How to Develop CFRP with Improved Fire Retardancy

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Fire Retardancy Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance applications due to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. Since their commercial introduction in the 1960s, CFRPs have transformed industries ranging from aerospace and automotive to construction and sporting goods. However, their inherent flammability presents a significant limitation that restricts broader adoption in safety-critical applications.

The evolution of CFRP technology has been marked by continuous improvements in manufacturing processes, matrix formulations, and fiber treatments. Initially developed for specialized aerospace applications, CFRPs have gradually penetrated mainstream engineering sectors. This expansion has highlighted the critical need to address their fire performance limitations, particularly as regulatory requirements become increasingly stringent across industries.

Fire safety concerns with CFRPs stem from their organic polymer matrix, typically epoxy-based, which can decompose at relatively low temperatures (300-400°C), releasing heat, smoke, and toxic gases. When exposed to fire, CFRPs can experience matrix degradation, delamination, and significant reduction in mechanical properties, potentially leading to catastrophic structural failure. This vulnerability represents a fundamental challenge to their implementation in applications where fire resistance is paramount.

Recent technological trends indicate growing research interest in developing fire-retardant CFRPs without compromising their mechanical properties. The industry has witnessed a shift from traditional halogenated flame retardants toward more environmentally friendly and efficient solutions, including nanoparticle additives, phosphorus-based compounds, and novel matrix formulations. This evolution reflects broader sustainability concerns and increasingly strict environmental regulations.

The primary objective of fire-retardant CFRP development is to create materials that maintain structural integrity during fire exposure while minimizing smoke production and toxic emissions. Specifically, the goals include extending the time to ignition, reducing heat release rates, minimizing flame spread, and preserving mechanical properties at elevated temperatures. These improvements would significantly expand the application range of CFRPs in transportation, infrastructure, and building sectors.

Additionally, there is a growing emphasis on developing cost-effective fire-retardant solutions that can be integrated into existing manufacturing processes without substantial modifications. This practical consideration is crucial for industry adoption, as prohibitive costs have historically limited the implementation of advanced fire-retardant technologies in commercial applications.

The convergence of nanotechnology, polymer science, and computational modeling is creating unprecedented opportunities to engineer CFRPs with tailored fire performance characteristics. These interdisciplinary approaches promise to overcome the traditional trade-offs between fire retardancy and mechanical properties that have constrained previous generations of composite materials.

The evolution of CFRP technology has been marked by continuous improvements in manufacturing processes, matrix formulations, and fiber treatments. Initially developed for specialized aerospace applications, CFRPs have gradually penetrated mainstream engineering sectors. This expansion has highlighted the critical need to address their fire performance limitations, particularly as regulatory requirements become increasingly stringent across industries.

Fire safety concerns with CFRPs stem from their organic polymer matrix, typically epoxy-based, which can decompose at relatively low temperatures (300-400°C), releasing heat, smoke, and toxic gases. When exposed to fire, CFRPs can experience matrix degradation, delamination, and significant reduction in mechanical properties, potentially leading to catastrophic structural failure. This vulnerability represents a fundamental challenge to their implementation in applications where fire resistance is paramount.

Recent technological trends indicate growing research interest in developing fire-retardant CFRPs without compromising their mechanical properties. The industry has witnessed a shift from traditional halogenated flame retardants toward more environmentally friendly and efficient solutions, including nanoparticle additives, phosphorus-based compounds, and novel matrix formulations. This evolution reflects broader sustainability concerns and increasingly strict environmental regulations.

The primary objective of fire-retardant CFRP development is to create materials that maintain structural integrity during fire exposure while minimizing smoke production and toxic emissions. Specifically, the goals include extending the time to ignition, reducing heat release rates, minimizing flame spread, and preserving mechanical properties at elevated temperatures. These improvements would significantly expand the application range of CFRPs in transportation, infrastructure, and building sectors.

Additionally, there is a growing emphasis on developing cost-effective fire-retardant solutions that can be integrated into existing manufacturing processes without substantial modifications. This practical consideration is crucial for industry adoption, as prohibitive costs have historically limited the implementation of advanced fire-retardant technologies in commercial applications.

The convergence of nanotechnology, polymer science, and computational modeling is creating unprecedented opportunities to engineer CFRPs with tailored fire performance characteristics. These interdisciplinary approaches promise to overcome the traditional trade-offs between fire retardancy and mechanical properties that have constrained previous generations of composite materials.

Market Analysis for Fire-Resistant CFRP Applications

The global market for fire-resistant Carbon Fiber Reinforced Polymers (CFRP) is experiencing significant growth driven by stringent safety regulations across industries and increasing awareness of fire safety. The aerospace sector represents the largest market segment, with an estimated demand growth of 7.2% annually through 2030, as aircraft manufacturers seek lightweight materials that meet strict fire safety standards without compromising structural integrity.

Construction and infrastructure applications form the second-largest market segment, particularly in high-rise buildings, tunnels, and bridges where fire resistance is critical. This sector is projected to grow at 6.5% annually, fueled by urbanization trends and updated building codes that emphasize fire safety in structural components.

