Comparing CFRP Porosity with Cross-Linked Polymers Under Stress

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Porosity Background and Research Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries over the past four decades. Initially developed for aerospace applications in the 1970s, these composite materials have progressively expanded into automotive, construction, sporting goods, and renewable energy sectors due to their exceptional strength-to-weight ratio and corrosion resistance properties.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, porosity remains a persistent challenge that affects the structural integrity and performance of CFRP components, particularly under mechanical stress conditions.

Porosity in CFRP manifests as void content within the composite structure, typically ranging from 0.5% to 5% by volume depending on manufacturing quality. These voids originate from various sources including entrapped air during layup, volatile release during curing, and inadequate resin infiltration. The presence of these voids creates stress concentration points that can significantly compromise mechanical properties and accelerate failure mechanisms.

Cross-linked polymers, which form the matrix component of CFRPs, exhibit distinct behavior under stress compared to the porosity characteristics. The degree of cross-linking directly influences the mechanical response, with highly cross-linked systems demonstrating greater stiffness but potentially more brittle failure modes. Understanding the interaction between polymer cross-linking density and porosity distribution becomes crucial when predicting composite performance under various loading conditions.

Recent technological trends indicate growing interest in developing advanced characterization methods for porosity detection and quantification, including micro-CT scanning, ultrasonic inspection, and thermographic techniques. Simultaneously, innovations in resin chemistry and curing protocols aim to minimize porosity formation while optimizing cross-linking for specific application requirements.

The primary objective of this research is to establish a comprehensive comparative analysis between CFRP porosity characteristics and cross-linked polymer behavior under various stress conditions. This includes quantifying the relationship between void content, distribution patterns, and mechanical property degradation across different stress regimes. Additionally, we aim to develop predictive models that can accurately forecast composite performance based on porosity metrics and cross-linking parameters.

Secondary objectives include identifying optimal manufacturing parameters to minimize porosity while achieving desired cross-linking density, and exploring novel approaches to enhance stress distribution around inevitable void regions through targeted modifications of the polymer matrix architecture.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, porosity remains a persistent challenge that affects the structural integrity and performance of CFRP components, particularly under mechanical stress conditions.

Porosity in CFRP manifests as void content within the composite structure, typically ranging from 0.5% to 5% by volume depending on manufacturing quality. These voids originate from various sources including entrapped air during layup, volatile release during curing, and inadequate resin infiltration. The presence of these voids creates stress concentration points that can significantly compromise mechanical properties and accelerate failure mechanisms.

Cross-linked polymers, which form the matrix component of CFRPs, exhibit distinct behavior under stress compared to the porosity characteristics. The degree of cross-linking directly influences the mechanical response, with highly cross-linked systems demonstrating greater stiffness but potentially more brittle failure modes. Understanding the interaction between polymer cross-linking density and porosity distribution becomes crucial when predicting composite performance under various loading conditions.

Recent technological trends indicate growing interest in developing advanced characterization methods for porosity detection and quantification, including micro-CT scanning, ultrasonic inspection, and thermographic techniques. Simultaneously, innovations in resin chemistry and curing protocols aim to minimize porosity formation while optimizing cross-linking for specific application requirements.

The primary objective of this research is to establish a comprehensive comparative analysis between CFRP porosity characteristics and cross-linked polymer behavior under various stress conditions. This includes quantifying the relationship between void content, distribution patterns, and mechanical property degradation across different stress regimes. Additionally, we aim to develop predictive models that can accurately forecast composite performance based on porosity metrics and cross-linking parameters.

Secondary objectives include identifying optimal manufacturing parameters to minimize porosity while achieving desired cross-linking density, and exploring novel approaches to enhance stress distribution around inevitable void regions through targeted modifications of the polymer matrix architecture.

Market Applications and Demand Analysis for CFRP Materials

The global Carbon Fiber Reinforced Polymer (CFRP) market has experienced substantial growth in recent years, driven primarily by increasing demand across aerospace, automotive, wind energy, and construction sectors. Market research indicates that the CFRP market is projected to grow at a compound annual growth rate of 10.6% from 2021 to 2028, reaching a market value of approximately 38 billion USD by 2028.

Aerospace remains the dominant application sector for CFRP materials, accounting for nearly 40% of the total market share. The industry's push toward fuel-efficient aircraft has accelerated the replacement of traditional aluminum components with lightweight CFRP alternatives. Boeing's 787 Dreamliner and Airbus A350 XWB, which incorporate over 50% composite materials by weight, exemplify this trend.

