How to Validate CFRP Conductivity Improvements Through Nano-Engineering

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Conductivity Enhancement Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in aerospace, automotive, and construction industries due to their exceptional strength-to-weight ratio. However, their inherent electrical conductivity limitations have restricted broader applications in electronics, electromagnetic shielding, and lightning strike protection. The evolution of CFRP technology has progressed from basic composite structures to increasingly sophisticated engineered materials, with electrical conductivity enhancement representing the next frontier in their development.

The field of nano-engineering has opened promising avenues for addressing CFRP conductivity challenges. Since the early 2000s, researchers have explored various nanomaterials including carbon nanotubes (CNTs), graphene, and metallic nanoparticles as potential conductivity enhancers. The incorporation of these nanomaterials into the polymer matrix or fiber-matrix interface has demonstrated significant improvements in electrical properties while maintaining mechanical integrity.

Recent technological breakthroughs have accelerated interest in this domain, particularly with the development of scalable manufacturing processes for nanomaterial production and integration. The conductivity enhancement of CFRPs through nano-engineering represents a critical technological advancement that bridges the gap between structural and functional materials, potentially enabling multifunctional composites that serve both structural and electrical purposes simultaneously.

The primary objective of this research is to establish reliable, reproducible validation methodologies for quantifying conductivity improvements in nano-engineered CFRPs. This includes developing standardized testing protocols that account for the anisotropic nature of these composites and the complex interactions between nanomaterials and the carbon fiber/polymer matrix system. Additionally, we aim to correlate electrical performance with processing parameters to enable predictive capabilities for tailored conductivity profiles.

Secondary objectives include investigating the long-term stability of conductivity enhancements under various environmental conditions, mechanical loading scenarios, and aging processes. Understanding these factors is crucial for ensuring the reliability of nano-engineered CFRPs in demanding applications such as aerospace components or automotive structures where consistent electrical performance is essential throughout the product lifecycle.

The technological trajectory suggests that successful validation methodologies will accelerate the adoption of nano-engineered CFRPs across multiple industries, potentially revolutionizing applications ranging from embedded sensors and structural health monitoring to electromagnetic interference shielding and lightning strike protection systems. This research addresses a critical gap between laboratory demonstrations and industrial implementation, potentially enabling the next generation of multifunctional composite materials.

The field of nano-engineering has opened promising avenues for addressing CFRP conductivity challenges. Since the early 2000s, researchers have explored various nanomaterials including carbon nanotubes (CNTs), graphene, and metallic nanoparticles as potential conductivity enhancers. The incorporation of these nanomaterials into the polymer matrix or fiber-matrix interface has demonstrated significant improvements in electrical properties while maintaining mechanical integrity.

Recent technological breakthroughs have accelerated interest in this domain, particularly with the development of scalable manufacturing processes for nanomaterial production and integration. The conductivity enhancement of CFRPs through nano-engineering represents a critical technological advancement that bridges the gap between structural and functional materials, potentially enabling multifunctional composites that serve both structural and electrical purposes simultaneously.

The primary objective of this research is to establish reliable, reproducible validation methodologies for quantifying conductivity improvements in nano-engineered CFRPs. This includes developing standardized testing protocols that account for the anisotropic nature of these composites and the complex interactions between nanomaterials and the carbon fiber/polymer matrix system. Additionally, we aim to correlate electrical performance with processing parameters to enable predictive capabilities for tailored conductivity profiles.

Secondary objectives include investigating the long-term stability of conductivity enhancements under various environmental conditions, mechanical loading scenarios, and aging processes. Understanding these factors is crucial for ensuring the reliability of nano-engineered CFRPs in demanding applications such as aerospace components or automotive structures where consistent electrical performance is essential throughout the product lifecycle.

The technological trajectory suggests that successful validation methodologies will accelerate the adoption of nano-engineered CFRPs across multiple industries, potentially revolutionizing applications ranging from embedded sensors and structural health monitoring to electromagnetic interference shielding and lightning strike protection systems. This research addresses a critical gap between laboratory demonstrations and industrial implementation, potentially enabling the next generation of multifunctional composite materials.

