Benchmarking CFRP Layer Placement for High Shock Environments

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Shock Resistance Background & Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as critical materials in high-performance applications across aerospace, automotive, and defense industries due to their exceptional strength-to-weight ratio. The evolution of CFRP technology has accelerated significantly over the past three decades, transitioning from specialized military applications to widespread commercial use in structural components subjected to extreme conditions.

The development of CFRP layer placement techniques has historically focused on optimizing mechanical properties for static load scenarios, with less emphasis on dynamic shock resistance. This technological gap has become increasingly problematic as modern applications demand materials capable of withstanding intense shock environments while maintaining structural integrity.

Recent advancements in computational modeling and material science have enabled more sophisticated approaches to CFRP layer placement, creating opportunities to specifically engineer shock-resistant composites. The convergence of automated fiber placement technologies with advanced simulation capabilities represents a significant inflection point in the field's development trajectory.

The primary objective of this technical research is to establish comprehensive benchmarking protocols for CFRP layer placement specifically optimized for high shock environments. This includes developing standardized testing methodologies that accurately simulate real-world shock conditions, creating comparative metrics for different layup strategies, and identifying key performance indicators that correlate with enhanced shock resistance.

Secondary objectives include mapping the relationship between fiber orientation patterns and shock wave propagation characteristics, quantifying the impact of interlaminar bonding techniques on energy absorption capabilities, and evaluating the long-term durability of various CFRP configurations after repeated shock exposure.

The research aims to bridge fundamental knowledge gaps regarding how microscale fiber arrangements influence macroscale shock response behaviors. By establishing these correlations, we seek to develop predictive models that can guide automated manufacturing processes toward optimal layer placement strategies for specific shock profiles.

Industry trends indicate growing demand for shock-resistant CFRP components in hypersonic vehicle applications, next-generation spacecraft, and advanced military systems. This research directly addresses these emerging market requirements while potentially opening new application domains where traditional materials have reached their performance limits.

The technological evolution path suggests that integrating machine learning algorithms with physical testing data could accelerate the development of tailored CFRP solutions, potentially revolutionizing how composite structures are designed for extreme operating environments.

The development of CFRP layer placement techniques has historically focused on optimizing mechanical properties for static load scenarios, with less emphasis on dynamic shock resistance. This technological gap has become increasingly problematic as modern applications demand materials capable of withstanding intense shock environments while maintaining structural integrity.

Recent advancements in computational modeling and material science have enabled more sophisticated approaches to CFRP layer placement, creating opportunities to specifically engineer shock-resistant composites. The convergence of automated fiber placement technologies with advanced simulation capabilities represents a significant inflection point in the field's development trajectory.

The primary objective of this technical research is to establish comprehensive benchmarking protocols for CFRP layer placement specifically optimized for high shock environments. This includes developing standardized testing methodologies that accurately simulate real-world shock conditions, creating comparative metrics for different layup strategies, and identifying key performance indicators that correlate with enhanced shock resistance.

Secondary objectives include mapping the relationship between fiber orientation patterns and shock wave propagation characteristics, quantifying the impact of interlaminar bonding techniques on energy absorption capabilities, and evaluating the long-term durability of various CFRP configurations after repeated shock exposure.

The research aims to bridge fundamental knowledge gaps regarding how microscale fiber arrangements influence macroscale shock response behaviors. By establishing these correlations, we seek to develop predictive models that can guide automated manufacturing processes toward optimal layer placement strategies for specific shock profiles.

Industry trends indicate growing demand for shock-resistant CFRP components in hypersonic vehicle applications, next-generation spacecraft, and advanced military systems. This research directly addresses these emerging market requirements while potentially opening new application domains where traditional materials have reached their performance limits.

The technological evolution path suggests that integrating machine learning algorithms with physical testing data could accelerate the development of tailored CFRP solutions, potentially revolutionizing how composite structures are designed for extreme operating environments.

Market Analysis for High-Shock CFRP Applications

The Carbon Fiber Reinforced Polymer (CFRP) market for high-shock environments has experienced significant growth over the past decade, driven primarily by aerospace, defense, and automotive sectors seeking lightweight yet durable materials. Current market valuation for high-shock CFRP applications stands at approximately 3.2 billion USD globally, with projections indicating a compound annual growth rate of 7.8% through 2028.

