Evaluate CFRP Surface Treatment for Improved Adhesion

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Surface Treatment Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries since their commercial introduction in the 1960s. Initially developed for aerospace applications, these lightweight composites have progressively expanded into automotive, marine, sporting goods, and civil infrastructure sectors due to their exceptional strength-to-weight ratio and corrosion resistance properties.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, one persistent challenge has remained: achieving optimal adhesion between CFRP surfaces and other materials in bonded structures. This interface quality directly impacts structural integrity, durability, and overall performance of composite assemblies.

Surface treatment technologies for CFRP have evolved from basic mechanical abrasion methods to sophisticated plasma treatments and laser surface modification techniques. The historical progression reflects a growing understanding of the complex surface chemistry involved in adhesion mechanisms. Early approaches focused primarily on physical roughening, while contemporary methods emphasize both topographical modification and chemical activation of surfaces.

Recent market trends indicate a growing demand for reliable, scalable, and environmentally sustainable surface treatment solutions that can be integrated into high-volume manufacturing processes. This demand is particularly pronounced in automotive and aerospace sectors, where lightweighting initiatives are driving increased adoption of multi-material structures requiring effective bonding strategies.

The primary objective of this technical evaluation is to comprehensively assess current and emerging CFRP surface treatment technologies for enhanced adhesion performance. Specifically, we aim to identify methods that optimize bond strength, durability under environmental exposure, and compatibility with automated manufacturing processes. Additionally, we seek to establish quantifiable metrics for surface treatment effectiveness that correlate with long-term bond performance.

Secondary objectives include evaluating the environmental impact and cost-effectiveness of various treatment methods, determining their scalability for industrial implementation, and identifying potential innovation pathways for next-generation surface modification technologies. The assessment will consider both thermoset and thermoplastic CFRP variants, as their distinct chemical compositions necessitate different surface preparation approaches.

This evaluation will serve as a foundation for strategic technology development decisions, helping to prioritize research investments and identify potential partnership opportunities with technology providers, academic institutions, and industry collaborators in the composite materials ecosystem.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, one persistent challenge has remained: achieving optimal adhesion between CFRP surfaces and other materials in bonded structures. This interface quality directly impacts structural integrity, durability, and overall performance of composite assemblies.

Surface treatment technologies for CFRP have evolved from basic mechanical abrasion methods to sophisticated plasma treatments and laser surface modification techniques. The historical progression reflects a growing understanding of the complex surface chemistry involved in adhesion mechanisms. Early approaches focused primarily on physical roughening, while contemporary methods emphasize both topographical modification and chemical activation of surfaces.

Recent market trends indicate a growing demand for reliable, scalable, and environmentally sustainable surface treatment solutions that can be integrated into high-volume manufacturing processes. This demand is particularly pronounced in automotive and aerospace sectors, where lightweighting initiatives are driving increased adoption of multi-material structures requiring effective bonding strategies.

The primary objective of this technical evaluation is to comprehensively assess current and emerging CFRP surface treatment technologies for enhanced adhesion performance. Specifically, we aim to identify methods that optimize bond strength, durability under environmental exposure, and compatibility with automated manufacturing processes. Additionally, we seek to establish quantifiable metrics for surface treatment effectiveness that correlate with long-term bond performance.

Secondary objectives include evaluating the environmental impact and cost-effectiveness of various treatment methods, determining their scalability for industrial implementation, and identifying potential innovation pathways for next-generation surface modification technologies. The assessment will consider both thermoset and thermoplastic CFRP variants, as their distinct chemical compositions necessitate different surface preparation approaches.

This evaluation will serve as a foundation for strategic technology development decisions, helping to prioritize research investments and identify potential partnership opportunities with technology providers, academic institutions, and industry collaborators in the composite materials ecosystem.

Adhesion Enhancement Market Analysis

The global market for adhesion enhancement technologies in Carbon Fiber Reinforced Polymer (CFRP) applications has experienced significant growth over the past decade, driven primarily by increasing adoption of lightweight materials in aerospace, automotive, and renewable energy sectors. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 7.8% projected through 2028.