Market Analysis for Conductive CFRP Applications

The global market for conductive Carbon Fiber Reinforced Polymers (CFRP) is experiencing significant growth, driven by increasing demand across multiple high-value industries. The aerospace sector represents the largest market segment, with an estimated demand growth of 7.8% annually through 2028, as manufacturers seek lightweight alternatives to traditional metallic components while maintaining electromagnetic shielding and lightning strike protection capabilities.

Automotive applications constitute the fastest-growing segment for conductive CFRP, particularly in electric vehicles where weight reduction directly impacts range performance. The market is witnessing a transition from luxury and high-performance vehicles to mid-range electric models, expanding the addressable market substantially. This shift is accelerated by regulatory pressures for emissions reduction and fuel efficiency improvements across global markets.

Electronics and telecommunications industries present emerging opportunities for nano-engineered conductive CFRP, particularly in EMI shielding applications and antenna structures. The miniaturization trend in consumer electronics creates demand for materials that can provide structural support while maintaining electrical functionality in compact form factors.

Wind energy represents another significant growth sector, with blade manufacturers increasingly incorporating conductive CFRP to address lightning protection challenges in larger turbine designs. The offshore wind segment shows particular promise due to heightened lightning strike risks in marine environments.

Market analysis reveals a price sensitivity threshold that varies by application. Aerospace customers demonstrate willingness to pay premium prices (30-50% above standard CFRP) for validated conductivity improvements, while automotive applications require more modest price increases (10-20%) to maintain commercial viability. This price-performance relationship creates distinct market entry strategies for different conductivity enhancement technologies.

Regional market distribution shows North America and Europe leading in aerospace and automotive applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in electronics applications. China's strategic investments in advanced materials manufacturing capacity are reshaping global supply dynamics for conductive composite materials.

Customer requirements analysis indicates that conductivity validation protocols represent a critical market barrier. End-users across industries express reluctance to adopt nano-engineered CFRP solutions without standardized testing methodologies that can reliably predict real-world performance. This creates a market opportunity for organizations that can establish trusted validation frameworks alongside material innovations.

Automotive applications constitute the fastest-growing segment for conductive CFRP, particularly in electric vehicles where weight reduction directly impacts range performance. The market is witnessing a transition from luxury and high-performance vehicles to mid-range electric models, expanding the addressable market substantially. This shift is accelerated by regulatory pressures for emissions reduction and fuel efficiency improvements across global markets.

Electronics and telecommunications industries present emerging opportunities for nano-engineered conductive CFRP, particularly in EMI shielding applications and antenna structures. The miniaturization trend in consumer electronics creates demand for materials that can provide structural support while maintaining electrical functionality in compact form factors.

Wind energy represents another significant growth sector, with blade manufacturers increasingly incorporating conductive CFRP to address lightning protection challenges in larger turbine designs. The offshore wind segment shows particular promise due to heightened lightning strike risks in marine environments.

Market analysis reveals a price sensitivity threshold that varies by application. Aerospace customers demonstrate willingness to pay premium prices (30-50% above standard CFRP) for validated conductivity improvements, while automotive applications require more modest price increases (10-20%) to maintain commercial viability. This price-performance relationship creates distinct market entry strategies for different conductivity enhancement technologies.

Regional market distribution shows North America and Europe leading in aerospace and automotive applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in electronics applications. China's strategic investments in advanced materials manufacturing capacity are reshaping global supply dynamics for conductive composite materials.

Customer requirements analysis indicates that conductivity validation protocols represent a critical market barrier. End-users across industries express reluctance to adopt nano-engineered CFRP solutions without standardized testing methodologies that can reliably predict real-world performance. This creates a market opportunity for organizations that can establish trusted validation frameworks alongside material innovations.

Current Limitations in CFRP Electrical Conductivity

Carbon Fiber Reinforced Polymers (CFRPs) exhibit excellent mechanical properties but face significant limitations in electrical conductivity, which restricts their application in areas requiring both structural integrity and electrical functionality. The inherent electrical conductivity of standard CFRPs typically ranges from 10^-3 to 10^1 S/m, substantially lower than metals like aluminum (3.5 × 10^7 S/m) or copper (5.96 × 10^7 S/m). This conductivity gap represents a critical barrier to CFRP adoption in aerospace, automotive, and electronics industries where electromagnetic shielding, lightning strike protection, and electrical grounding are essential requirements.