The automotive industry presents an emerging opportunity for fire-resistant CFRP, especially in electric vehicles where battery fire containment is a primary concern. Market penetration in this sector remains relatively low but is expected to accelerate as EV production increases and safety standards evolve specifically for electric powertrains.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate due to rapid industrialization, infrastructure development, and increasing adoption of advanced materials in countries like China, Japan, and South Korea.

Price sensitivity remains a significant market constraint, as fire-resistant CFRP commands a premium of 30-40% over standard CFRP. This price differential limits adoption in cost-sensitive applications and creates opportunities for alternative materials with lower performance but better cost profiles.

Customer requirements analysis indicates that end-users prioritize three key performance metrics: flame spread index, smoke development index, and heat release rate. Secondary considerations include toxicity of combustion products and maintenance of mechanical properties at elevated temperatures. These requirements vary significantly across industries, necessitating customized formulations for different applications.

Market forecasts suggest that technological innovations reducing the cost premium of fire-resistant CFRP could expand the addressable market by 40-50% within five years. Particularly promising are applications in public transportation, marine vessels, and industrial equipment where the combination of lightweight properties and fire resistance provides compelling value despite higher initial costs.

Construction and infrastructure applications form the second-largest market segment, particularly in high-rise buildings, tunnels, and bridges where fire resistance is critical. This sector is projected to grow at 6.5% annually, fueled by urbanization trends and updated building codes that emphasize fire safety in structural components.

The automotive industry presents an emerging opportunity for fire-resistant CFRP, especially in electric vehicles where battery fire containment is a primary concern. Market penetration in this sector remains relatively low but is expected to accelerate as EV production increases and safety standards evolve specifically for electric powertrains.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate due to rapid industrialization, infrastructure development, and increasing adoption of advanced materials in countries like China, Japan, and South Korea.

Price sensitivity remains a significant market constraint, as fire-resistant CFRP commands a premium of 30-40% over standard CFRP. This price differential limits adoption in cost-sensitive applications and creates opportunities for alternative materials with lower performance but better cost profiles.

Customer requirements analysis indicates that end-users prioritize three key performance metrics: flame spread index, smoke development index, and heat release rate. Secondary considerations include toxicity of combustion products and maintenance of mechanical properties at elevated temperatures. These requirements vary significantly across industries, necessitating customized formulations for different applications.

Market forecasts suggest that technological innovations reducing the cost premium of fire-resistant CFRP could expand the addressable market by 40-50% within five years. Particularly promising are applications in public transportation, marine vessels, and industrial equipment where the combination of lightweight properties and fire resistance provides compelling value despite higher initial costs.

Current Challenges in CFRP Fire Protection

Despite significant advancements in carbon fiber reinforced polymers (CFRP) technology, fire protection remains one of the most critical challenges limiting their broader application in safety-critical sectors. The inherent flammability of the polymer matrix in CFRP composites presents a substantial risk, as these materials can ignite at relatively low temperatures (typically 300-400°C), releasing toxic gases and smoke while rapidly losing their mechanical properties under fire conditions.

The primary technical challenge lies in the fundamental conflict between fire retardancy and mechanical performance. Most conventional fire retardant additives, when incorporated into the polymer matrix, tend to disrupt the fiber-matrix interface, leading to significant reductions in mechanical properties such as tensile strength, impact resistance, and interlaminar shear strength. This trade-off has proven difficult to overcome, particularly when high levels of fire protection are required.

Another significant obstacle is the complex degradation mechanism of CFRP during fire exposure. Unlike homogeneous materials, composites exhibit multi-phase degradation involving matrix decomposition, fiber-matrix debonding, delamination, and char formation. This complexity makes it difficult to develop comprehensive fire protection strategies that address all failure modes simultaneously.

The aerospace and automotive industries face particularly stringent regulatory requirements for fire safety that current CFRP solutions struggle to meet without significant weight penalties. FAR 25.853 for aviation and ECE R118 for automotive applications set demanding standards for flame spread, heat release, and smoke density that often necessitate additional protective layers or treatments, negating some of the weight advantages of CFRP.

Manufacturing integration presents another substantial challenge. Many promising fire-retardant technologies developed in laboratory settings prove difficult to scale up or incorporate into existing manufacturing processes without compromising production efficiency or increasing costs prohibitively. This is especially problematic for complex-shaped components or high-volume production scenarios.

Environmental and health concerns further complicate the development landscape. Traditional halogenated flame retardants, while effective, face increasing regulatory restrictions due to their persistence in the environment and potential toxicity. Alternative solutions must not only provide adequate fire protection but also meet increasingly stringent environmental regulations and sustainability requirements.

The durability of fire protection systems over the service life of CFRP components remains problematic. Environmental factors such as moisture, UV exposure, and temperature cycling can degrade fire retardant properties over time, potentially compromising safety during the later stages of a product's lifecycle when testing and inspection may be less frequent.