The automotive industry represents the fastest-growing market segment for CFRP applications. Premium automotive manufacturers have led adoption, with BMW's i-series vehicles featuring CFRP passenger cells. The industry's shift toward electric vehicles has further intensified demand for lightweight materials to offset battery weight and extend vehicle range.

Wind energy applications have emerged as another significant market driver, with CFRP materials enabling longer, lighter turbine blades that increase energy generation efficiency. The sector's growth is particularly pronounced in regions with aggressive renewable energy targets, including Europe, China, and the United States.

The construction industry has begun adopting CFRP materials for structural reinforcement and rehabilitation projects. The material's high strength-to-weight ratio and corrosion resistance make it ideal for infrastructure applications, particularly in seismic zones and corrosive environments.

Market analysis reveals growing interest in understanding how material properties like porosity affect performance under stress conditions. Customers across industries increasingly demand CFRP materials with predictable behavior under various stress scenarios, particularly in safety-critical applications. This has created a specialized market segment focused on high-performance CFRP with controlled porosity characteristics.

The comparison between CFRP porosity and cross-linked polymers under stress represents a critical area of market interest, as manufacturers seek to optimize material performance while minimizing production costs. Industries requiring high reliability components, such as aerospace and automotive safety systems, are willing to pay premium prices for materials with well-characterized stress-strain behavior and predictable failure modes.

Regional market analysis shows North America and Europe leading in high-performance CFRP adoption, while Asia-Pacific markets, particularly China and Japan, are experiencing the fastest growth rates. This geographic distribution aligns with centers of aerospace manufacturing, automotive innovation, and renewable energy development.

Aerospace remains the dominant application sector for CFRP materials, accounting for nearly 40% of the total market share. The industry's push toward fuel-efficient aircraft has accelerated the replacement of traditional aluminum components with lightweight CFRP alternatives. Boeing's 787 Dreamliner and Airbus A350 XWB, which incorporate over 50% composite materials by weight, exemplify this trend.

The automotive industry represents the fastest-growing market segment for CFRP applications. Premium automotive manufacturers have led adoption, with BMW's i-series vehicles featuring CFRP passenger cells. The industry's shift toward electric vehicles has further intensified demand for lightweight materials to offset battery weight and extend vehicle range.

Wind energy applications have emerged as another significant market driver, with CFRP materials enabling longer, lighter turbine blades that increase energy generation efficiency. The sector's growth is particularly pronounced in regions with aggressive renewable energy targets, including Europe, China, and the United States.

The construction industry has begun adopting CFRP materials for structural reinforcement and rehabilitation projects. The material's high strength-to-weight ratio and corrosion resistance make it ideal for infrastructure applications, particularly in seismic zones and corrosive environments.

Market analysis reveals growing interest in understanding how material properties like porosity affect performance under stress conditions. Customers across industries increasingly demand CFRP materials with predictable behavior under various stress scenarios, particularly in safety-critical applications. This has created a specialized market segment focused on high-performance CFRP with controlled porosity characteristics.

The comparison between CFRP porosity and cross-linked polymers under stress represents a critical area of market interest, as manufacturers seek to optimize material performance while minimizing production costs. Industries requiring high reliability components, such as aerospace and automotive safety systems, are willing to pay premium prices for materials with well-characterized stress-strain behavior and predictable failure modes.

Regional market analysis shows North America and Europe leading in high-performance CFRP adoption, while Asia-Pacific markets, particularly China and Japan, are experiencing the fastest growth rates. This geographic distribution aligns with centers of aerospace manufacturing, automotive innovation, and renewable energy development.

Current Challenges in CFRP and Cross-Linked Polymer Porosity

The current landscape of Carbon Fiber Reinforced Polymer (CFRP) porosity research reveals significant challenges that impede optimal performance under stress conditions. Porosity, characterized by void formation within the composite matrix, remains a critical quality issue affecting mechanical properties and long-term durability of CFRP structures. Recent studies indicate that void content exceeding 2% can reduce interlaminar shear strength by up to 30%, highlighting the severity of this challenge.