Aerospace remains the dominant market segment, accounting for nearly 42% of total demand for advanced adhesion solutions. This is attributed to the critical nature of bonding requirements in aircraft structures where failure is not an option. The automotive sector follows with 28% market share, showing the fastest growth trajectory as manufacturers increasingly incorporate CFRP components in premium and electric vehicle designs to meet stringent emissions standards.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are emerging as high-potential markets with annual growth rates exceeding 12%, driven by expanding manufacturing capabilities and increasing domestic demand for high-performance materials.

Customer demand patterns indicate a clear shift toward environmentally sustainable surface treatment solutions. Traditional solvent-based treatments face increasing regulatory pressure, creating market opportunities for water-based and plasma treatment alternatives. Industry surveys show 67% of end-users are willing to pay premium prices for adhesion enhancement technologies that demonstrate improved environmental profiles alongside performance benefits.

The competitive landscape features both specialized surface treatment providers and integrated material suppliers. Major chemical companies have strengthened their market positions through strategic acquisitions of specialized treatment technology firms, indicating market consolidation trends. Price sensitivity varies significantly by application sector, with aerospace customers prioritizing performance reliability over cost considerations, while automotive applications demonstrate higher price elasticity.

Market barriers include high initial investment requirements for advanced treatment technologies and complex qualification processes, particularly for aerospace applications. The average qualification timeline for new adhesion enhancement solutions in critical applications exceeds 24 months, creating significant barriers to market entry for emerging technologies.

Future market growth will likely be driven by increasing demand for multi-material joining solutions as manufacturers combine CFRP with metals and other composites in hybrid structures. This trend creates opportunities for versatile surface treatment technologies capable of addressing diverse substrate combinations.

Aerospace remains the dominant market segment, accounting for nearly 42% of total demand for advanced adhesion solutions. This is attributed to the critical nature of bonding requirements in aircraft structures where failure is not an option. The automotive sector follows with 28% market share, showing the fastest growth trajectory as manufacturers increasingly incorporate CFRP components in premium and electric vehicle designs to meet stringent emissions standards.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are emerging as high-potential markets with annual growth rates exceeding 12%, driven by expanding manufacturing capabilities and increasing domestic demand for high-performance materials.

Customer demand patterns indicate a clear shift toward environmentally sustainable surface treatment solutions. Traditional solvent-based treatments face increasing regulatory pressure, creating market opportunities for water-based and plasma treatment alternatives. Industry surveys show 67% of end-users are willing to pay premium prices for adhesion enhancement technologies that demonstrate improved environmental profiles alongside performance benefits.

The competitive landscape features both specialized surface treatment providers and integrated material suppliers. Major chemical companies have strengthened their market positions through strategic acquisitions of specialized treatment technology firms, indicating market consolidation trends. Price sensitivity varies significantly by application sector, with aerospace customers prioritizing performance reliability over cost considerations, while automotive applications demonstrate higher price elasticity.

Market barriers include high initial investment requirements for advanced treatment technologies and complex qualification processes, particularly for aerospace applications. The average qualification timeline for new adhesion enhancement solutions in critical applications exceeds 24 months, creating significant barriers to market entry for emerging technologies.

Future market growth will likely be driven by increasing demand for multi-material joining solutions as manufacturers combine CFRP with metals and other composites in hybrid structures. This trend creates opportunities for versatile surface treatment technologies capable of addressing diverse substrate combinations.

Current CFRP Surface Treatment Technologies and Challenges

Carbon Fiber Reinforced Polymers (CFRP) surface treatment technologies have evolved significantly over the past decades, driven by the increasing demand for high-performance composite materials in aerospace, automotive, and renewable energy sectors. Currently, several established methods dominate the industry landscape, each with specific advantages and limitations.

Mechanical treatments, including abrasion, grit blasting, and peel-ply techniques, represent the most traditional approaches. These methods physically alter the surface topography, increasing surface area and creating mechanical interlocking sites. While cost-effective and straightforward to implement, they often result in inconsistent surface quality and potential fiber damage, limiting their application in high-precision industries.

