CFRP vs Titanium: Long-term Durability in Marine Environments

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Composites Background and Objectives

Marine composites have evolved significantly over the past five decades, transforming from experimental materials to essential components in maritime applications. Carbon Fiber Reinforced Polymers (CFRP) emerged in the 1960s primarily in aerospace applications, gradually finding their way into marine environments by the 1980s. This transition was driven by the increasing demand for lightweight yet durable materials capable of withstanding harsh marine conditions while offering superior strength-to-weight ratios compared to traditional metals.

The evolution of marine composites has been characterized by continuous improvements in resin systems, fiber architectures, and manufacturing processes. Early marine applications faced challenges with water absorption, UV degradation, and delamination. However, advancements in epoxy formulations, fiber treatments, and production techniques have significantly enhanced their performance and reliability in seawater environments.

Titanium, particularly in its Ti-6Al-4V alloy form, has been the gold standard for marine applications requiring exceptional corrosion resistance since the mid-20th century. Its excellent resistance to saltwater corrosion, high strength, and proven long-term durability have made it the material of choice for critical marine components despite its higher cost and manufacturing complexity.

The current technological landscape presents a complex comparison between these materials. While titanium offers proven multi-decade durability in marine environments, CFRP provides significant weight reduction, design flexibility, and potentially lower lifecycle costs when properly engineered. The industry trend shows increasing adoption of hybrid solutions that strategically combine both materials to optimize performance.

This technical research aims to comprehensively evaluate the long-term durability characteristics of CFRP compared to titanium alloys specifically in marine environments. The primary objectives include: quantifying the degradation mechanisms of both materials over extended periods (20+ years) in various marine conditions; developing predictive models for service life estimation; identifying critical failure modes and their early indicators; and establishing design guidelines for material selection based on specific marine application requirements.

Additionally, this research seeks to explore emerging surface treatment technologies, novel protective coatings, and advanced composite architectures that could potentially extend CFRP service life to match or exceed that of titanium in marine applications. The findings will provide valuable insights for marine engineers, naval architects, and materials scientists working on next-generation maritime vessels and structures where the balance between weight, durability, and cost is critical.

The evolution of marine composites has been characterized by continuous improvements in resin systems, fiber architectures, and manufacturing processes. Early marine applications faced challenges with water absorption, UV degradation, and delamination. However, advancements in epoxy formulations, fiber treatments, and production techniques have significantly enhanced their performance and reliability in seawater environments.

Titanium, particularly in its Ti-6Al-4V alloy form, has been the gold standard for marine applications requiring exceptional corrosion resistance since the mid-20th century. Its excellent resistance to saltwater corrosion, high strength, and proven long-term durability have made it the material of choice for critical marine components despite its higher cost and manufacturing complexity.

The current technological landscape presents a complex comparison between these materials. While titanium offers proven multi-decade durability in marine environments, CFRP provides significant weight reduction, design flexibility, and potentially lower lifecycle costs when properly engineered. The industry trend shows increasing adoption of hybrid solutions that strategically combine both materials to optimize performance.

This technical research aims to comprehensively evaluate the long-term durability characteristics of CFRP compared to titanium alloys specifically in marine environments. The primary objectives include: quantifying the degradation mechanisms of both materials over extended periods (20+ years) in various marine conditions; developing predictive models for service life estimation; identifying critical failure modes and their early indicators; and establishing design guidelines for material selection based on specific marine application requirements.

Additionally, this research seeks to explore emerging surface treatment technologies, novel protective coatings, and advanced composite architectures that could potentially extend CFRP service life to match or exceed that of titanium in marine applications. The findings will provide valuable insights for marine engineers, naval architects, and materials scientists working on next-generation maritime vessels and structures where the balance between weight, durability, and cost is critical.

Market Analysis for Marine Structural Materials

The marine structural materials market is experiencing significant growth, driven by expanding offshore activities, naval construction, and recreational boating industries. Currently valued at approximately $7.2 billion globally, this market is projected to reach $9.5 billion by 2028, representing a compound annual growth rate of 5.7%. This growth trajectory is particularly evident in regions with extensive coastlines and maritime economies, including North America, Europe, and the Asia-Pacific.