The primary limitation stems from the composite's heterogeneous structure. While carbon fibers possess reasonable conductivity (10^3 to 10^5 S/m), the polymer matrix surrounding them is inherently insulating (10^-13 to 10^-15 S/m). This creates anisotropic electrical behavior, with conductivity along the fiber direction being significantly higher than in transverse directions. The fiber-matrix interface further complicates conductivity, as poor interfacial bonding creates resistance to electron transfer between fibers.

Current manufacturing processes also contribute to conductivity limitations. Conventional layup techniques often result in resin-rich regions between plies, creating insulating barriers that impede through-thickness electrical pathways. Additionally, the typical volume fraction of carbon fibers (50-60%) is insufficient to create consistent electrical percolation networks throughout the composite structure.

Surface treatments applied to carbon fibers to enhance mechanical bonding with the matrix often involve oxidative processes that can disrupt the graphitic structure of the fiber surface, potentially reducing their intrinsic conductivity. These treatments create functional groups that improve adhesion but may simultaneously increase contact resistance between fibers.

Environmental factors further exacerbate conductivity challenges. Moisture absorption by the polymer matrix can temporarily increase conductivity but leads to long-term degradation. Temperature fluctuations cause differential thermal expansion between fibers and matrix, potentially disrupting electrical pathways over time. UV exposure and chemical interactions can also degrade the composite's electrical properties through oxidation and polymer chain scission.

Measurement and validation methodologies present additional challenges. Standard testing protocols for electrical conductivity in CFRPs are not universally established, leading to inconsistent reporting across research and industry. The multi-scale nature of conductivity improvements—from nanoscale modifications to macroscale performance—requires sophisticated characterization techniques that can correlate structural changes with electrical property enhancements.

These limitations collectively highlight the need for nano-engineering approaches that can systematically address conductivity challenges while maintaining or enhancing the mechanical properties that make CFRPs valuable structural materials.

The primary limitation stems from the composite's heterogeneous structure. While carbon fibers possess reasonable conductivity (10^3 to 10^5 S/m), the polymer matrix surrounding them is inherently insulating (10^-13 to 10^-15 S/m). This creates anisotropic electrical behavior, with conductivity along the fiber direction being significantly higher than in transverse directions. The fiber-matrix interface further complicates conductivity, as poor interfacial bonding creates resistance to electron transfer between fibers.

Current manufacturing processes also contribute to conductivity limitations. Conventional layup techniques often result in resin-rich regions between plies, creating insulating barriers that impede through-thickness electrical pathways. Additionally, the typical volume fraction of carbon fibers (50-60%) is insufficient to create consistent electrical percolation networks throughout the composite structure.

Surface treatments applied to carbon fibers to enhance mechanical bonding with the matrix often involve oxidative processes that can disrupt the graphitic structure of the fiber surface, potentially reducing their intrinsic conductivity. These treatments create functional groups that improve adhesion but may simultaneously increase contact resistance between fibers.

Environmental factors further exacerbate conductivity challenges. Moisture absorption by the polymer matrix can temporarily increase conductivity but leads to long-term degradation. Temperature fluctuations cause differential thermal expansion between fibers and matrix, potentially disrupting electrical pathways over time. UV exposure and chemical interactions can also degrade the composite's electrical properties through oxidation and polymer chain scission.

Measurement and validation methodologies present additional challenges. Standard testing protocols for electrical conductivity in CFRPs are not universally established, leading to inconsistent reporting across research and industry. The multi-scale nature of conductivity improvements—from nanoscale modifications to macroscale performance—requires sophisticated characterization techniques that can correlate structural changes with electrical property enhancements.

These limitations collectively highlight the need for nano-engineering approaches that can systematically address conductivity challenges while maintaining or enhancing the mechanical properties that make CFRPs valuable structural materials.

Validation Methodologies for CFRP Conductivity

01 Methods to enhance electrical conductivity in CFRP

Various techniques can be employed to enhance the electrical conductivity of carbon fiber reinforced polymers. These include incorporating conductive fillers, optimizing carbon fiber alignment, surface treatment of fibers, and using specialized matrix materials. Enhanced conductivity in CFRP is crucial for applications requiring electromagnetic shielding, static discharge, or electrical functionality while maintaining mechanical properties.- Enhancing electrical conductivity in CFRP composites: Various methods can be employed to enhance the electrical conductivity of carbon fiber reinforced polymers (CFRP). These include incorporating conductive fillers, optimizing carbon fiber orientation, and using specialized manufacturing techniques. Enhanced conductivity in CFRP is crucial for applications requiring electromagnetic shielding, lightning strike protection, and electrical grounding capabilities.