Chemical treatments have gained prominence for their ability to modify surface chemistry without compromising structural integrity. Techniques such as solvent cleaning, acid etching, and oxidative treatments effectively remove contaminants and introduce functional groups that enhance chemical bonding. However, these methods frequently involve environmentally hazardous chemicals, presenting significant disposal challenges and regulatory concerns.

Plasma treatment has emerged as a leading advanced technique, offering precise control over surface modification without dimensional changes. Low-pressure plasma and atmospheric plasma treatments can simultaneously clean surfaces and introduce specific functional groups. Despite their effectiveness, the high equipment costs and technical expertise requirements limit widespread adoption, particularly among smaller manufacturers.

Laser surface treatment represents the cutting edge of CFRP surface modification, enabling highly controlled, localized surface alterations without thermal damage to the substrate. This technology allows for precise patterning and selective functionalization but remains constrained by high capital investment and limited scalability for large components.

The primary technical challenges facing CFRP surface treatment include achieving uniform modification across complex geometries, developing environmentally sustainable processes, and establishing reliable quality control methods. Surface characterization remains particularly problematic, as conventional techniques often fail to accurately assess the nanoscale changes critical for adhesion performance.

Another significant challenge is the development of treatments compatible with automated manufacturing processes. Current methods frequently require manual intervention, creating bottlenecks in production lines and introducing variability in treatment quality. This incompatibility with Industry 4.0 principles represents a major obstacle to wider CFRP adoption in mass-production industries.

Furthermore, the industry faces difficulties in establishing standardized testing protocols that reliably predict long-term adhesion performance under various environmental conditions. This uncertainty complicates material selection and design processes, particularly for applications with extended service lifetimes or extreme operating environments.

Mechanical treatments, including abrasion, grit blasting, and peel-ply techniques, represent the most traditional approaches. These methods physically alter the surface topography, increasing surface area and creating mechanical interlocking sites. While cost-effective and straightforward to implement, they often result in inconsistent surface quality and potential fiber damage, limiting their application in high-precision industries.

Chemical treatments have gained prominence for their ability to modify surface chemistry without compromising structural integrity. Techniques such as solvent cleaning, acid etching, and oxidative treatments effectively remove contaminants and introduce functional groups that enhance chemical bonding. However, these methods frequently involve environmentally hazardous chemicals, presenting significant disposal challenges and regulatory concerns.

Plasma treatment has emerged as a leading advanced technique, offering precise control over surface modification without dimensional changes. Low-pressure plasma and atmospheric plasma treatments can simultaneously clean surfaces and introduce specific functional groups. Despite their effectiveness, the high equipment costs and technical expertise requirements limit widespread adoption, particularly among smaller manufacturers.

Laser surface treatment represents the cutting edge of CFRP surface modification, enabling highly controlled, localized surface alterations without thermal damage to the substrate. This technology allows for precise patterning and selective functionalization but remains constrained by high capital investment and limited scalability for large components.

The primary technical challenges facing CFRP surface treatment include achieving uniform modification across complex geometries, developing environmentally sustainable processes, and establishing reliable quality control methods. Surface characterization remains particularly problematic, as conventional techniques often fail to accurately assess the nanoscale changes critical for adhesion performance.

Another significant challenge is the development of treatments compatible with automated manufacturing processes. Current methods frequently require manual intervention, creating bottlenecks in production lines and introducing variability in treatment quality. This incompatibility with Industry 4.0 principles represents a major obstacle to wider CFRP adoption in mass-production industries.

Furthermore, the industry faces difficulties in establishing standardized testing protocols that reliably predict long-term adhesion performance under various environmental conditions. This uncertainty complicates material selection and design processes, particularly for applications with extended service lifetimes or extreme operating environments.

Existing CFRP Adhesion Enhancement Solutions

01 Chemical surface treatments for CFRP adhesion enhancement

Various chemical treatments can be applied to CFRP surfaces to improve adhesion properties. These treatments include oxidation processes, acid treatments, and application of specific chemical agents that modify the surface chemistry of the carbon fiber reinforced polymer. These methods create functional groups on the surface that can form stronger bonds with adhesives, resulting in improved interfacial strength between the CFRP and bonding materials.- Chemical surface treatments for improved adhesion: Various chemical treatments can be applied to CFRP surfaces to enhance adhesion properties. These treatments modify the surface chemistry by introducing functional groups that can form stronger bonds with adhesives. Common chemical treatments include oxidation processes, acid treatments, and application of coupling agents that create chemical bridges between the CFRP substrate and adhesive layers. These methods effectively increase surface energy and wettability, resulting in improved adhesion strength and durability of bonded joints.