The primary technical challenge lies in the fundamental conflict between fire retardancy and mechanical performance. Most conventional fire retardant additives, when incorporated into the polymer matrix, tend to disrupt the fiber-matrix interface, leading to significant reductions in mechanical properties such as tensile strength, impact resistance, and interlaminar shear strength. This trade-off has proven difficult to overcome, particularly when high levels of fire protection are required.

Another significant obstacle is the complex degradation mechanism of CFRP during fire exposure. Unlike homogeneous materials, composites exhibit multi-phase degradation involving matrix decomposition, fiber-matrix debonding, delamination, and char formation. This complexity makes it difficult to develop comprehensive fire protection strategies that address all failure modes simultaneously.

The aerospace and automotive industries face particularly stringent regulatory requirements for fire safety that current CFRP solutions struggle to meet without significant weight penalties. FAR 25.853 for aviation and ECE R118 for automotive applications set demanding standards for flame spread, heat release, and smoke density that often necessitate additional protective layers or treatments, negating some of the weight advantages of CFRP.

Manufacturing integration presents another substantial challenge. Many promising fire-retardant technologies developed in laboratory settings prove difficult to scale up or incorporate into existing manufacturing processes without compromising production efficiency or increasing costs prohibitively. This is especially problematic for complex-shaped components or high-volume production scenarios.

Environmental and health concerns further complicate the development landscape. Traditional halogenated flame retardants, while effective, face increasing regulatory restrictions due to their persistence in the environment and potential toxicity. Alternative solutions must not only provide adequate fire protection but also meet increasingly stringent environmental regulations and sustainability requirements.

The durability of fire protection systems over the service life of CFRP components remains problematic. Environmental factors such as moisture, UV exposure, and temperature cycling can degrade fire retardant properties over time, potentially compromising safety during the later stages of a product's lifecycle when testing and inspection may be less frequent.

Existing Fire Retardancy Solutions for CFRP

01 Incorporation of flame retardant additives in CFRP

Various flame retardant additives can be incorporated into carbon fiber reinforced polymers to enhance their fire resistance properties. These additives work by different mechanisms such as forming a protective char layer, releasing flame-inhibiting gases, or promoting endothermic reactions that absorb heat. Common additives include phosphorus compounds, halogenated compounds, and mineral fillers that can be integrated during the manufacturing process of CFRP composites.- Incorporation of flame retardant additives in CFRP: Various flame retardant additives can be incorporated into carbon fiber reinforced polymers to enhance their fire resistance properties. These additives work by different mechanisms such as forming a protective char layer, releasing flame-inhibiting gases, or promoting endothermic reactions that absorb heat. Common additives include phosphorus compounds, halogenated compounds, and mineral fillers that can be integrated during the manufacturing process of CFRP composites.

- Surface treatments and coatings for CFRP fire protection: Specialized surface treatments and protective coatings can be applied to CFRP components to improve their fire retardancy. These include intumescent coatings that expand when exposed to heat to form an insulating barrier, ceramic-based coatings that provide thermal shielding, and multi-layer protective systems designed specifically for composite materials. These treatments can be applied post-manufacturing and provide an additional layer of protection without significantly altering the mechanical properties of the base CFRP material.

- Modified resin systems with inherent fire resistance: Development of specialized resin systems with inherent fire-resistant properties for use in CFRP manufacturing. These include phenolic resins, bismaleimides, and modified epoxy systems that have been chemically altered to reduce flammability. The molecular structure of these resins can be designed to promote char formation rather than combustible gas release when exposed to heat, thereby improving the overall fire performance of the composite material.

- Structural design approaches for fire-resistant CFRP: Innovative structural design approaches can enhance the fire resistance of CFRP components without relying solely on chemical additives. These include sandwich structures with fire-resistant core materials, hybrid composites combining CFRP with other fire-resistant materials, and strategic placement of thermal barriers within the composite layup. These design strategies can compartmentalize fire spread and maintain structural integrity during fire exposure for longer periods.

- Testing and certification methodologies for fire-retardant CFRP: Specialized testing protocols and certification methodologies have been developed to evaluate and validate the fire performance of CFRP materials. These include cone calorimeter testing, vertical burn tests, smoke density measurements, and toxicity analysis of combustion products. These standardized approaches allow for consistent evaluation of different fire retardancy solutions and ensure that CFRP components meet industry-specific safety requirements for applications in aerospace, automotive, and construction sectors.