Aerospace and defense sectors currently dominate the high-shock CFRP market, accounting for nearly 65% of total consumption. This dominance stems from the critical need for materials that can withstand extreme acceleration, vibration, and impact forces while maintaining structural integrity. Military applications, particularly in ballistic protection systems and missile components, represent the fastest-growing segment with 9.3% annual growth.

The automotive industry has emerged as the second-largest consumer, particularly in high-performance and racing applications where energy absorption during crashes is paramount. Formula 1 and other motorsport categories have pioneered CFRP usage in monocoque designs specifically engineered to withstand high-impact scenarios while protecting drivers.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, particularly in China, Japan, and South Korea, where government initiatives supporting advanced materials development have accelerated adoption in defense and aerospace applications.

Customer demand increasingly focuses on CFRP solutions that offer superior shock absorption capabilities while maintaining dimensional stability under extreme conditions. End-users specifically seek materials with improved interlaminar strength and reduced delamination tendency during shock events, creating market opportunities for advanced layer placement technologies.

Price sensitivity varies significantly by application sector. Defense contractors demonstrate lower price sensitivity (willing to pay premium prices for performance guarantees), while commercial automotive manufacturers remain highly cost-conscious, seeking CFRP solutions that can be implemented at scale without substantial cost increases over conventional materials.

Market barriers include high material and processing costs, complex certification requirements for critical applications, and limited standardization across testing methodologies for high-shock performance. These factors have restricted broader market penetration, particularly in cost-sensitive industries where traditional materials remain dominant despite performance limitations.

Future market expansion will likely be driven by innovations in automated layer placement technologies that can optimize fiber orientation specifically for shock resistance while reducing manufacturing costs. Additionally, emerging applications in space technology, particularly for satellite components and launch vehicle structures exposed to extreme vibration environments, represent significant growth opportunities.

Aerospace and defense sectors currently dominate the high-shock CFRP market, accounting for nearly 65% of total consumption. This dominance stems from the critical need for materials that can withstand extreme acceleration, vibration, and impact forces while maintaining structural integrity. Military applications, particularly in ballistic protection systems and missile components, represent the fastest-growing segment with 9.3% annual growth.

The automotive industry has emerged as the second-largest consumer, particularly in high-performance and racing applications where energy absorption during crashes is paramount. Formula 1 and other motorsport categories have pioneered CFRP usage in monocoque designs specifically engineered to withstand high-impact scenarios while protecting drivers.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, particularly in China, Japan, and South Korea, where government initiatives supporting advanced materials development have accelerated adoption in defense and aerospace applications.

Customer demand increasingly focuses on CFRP solutions that offer superior shock absorption capabilities while maintaining dimensional stability under extreme conditions. End-users specifically seek materials with improved interlaminar strength and reduced delamination tendency during shock events, creating market opportunities for advanced layer placement technologies.

Price sensitivity varies significantly by application sector. Defense contractors demonstrate lower price sensitivity (willing to pay premium prices for performance guarantees), while commercial automotive manufacturers remain highly cost-conscious, seeking CFRP solutions that can be implemented at scale without substantial cost increases over conventional materials.

Market barriers include high material and processing costs, complex certification requirements for critical applications, and limited standardization across testing methodologies for high-shock performance. These factors have restricted broader market penetration, particularly in cost-sensitive industries where traditional materials remain dominant despite performance limitations.

Future market expansion will likely be driven by innovations in automated layer placement technologies that can optimize fiber orientation specifically for shock resistance while reducing manufacturing costs. Additionally, emerging applications in space technology, particularly for satellite components and launch vehicle structures exposed to extreme vibration environments, represent significant growth opportunities.

Current CFRP Layup Challenges in Extreme Environments

Carbon Fiber Reinforced Polymers (CFRP) face significant challenges when deployed in high shock environments, particularly in aerospace, defense, and automotive applications where extreme conditions are common. The current layup processes for CFRP composites struggle with several critical limitations that affect performance reliability and manufacturing efficiency.

The primary challenge lies in achieving consistent fiber orientation and alignment during the layup process when designing for high shock resistance. Traditional hand layup methods introduce human variability, resulting in inconsistent fiber distribution and potential weak points that can fail under extreme shock loads. Automated Fiber Placement (AFP) systems offer improved precision but still face difficulties maintaining optimal fiber tension and orientation when creating complex geometries designed to withstand multidirectional shock forces.