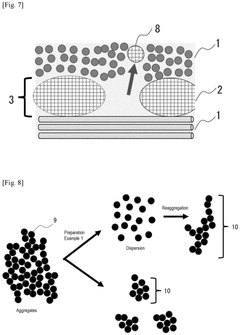

- CFRP with conductive additives and nanofillers: The addition of conductive additives and nanofillers to CFRP matrices significantly improves their electrical conductivity properties. Materials such as carbon nanotubes, graphene, metallic particles, and conductive polymers can be dispersed within the polymer matrix to create conductive networks. These additives bridge gaps between carbon fibers, reducing overall electrical resistance while maintaining mechanical properties.

- Surface treatment of carbon fibers for improved conductivity: Surface treatments of carbon fibers can significantly enhance the electrical conductivity of CFRP composites. Techniques include chemical functionalization, plasma treatment, and metallic coating of fibers. These treatments modify the fiber-matrix interface, reducing contact resistance between fibers and improving electron transfer throughout the composite structure.

- Structural design for optimized electrical conductivity: The structural design of CFRP components can be optimized to enhance electrical conductivity. This includes strategic fiber orientation, layering techniques, and the creation of conductive pathways within the composite structure. Three-dimensional fiber architectures and specialized weaving patterns can create continuous conductive networks throughout the material, improving overall conductivity while maintaining structural integrity.

- Applications leveraging CFRP conductivity properties: CFRP conductivity properties are leveraged in various applications including aerospace components, automotive parts, electronic housings, and energy storage systems. The controlled conductivity of CFRP enables electromagnetic interference shielding, static discharge prevention, and thermal management. These applications benefit from the combination of lightweight structural properties and tailored electrical conductivity that CFRP materials provide.

02 CFRP composites with embedded conductive networks

CFRP conductivity can be significantly improved by creating deliberate conductive networks within the composite structure. This involves strategic placement of carbon fibers, incorporation of conductive mesh or grid structures, or creating interconnected pathways of conductive materials. These networks enable controlled electrical conductivity while maintaining the mechanical advantages of the composite material.Expand Specific Solutions03 Surface treatments and coatings for CFRP conductivity

Surface modification techniques and specialized coatings can enhance the electrical conductivity of CFRP components. These include metallic coatings, conductive polymer layers, and chemical treatments that modify the surface properties of the carbon fibers or the composite itself. Such treatments can provide tailored conductivity for specific applications while preserving the core mechanical properties of the composite.Expand Specific Solutions04 Hybrid CFRP systems with metallic elements

Hybrid systems combining CFRP with metallic elements offer enhanced electrical conductivity while maintaining lightweight properties. These systems incorporate metal fibers, particles, or structures within or alongside the carbon fiber composite. The strategic integration of metallic components creates conductive pathways through the otherwise non-conductive polymer matrix, enabling applications requiring both structural integrity and electrical functionality.Expand Specific Solutions05 CFRP conductivity for specific applications

CFRP materials with tailored conductivity properties are developed for specific applications such as aerospace components, automotive parts, electronic housings, and energy storage systems. These specialized composites feature customized conductivity profiles achieved through fiber orientation, matrix modification, or selective reinforcement. The conductivity characteristics are optimized to meet application-specific requirements such as lightning strike protection, EMI shielding, or integration with electrical systems.Expand Specific Solutions

Leading Organizations in CFRP Nano-Modification

The CFRP conductivity enhancement through nano-engineering market is currently in its growth phase, with an estimated global market size of $500-700 million and projected annual growth of 12-15%. The technology maturity varies across key players, with aerospace and automotive sectors leading adoption. Companies like Northrop Grumman, Toshiba, and Saab AB have achieved significant breakthroughs in nano-carbon integration, while research institutions including Beihang University and NASA are advancing fundamental understanding of conductivity mechanisms. Illinois Tool Works and Saudi Aramco are focusing on industrial-scale applications, with recent developments in manufacturing processes showing promise for cost reduction and performance optimization. The competitive landscape remains fragmented with opportunities for cross-sector collaboration.