02 Surface treatments and coatings for CFRP fire protection

Specialized surface treatments and protective coatings can be applied to CFRP components to enhance their fire retardancy without altering the core material properties. These include intumescent coatings that expand upon heating to form an insulating barrier, ceramic-based coatings that provide thermal shielding, and multi-layer protective systems designed specifically for composite materials. These treatments can significantly improve the fire performance of CFRP structures in high-temperature environments.Expand Specific Solutions03 Modified resin systems with inherent fire resistance

Development of specialized resin systems with inherent fire-resistant properties for use in CFRP manufacturing. These include modified epoxy, phenolic, and bismaleimide resins that have been chemically altered to reduce flammability. The molecular structure of these resins can be designed to promote char formation, reduce heat release rates, and minimize the production of toxic gases during combustion, thereby improving the overall fire performance of the composite material.Expand Specific Solutions04 Hybrid composite structures for enhanced fire performance

Creating hybrid composite structures by combining CFRP with other fire-resistant materials to achieve enhanced fire retardancy. These hybrid structures may incorporate layers of different materials such as ceramic fibers, glass fibers, or metal foils strategically placed within the CFRP laminate. The synergistic effect of these material combinations can significantly improve fire resistance while maintaining the mechanical advantages of carbon fiber reinforcement.Expand Specific Solutions05 Nano-enhanced CFRP for improved fire retardancy

Integration of nanomaterials into CFRP composites to enhance fire retardant properties. Nanomaterials such as clay nanoparticles, carbon nanotubes, graphene, and nano-sized metal oxides can be dispersed within the polymer matrix to create more effective barriers against heat and flame propagation. These nano-additives can improve char formation, reduce heat release rates, and enhance the overall thermal stability of the composite material at relatively low loading levels.Expand Specific Solutions

Leading Manufacturers and Research Institutions in FR-CFRP

The carbon fiber reinforced polymer (CFRP) fire retardancy market is currently in a growth phase, with increasing demand driven by stringent safety regulations in aerospace and automotive sectors. The global market size for flame-retardant composites is projected to reach approximately $5-7 billion by 2027, growing at 6-8% CAGR. Technologically, the field is advancing from traditional approaches toward innovative solutions, with varying maturity levels across applications. Leading players include Toray Industries and Mitsubishi Heavy Industries, who have established comprehensive fire-retardant CFRP portfolios, while aerospace giants Boeing and Airbus are driving application-specific developments. Academic institutions like Donghua University and Xi'an Jiaotong University are pioneering nano-additive approaches, collaborating with automotive manufacturers like Toyota and BMW to develop next-generation solutions balancing fire performance with mechanical properties.

Toray Industries, Inc.

Technical Solution: Toray has developed innovative fire-retardant CFRP systems utilizing phosphorus-based additives integrated directly into the resin matrix. Their proprietary technology involves nano-scale dispersion of flame retardants that maintain the mechanical properties of the composite while achieving UL94 V-0 ratings. The company employs a multi-functional approach where phosphorus compounds act both in condensed and gas phases, forming a protective char layer while simultaneously releasing flame-inhibiting gases. Toray's T800H/3900-2 prepreg system incorporates these fire-retardant technologies while maintaining 95% of the original mechanical strength. Additionally, they've developed surface treatments for carbon fibers that enhance the fiber-matrix interface stability during combustion, preventing delamination and structural collapse during fire exposure. Their latest generation systems utilize synergistic combinations of phosphorus compounds with inorganic fillers to achieve self-extinguishing properties within seconds of flame removal.

Strengths: Maintains excellent mechanical properties while achieving high fire retardancy; proprietary fiber surface treatments enhance fiber-matrix interface stability during combustion; multi-functional approach addresses both condensed and gas phase fire protection. Weaknesses: Higher production costs compared to standard CFRP; slightly increased weight due to additive content; potential for increased water absorption in humid environments.

The Boeing Co.

Technical Solution: Boeing has pioneered advanced fire-retardant CFRP technologies specifically for aerospace applications where safety standards are exceptionally stringent. Their approach combines intumescent resin systems with proprietary fiber treatments to create multi-layer protection mechanisms. Boeing's BMS 8-276 specification CFRP incorporates phosphorus-nitrogen synergistic flame retardants that activate at different temperature thresholds, providing protection across various fire scenarios. The company has developed a gradient distribution technology that concentrates flame retardants near potential ignition surfaces while maintaining optimal mechanical properties in the core. Their latest innovation involves microencapsulated flame retardants that remain dormant until activated by heat, preventing negative interactions with the resin during processing and storage. Boeing has also pioneered self-healing fire barriers within the composite structure that expand to seal damaged areas when exposed to heat, preventing flame propagation through the material. Testing shows these systems can withstand direct flame exposure (1100°C) for over 4 minutes while maintaining structural integrity.

Strengths: Exceptional fire resistance meeting FAA FAR 25.853 requirements; minimal impact on mechanical properties; multi-stage protection system effective across various fire scenarios. Weaknesses: Significantly higher cost compared to standard CFRP; complex manufacturing process requiring specialized equipment; limited to aerospace applications due to cost constraints.

