Comparing CFRP with Advanced Polymer Matrix Composites in Cycling

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP and Polymer Composites Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in the cycling industry since their introduction in the 1980s. Initially limited to high-end racing bicycles, these composites have progressively transformed the entire cycling market by offering unprecedented combinations of strength, stiffness, and lightweight properties. The evolution of CFRP technology has been marked by significant improvements in manufacturing processes, from early hand lay-up techniques to advanced automated systems, enabling more consistent quality and reduced production costs.

The cycling industry has witnessed a parallel development of various polymer matrix composites beyond traditional carbon fiber systems. These include hybrid composites incorporating materials such as aramid, glass fibers, and more recently, natural fibers. Each iteration has aimed to address specific performance characteristics while managing the inherent trade-offs between mechanical properties, weight, durability, and cost.

Current technological trends indicate a shift toward more specialized composite formulations tailored to specific cycling applications. The industry is moving beyond the "carbon is better" paradigm to a more nuanced understanding of how different composite architectures can be optimized for particular components and riding conditions. This includes developments in nano-reinforced matrices, thermoplastic composites with improved impact resistance, and multi-functional composites with integrated sensing capabilities.

The global push for sustainability has also influenced the trajectory of composite development in cycling. Research efforts are increasingly focused on recyclable thermoset systems, bio-based resins, and end-of-life considerations for composite components. This represents a significant departure from earlier generations of composites that prioritized performance with minimal consideration for environmental impact.

The primary technical objectives in this field include developing composite systems that offer improved impact resistance without weight penalties, enhancing fatigue performance for longer component lifespans, and creating more environmentally sustainable solutions. Additionally, there is growing interest in composites that can be more easily repaired or recycled, addressing a longstanding limitation of traditional CFRP systems.

Manufacturing scalability remains another critical objective, as the industry seeks to bring advanced composite technologies to mid-market products while maintaining quality and performance standards. This includes innovations in out-of-autoclave processing, rapid curing systems, and automated manufacturing techniques that can reduce production costs while maintaining or improving material properties.

The convergence of computational design tools with advanced manufacturing capabilities is enabling more precise optimization of composite structures for cycling applications, allowing engineers to tailor fiber orientations and resin systems to specific load cases and performance requirements with unprecedented precision.

The cycling industry has witnessed a parallel development of various polymer matrix composites beyond traditional carbon fiber systems. These include hybrid composites incorporating materials such as aramid, glass fibers, and more recently, natural fibers. Each iteration has aimed to address specific performance characteristics while managing the inherent trade-offs between mechanical properties, weight, durability, and cost.

Current technological trends indicate a shift toward more specialized composite formulations tailored to specific cycling applications. The industry is moving beyond the "carbon is better" paradigm to a more nuanced understanding of how different composite architectures can be optimized for particular components and riding conditions. This includes developments in nano-reinforced matrices, thermoplastic composites with improved impact resistance, and multi-functional composites with integrated sensing capabilities.

The global push for sustainability has also influenced the trajectory of composite development in cycling. Research efforts are increasingly focused on recyclable thermoset systems, bio-based resins, and end-of-life considerations for composite components. This represents a significant departure from earlier generations of composites that prioritized performance with minimal consideration for environmental impact.

The primary technical objectives in this field include developing composite systems that offer improved impact resistance without weight penalties, enhancing fatigue performance for longer component lifespans, and creating more environmentally sustainable solutions. Additionally, there is growing interest in composites that can be more easily repaired or recycled, addressing a longstanding limitation of traditional CFRP systems.

Manufacturing scalability remains another critical objective, as the industry seeks to bring advanced composite technologies to mid-market products while maintaining quality and performance standards. This includes innovations in out-of-autoclave processing, rapid curing systems, and automated manufacturing techniques that can reduce production costs while maintaining or improving material properties.