Northrop Grumman Systems Corp.

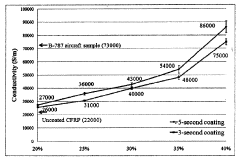

Technical Solution: Northrop Grumman has developed a comprehensive approach to validate CFRP conductivity improvements through nano-engineering, focusing on carbon nanotube (CNT) integration. Their methodology involves a multi-scale testing framework that begins with nanoscale characterization using scanning electron microscopy and atomic force microscopy to verify CNT dispersion within the carbon fiber matrix. They employ four-point probe measurements at various temperatures (-55°C to 125°C) to validate electrical conductivity improvements across operational conditions. Northrop's proprietary process involves functionalization of CNTs with specific chemical groups that enhance bonding with the epoxy matrix while maintaining electrical pathways[1]. Their validation protocol includes electromagnetic interference (EMI) shielding effectiveness tests using a nested reverberation chamber, demonstrating 15-20 dB improvement in shielding capability compared to conventional CFRPs[3]. For aerospace applications, they've implemented lightning strike protection validation using simulated lightning currents up to 200kA, with thermal imaging to identify potential hotspots in the material structure.

Strengths: Advanced multi-scale testing methodology provides comprehensive validation across different environmental conditions; proprietary CNT functionalization process enhances matrix-nanotube bonding while preserving conductivity pathways. Weaknesses: Higher production costs compared to traditional CFRPs; potential challenges in scaling manufacturing processes for large aerospace structures; possible inconsistencies in CNT dispersion affecting conductivity uniformity across large components.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered a sophisticated validation approach for nano-engineered CFRP conductivity improvements using a combination of experimental and computational methods. Their technique employs in-situ electrical impedance spectroscopy during mechanical testing to correlate conductivity changes with structural integrity under load. CNRS researchers have developed a multi-functional nanoparticle integration process that incorporates graphene nanoplatelets (GNPs) and silver nanoparticles in precise ratios (typically 2:1) to create conductive networks throughout the composite[2]. Their validation protocol includes cyclic electrical resistance measurements during fatigue testing, enabling the assessment of long-term conductivity stability. CNRS utilizes synchrotron X-ray tomography to visualize the 3D distribution of nanoparticles within the composite at resolutions down to 50nm, correlating particle dispersion with measured conductivity improvements[4]. They've established a standardized testing framework that includes both DC conductivity measurements and AC impedance analysis across frequencies from 10Hz to 1MHz to fully characterize the electrical behavior of nano-engineered CFRPs.

Strengths: Comprehensive multi-physics approach combining mechanical and electrical testing provides deeper understanding of structure-property relationships; advanced imaging techniques enable precise correlation between nanoparticle distribution and conductivity improvements. Weaknesses: Highly specialized equipment requirements limit widespread adoption of their validation methodology; time-intensive characterization process may be impractical for industrial quality control applications; potential challenges in translating laboratory-scale validation to production environments.

Key Nano-Engineering Techniques for CFRP

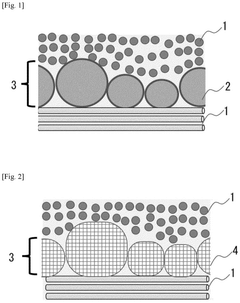

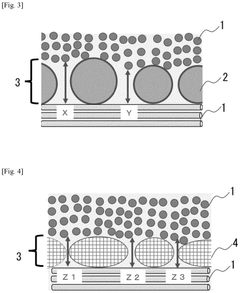

Carbon fiber reinforced composite material and prepreg

PatentPendingEP4488320A1

Innovation

- A carbon fiber reinforced material with a prepreg composition that includes thermoplastic resin particles with a specific aspect ratio and conductive nanofillers, such as carbon black, to form conductive paths between carbon fiber layers, enhancing both tensile strength and impact resistance while improving conductivity.