Key Patents and Research in CFRP Fire Protection

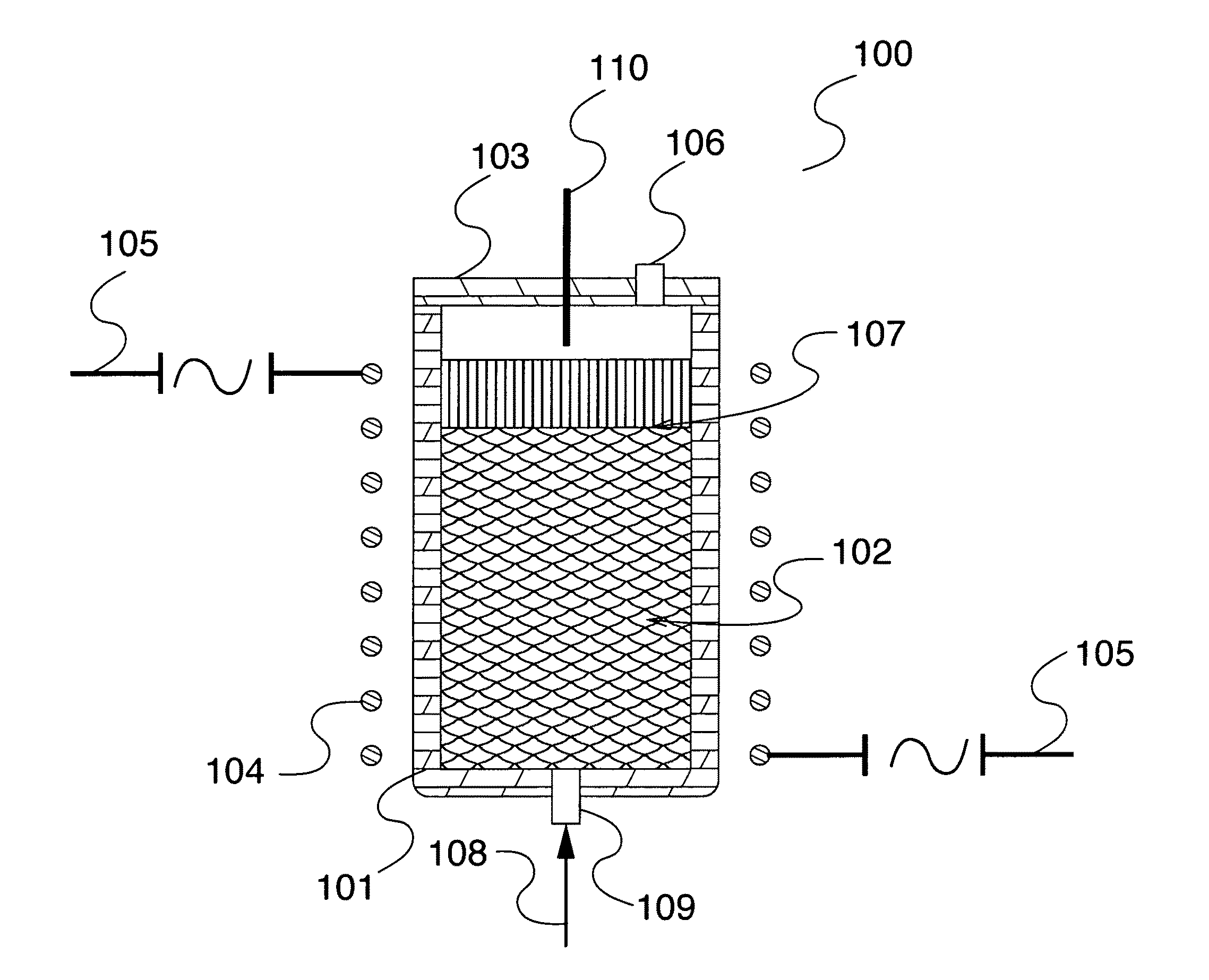

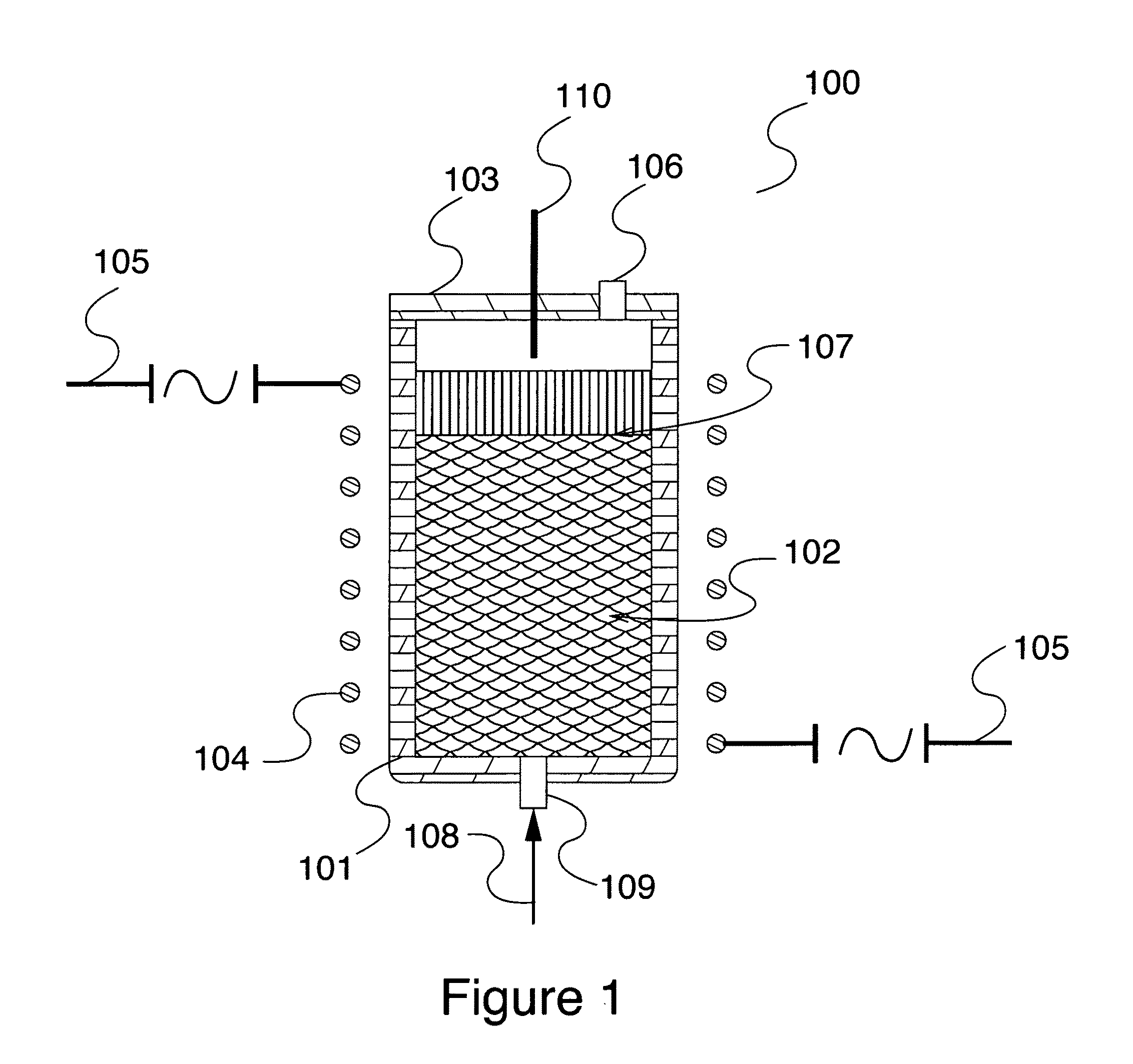

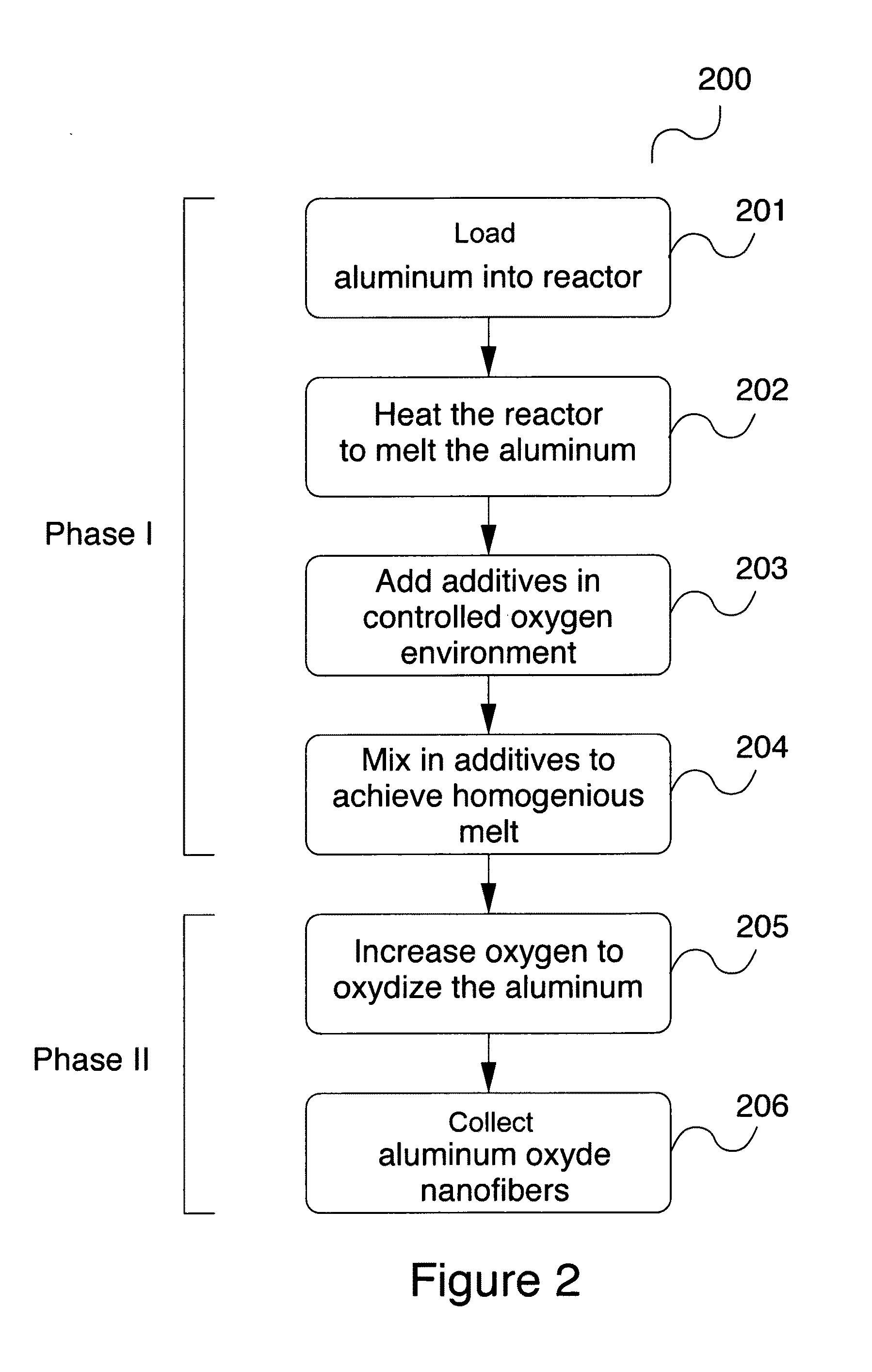

Method and apparatus for producing a carbon-fiber-reinforced polymers additiuonally reinforced by alumina nanofibers

PatentInactiveUS20160114500A1

Innovation

- The method involves saturating a structure of co-oriented pre-dispersed alumina Al2O3 nanofibers with a polymer matrix and facilitating polymerization, which includes pre-heating, cooling, exposure to ultraviolet light or electron beams, adding chemical hardeners, and applying ultrasound or hydrodynamic stress to enhance the dispersion and properties of the nanocomposite material.

Environmental Impact and Sustainability Considerations

The development of Carbon Fiber Reinforced Polymers (CFRP) with improved fire retardancy must carefully consider environmental impacts and sustainability throughout the entire lifecycle. Traditional fire retardants often contain halogenated compounds that pose significant environmental hazards, including bioaccumulation in ecosystems and potential toxicity to aquatic organisms. When CFRP components reach end-of-life, these compounds can leach into soil and water systems, creating long-term environmental contamination. Recent regulatory frameworks, such as the European Union's REACH regulation and RoHS directive, have increasingly restricted the use of many conventional flame retardants due to these environmental concerns.