- Plasma and laser surface modification techniques: Advanced physical modification techniques such as plasma treatment and laser ablation can significantly improve the adhesion properties of CFRP surfaces. Plasma treatment introduces reactive functional groups and removes contaminants without damaging the underlying carbon fibers. Laser ablation selectively removes the polymer matrix to expose carbon fibers and create a micro-textured surface with increased mechanical interlocking capabilities. These non-contact methods provide precise control over surface modification and can be optimized for specific adhesive systems.

- Mechanical surface preparation methods: Mechanical surface preparation techniques create roughened surfaces on CFRP to enhance adhesion through increased surface area and mechanical interlocking. Methods include abrasive blasting with various media, sanding with different grit sizes, and mechanical scoring. These processes remove surface contaminants, weak boundary layers, and create micro-textures that improve adhesive penetration and bonding. The effectiveness depends on controlling parameters such as abrasive type, pressure, and treatment duration to avoid damaging the carbon fibers.

- Specialized primers and coupling agents: Specialized primers and coupling agents can be applied to CFRP surfaces to create an intermediate layer that enhances adhesion between the composite and subsequent adhesive or coating. Silane-based coupling agents form chemical bonds with both the CFRP surface and the adhesive. Epoxy-based primers provide compatibility with common structural adhesives. These intermediate layers can compensate for surface irregularities, improve wetting characteristics, and create chemical bridges that strengthen the adhesive interface, resulting in more durable bonds.

- Combined and hybrid surface treatment approaches: Hybrid approaches combining multiple surface treatment methods often yield superior adhesion results for CFRP materials. Sequential treatments such as mechanical abrasion followed by chemical activation, or plasma treatment followed by primer application, can address different aspects of surface preparation. These combined approaches typically clean the surface, create mechanical interlocking features, and modify surface chemistry to maximize both mechanical and chemical bonding mechanisms. The synergistic effects of combined treatments often result in adhesion strengths exceeding those achieved by individual methods.

02 Physical surface modification techniques

Physical modification of CFRP surfaces involves techniques such as plasma treatment, laser ablation, and mechanical abrasion to enhance surface roughness and increase the effective bonding area. These methods remove contaminants, expose fresh material, and create micro-textures on the surface that provide mechanical interlocking with adhesives. The increased surface area and modified topography significantly improve adhesion strength between CFRP components and adhesive materials.Expand Specific Solutions03 Specialized adhesive formulations for CFRP bonding

Specialized adhesive systems have been developed specifically for CFRP applications. These formulations include modified epoxy resins, polyurethane-based adhesives, and hybrid adhesive systems that are designed to be compatible with carbon fiber reinforced polymers. These adhesives often contain additives that enhance wetting, penetration, and cross-linking with CFRP surfaces, resulting in stronger and more durable bonds even under challenging environmental conditions.Expand Specific Solutions04 Surface preparation processes and cleaning methods

Proper surface preparation is critical for achieving optimal adhesion to CFRP materials. This includes cleaning processes to remove release agents, contaminants, and weak boundary layers that can interfere with bonding. Methods such as solvent cleaning, detergent washing, and specialized degreasing techniques ensure that the CFRP surface is free from substances that could impair adhesion. These preparation steps are often performed prior to other surface treatments to maximize their effectiveness.Expand Specific Solutions05 Primer and coupling agent applications

Primers and coupling agents serve as intermediary layers between CFRP surfaces and adhesives to enhance bonding performance. These materials are designed to be compatible with both the CFRP substrate and the adhesive system. Silane coupling agents, titanate primers, and specialized CFRP primers create chemical bridges between the dissimilar materials, improving wetting characteristics and forming strong chemical bonds that enhance overall adhesion strength and durability in various environmental conditions.Expand Specific Solutions