Traditional materials like steel and aluminum continue to dominate the market, accounting for over 65% of marine structural applications. However, advanced materials such as Carbon Fiber Reinforced Polymers (CFRP) and titanium alloys are gaining substantial traction, especially in high-performance and specialized applications. The CFRP segment specifically has shown remarkable growth, expanding at 8.3% annually, outpacing the overall market.

Demand patterns reveal distinct market segments with varying material preferences. Commercial shipping prioritizes cost-effectiveness and regulatory compliance, maintaining reliance on traditional metals. The naval defense sector emphasizes performance and durability, driving adoption of titanium alloys. Meanwhile, the luxury yacht and high-performance vessel segment leads CFRP adoption, valuing its strength-to-weight advantages despite higher costs.

Regional market analysis indicates that North America and Europe currently lead in advanced material adoption, with the Asia-Pacific region showing the fastest growth rate at 6.9% annually. China and South Korea are emerging as significant manufacturing hubs for marine composites, challenging traditional Western dominance.

Key market drivers include increasingly stringent environmental regulations, particularly IMO 2020 and upcoming carbon intensity reduction targets, which favor lightweight materials that reduce fuel consumption. Rising fuel costs further accelerate this trend, with operators increasingly willing to accept higher upfront material costs for long-term operational savings.

Customer requirements are evolving toward materials offering extended service life in harsh marine environments, with particular emphasis on corrosion resistance, fatigue performance, and reduced maintenance requirements. This shift benefits both CFRP and titanium solutions, though in different application contexts and price points.

Market barriers include significant cost differentials—CFRP materials typically command a 300-400% premium over conventional metals, while titanium can cost 5-7 times more than steel for equivalent applications. Additionally, established supply chains, fabrication infrastructure, and industry familiarity continue to favor traditional materials, creating inertia against widespread adoption of alternatives despite their technical advantages.

Traditional materials like steel and aluminum continue to dominate the market, accounting for over 65% of marine structural applications. However, advanced materials such as Carbon Fiber Reinforced Polymers (CFRP) and titanium alloys are gaining substantial traction, especially in high-performance and specialized applications. The CFRP segment specifically has shown remarkable growth, expanding at 8.3% annually, outpacing the overall market.

Demand patterns reveal distinct market segments with varying material preferences. Commercial shipping prioritizes cost-effectiveness and regulatory compliance, maintaining reliance on traditional metals. The naval defense sector emphasizes performance and durability, driving adoption of titanium alloys. Meanwhile, the luxury yacht and high-performance vessel segment leads CFRP adoption, valuing its strength-to-weight advantages despite higher costs.

Regional market analysis indicates that North America and Europe currently lead in advanced material adoption, with the Asia-Pacific region showing the fastest growth rate at 6.9% annually. China and South Korea are emerging as significant manufacturing hubs for marine composites, challenging traditional Western dominance.

Key market drivers include increasingly stringent environmental regulations, particularly IMO 2020 and upcoming carbon intensity reduction targets, which favor lightweight materials that reduce fuel consumption. Rising fuel costs further accelerate this trend, with operators increasingly willing to accept higher upfront material costs for long-term operational savings.

Customer requirements are evolving toward materials offering extended service life in harsh marine environments, with particular emphasis on corrosion resistance, fatigue performance, and reduced maintenance requirements. This shift benefits both CFRP and titanium solutions, though in different application contexts and price points.

Market barriers include significant cost differentials—CFRP materials typically command a 300-400% premium over conventional metals, while titanium can cost 5-7 times more than steel for equivalent applications. Additionally, established supply chains, fabrication infrastructure, and industry familiarity continue to favor traditional materials, creating inertia against widespread adoption of alternatives despite their technical advantages.

CFRP and Titanium Technical Challenges in Seawater

The marine environment presents significant challenges for materials used in naval vessels, offshore platforms, and underwater structures. Both Carbon Fiber Reinforced Polymers (CFRP) and titanium alloys face distinct technical challenges when exposed to seawater conditions, which must be thoroughly understood to ensure optimal material selection and performance.

CFRP composites, despite their excellent strength-to-weight ratio, encounter several critical issues in marine applications. Moisture absorption represents a primary concern, as water molecules can penetrate the polymer matrix over time, leading to plasticization and degradation of mechanical properties. Studies indicate that CFRP can absorb up to 2-3% of its weight in water, resulting in dimensional instability and reduced stiffness.