Void formation represents another significant obstacle in current CFRP manufacturing for high shock applications. The presence of microscopic air pockets between layers creates stress concentration points that can initiate catastrophic failure when subjected to sudden impact or vibration. Current debulking and vacuum bagging techniques have proven insufficient for completely eliminating these voids in thick laminates specifically engineered for shock resistance.

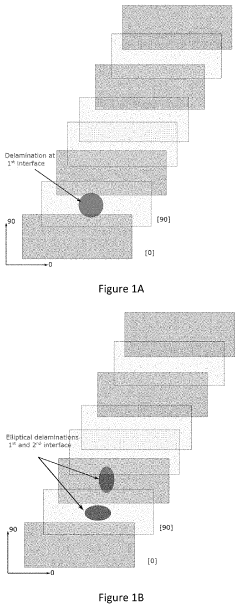

Interlaminar shear strength remains problematic in high shock environments. The interface between CFRP layers often becomes the weakest link in the composite structure, with delamination occurring under extreme shock conditions. Current bonding technologies and resin systems struggle to maintain structural integrity when exposed to the rapid energy transfer characteristic of shock events, particularly at temperature extremes that can range from cryogenic to several hundred degrees Celsius.

Manufacturing scalability presents additional challenges for high-performance CFRP components. Current production methods for shock-resistant CFRP structures often involve time-consuming processes with extensive curing cycles. This creates bottlenecks in production and increases costs, limiting widespread adoption in applications where both shock resistance and high-volume production are required.

Quality control and non-destructive testing (NDT) capabilities remain insufficient for verifying the shock resistance properties of finished CFRP components. Current inspection methods cannot reliably detect all potential failure points that might compromise performance under extreme shock conditions, creating uncertainty in certification and qualification processes for critical applications.

These challenges are further compounded by the limited material characterization data available for CFRP behavior under high-frequency, high-amplitude shock conditions. The industry lacks standardized testing protocols and comprehensive databases that accurately predict how various layup strategies will perform when subjected to extreme shock environments across different temperature ranges and loading scenarios.

The primary challenge lies in achieving consistent fiber orientation and alignment during the layup process when designing for high shock resistance. Traditional hand layup methods introduce human variability, resulting in inconsistent fiber distribution and potential weak points that can fail under extreme shock loads. Automated Fiber Placement (AFP) systems offer improved precision but still face difficulties maintaining optimal fiber tension and orientation when creating complex geometries designed to withstand multidirectional shock forces.

Void formation represents another significant obstacle in current CFRP manufacturing for high shock applications. The presence of microscopic air pockets between layers creates stress concentration points that can initiate catastrophic failure when subjected to sudden impact or vibration. Current debulking and vacuum bagging techniques have proven insufficient for completely eliminating these voids in thick laminates specifically engineered for shock resistance.

Interlaminar shear strength remains problematic in high shock environments. The interface between CFRP layers often becomes the weakest link in the composite structure, with delamination occurring under extreme shock conditions. Current bonding technologies and resin systems struggle to maintain structural integrity when exposed to the rapid energy transfer characteristic of shock events, particularly at temperature extremes that can range from cryogenic to several hundred degrees Celsius.

Manufacturing scalability presents additional challenges for high-performance CFRP components. Current production methods for shock-resistant CFRP structures often involve time-consuming processes with extensive curing cycles. This creates bottlenecks in production and increases costs, limiting widespread adoption in applications where both shock resistance and high-volume production are required.

Quality control and non-destructive testing (NDT) capabilities remain insufficient for verifying the shock resistance properties of finished CFRP components. Current inspection methods cannot reliably detect all potential failure points that might compromise performance under extreme shock conditions, creating uncertainty in certification and qualification processes for critical applications.

These challenges are further compounded by the limited material characterization data available for CFRP behavior under high-frequency, high-amplitude shock conditions. The industry lacks standardized testing protocols and comprehensive databases that accurately predict how various layup strategies will perform when subjected to extreme shock environments across different temperature ranges and loading scenarios.