Sustainable alternatives are emerging in the form of bio-based and non-toxic flame retardants. Phosphorus-based compounds derived from renewable resources show promising fire-retardant properties while demonstrating reduced environmental impact. Similarly, nano-materials such as clay and silica-based additives offer enhanced fire performance with minimal ecological footprint compared to halogenated systems. Life Cycle Assessment (LCA) studies indicate that these newer solutions can reduce the carbon footprint of fire-retardant CFRP by up to 30% compared to traditional methods.

The manufacturing processes for fire-retardant CFRP also present environmental challenges. Energy-intensive curing processes contribute significantly to the carbon footprint of these materials. Innovations in low-temperature curing technologies and renewable energy integration in manufacturing facilities are helping mitigate these impacts. Additionally, water consumption and chemical waste generation during production require careful management through closed-loop systems and advanced filtration technologies to prevent environmental contamination.

End-of-life considerations represent another critical sustainability aspect. Current CFRP recycling technologies face additional complications when fire retardants are present, as these compounds can interfere with reclamation processes or produce toxic byproducts during recycling. Research into pyrolysis methods specifically designed for fire-retardant CFRP shows promise for recovering carbon fibers while safely handling flame retardant compounds. Design for disassembly approaches are also gaining traction, allowing easier separation of components and more efficient recycling.