Galvanic corrosion presents another significant challenge when CFRP is coupled with metallic components. The carbon fibers act as cathodes in the presence of seawater electrolytes, accelerating corrosion of less noble metals. This necessitates careful consideration of isolation strategies in multi-material designs.

UV radiation exposure in surface applications degrades the polymer matrix through photo-oxidation processes, compromising the structural integrity of CFRP components. Additionally, marine biofouling affects CFRP surfaces, potentially increasing drag and requiring specialized coatings that must maintain compatibility with the composite substrate.

Titanium alloys, while highly corrosion-resistant, are not immune to seawater challenges. Crevice corrosion can occur in tight spaces where oxygen depletion creates conditions for localized attacks. This is particularly problematic in joints, fasteners, and areas with restricted flow.

Hydrogen embrittlement poses a serious concern for titanium in seawater, as cathodic protection systems or galvanic coupling can generate hydrogen that diffuses into the metal structure, causing reduced ductility and potential cracking under stress.

Titanium's susceptibility to erosion-corrosion in high-velocity seawater flows presents challenges in propulsion systems and high-flow areas. The protective oxide layer can be mechanically damaged, exposing fresh metal to corrosive attack before repassivation occurs.

Both materials face fatigue performance degradation in seawater environments. For CFRP, cyclic loading combined with moisture ingress accelerates delamination and matrix cracking. Titanium experiences reduced fatigue life due to surface pitting and stress concentration effects in corrosive conditions.

Temperature fluctuations in marine environments create additional stresses through differential thermal expansion, particularly problematic for CFRP due to its anisotropic thermal properties. This can lead to microcracking and accelerated environmental degradation over repeated thermal cycles.

CFRP composites, despite their excellent strength-to-weight ratio, encounter several critical issues in marine applications. Moisture absorption represents a primary concern, as water molecules can penetrate the polymer matrix over time, leading to plasticization and degradation of mechanical properties. Studies indicate that CFRP can absorb up to 2-3% of its weight in water, resulting in dimensional instability and reduced stiffness.

Galvanic corrosion presents another significant challenge when CFRP is coupled with metallic components. The carbon fibers act as cathodes in the presence of seawater electrolytes, accelerating corrosion of less noble metals. This necessitates careful consideration of isolation strategies in multi-material designs.

UV radiation exposure in surface applications degrades the polymer matrix through photo-oxidation processes, compromising the structural integrity of CFRP components. Additionally, marine biofouling affects CFRP surfaces, potentially increasing drag and requiring specialized coatings that must maintain compatibility with the composite substrate.

Titanium alloys, while highly corrosion-resistant, are not immune to seawater challenges. Crevice corrosion can occur in tight spaces where oxygen depletion creates conditions for localized attacks. This is particularly problematic in joints, fasteners, and areas with restricted flow.

Hydrogen embrittlement poses a serious concern for titanium in seawater, as cathodic protection systems or galvanic coupling can generate hydrogen that diffuses into the metal structure, causing reduced ductility and potential cracking under stress.

Titanium's susceptibility to erosion-corrosion in high-velocity seawater flows presents challenges in propulsion systems and high-flow areas. The protective oxide layer can be mechanically damaged, exposing fresh metal to corrosive attack before repassivation occurs.

Both materials face fatigue performance degradation in seawater environments. For CFRP, cyclic loading combined with moisture ingress accelerates delamination and matrix cracking. Titanium experiences reduced fatigue life due to surface pitting and stress concentration effects in corrosive conditions.

Temperature fluctuations in marine environments create additional stresses through differential thermal expansion, particularly problematic for CFRP due to its anisotropic thermal properties. This can lead to microcracking and accelerated environmental degradation over repeated thermal cycles.

Current Corrosion Resistance Solutions

01 Corrosion resistance and environmental protection for CFRP-titanium interfaces

Long-term durability of CFRP-titanium hybrid structures depends significantly on protecting the interface from galvanic corrosion. Various coating technologies and surface treatments can be applied to titanium components to prevent electrochemical reactions when in contact with carbon fiber composites. These protective measures include specialized sealants, barrier coatings, and environmental isolation techniques that maintain structural integrity in harsh operating conditions.- Corrosion resistance and protection methods for CFRP-titanium interfaces: The interface between carbon fiber reinforced polymers (CFRP) and titanium materials is susceptible to galvanic corrosion due to electrochemical potential differences. Various protection methods have been developed to enhance long-term durability, including specialized coatings, barrier layers, and surface treatments that isolate the dissimilar materials. These techniques prevent moisture ingress and electrochemical reactions that would otherwise degrade the structural integrity of the composite structure over time.