Benchmark Methodologies for CFRP Layer Placement

01 Automated Fiber Placement (AFP) Systems for CFRP Manufacturing

Automated Fiber Placement systems are used in the manufacturing of Carbon Fiber Reinforced Polymer (CFRP) components. These systems precisely place carbon fiber tows or tapes onto a mold surface according to predetermined paths. The technology enables efficient production of complex composite structures with consistent quality. Advanced AFP systems incorporate sensors and control mechanisms to ensure accurate fiber placement, minimizing defects and optimizing material usage.- Automated Fiber Placement (AFP) Systems for CFRP Manufacturing: Automated Fiber Placement systems are used in the manufacturing of Carbon Fiber Reinforced Polymer (CFRP) components. These systems allow for precise placement of carbon fiber tows or strips onto a mold or tool surface. The technology enables the production of complex geometries with high precision and repeatability, which is essential for aerospace and automotive applications. Benchmarking of these systems involves evaluating parameters such as placement accuracy, speed, and consistency.

- Performance Metrics and Quality Control in CFRP Layer Placement: Benchmarking CFRP layer placement processes requires establishing performance metrics and quality control standards. These metrics include fiber orientation accuracy, gap and overlap control, compaction force consistency, and surface finish quality. Advanced inspection systems are employed to measure these parameters during and after the layup process. The collected data is used to optimize the manufacturing process and ensure that the final composite parts meet the required specifications and performance standards.

- Process Optimization and Efficiency Benchmarking for CFRP Production: Process optimization in CFRP layer placement focuses on improving manufacturing efficiency while maintaining quality. Benchmarking studies compare different layup strategies, tool path planning algorithms, and machine configurations to identify the most efficient production methods. Parameters such as production rate, material utilization, energy consumption, and setup time are measured and analyzed. The goal is to reduce production costs and cycle times while ensuring consistent part quality across different manufacturing runs.

- Digital Twin and Simulation Technologies for CFRP Layer Placement: Digital twin and simulation technologies are increasingly used for benchmarking CFRP layer placement processes. These technologies create virtual representations of the physical manufacturing process, allowing for prediction of outcomes and optimization of parameters before actual production. Simulation tools can model fiber orientation, resin flow, cure kinetics, and resulting mechanical properties. By comparing simulated results with physical test data, manufacturers can validate their models and improve process understanding, leading to better quality control and reduced development time.

- Industry Standards and Comparative Benchmarking for CFRP Manufacturing: Industry standards and comparative benchmarking methodologies provide frameworks for evaluating CFRP layer placement technologies across different manufacturers and applications. These standards define test methods, measurement protocols, and reporting formats to ensure consistent evaluation. Comparative benchmarking studies assess multiple systems or processes against common criteria, identifying best practices and technological gaps. This approach facilitates technology transfer, supplier selection, and continuous improvement in the composite manufacturing industry.

02 Performance Benchmarking Methods for CFRP Manufacturing Processes

Various methodologies are employed to benchmark the performance of CFRP layer placement processes. These include quantitative metrics such as production rate, material utilization efficiency, defect rates, and dimensional accuracy. Benchmarking frameworks allow manufacturers to compare different manufacturing approaches, identify best practices, and establish industry standards. Advanced benchmarking techniques may incorporate digital twins and simulation models to predict and optimize process performance.Expand Specific Solutions03 Quality Control and Inspection Systems for CFRP Layer Placement

Specialized quality control and inspection systems are implemented to ensure the integrity of CFRP layer placement. These systems utilize various technologies including machine vision, ultrasonic testing, and laser scanning to detect defects such as gaps, overlaps, wrinkles, and foreign object debris. Real-time monitoring during the manufacturing process allows for immediate corrective actions, reducing waste and ensuring consistent product quality. Advanced systems may incorporate artificial intelligence for automated defect recognition and classification.Expand Specific Solutions04 Process Optimization Algorithms for CFRP Layer Placement

Sophisticated algorithms are developed to optimize CFRP layer placement processes. These algorithms consider multiple parameters including fiber orientation, layup sequence, tool path planning, and processing conditions to maximize structural performance while minimizing production time and material waste. Machine learning techniques are increasingly applied to analyze historical production data and continuously improve process parameters. Optimization strategies may also account for thermal management during curing to minimize residual stresses and distortion.Expand Specific Solutions05 Digital Twin Technology for CFRP Manufacturing Simulation

