-term strategic benefits include enhanced product reliability data collection, which enables predictive maintenance strategies and lifecycle cost reductions for end-users. Organizations implementing comprehensive X-ray inspection programs report 20-35% reductions in field failures over 5-year periods, strengthening brand reputation and customer confidence.

The payback period for X-ray inspection systems varies significantly by application, ranging from 12-18 months in high-volume aerospace manufacturing to 3-5 years in lower-volume specialty applications. Organizations should develop detailed ROI models incorporating both direct cost savings and indirect benefits such as improved design feedback loops and reduced time-to-market for new CFRP applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!