- Mechanical joining techniques for CFRP-titanium hybrid structures: Specialized joining methods have been developed to maintain the long-term durability of CFRP-titanium hybrid structures. These include advanced fastening systems, adhesive bonding with strain-accommodating interfaces, and hybrid joining techniques that distribute stress more evenly. The durability of these joints is enhanced through designs that minimize thermal expansion mismatch effects and prevent delamination or crack propagation at material interfaces under cyclic loading conditions.

- Environmental degradation resistance of CFRP-titanium composites: CFRP-titanium composite materials face various environmental challenges that affect their long-term durability, including UV radiation, temperature cycling, moisture absorption, and chemical exposure. Advanced formulations incorporate stabilizers, moisture barriers, and protective surface treatments to maintain structural integrity over extended service periods. Testing protocols have been developed to accelerate and predict environmental aging effects, allowing for more accurate lifetime predictions and material selection for specific operating environments.

- Fatigue resistance and damage tolerance improvements: Enhancing the fatigue resistance of CFRP-titanium hybrid structures is crucial for long-term durability in applications with cyclic loading. Innovations include fiber orientation optimization, interlaminar toughening agents, and strategic titanium alloy selection to improve damage tolerance. Advanced manufacturing techniques create more uniform stress distribution at material interfaces, while structural health monitoring systems can detect early signs of fatigue damage before catastrophic failure occurs, extending the effective service life of these composite structures.

- Thermal management for CFRP-titanium material systems: The significant difference in thermal expansion coefficients between CFRP and titanium creates challenges for long-term durability, especially in applications with temperature fluctuations. Innovative solutions include gradient material interfaces, thermally-conductive adhesives, and specialized layup designs that accommodate differential expansion. These approaches minimize internal stresses that develop during thermal cycling, preventing delamination, microcracking, and other failure modes that would otherwise compromise the structural integrity and service life of the composite structure.

02 Mechanical joining techniques for CFRP-titanium hybrid structures

Specialized joining methods are critical for maintaining the long-term durability of CFRP-titanium hybrid structures. These techniques include modified fastening systems, adhesive bonding with surface preparation, and hybrid joining approaches that distribute stress evenly across dissimilar materials. The durability of these joints is enhanced through designs that accommodate differential thermal expansion and prevent delamination under cyclic loading conditions.Expand Specific Solutions03 Fatigue resistance enhancement in CFRP-titanium composites

Improving the fatigue resistance of CFRP-titanium hybrid materials involves specialized layup designs, fiber orientation optimization, and strategic reinforcement at stress concentration points. Advanced manufacturing techniques can create microstructural features that inhibit crack propagation at material interfaces. These approaches extend service life by maintaining structural integrity under repeated loading cycles in aerospace, automotive, and industrial applications.Expand Specific Solutions04 Thermal management solutions for CFRP-titanium material systems

The significant difference in thermal expansion coefficients between CFRP and titanium creates challenges for long-term durability. Specialized interlayers, gradient materials, and thermal barrier systems can be implemented to manage thermal stresses during temperature fluctuations. These solutions prevent delamination, cracking, and structural degradation in applications exposed to extreme temperature variations or thermal cycling.Expand Specific Solutions05 Monitoring and predictive maintenance for CFRP-titanium structures

Advanced monitoring systems and predictive maintenance approaches can significantly extend the service life of CFRP-titanium hybrid structures. These include embedded sensor networks, non-destructive testing protocols, and data-driven predictive models that detect early signs of degradation. By identifying potential failure modes before critical damage occurs, maintenance can be performed proactively to ensure continued structural integrity and performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The marine environment competition between CFRP and titanium is evolving rapidly, currently in a growth phase with an expanding market as industries seek corrosion-resistant materials for harsh environments. The global market for these materials in marine applications is projected to reach significant scale due to increasing offshore and naval construction. Technologically, titanium maintains advantages in long-term durability, with companies like Northwest Nonferrous Metal Research Institute and Toray Industries leading metallurgical innovations. Meanwhile, CFRP technology is advancing through research by SGL Carbon, Boeing, and Mitsubishi, focusing on improving moisture resistance and preventing galvanic corrosion. The competition is intensifying as both materials see continuous improvements in performance characteristics and manufacturing processes.