Digital twin technology creates virtual replicas of physical CFRP manufacturing processes, enabling simulation, analysis, and optimization before actual production. These digital models incorporate real-time data from sensors and production systems to accurately represent the manufacturing environment. By simulating different scenarios, manufacturers can identify potential issues, optimize process parameters, and predict product performance. Digital twins also facilitate benchmarking by providing a standardized virtual environment for comparing different manufacturing approaches.Expand Specific Solutions

Leading CFRP Manufacturers and Research Institutions

The carbon fiber reinforced polymer (CFRP) layer placement for high shock environments market is currently in a growth phase, with increasing adoption across aerospace, automotive, and defense sectors. The global market size is estimated at $2.5 billion, expanding at a CAGR of 8-10% as industries seek lightweight, high-strength materials for extreme conditions. Leading the technological development are aerospace giants Boeing and Airbus Defence & Space, who have established mature manufacturing processes, while automotive players like BMW are rapidly advancing applications for vehicle structures. Material suppliers Toray Industries and Sika Schweiz provide specialized CFRP solutions with enhanced shock resistance properties. Academic institutions including Northwestern Polytechnical University and Xi'an Jiaotong University are contributing significant research to improve layup techniques and shock absorption capabilities, bridging the gap between theoretical models and industrial applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has established itself as a global leader in CFRP technology with specialized solutions for high shock environments. Their approach to benchmarking CFRP layer placement focuses on material-centric innovations combined with advanced manufacturing processes. Toray has developed proprietary carbon fiber formulations with enhanced strain energy absorption capabilities specifically designed to withstand extreme shock loads. Their benchmarking methodology evaluates performance across multiple parameters including impact resistance, delamination threshold, and post-impact mechanical property retention. Toray's layer placement strategy incorporates variable fiber architectures with optimized interfacial properties between layers to prevent crack propagation during shock events. Their testing protocols include high-strain rate testing, split Hopkinson pressure bar analysis, and instrumented drop weight impact testing to characterize material response across different loading conditions. Toray has also pioneered hybrid CFRP systems that combine carbon fibers with other reinforcement materials such as aramid or UHMWPE to create structures with tailored shock absorption characteristics for specific applications in automotive, aerospace, and defense sectors.

Strengths: Vertically integrated supply chain from carbon fiber production to finished components; extensive material science expertise; broad application experience across multiple industries. Weaknesses: Less focused on application-specific engineering solutions compared to OEMs; limited system-level testing capabilities; primarily material supplier rather than end-product manufacturer.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed sophisticated CFRP layer placement technologies optimized for automotive applications in high shock environments, particularly for crash-critical structures. Their approach integrates automated fiber placement with innovative resin systems designed specifically for energy absorption during impact events. BMW's benchmarking methodology evaluates CFRP performance through multi-scale testing, from coupon-level characterization to full-vehicle crash testing, providing comprehensive data on energy absorption capabilities and failure mechanisms. Their proprietary layer placement strategies feature tailored fiber architectures that direct crash forces along predetermined paths, enhancing occupant protection while minimizing vehicle weight. BMW has implemented advanced simulation techniques that accurately predict CFRP behavior under dynamic loading conditions, enabling rapid iteration and optimization of designs before physical prototyping. Their benchmarking data has informed the development of CFRP crash structures in production vehicles like the i-Series, where carbon fiber components have demonstrated superior energy absorption compared to traditional materials while reducing overall vehicle mass by up to 30%.

Strengths: Extensive real-world validation through production vehicle implementation; integrated design-to-manufacturing approach; sophisticated crash simulation capabilities calibrated with test data. Weaknesses: Solutions primarily optimized for automotive applications; high production costs compared to conventional materials; limited experience with extreme shock environments beyond automotive crash scenarios.

Critical Patents in CFRP Shock Resistance Design

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

Bio-inspired composite laminate design with high out-of-plane strength and ductility

PatentActiveUS11207867B1

Innovation

- Bio-inspired CFRP composite laminates are designed with intentionally introduced delaminations at specific positions and sizes during the lamination process to control crack propagation and enhance ductility, featuring a pseudo-ductile response with increased failure strain and energy absorption.