Leading Companies in CFRP Surface Treatment Industry

The CFRP surface treatment market for improved adhesion is in a growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The market size is expanding due to rising demand for lightweight, high-strength materials in transportation and construction applications. Technologically, the field shows moderate maturity with established players like Airbus Operations GmbH and Toray Industries leading innovation, while research institutions such as Fraunhofer-Gesellschaft and Sichuan University contribute fundamental advancements. Companies including Honda Motor, Mitsubishi Electric, and Nitto Denko are developing specialized applications, while smaller firms like Linde AMT Schluechtern and ADTEC Engineering focus on niche treatment technologies. The competitive landscape features a mix of large industrial conglomerates, specialized materials companies, and academic research centers collaborating to overcome remaining technical challenges in durability and cost-effectiveness.

Airbus Operations GmbH

Technical Solution: Airbus Operations has pioneered a multi-stage CFRP surface treatment protocol combining mechanical abrasion and chemical activation processes. Their approach begins with precision-controlled laser ablation that selectively removes the resin-rich surface layer without damaging the structural integrity of the carbon fibers. This is followed by an atmospheric pressure plasma treatment using proprietary gas mixtures that introduces oxygen-containing functional groups to enhance chemical bonding. The final stage involves application of specially formulated primers containing nanoparticles that create mechanical interlocking with adhesives. This comprehensive treatment has been implemented in critical primary structures of commercial aircraft, demonstrating a 35% increase in bond durability under cyclic loading conditions and improved resistance to hot/wet environmental conditions. Airbus has also developed in-line quality control methods using spectroscopic analysis to verify surface treatment effectiveness before bonding operations.

Strengths: Comprehensive approach addressing both mechanical and chemical aspects of adhesion; proven reliability in demanding aerospace applications; integrated quality control systems. Weaknesses: Complex multi-step process requiring precise control; higher processing time compared to single-treatment methods; requires specialized equipment and trained operators.

Toray Industries, Inc.

Technical Solution: Toray has developed a proprietary plasma surface treatment technology specifically for CFRP (Carbon Fiber Reinforced Polymer) materials that significantly enhances adhesion properties. Their approach utilizes low-pressure plasma treatment with carefully controlled gas mixtures (typically oxygen, nitrogen, and argon) to create functional groups on the CFRP surface. This process increases surface energy and creates micro-roughness without damaging the underlying carbon fibers. Toray's system incorporates real-time plasma parameter monitoring to ensure consistent treatment quality across large composite structures. Their technology has demonstrated up to 40% improvement in lap shear strength for adhesively bonded CFRP joints compared to untreated surfaces. Additionally, Toray has integrated this surface treatment into their manufacturing workflow with automated systems that can process complex geometries while maintaining uniform treatment effectiveness.

Strengths: Exceptional control over surface chemistry with minimal fiber damage; scalable to industrial production volumes; proven effectiveness in aerospace applications. Weaknesses: Requires specialized equipment and controlled environment; higher implementation cost compared to mechanical treatments; process parameters must be carefully optimized for different resin systems.

Key Surface Treatment Patents and Technical Literature

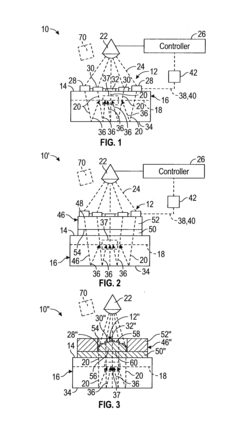

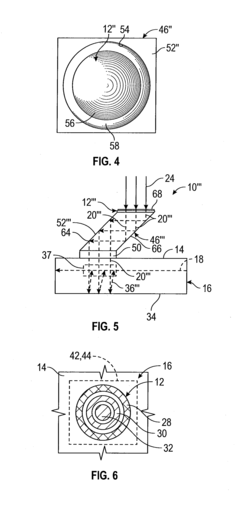

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

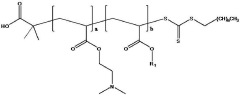

Polymer composite reinforced with carbon fibers and method of preparing the same

PatentActiveKR1020190025461A

Innovation

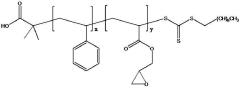

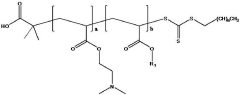

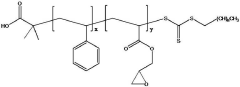

- The surface of carbon fibers is modified with an amphiphilic block copolymer, which enhances compatibility with both hydrophilic and hydrophobic polymers, eliminating the need for pretreatment processes and improving mechanical properties.