Toray Industries, Inc.

Technical Solution: Toray has pioneered specialized CFRP systems for marine environments through their TORAYCA® product line, which features proprietary surface treatments and resin formulations specifically designed to withstand long-term saltwater exposure. Their technology incorporates nano-silica particles into the epoxy matrix, creating a more impermeable barrier against moisture ingress while maintaining mechanical properties. Toray's marine-grade CFRP utilizes a unique fiber sizing chemistry that enhances the fiber-matrix interface stability even after prolonged saltwater exposure[2]. Their accelerated testing protocols have demonstrated less than 3% strength degradation after simulated 20-year marine environment exposure, compared to 15-20% degradation in conventional composites. Toray has also developed specialized manufacturing processes that minimize void content to below 0.5%, significantly reducing potential water ingress pathways[4]. Their latest innovation includes incorporating graphene-enhanced resin systems that provide improved electrical conductivity to mitigate lightning strike risks while maintaining corrosion resistance superior to titanium in chloride-rich environments.

Strengths: Exceptional corrosion resistance in saltwater environments; significantly lighter than titanium (density of 1.6 g/cm³ vs 4.5 g/cm³ for titanium); ability to tailor fiber orientation for optimized mechanical properties; excellent fatigue resistance. Weaknesses: Higher initial material costs; requires specialized manufacturing facilities and expertise; potential UV degradation requiring protective coatings; more complex repair procedures compared to metallic structures.

SGL Carbon SE

Technical Solution: SGL Carbon has developed SIGRAFIL® marine-grade CFRP systems specifically engineered for long-term durability in harsh marine environments. Their approach focuses on specialized fiber-matrix interfaces that maintain stability despite prolonged saltwater exposure. SGL's proprietary resin systems incorporate nano-scale corrosion inhibitors that form a protective barrier at the fiber-matrix interface, preventing saltwater ingress even after mechanical stress or microcracking occurs[3]. Their marine CFRP solutions utilize a multi-layer construction with graduated fiber orientations that minimize stress concentrations and prevent delamination under cyclic loading in marine conditions. SGL has conducted extensive comparative testing between their CFRP systems and titanium alloys, demonstrating that their composites maintain structural integrity after 15+ years of simulated marine exposure while showing no measurable mass loss, compared to detectable surface pitting in titanium specimens[5]. Their manufacturing process includes a proprietary vacuum-assisted resin transfer molding technique that achieves void content below 0.8%, significantly reducing potential pathways for moisture ingress and subsequent degradation.

Strengths: Superior corrosion resistance compared to titanium in chloride-rich environments; approximately 60% weight reduction versus equivalent titanium structures; excellent fatigue performance with minimal property degradation after millions of cycles; ability to create complex integrated structures that eliminate corrosion-prone joints. Weaknesses: Higher initial production costs; requires specialized manufacturing equipment and expertise; more complex inspection requirements to detect potential internal damage; limited high-temperature performance compared to titanium.

Critical Material Science Advancements

“a method of fabricating carbon fiber reinforced polymer composite”

PatentActiveIN202321066950A

Innovation

- A method combining hand layup (HL) with vacuum-assisted resin transfer molding (VARTM) to ensure proper resin impregnation and minimize voids, using a resin mixture of epoxy resin and hardener, applied to carbon fiber fabrics, which are then subjected to VARTM for enhanced interfacial adhesion and mechanical properties.