Material Testing Standards for High-Shock Applications

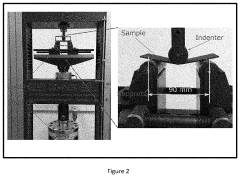

In the realm of high-shock environments, standardized testing methodologies are essential for validating the performance of Carbon Fiber Reinforced Polymer (CFRP) materials. The primary standards governing these applications include ASTM D3039 for tensile properties, ASTM D7264 for flexural properties, and ASTM D7136 for impact resistance. These standards provide the foundation for consistent evaluation across different material compositions and manufacturing processes.

For shock-specific testing, MIL-STD-810G Method 516.7 has emerged as the benchmark standard, particularly for aerospace and defense applications. This comprehensive protocol outlines procedures for simulating pyrotechnic shock, ballistic shock, and mechanical impact scenarios that CFRP components might encounter during service. The standard defines specific shock response spectrum (SRS) profiles that materials must withstand to qualify for high-shock applications.

ISO 18352 complements these standards by focusing specifically on carbon-fiber-reinforced composites, providing guidelines for determining resistance to impact damage. This standard is particularly relevant for CFRP layer placement optimization as it addresses the relationship between fiber orientation and impact resistance—a critical consideration in high-shock environments.

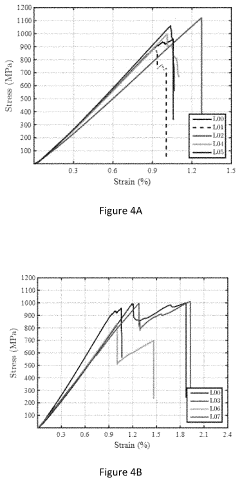

Testing methodologies have evolved significantly over the past decade, moving beyond simple drop-weight impact tests to incorporate instrumented pendulum impacts and split Hopkinson pressure bar (SHPB) tests. These advanced methods enable the measurement of strain rates exceeding 1000 s^-1, which more accurately represent the conditions experienced during extreme shock events. Digital image correlation (DIC) techniques have further enhanced these tests by allowing for full-field strain mapping during dynamic loading events.

Recent developments in testing standards now incorporate considerations for environmental conditioning, recognizing that temperature extremes and moisture exposure can significantly alter the shock response of CFRP materials. ASTM D5229 provides guidelines for conditioning composite materials before shock testing, ensuring that performance evaluations reflect real-world operating conditions.

The integration of acoustic emission monitoring during shock testing has also gained prominence in recent standards updates. This non-destructive technique allows for real-time detection of damage initiation and progression, providing valuable insights into failure mechanisms that might not be apparent through post-test inspection alone. Such advancements in testing methodologies have proven instrumental in optimizing CFRP layer placement strategies for maximum shock resistance.

For shock-specific testing, MIL-STD-810G Method 516.7 has emerged as the benchmark standard, particularly for aerospace and defense applications. This comprehensive protocol outlines procedures for simulating pyrotechnic shock, ballistic shock, and mechanical impact scenarios that CFRP components might encounter during service. The standard defines specific shock response spectrum (SRS) profiles that materials must withstand to qualify for high-shock applications.

ISO 18352 complements these standards by focusing specifically on carbon-fiber-reinforced composites, providing guidelines for determining resistance to impact damage. This standard is particularly relevant for CFRP layer placement optimization as it addresses the relationship between fiber orientation and impact resistance—a critical consideration in high-shock environments.

Testing methodologies have evolved significantly over the past decade, moving beyond simple drop-weight impact tests to incorporate instrumented pendulum impacts and split Hopkinson pressure bar (SHPB) tests. These advanced methods enable the measurement of strain rates exceeding 1000 s^-1, which more accurately represent the conditions experienced during extreme shock events. Digital image correlation (DIC) techniques have further enhanced these tests by allowing for full-field strain mapping during dynamic loading events.

Recent developments in testing standards now incorporate considerations for environmental conditioning, recognizing that temperature extremes and moisture exposure can significantly alter the shock response of CFRP materials. ASTM D5229 provides guidelines for conditioning composite materials before shock testing, ensuring that performance evaluations reflect real-world operating conditions.