Environmental Impact of Surface Treatment Processes

The surface treatment processes employed for CFRP (Carbon Fiber Reinforced Polymer) adhesion improvement carry significant environmental implications that warrant careful consideration in industrial applications. Chemical treatments such as acid etching and oxidation processes typically involve hazardous substances including strong acids, oxidizing agents, and volatile organic compounds (VOCs) that pose environmental risks through air emissions, wastewater discharge, and potential soil contamination.

Plasma treatment methods, while generally considered more environmentally friendly than chemical approaches, still consume substantial energy and may utilize greenhouse gases like methane or oxygen as process gases. The environmental footprint of plasma systems depends largely on the energy source powering the equipment and the specific gases employed in the treatment process.

Mechanical abrasion techniques generate particulate matter that requires proper containment and disposal systems. The fine carbon and polymer dust created during sanding or grit blasting processes can present respiratory hazards and environmental contamination if not adequately controlled. Additionally, the consumables used in these processes (sandpaper, abrasive media) contribute to solid waste streams.

Laser surface treatments offer potential environmental advantages through precise application and minimal waste generation, but their high energy consumption remains a significant consideration. The carbon footprint of laser treatments correlates directly with the energy efficiency of the laser system and the power source utilized.

Regulatory frameworks governing these processes continue to evolve globally, with increasing restrictions on VOC emissions, hazardous waste disposal, and energy consumption. The European Union's REACH regulations and similar frameworks in other regions impose strict controls on chemicals used in surface treatment processes, driving industry innovation toward greener alternatives.

Life cycle assessment (LCA) studies indicate that the environmental impact of surface treatments extends beyond the immediate processing phase to include raw material extraction, transportation, and end-of-life considerations. Recent research suggests that optimizing treatment parameters can significantly reduce environmental impacts while maintaining adhesion performance.

Industry trends show increasing adoption of water-based and solvent-free treatment systems, along with closed-loop processing that captures and recycles treatment chemicals. Emerging technologies such as supercritical CO2 cleaning and biobased surface preparation agents represent promising directions for reducing the environmental footprint of CFRP surface treatments while maintaining or enhancing adhesion properties.

Plasma treatment methods, while generally considered more environmentally friendly than chemical approaches, still consume substantial energy and may utilize greenhouse gases like methane or oxygen as process gases. The environmental footprint of plasma systems depends largely on the energy source powering the equipment and the specific gases employed in the treatment process.

Mechanical abrasion techniques generate particulate matter that requires proper containment and disposal systems. The fine carbon and polymer dust created during sanding or grit blasting processes can present respiratory hazards and environmental contamination if not adequately controlled. Additionally, the consumables used in these processes (sandpaper, abrasive media) contribute to solid waste streams.

Laser surface treatments offer potential environmental advantages through precise application and minimal waste generation, but their high energy consumption remains a significant consideration. The carbon footprint of laser treatments correlates directly with the energy efficiency of the laser system and the power source utilized.

Regulatory frameworks governing these processes continue to evolve globally, with increasing restrictions on VOC emissions, hazardous waste disposal, and energy consumption. The European Union's REACH regulations and similar frameworks in other regions impose strict controls on chemicals used in surface treatment processes, driving industry innovation toward greener alternatives.

Life cycle assessment (LCA) studies indicate that the environmental impact of surface treatments extends beyond the immediate processing phase to include raw material extraction, transportation, and end-of-life considerations. Recent research suggests that optimizing treatment parameters can significantly reduce environmental impacts while maintaining adhesion performance.

Industry trends show increasing adoption of water-based and solvent-free treatment systems, along with closed-loop processing that captures and recycles treatment chemicals. Emerging technologies such as supercritical CO2 cleaning and biobased surface preparation agents represent promising directions for reducing the environmental footprint of CFRP surface treatments while maintaining or enhancing adhesion properties.