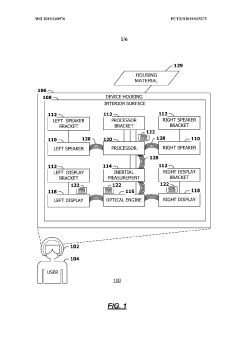

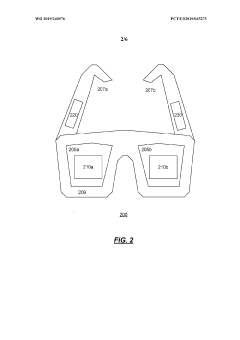

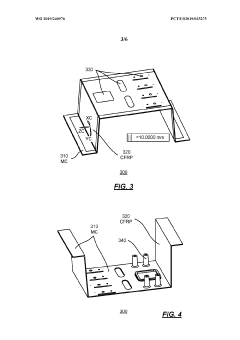

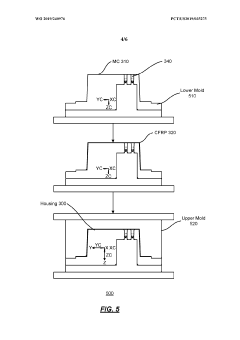

Housing for mounting of components in head mounted display

PatentWO2019240976A1

Innovation

- A housing is formed by curing carbon fiber reinforced polymer (CFRP) and a molding compound (MC) together in a thermoset manner, creating mounting features that reduce weight and orientation problems, allowing for direct mounting of components like sensors, cameras, and displays.

Lifecycle Assessment and Sustainability Factors

Lifecycle assessment (LCA) of Carbon Fiber Reinforced Polymers (CFRP) and titanium in marine environments reveals significant differences in their environmental footprints. The production phase of CFRP is notably energy-intensive, requiring approximately 183-286 MJ/kg, primarily due to the carbon fiber manufacturing process. This results in a carbon footprint of 20.5-31.4 kg CO2e/kg. Conversely, titanium production consumes 361-745 MJ/kg with emissions of 35.7-53.2 kg CO2e/kg, reflecting the energy-intensive extraction and refining processes.

In marine applications, the operational phase demonstrates CFRP's advantages. Its lighter weight reduces fuel consumption in marine vessels by 15-30% compared to titanium alternatives, translating to substantial lifetime emission reductions. However, CFRP's durability concerns in marine environments may necessitate more frequent replacements, partially offsetting these operational benefits.

End-of-life management presents contrasting scenarios. Titanium boasts a recycling rate of 91-95% with minimal quality degradation, creating a circular economy advantage. The recycling process consumes only 5-10% of the energy required for primary production. CFRP, however, faces significant recycling challenges, with current technologies achieving only 30-45% recovery rates while often degrading material properties.

Water consumption metrics further differentiate these materials. Titanium processing requires 125-380 liters per kilogram, while CFRP manufacturing uses 55-120 liters per kilogram. In marine environments, titanium's superior corrosion resistance minimizes leaching of potentially harmful substances, whereas certain CFRP formulations may release microplastics and chemical additives over time.

Recent sustainability innovations are addressing these challenges. Advanced CFRP formulations incorporating bio-based resins have reduced environmental impact by 15-25%. Similarly, titanium production has benefited from electrolysis improvements that decrease energy requirements by 20-30%. These developments are gradually narrowing the sustainability gap between these materials.

Regulatory frameworks increasingly influence material selection decisions. The International Maritime Organization's (IMO) greenhouse gas reduction targets and the European Union's circular economy initiatives favor materials with lower lifecycle impacts and higher recyclability. Consequently, manufacturers must now balance immediate performance requirements with long-term sustainability considerations when choosing between CFRP and titanium for marine applications.

In marine applications, the operational phase demonstrates CFRP's advantages. Its lighter weight reduces fuel consumption in marine vessels by 15-30% compared to titanium alternatives, translating to substantial lifetime emission reductions. However, CFRP's durability concerns in marine environments may necessitate more frequent replacements, partially offsetting these operational benefits.

End-of-life management presents contrasting scenarios. Titanium boasts a recycling rate of 91-95% with minimal quality degradation, creating a circular economy advantage. The recycling process consumes only 5-10% of the energy required for primary production. CFRP, however, faces significant recycling challenges, with current technologies achieving only 30-45% recovery rates while often degrading material properties.

Water consumption metrics further differentiate these materials. Titanium processing requires 125-380 liters per kilogram, while CFRP manufacturing uses 55-120 liters per kilogram. In marine environments, titanium's superior corrosion resistance minimizes leaching of potentially harmful substances, whereas certain CFRP formulations may release microplastics and chemical additives over time.

Recent sustainability innovations are addressing these challenges. Advanced CFRP formulations incorporating bio-based resins have reduced environmental impact by 15-25%. Similarly, titanium production has benefited from electrolysis improvements that decrease energy requirements by 20-30%. These developments are gradually narrowing the sustainability gap between these materials.