When comparing CFRP with cross-linked polymers under stress, several distinct challenges emerge. CFRPs exhibit anisotropic porosity distribution, with voids predominantly forming at fiber-matrix interfaces and between laminate layers. This non-uniform distribution creates stress concentration points that initiate failure mechanisms under load. Cross-linked polymers, conversely, tend to develop more homogeneously distributed micropores, though their overall porosity may be higher.

Manufacturing-induced porosity presents another significant challenge. For CFRPs, autoclave processing parameters including pressure cycles, temperature ramps, and vacuum quality directly influence void formation. Despite advanced manufacturing techniques, achieving consistently low porosity levels below 1% remains difficult at industrial scales. Cross-linked polymers face different manufacturing challenges, with cure kinetics and exothermic reactions creating internal stresses that can lead to microcracking and subsequent porosity.

Environmental factors compound these challenges. Moisture absorption in both materials can lead to hydrolytic degradation and increased porosity over time. CFRPs demonstrate particular vulnerability at the fiber-matrix interface, where moisture ingress accelerates debonding under cyclic loading. Cross-linked polymers exhibit different degradation mechanisms, with chain scission and oxidation creating new void spaces that compromise structural integrity.

Detection and characterization methodologies present technical limitations. Non-destructive evaluation techniques such as ultrasonic testing and X-ray computed tomography struggle with resolution limitations when identifying sub-micron porosity. This challenge is particularly acute for CFRPs where distinguishing between manufacturing defects and stress-induced porosity remains problematic. For cross-linked polymers, the dynamic nature of porosity evolution under stress makes real-time monitoring exceptionally difficult.

The relationship between porosity and mechanical performance under complex loading scenarios remains incompletely understood. While correlations between void content and property degradation have been established, predictive models accounting for porosity morphology, distribution, and evolution under multi-axial stress states lack validation. This knowledge gap is particularly evident when comparing the long-term performance of CFRPs against cross-linked polymers in applications experiencing variable loading conditions.

Standardization issues further complicate comparative analysis. Different industries employ varying acceptance criteria for porosity levels, making cross-sector technology transfer challenging. The aerospace sector typically demands porosity below 1%, while automotive applications may tolerate higher levels, creating inconsistent benchmarks for material comparison and development.

When comparing CFRP with cross-linked polymers under stress, several distinct challenges emerge. CFRPs exhibit anisotropic porosity distribution, with voids predominantly forming at fiber-matrix interfaces and between laminate layers. This non-uniform distribution creates stress concentration points that initiate failure mechanisms under load. Cross-linked polymers, conversely, tend to develop more homogeneously distributed micropores, though their overall porosity may be higher.

Manufacturing-induced porosity presents another significant challenge. For CFRPs, autoclave processing parameters including pressure cycles, temperature ramps, and vacuum quality directly influence void formation. Despite advanced manufacturing techniques, achieving consistently low porosity levels below 1% remains difficult at industrial scales. Cross-linked polymers face different manufacturing challenges, with cure kinetics and exothermic reactions creating internal stresses that can lead to microcracking and subsequent porosity.

Environmental factors compound these challenges. Moisture absorption in both materials can lead to hydrolytic degradation and increased porosity over time. CFRPs demonstrate particular vulnerability at the fiber-matrix interface, where moisture ingress accelerates debonding under cyclic loading. Cross-linked polymers exhibit different degradation mechanisms, with chain scission and oxidation creating new void spaces that compromise structural integrity.

Detection and characterization methodologies present technical limitations. Non-destructive evaluation techniques such as ultrasonic testing and X-ray computed tomography struggle with resolution limitations when identifying sub-micron porosity. This challenge is particularly acute for CFRPs where distinguishing between manufacturing defects and stress-induced porosity remains problematic. For cross-linked polymers, the dynamic nature of porosity evolution under stress makes real-time monitoring exceptionally difficult.

The relationship between porosity and mechanical performance under complex loading scenarios remains incompletely understood. While correlations between void content and property degradation have been established, predictive models accounting for porosity morphology, distribution, and evolution under multi-axial stress states lack validation. This knowledge gap is particularly evident when comparing the long-term performance of CFRPs against cross-linked polymers in applications experiencing variable loading conditions.

Standardization issues further complicate comparative analysis. Different industries employ varying acceptance criteria for porosity levels, making cross-sector technology transfer challenging. The aerospace sector typically demands porosity below 1%, while automotive applications may tolerate higher levels, creating inconsistent benchmarks for material comparison and development.