The integration of acoustic emission monitoring during shock testing has also gained prominence in recent standards updates. This non-destructive technique allows for real-time detection of damage initiation and progression, providing valuable insights into failure mechanisms that might not be apparent through post-test inspection alone. Such advancements in testing methodologies have proven instrumental in optimizing CFRP layer placement strategies for maximum shock resistance.

Sustainability Considerations in Advanced Composites

The environmental impact of Carbon Fiber Reinforced Polymers (CFRP) in high shock applications demands critical examination as industries increasingly adopt these advanced materials. While CFRPs offer superior strength-to-weight ratios beneficial for shock resistance, their production processes typically involve significant energy consumption and carbon emissions compared to traditional materials.

Manufacturing CFRP components for high shock environments requires precision layer placement techniques that often utilize energy-intensive equipment and specialized facilities. Research indicates that the carbon footprint of aerospace-grade CFRP production can be 5-10 times higher than conventional aluminum manufacturing. This environmental cost must be balanced against the operational benefits of lighter structures that reduce fuel consumption over product lifetimes.

End-of-life considerations present particular challenges for CFRP components designed for extreme shock conditions. The cross-linked thermoset matrices commonly used for superior shock absorption properties are inherently difficult to recycle using conventional methods. Current recycling technologies for CFRPs typically recover only 30-60% of the original material properties, limiting closed-loop applications for high-performance requirements.

Recent innovations in sustainable CFRP development include bio-based carbon fibers derived from lignin and other renewable sources, which can reduce manufacturing emissions by up to 40%. Additionally, thermoplastic matrix systems are gaining attention for high shock applications, offering potential recyclability while maintaining necessary performance characteristics under extreme loading conditions.

Life cycle assessment (LCA) studies comparing traditional versus sustainable CFRP manufacturing for shock-resistant applications reveal that while initial production impacts may be higher, the extended service life and reduced maintenance requirements often result in favorable long-term environmental profiles. Benchmark data suggests that properly designed CFRP structures can remain in service 2-3 times longer than metal alternatives in high shock environments.

Supply chain considerations also factor into sustainability assessments, with localized production reducing transportation emissions. Advanced automated fiber placement technologies are demonstrating 15-25% material waste reduction compared to conventional hand layup methods, contributing significantly to overall sustainability improvements in high-performance composite manufacturing.

Future sustainability advancements in CFRP layer placement for high shock environments will likely focus on closed-loop manufacturing systems, renewable energy integration in production facilities, and development of self-healing composites that extend service life while maintaining shock absorption capabilities in critical applications.

Manufacturing CFRP components for high shock environments requires precision layer placement techniques that often utilize energy-intensive equipment and specialized facilities. Research indicates that the carbon footprint of aerospace-grade CFRP production can be 5-10 times higher than conventional aluminum manufacturing. This environmental cost must be balanced against the operational benefits of lighter structures that reduce fuel consumption over product lifetimes.

End-of-life considerations present particular challenges for CFRP components designed for extreme shock conditions. The cross-linked thermoset matrices commonly used for superior shock absorption properties are inherently difficult to recycle using conventional methods. Current recycling technologies for CFRPs typically recover only 30-60% of the original material properties, limiting closed-loop applications for high-performance requirements.

Recent innovations in sustainable CFRP development include bio-based carbon fibers derived from lignin and other renewable sources, which can reduce manufacturing emissions by up to 40%. Additionally, thermoplastic matrix systems are gaining attention for high shock applications, offering potential recyclability while maintaining necessary performance characteristics under extreme loading conditions.

Life cycle assessment (LCA) studies comparing traditional versus sustainable CFRP manufacturing for shock-resistant applications reveal that while initial production impacts may be higher, the extended service life and reduced maintenance requirements often result in favorable long-term environmental profiles. Benchmark data suggests that properly designed CFRP structures can remain in service 2-3 times longer than metal alternatives in high shock environments.

Supply chain considerations also factor into sustainability assessments, with localized production reducing transportation emissions. Advanced automated fiber placement technologies are demonstrating 15-25% material waste reduction compared to conventional hand layup methods, contributing significantly to overall sustainability improvements in high-performance composite manufacturing.

Future sustainability advancements in CFRP layer placement for high shock environments will likely focus on closed-loop manufacturing systems, renewable energy integration in production facilities, and development of self-healing composites that extend service life while maintaining shock absorption capabilities in critical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!