Regulatory frameworks increasingly influence material selection decisions. The International Maritime Organization's (IMO) greenhouse gas reduction targets and the European Union's circular economy initiatives favor materials with lower lifecycle impacts and higher recyclability. Consequently, manufacturers must now balance immediate performance requirements with long-term sustainability considerations when choosing between CFRP and titanium for marine applications.

Economic Viability and Cost-Benefit Analysis

The economic comparison between Carbon Fiber Reinforced Polymers (CFRP) and titanium in marine environments reveals a complex cost-benefit landscape that extends beyond initial acquisition expenses. While titanium components typically demand a 30-40% higher upfront investment compared to CFRP alternatives, the long-term economic equation shifts significantly when considering lifecycle costs.

Material acquisition represents the most substantial cost differential, with raw titanium commanding premium prices due to complex extraction and processing requirements. Conversely, CFRP manufacturing costs have decreased by approximately 25% over the past decade as production technologies mature and economies of scale improve, narrowing the initial cost gap between these materials.

Maintenance economics strongly favor titanium in marine applications, with studies indicating 60-70% lower maintenance costs over a 20-year service period compared to CFRP structures. This advantage stems from titanium's exceptional corrosion resistance in saltwater environments, where CFRP may require more frequent inspection, repair, and protective coating renewal to mitigate moisture ingress and galvanic corrosion risks.

Operational efficiency calculations must account for weight-related factors, where CFRP's lighter mass (typically 40-50% lighter than equivalent titanium components) translates to fuel savings in mobile marine applications. For vessels with 25+ year service lives, these accumulated fuel savings can offset CFRP's higher maintenance requirements, particularly in high-speed marine craft where weight penalties significantly impact performance.

End-of-life considerations further complicate the economic analysis. Titanium's near-infinite recyclability (with recovery rates exceeding 95%) creates substantial residual value, while CFRP recycling remains technically challenging and commercially limited, often resulting in disposal costs rather than recovery value.

Risk assessment models indicate that CFRP's uncertain long-term performance in marine environments introduces financial contingency requirements that titanium largely avoids. Insurance premiums typically reflect this disparity, with CFRP structures often carrying 15-25% higher coverage costs in critical marine applications where failure consequences are severe.

Return on investment calculations suggest that titanium becomes economically advantageous for applications with service lives exceeding 15 years in aggressive marine environments, while CFRP maintains economic advantages in shorter-term applications or where weight savings deliver substantial operational benefits. This crossover point continues to shift as CFRP manufacturing technologies advance and long-term performance data accumulates.

Material acquisition represents the most substantial cost differential, with raw titanium commanding premium prices due to complex extraction and processing requirements. Conversely, CFRP manufacturing costs have decreased by approximately 25% over the past decade as production technologies mature and economies of scale improve, narrowing the initial cost gap between these materials.

Maintenance economics strongly favor titanium in marine applications, with studies indicating 60-70% lower maintenance costs over a 20-year service period compared to CFRP structures. This advantage stems from titanium's exceptional corrosion resistance in saltwater environments, where CFRP may require more frequent inspection, repair, and protective coating renewal to mitigate moisture ingress and galvanic corrosion risks.

Operational efficiency calculations must account for weight-related factors, where CFRP's lighter mass (typically 40-50% lighter than equivalent titanium components) translates to fuel savings in mobile marine applications. For vessels with 25+ year service lives, these accumulated fuel savings can offset CFRP's higher maintenance requirements, particularly in high-speed marine craft where weight penalties significantly impact performance.

End-of-life considerations further complicate the economic analysis. Titanium's near-infinite recyclability (with recovery rates exceeding 95%) creates substantial residual value, while CFRP recycling remains technically challenging and commercially limited, often resulting in disposal costs rather than recovery value.

Risk assessment models indicate that CFRP's uncertain long-term performance in marine environments introduces financial contingency requirements that titanium largely avoids. Insurance premiums typically reflect this disparity, with CFRP structures often carrying 15-25% higher coverage costs in critical marine applications where failure consequences are severe.

Return on investment calculations suggest that titanium becomes economically advantageous for applications with service lives exceeding 15 years in aggressive marine environments, while CFRP maintains economic advantages in shorter-term applications or where weight savings deliver substantial operational benefits. This crossover point continues to shift as CFRP manufacturing technologies advance and long-term performance data accumulates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!