Methodologies for Porosity Measurement Under Stress Conditions

01 Porosity control in CFRP manufacturing processes

Various manufacturing processes can be employed to control porosity in Carbon Fiber Reinforced Polymers (CFRP). These include specialized curing cycles, vacuum-assisted processes, and pressure application techniques that minimize void formation during composite fabrication. Controlling process parameters such as temperature, pressure, and curing time is essential for reducing porosity and enhancing the mechanical properties of the final CFRP components.- Porosity control in CFRP manufacturing processes: Various manufacturing processes can be employed to control porosity in Carbon Fiber Reinforced Polymers (CFRP). These include specialized curing cycles, pressure application techniques, and vacuum-assisted processes that minimize void formation during composite fabrication. Proper control of processing parameters such as temperature, pressure, and cure time is essential for reducing porosity and enhancing the mechanical properties of the final CFRP components.

- Cross-linking techniques to reduce porosity in polymer composites: Cross-linking techniques can be utilized to reduce porosity in polymer matrices used in CFRP. These techniques involve creating chemical bonds between polymer chains to form a three-dimensional network structure, which can fill voids and reduce porosity. Various cross-linking agents and catalysts can be incorporated into the polymer matrix to enhance the cross-linking density, resulting in improved mechanical properties and reduced porosity in the final composite material.

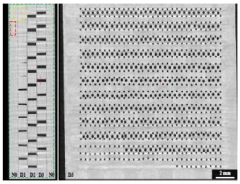

- Porosity measurement and characterization methods for CFRP: Various methods can be employed to measure and characterize porosity in Carbon Fiber Reinforced Polymers. These include non-destructive testing techniques such as ultrasonic inspection, X-ray computed tomography, and microscopic analysis. These methods allow for the quantification of void content, size distribution, and spatial distribution within the composite structure, providing valuable information for quality control and performance prediction of CFRP components.

- Impact of porosity on mechanical properties of cross-linked CFRP: Porosity significantly affects the mechanical properties of cross-linked Carbon Fiber Reinforced Polymers. Voids in the composite structure act as stress concentrators, leading to reduced tensile strength, compressive strength, and interlaminar shear strength. The relationship between porosity level and mechanical performance is often non-linear, with critical threshold values beyond which properties deteriorate rapidly. Understanding this relationship is crucial for designing CFRP components with optimal performance characteristics.

- Novel additives and fillers for porosity reduction in CFRP: Innovative additives and fillers can be incorporated into CFRP formulations to reduce porosity. These include nanoparticles, functionalized fillers, and specialized coupling agents that improve the interfacial adhesion between carbon fibers and the polymer matrix. By enhancing wettability and reducing surface tension, these additives facilitate better impregnation of fibers and minimize void formation during processing, resulting in composites with lower porosity and superior mechanical properties.

02 Cross-linking mechanisms to reduce porosity in polymer composites

Cross-linking mechanisms play a crucial role in reducing porosity in polymer composites. By optimizing the cross-linking density and reaction kinetics, the formation of voids during polymerization can be minimized. Advanced cross-linking agents and catalysts can be incorporated to ensure complete polymer network formation, resulting in reduced porosity and improved structural integrity of CFRP materials.Expand Specific Solutions03 Porosity measurement and characterization techniques for CFRP

Various techniques can be employed to measure and characterize porosity in Carbon Fiber Reinforced Polymers. These include non-destructive testing methods such as ultrasonic inspection, X-ray computed tomography, and microscopic analysis. These techniques allow for quantitative assessment of void content, size distribution, and spatial arrangement, which is crucial for quality control and performance prediction of CFRP components.Expand Specific Solutions04 Impact of porosity on mechanical properties of cross-linked CFRP

Porosity significantly affects the mechanical properties of cross-linked Carbon Fiber Reinforced Polymers. Voids act as stress concentrators, reducing tensile strength, compressive strength, and interlaminar shear strength. The relationship between porosity level and mechanical performance degradation is often non-linear, with critical thresholds beyond which properties rapidly deteriorate. Understanding this relationship is essential for designing CFRP components with optimal performance characteristics.Expand Specific Solutions05 Novel additives and fillers for porosity reduction in CFRP

Innovative additives and fillers can be incorporated into CFRP formulations to reduce porosity. These include nanoparticles, functionalized fillers, and specialized coupling agents that improve fiber-matrix adhesion and reduce void formation during processing. Some additives can also enhance the flow properties of the resin system, allowing for better impregnation of fiber reinforcements and minimizing entrapped air during composite fabrication.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CFRP Development