Quality Control Methods for Surface Treatment Evaluation

Quality control methods for evaluating CFRP surface treatments require systematic approaches to ensure consistent adhesion performance. Standardized testing protocols form the foundation of these methods, with peel tests, lap shear tests, and fracture toughness measurements being the most widely adopted in industry. These tests provide quantitative data on bond strength and failure modes, enabling objective comparison between different treatment methods.

Surface characterization techniques play a crucial role in quality control processes. Contact angle measurements offer rapid assessment of surface energy changes resulting from treatments, with lower contact angles generally indicating improved wettability and adhesion potential. X-ray photoelectron spectroscopy (XPS) and Fourier-transform infrared spectroscopy (FTIR) provide detailed chemical composition analysis of treated surfaces, allowing verification of functional group formation and contaminant removal.

Microscopic evaluation methods complement chemical analysis by revealing physical surface modifications. Scanning electron microscopy (SEM) enables visualization of micro-roughness patterns created by treatments, while atomic force microscopy (AFM) provides nanoscale topographical mapping with quantitative roughness parameters. These visual inspections help correlate surface morphology with adhesion performance.

Process control parameters must be continuously monitored to ensure treatment consistency. For plasma treatments, key variables include power settings, exposure time, gas composition, and chamber pressure. For chemical treatments, concentration, temperature, immersion time, and pH require strict control. Statistical process control (SPC) charts help identify trends and deviations before they impact product quality.

Non-destructive testing (NDT) methods enable in-line quality verification without sacrificing production parts. Ultrasonic inspection can detect disbonds or weak interfaces, while thermography identifies areas of poor adhesion through thermal response differences. These techniques allow 100% inspection of critical components rather than relying solely on sampling methods.

Accelerated aging tests provide predictive data on long-term bond durability. Environmental cycling between temperature and humidity extremes, combined with mechanical loading, reveals potential weaknesses in surface treatment effectiveness. Correlation between accelerated test results and real-world performance requires careful validation through field testing and historical data analysis.

Documentation and traceability systems ensure that all quality control data is properly recorded and retrievable. Digital systems that link surface treatment parameters, inspection results, and final adhesion performance create a comprehensive quality assurance framework that supports continuous improvement efforts and regulatory compliance.

Surface characterization techniques play a crucial role in quality control processes. Contact angle measurements offer rapid assessment of surface energy changes resulting from treatments, with lower contact angles generally indicating improved wettability and adhesion potential. X-ray photoelectron spectroscopy (XPS) and Fourier-transform infrared spectroscopy (FTIR) provide detailed chemical composition analysis of treated surfaces, allowing verification of functional group formation and contaminant removal.

Microscopic evaluation methods complement chemical analysis by revealing physical surface modifications. Scanning electron microscopy (SEM) enables visualization of micro-roughness patterns created by treatments, while atomic force microscopy (AFM) provides nanoscale topographical mapping with quantitative roughness parameters. These visual inspections help correlate surface morphology with adhesion performance.

Process control parameters must be continuously monitored to ensure treatment consistency. For plasma treatments, key variables include power settings, exposure time, gas composition, and chamber pressure. For chemical treatments, concentration, temperature, immersion time, and pH require strict control. Statistical process control (SPC) charts help identify trends and deviations before they impact product quality.

Non-destructive testing (NDT) methods enable in-line quality verification without sacrificing production parts. Ultrasonic inspection can detect disbonds or weak interfaces, while thermography identifies areas of poor adhesion through thermal response differences. These techniques allow 100% inspection of critical components rather than relying solely on sampling methods.

Accelerated aging tests provide predictive data on long-term bond durability. Environmental cycling between temperature and humidity extremes, combined with mechanical loading, reveals potential weaknesses in surface treatment effectiveness. Correlation between accelerated test results and real-world performance requires careful validation through field testing and historical data analysis.

Documentation and traceability systems ensure that all quality control data is properly recorded and retrievable. Digital systems that link surface treatment parameters, inspection results, and final adhesion performance create a comprehensive quality assurance framework that supports continuous improvement efforts and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!