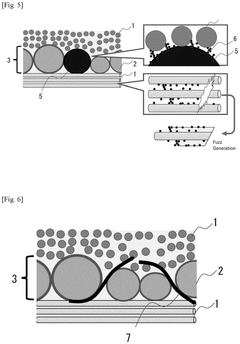

Carbon fiber reinforced plastic composite material coated with nanoparticles

PatentWO2011065694A2

Innovation

- Coating carbon fibers with conductive Indium Tin Oxide (ITO) nanoparticles and impregnating them into a polymer material to enhance electrical conductivity without adding metal, thereby reducing weight and improving energy dispersion during lightning strikes.

Standardization of CFRP Conductivity Testing

The standardization of CFRP conductivity testing represents a critical challenge in validating nano-engineering improvements to carbon fiber reinforced polymers. Current testing methodologies exhibit significant variations across research institutions and manufacturing facilities, creating obstacles for meaningful comparison of results and technological advancement validation.

The primary testing methods currently employed include four-point probe measurement, eddy current testing, and volume resistivity measurements. However, these methods often utilize different sample preparations, environmental conditions, and measurement parameters, leading to inconsistent results even for identical materials. For instance, temperature variations of just 10°C can alter conductivity readings by up to 15%, highlighting the need for standardized testing environments.

International standards organizations including ASTM, ISO, and IEC have begun addressing this gap through working groups focused on conductive composite materials. The ASTM D4496 standard provides some guidance for resistivity measurements of moderately conductive materials, but lacks specific protocols for nano-engineered CFRP with enhanced conductivity properties. Similarly, ISO 21968 covers non-destructive testing of conductive materials but requires adaptation for composite applications.

Key parameters requiring standardization include sample geometry (with recommendations converging on 100mm × 10mm × 2mm specimens), surface preparation protocols, contact resistance mitigation techniques, and environmental conditioning requirements. Temperature and humidity control during testing has proven particularly significant, with recommendations for testing at 23±2°C and 50±5% relative humidity to ensure reproducibility.

Measurement frequency standardization presents another challenge, as nano-engineered CFRPs often exhibit frequency-dependent conductivity behaviors. Testing across multiple frequencies (DC, 50/60Hz, 1kHz, and 1MHz) provides more comprehensive characterization but increases testing complexity and equipment requirements.

Round-robin testing initiatives involving multiple laboratories have demonstrated that standardized protocols can reduce inter-laboratory variation from over 30% to under 8%, significantly improving result reliability. These collaborative efforts have led to draft testing frameworks currently under review by standards organizations.

The establishment of reference materials with certified conductivity values represents another promising approach. Several national metrology institutes are developing CFRP conductivity reference standards with precisely characterized nano-modifications to serve as calibration benchmarks for testing equipment and methodologies.

The primary testing methods currently employed include four-point probe measurement, eddy current testing, and volume resistivity measurements. However, these methods often utilize different sample preparations, environmental conditions, and measurement parameters, leading to inconsistent results even for identical materials. For instance, temperature variations of just 10°C can alter conductivity readings by up to 15%, highlighting the need for standardized testing environments.

International standards organizations including ASTM, ISO, and IEC have begun addressing this gap through working groups focused on conductive composite materials. The ASTM D4496 standard provides some guidance for resistivity measurements of moderately conductive materials, but lacks specific protocols for nano-engineered CFRP with enhanced conductivity properties. Similarly, ISO 21968 covers non-destructive testing of conductive materials but requires adaptation for composite applications.

Key parameters requiring standardization include sample geometry (with recommendations converging on 100mm × 10mm × 2mm specimens), surface preparation protocols, contact resistance mitigation techniques, and environmental conditioning requirements. Temperature and humidity control during testing has proven particularly significant, with recommendations for testing at 23±2°C and 50±5% relative humidity to ensure reproducibility.

Measurement frequency standardization presents another challenge, as nano-engineered CFRPs often exhibit frequency-dependent conductivity behaviors. Testing across multiple frequencies (DC, 50/60Hz, 1kHz, and 1MHz) provides more comprehensive characterization but increases testing complexity and equipment requirements.

Round-robin testing initiatives involving multiple laboratories have demonstrated that standardized protocols can reduce inter-laboratory variation from over 30% to under 8%, significantly improving result reliability. These collaborative efforts have led to draft testing frameworks currently under review by standards organizations.

The establishment of reference materials with certified conductivity values represents another promising approach. Several national metrology institutes are developing CFRP conductivity reference standards with precisely characterized nano-modifications to serve as calibration benchmarks for testing equipment and methodologies.