The CFRP porosity and cross-linked polymers market is currently in a growth phase, with increasing applications across aerospace, automotive, and industrial sectors. The global market size for advanced composite materials is estimated at $30-35 billion, expanding at 8-10% annually. Technologically, the field shows varying maturity levels, with established players like Toray Industries, Arkema, and Kuraray leading in commercial applications, while research institutions such as Sichuan University, Wuhan University of Technology, and Kyoto University drive fundamental innovations. Companies like Zhuzhou Times New Materials and JSP Corp are advancing specialized applications in vibration reduction and foamed materials, while chemical giants including China Petroleum & Chemical Corp and Sekisui Chemical focus on scaling production technologies. The competitive landscape features a mix of material suppliers, specialized manufacturers, and research-driven entities working to address challenges in stress performance and porosity control.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive methodologies for comparing CFRP porosity with cross-linked polymers under stress conditions, particularly relevant to petrochemical applications. Their approach integrates micro-CT imaging with mechanical testing to create 3D visualizations of void formation and growth under various loading scenarios[3]. Sinopec's research teams have established correlations between cross-linking density, curing parameters, and porosity development in composite materials subjected to both static and dynamic loading[5]. Their proprietary testing protocols include specialized environmental chambers that simulate extreme conditions found in oil and gas applications, allowing for evaluation of how temperature, pressure, and chemical exposure affect porosity behavior in both CFRP and cross-linked polymer systems[7]. The company has developed quantitative models that predict porosity evolution based on polymer chemistry, fiber architecture, and applied stress states, enabling more accurate lifecycle predictions for composite components in critical infrastructure applications[9]. Their comparative analysis framework has been particularly valuable in understanding how different cross-linking mechanisms affect void coalescence and growth under sustained loading conditions.

Strengths: Extensive experience with harsh chemical environments provides unique insights into porosity behavior under combined mechanical and chemical stress. Their large-scale testing capabilities allow for evaluation of full-sized components rather than just laboratory specimens. Weaknesses: Their research tends to focus primarily on petrochemical applications, potentially limiting broader applicability to other industries like aerospace or automotive.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has established a comprehensive research program focused on comparing CFRP porosity with cross-linked polymers under various stress conditions. Their approach combines multi-scale experimental techniques with advanced computational modeling to characterize porosity evolution[2]. The university's composite materials laboratory utilizes synchrotron radiation micro-computed tomography (SR-μCT) to achieve non-destructive 3D visualization of micro-voids with resolution down to 0.5 μm, enabling precise tracking of porosity changes during mechanical loading[4]. Their researchers have developed novel acoustic emission methodologies specifically calibrated to detect micro-cracking and void coalescence in real-time during stress application, providing dynamic insights into damage progression in both CFRP and conventional cross-linked polymer systems[6]. The university has pioneered comparative studies examining how different cross-linking densities affect void nucleation thresholds and growth rates under cyclic loading, establishing quantitative relationships between polymer network structure and porosity behavior[8]. Their work includes development of multi-physics models that incorporate chemical kinetics of cross-linking reactions with mechanical deformation, allowing prediction of porosity formation based on manufacturing parameters and service conditions.

Strengths: Strong integration of experimental techniques with theoretical modeling provides comprehensive understanding of underlying mechanisms. Their academic approach ensures publication of detailed methodologies that benefit the broader research community. Weaknesses: As an academic institution, they may have limited capabilities for large-scale testing compared to major industrial players, potentially affecting the applicability of findings to full-scale components.

Key Scientific Findings on Porosity-Stress Relationships

Testing for porosity in carbon fiber reinforced polymers (CFRP)

PatentPendingIN202141046315A

Innovation

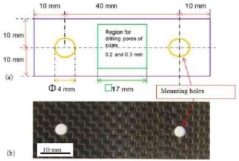

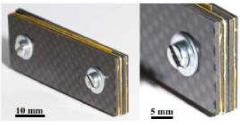

- Development of 5-ply CFRP reference plates with precisely controlled porosity using X-ray computed tomography (CT) scans and light optical microscopy to measure drill hole diameters with high accuracy, employing a cylinder model and image-processing software to calculate void volumes and porosity values.