The aerospace and automotive industries, as major CFRP consumers, are increasingly adopting sustainability metrics in their material selection processes. This market pressure is driving innovation toward environmentally responsible fire retardancy solutions. Certification systems like Cradle to Cradle and environmental product declarations are becoming valuable tools for manufacturers to demonstrate the sustainability credentials of their fire-retardant CFRP products, creating competitive advantages in environmentally conscious markets while meeting stringent fire safety requirements.

Sustainable alternatives are emerging in the form of bio-based and non-toxic flame retardants. Phosphorus-based compounds derived from renewable resources show promising fire-retardant properties while demonstrating reduced environmental impact. Similarly, nano-materials such as clay and silica-based additives offer enhanced fire performance with minimal ecological footprint compared to halogenated systems. Life Cycle Assessment (LCA) studies indicate that these newer solutions can reduce the carbon footprint of fire-retardant CFRP by up to 30% compared to traditional methods.

The manufacturing processes for fire-retardant CFRP also present environmental challenges. Energy-intensive curing processes contribute significantly to the carbon footprint of these materials. Innovations in low-temperature curing technologies and renewable energy integration in manufacturing facilities are helping mitigate these impacts. Additionally, water consumption and chemical waste generation during production require careful management through closed-loop systems and advanced filtration technologies to prevent environmental contamination.