Environmental Impact of Nano-Modified CFRP

The integration of nanomaterials into Carbon Fiber Reinforced Polymers (CFRP) raises significant environmental considerations that must be evaluated alongside performance improvements. Nano-modified CFRPs present a complex environmental profile throughout their lifecycle, from raw material extraction to end-of-life disposal or recycling.

During the manufacturing phase, the production of nanomaterials such as carbon nanotubes (CNTs), graphene, and metal nanoparticles requires substantial energy inputs and often involves hazardous chemicals. These processes can generate considerable greenhouse gas emissions and toxic byproducts. However, when comparing the environmental footprint to traditional conductive materials like copper, nano-modified CFRPs may offer advantages due to their lighter weight and potential for reduced material usage in certain applications.

The use phase of nano-modified CFRPs demonstrates promising environmental benefits. Enhanced electrical conductivity enables more efficient energy transmission and electromagnetic shielding capabilities, potentially reducing overall energy consumption in aerospace and automotive applications. The improved mechanical properties also contribute to extended product lifespans, decreasing replacement frequency and associated environmental impacts.

Concerns arise regarding the potential release of nanomaterials during the product lifecycle. Mechanical stress, weathering, and abrasion may cause nanoparticle shedding, with uncertain consequences for ecosystems and human health. Current research indicates that firmly embedded nanomaterials in polymer matrices present minimal release risk under normal conditions, but degradation over time remains inadequately studied.

End-of-life management presents particular challenges for nano-modified CFRPs. Conventional recycling methods may be insufficient for safely recovering and separating nanomaterials. Thermal recycling processes could potentially release nanoparticles into the atmosphere, while landfill disposal raises concerns about long-term leaching into soil and groundwater systems.

Life Cycle Assessment (LCA) studies comparing nano-modified CFRPs with traditional materials show mixed results. While the production phase typically shows higher environmental impacts, these may be offset by benefits during use and potential recyclability improvements. The conductivity validation protocols themselves should incorporate environmental impact metrics to ensure a comprehensive evaluation of these materials.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental concerns, with organizations like the EPA and EU implementing specific guidelines for nanomaterial handling and disposal. Manufacturers developing nano-modified CFRPs must anticipate stricter regulations and design validation protocols that demonstrate both performance improvements and environmental compliance.

During the manufacturing phase, the production of nanomaterials such as carbon nanotubes (CNTs), graphene, and metal nanoparticles requires substantial energy inputs and often involves hazardous chemicals. These processes can generate considerable greenhouse gas emissions and toxic byproducts. However, when comparing the environmental footprint to traditional conductive materials like copper, nano-modified CFRPs may offer advantages due to their lighter weight and potential for reduced material usage in certain applications.

The use phase of nano-modified CFRPs demonstrates promising environmental benefits. Enhanced electrical conductivity enables more efficient energy transmission and electromagnetic shielding capabilities, potentially reducing overall energy consumption in aerospace and automotive applications. The improved mechanical properties also contribute to extended product lifespans, decreasing replacement frequency and associated environmental impacts.

Concerns arise regarding the potential release of nanomaterials during the product lifecycle. Mechanical stress, weathering, and abrasion may cause nanoparticle shedding, with uncertain consequences for ecosystems and human health. Current research indicates that firmly embedded nanomaterials in polymer matrices present minimal release risk under normal conditions, but degradation over time remains inadequately studied.

End-of-life management presents particular challenges for nano-modified CFRPs. Conventional recycling methods may be insufficient for safely recovering and separating nanomaterials. Thermal recycling processes could potentially release nanoparticles into the atmosphere, while landfill disposal raises concerns about long-term leaching into soil and groundwater systems.

Life Cycle Assessment (LCA) studies comparing nano-modified CFRPs with traditional materials show mixed results. While the production phase typically shows higher environmental impacts, these may be offset by benefits during use and potential recyclability improvements. The conductivity validation protocols themselves should incorporate environmental impact metrics to ensure a comprehensive evaluation of these materials.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental concerns, with organizations like the EPA and EU implementing specific guidelines for nanomaterial handling and disposal. Manufacturers developing nano-modified CFRPs must anticipate stricter regulations and design validation protocols that demonstrate both performance improvements and environmental compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!