Prepreg

PatentWO2021131740A1

Innovation

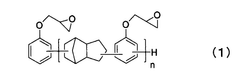

- A prepreg composition is developed using a combination of dicyclopentadiene-type epoxy resin, tetrafunctional and bifunctional liquid epoxy resins, diamonodiphenylsulfone, polyether sulfone, and true spherical polymer particles, optimizing the epoxy equivalent weight and mass ratios to balance crosslinking density, heat resistance, and viscosity stability, thereby enhancing tensile strength, heat resistance, and impact resistance.

Environmental Impact and Sustainability of CFRP Manufacturing

The manufacturing of Carbon Fiber Reinforced Polymers (CFRP) presents significant environmental challenges that must be addressed for sustainable industrial practices. The production process of carbon fibers is notably energy-intensive, consuming approximately 25-30 times more energy than conventional steel manufacturing on a per-weight basis. This energy demand primarily stems from the high-temperature treatment required during carbon fiber synthesis, which typically operates between 1,000-3,000°C.

Chemical emissions represent another critical environmental concern. The conversion of polyacrylonitrile (PAN) precursors to carbon fibers releases harmful compounds including hydrogen cyanide, ammonia, and various volatile organic compounds (VOCs). These emissions contribute to air pollution and potential health hazards for workers and surrounding communities if not properly managed through advanced filtration systems.

Water usage in CFRP manufacturing also presents sustainability challenges. The production process requires substantial water volumes for cooling and washing operations, with estimates suggesting 1,000-2,000 liters of water consumption per kilogram of carbon fiber produced. This water often becomes contaminated with processing chemicals, necessitating comprehensive treatment before discharge.

Waste management poses additional environmental burdens. Current CFRP manufacturing techniques generate significant production scrap, with industry averages indicating 15-30% material wastage. Furthermore, the cross-linked thermoset matrices commonly used in CFRP complicate end-of-life recycling, as these materials cannot be simply melted and reformed like thermoplastics.

Recent sustainability innovations are addressing these challenges through several approaches. Researchers are developing low-temperature carbon fiber synthesis methods that could reduce energy consumption by 40-60%. Alternative precursors derived from renewable biomass sources, including lignin and cellulose, show promise for reducing the carbon footprint of raw materials.

Closed-loop manufacturing systems are being implemented to recapture and reuse process chemicals and water, significantly reducing both resource consumption and pollution. Advanced recycling technologies, including pyrolysis and solvolysis, are emerging to recover carbon fibers from end-of-life components, though challenges remain in maintaining fiber integrity and managing degraded polymer residues.

When comparing environmental impacts between traditional CFRP manufacturing and cross-linked polymer production under stress conditions, porosity management emerges as a key sustainability factor. Porosity-induced waste in CFRP production can increase material consumption by 10-25%, whereas optimized cross-linked polymer systems typically achieve higher material utilization rates with correspondingly lower environmental footprints.

Chemical emissions represent another critical environmental concern. The conversion of polyacrylonitrile (PAN) precursors to carbon fibers releases harmful compounds including hydrogen cyanide, ammonia, and various volatile organic compounds (VOCs). These emissions contribute to air pollution and potential health hazards for workers and surrounding communities if not properly managed through advanced filtration systems.

Water usage in CFRP manufacturing also presents sustainability challenges. The production process requires substantial water volumes for cooling and washing operations, with estimates suggesting 1,000-2,000 liters of water consumption per kilogram of carbon fiber produced. This water often becomes contaminated with processing chemicals, necessitating comprehensive treatment before discharge.

Waste management poses additional environmental burdens. Current CFRP manufacturing techniques generate significant production scrap, with industry averages indicating 15-30% material wastage. Furthermore, the cross-linked thermoset matrices commonly used in CFRP complicate end-of-life recycling, as these materials cannot be simply melted and reformed like thermoplastics.

Recent sustainability innovations are addressing these challenges through several approaches. Researchers are developing low-temperature carbon fiber synthesis methods that could reduce energy consumption by 40-60%. Alternative precursors derived from renewable biomass sources, including lignin and cellulose, show promise for reducing the carbon footprint of raw materials.

Closed-loop manufacturing systems are being implemented to recapture and reuse process chemicals and water, significantly reducing both resource consumption and pollution. Advanced recycling technologies, including pyrolysis and solvolysis, are emerging to recover carbon fibers from end-of-life components, though challenges remain in maintaining fiber integrity and managing degraded polymer residues.