End-of-life considerations represent another critical sustainability aspect. Current CFRP recycling technologies face additional complications when fire retardants are present, as these compounds can interfere with reclamation processes or produce toxic byproducts during recycling. Research into pyrolysis methods specifically designed for fire-retardant CFRP shows promise for recovering carbon fibers while safely handling flame retardant compounds. Design for disassembly approaches are also gaining traction, allowing easier separation of components and more efficient recycling.

The aerospace and automotive industries, as major CFRP consumers, are increasingly adopting sustainability metrics in their material selection processes. This market pressure is driving innovation toward environmentally responsible fire retardancy solutions. Certification systems like Cradle to Cradle and environmental product declarations are becoming valuable tools for manufacturers to demonstrate the sustainability credentials of their fire-retardant CFRP products, creating competitive advantages in environmentally conscious markets while meeting stringent fire safety requirements.

Testing Standards and Certification Requirements

The development of Carbon Fiber Reinforced Polymers (CFRP) with improved fire retardancy must adhere to rigorous testing standards and certification requirements to ensure safety and compliance across various industries. The primary international standard governing fire testing for composite materials is ISO 5660, which evaluates heat release rate, smoke production, and mass loss during combustion. This test provides critical data on how CFRP materials behave under fire conditions and is widely recognized across global markets.

In the aerospace sector, the Federal Aviation Administration (FAA) mandates compliance with FAR 25.853 for interior components, which includes vertical burn tests, heat release rate tests, and smoke density evaluations. The European Aviation Safety Agency (EASA) maintains similar requirements through CS-25, creating a harmonized approach for aviation applications of fire-retardant CFRP.

For building and construction applications, ASTM E84 (Surface Burning Characteristics) and ASTM E119 (Fire Tests of Building Construction) serve as benchmark standards in North America. The European counterparts include EN 13501 (Fire Classification of Construction Products) and the Single Burning Item test (EN 13823), which evaluate flame spread, heat release, and smoke production.

The transportation sector, particularly automotive and rail, follows standards such as FMVSS 302 in the US and ECE R118 in Europe, focusing on horizontal burning rates of materials used in vehicle interiors. For rail applications, EN 45545 provides a comprehensive framework for fire safety requirements of materials and components.

Certification processes typically involve third-party testing by accredited laboratories such as Underwriters Laboratories (UL), Intertek, or SGS. These organizations issue certifications that manufacturers can use to demonstrate compliance with relevant standards. The certification process generally includes material sampling, standardized testing, documentation review, and periodic re-evaluation to maintain certification status.

Emerging trends in testing standards include the development of more sophisticated methods to evaluate toxicity of combustion gases (ISO 19700), which is particularly relevant for enclosed spaces where CFRP materials might be deployed. Additionally, there is growing emphasis on full-scale testing that better simulates real-world fire scenarios, moving beyond the limitations of small-scale laboratory tests.

Manufacturers developing fire-retardant CFRP must consider these standards early in the design process, as retrofitting fire retardancy into existing formulations often proves challenging and costly. Strategic planning for certification pathways can significantly reduce time-to-market and ensure broader acceptance across global markets and diverse industry applications.

In the aerospace sector, the Federal Aviation Administration (FAA) mandates compliance with FAR 25.853 for interior components, which includes vertical burn tests, heat release rate tests, and smoke density evaluations. The European Aviation Safety Agency (EASA) maintains similar requirements through CS-25, creating a harmonized approach for aviation applications of fire-retardant CFRP.

For building and construction applications, ASTM E84 (Surface Burning Characteristics) and ASTM E119 (Fire Tests of Building Construction) serve as benchmark standards in North America. The European counterparts include EN 13501 (Fire Classification of Construction Products) and the Single Burning Item test (EN 13823), which evaluate flame spread, heat release, and smoke production.

The transportation sector, particularly automotive and rail, follows standards such as FMVSS 302 in the US and ECE R118 in Europe, focusing on horizontal burning rates of materials used in vehicle interiors. For rail applications, EN 45545 provides a comprehensive framework for fire safety requirements of materials and components.

Certification processes typically involve third-party testing by accredited laboratories such as Underwriters Laboratories (UL), Intertek, or SGS. These organizations issue certifications that manufacturers can use to demonstrate compliance with relevant standards. The certification process generally includes material sampling, standardized testing, documentation review, and periodic re-evaluation to maintain certification status.

Emerging trends in testing standards include the development of more sophisticated methods to evaluate toxicity of combustion gases (ISO 19700), which is particularly relevant for enclosed spaces where CFRP materials might be deployed. Additionally, there is growing emphasis on full-scale testing that better simulates real-world fire scenarios, moving beyond the limitations of small-scale laboratory tests.

Manufacturers developing fire-retardant CFRP must consider these standards early in the design process, as retrofitting fire retardancy into existing formulations often proves challenging and costly. Strategic planning for certification pathways can significantly reduce time-to-market and ensure broader acceptance across global markets and diverse industry applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!