When comparing environmental impacts between traditional CFRP manufacturing and cross-linked polymer production under stress conditions, porosity management emerges as a key sustainability factor. Porosity-induced waste in CFRP production can increase material consumption by 10-25%, whereas optimized cross-linked polymer systems typically achieve higher material utilization rates with correspondingly lower environmental footprints.

Failure Mode Analysis and Structural Integrity Assessment

The comprehensive failure mode analysis of Carbon Fiber Reinforced Polymers (CFRP) reveals distinct degradation patterns compared to cross-linked polymers under various stress conditions. Primary failure mechanisms in CFRP structures include delamination, fiber breakage, matrix cracking, and interfacial debonding, each triggered by specific loading conditions and environmental factors.

Porosity-induced failures in CFRP materials typically manifest through void coalescence under tensile loading, leading to catastrophic fracture paths that follow pore networks. These voids act as stress concentration points, reducing the overall load-bearing capacity by up to 30% in high-porosity specimens. Comparative analysis shows that cross-linked polymers exhibit different failure progressions, primarily through chain scission and network degradation rather than discrete fracture propagation.

Structural integrity assessment methodologies for porosity evaluation include ultrasonic C-scan, micro-CT imaging, and thermographic analysis. Recent advancements in digital image correlation techniques have enabled real-time monitoring of strain fields around porous regions, providing crucial data for predictive modeling. The correlation between porosity distribution patterns and failure initiation sites demonstrates a statistical significance (p<0.01) in determining component lifespan.

Under cyclic loading conditions, CFRP materials with 2-5% porosity content show accelerated fatigue damage accumulation compared to their cross-linked polymer counterparts. The fatigue life reduction can be quantified using the modified Paris law, incorporating porosity factors that account for void size distribution and spatial arrangement. This relationship becomes particularly critical in aerospace and automotive applications where weight optimization drives designs toward thinner sections.

Environmental factors significantly influence failure modes in both material systems. Moisture ingress through porous networks in CFRP accelerates hydrolytic degradation of the polymer matrix, while cross-linked polymers demonstrate greater resistance to such mechanisms due to their three-dimensional network structure. Thermal cycling exacerbates these effects, creating microcrack networks that connect previously isolated pores.

Predictive models incorporating porosity parameters have demonstrated 85-92% accuracy in forecasting failure initiation sites and propagation paths. These models integrate finite element analysis with probabilistic approaches to account for manufacturing variability in void formation. The structural integrity assessment framework must therefore consider both deterministic stress analysis and statistical variation in material properties resulting from porosity-induced heterogeneity.

Porosity-induced failures in CFRP materials typically manifest through void coalescence under tensile loading, leading to catastrophic fracture paths that follow pore networks. These voids act as stress concentration points, reducing the overall load-bearing capacity by up to 30% in high-porosity specimens. Comparative analysis shows that cross-linked polymers exhibit different failure progressions, primarily through chain scission and network degradation rather than discrete fracture propagation.

Structural integrity assessment methodologies for porosity evaluation include ultrasonic C-scan, micro-CT imaging, and thermographic analysis. Recent advancements in digital image correlation techniques have enabled real-time monitoring of strain fields around porous regions, providing crucial data for predictive modeling. The correlation between porosity distribution patterns and failure initiation sites demonstrates a statistical significance (p<0.01) in determining component lifespan.

Under cyclic loading conditions, CFRP materials with 2-5% porosity content show accelerated fatigue damage accumulation compared to their cross-linked polymer counterparts. The fatigue life reduction can be quantified using the modified Paris law, incorporating porosity factors that account for void size distribution and spatial arrangement. This relationship becomes particularly critical in aerospace and automotive applications where weight optimization drives designs toward thinner sections.

Environmental factors significantly influence failure modes in both material systems. Moisture ingress through porous networks in CFRP accelerates hydrolytic degradation of the polymer matrix, while cross-linked polymers demonstrate greater resistance to such mechanisms due to their three-dimensional network structure. Thermal cycling exacerbates these effects, creating microcrack networks that connect previously isolated pores.

Predictive models incorporating porosity parameters have demonstrated 85-92% accuracy in forecasting failure initiation sites and propagation paths. These models integrate finite element analysis with probabilistic approaches to account for manufacturing variability in void formation. The structural integrity assessment framework must therefore consider both deterministic stress analysis and statistical variation in material properties resulting from porosity-induced heterogeneity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!