The convergence of computational design tools with advanced manufacturing capabilities is enabling more precise optimization of composite structures for cycling applications, allowing engineers to tailor fiber orientations and resin systems to specific load cases and performance requirements with unprecedented precision.

Cycling Industry Market Demand Analysis

The global cycling market has experienced significant growth in recent years, with a market value reaching $59.33 billion in 2021 and projected to grow at a CAGR of 7.7% through 2030. This expansion is driven by increasing health consciousness, environmental concerns, and the adoption of cycling as both a recreational activity and sustainable transportation mode. Within this growing market, there is a notable shift towards high-performance bicycles, particularly in premium segments where advanced materials play a crucial role.

Consumer demand for lightweight, durable, and high-performance bicycles has created a substantial market opportunity for advanced composite materials. Professional cyclists and enthusiastic amateurs are increasingly willing to invest in premium bicycles that offer improved performance characteristics. This segment shows price elasticity for technological advantages, with consumers readily accepting higher price points for measurable performance benefits.

Carbon Fiber Reinforced Polymers (CFRP) currently dominate the high-end bicycle component market, particularly in frames, wheels, handlebars, and seat posts. The global CFRP market in cycling applications was valued at approximately $2.1 billion in 2022, with a projected growth rate exceeding the overall bicycle market. This premium material segment represents a high-margin opportunity for manufacturers who can effectively leverage advanced composites.

Regional analysis reveals varying adoption patterns, with North America and Europe leading in premium composite bicycle adoption. The Asia-Pacific region, particularly China, Japan, and South Korea, shows the fastest growth rate in this segment, driven by increasing disposable income and growing cycling culture. Emerging markets demonstrate increasing interest in mid-tier composite solutions that balance performance and affordability.

Consumer research indicates evolving preferences beyond pure performance metrics. While weight reduction remains paramount (with 78% of premium bicycle buyers citing it as a primary consideration), durability (65%), vibration dampening (52%), and sustainability credentials (47%) are increasingly important factors. This multi-dimensional demand creates opportunities for Advanced Polymer Matrix Composites that can address these varied requirements.

Market segmentation analysis reveals distinct consumer groups: professional athletes focused primarily on performance metrics, enthusiastic amateurs balancing performance with durability, and environmentally conscious consumers seeking sustainable materials. Each segment presents unique opportunities for different composite formulations and marketing approaches. The growing e-bike sector, with 40% annual growth, represents a particularly promising application area for advanced composites that can address the specific structural requirements of these heavier, more powerful bicycles.

Consumer demand for lightweight, durable, and high-performance bicycles has created a substantial market opportunity for advanced composite materials. Professional cyclists and enthusiastic amateurs are increasingly willing to invest in premium bicycles that offer improved performance characteristics. This segment shows price elasticity for technological advantages, with consumers readily accepting higher price points for measurable performance benefits.

Carbon Fiber Reinforced Polymers (CFRP) currently dominate the high-end bicycle component market, particularly in frames, wheels, handlebars, and seat posts. The global CFRP market in cycling applications was valued at approximately $2.1 billion in 2022, with a projected growth rate exceeding the overall bicycle market. This premium material segment represents a high-margin opportunity for manufacturers who can effectively leverage advanced composites.

Regional analysis reveals varying adoption patterns, with North America and Europe leading in premium composite bicycle adoption. The Asia-Pacific region, particularly China, Japan, and South Korea, shows the fastest growth rate in this segment, driven by increasing disposable income and growing cycling culture. Emerging markets demonstrate increasing interest in mid-tier composite solutions that balance performance and affordability.

Consumer research indicates evolving preferences beyond pure performance metrics. While weight reduction remains paramount (with 78% of premium bicycle buyers citing it as a primary consideration), durability (65%), vibration dampening (52%), and sustainability credentials (47%) are increasingly important factors. This multi-dimensional demand creates opportunities for Advanced Polymer Matrix Composites that can address these varied requirements.

Market segmentation analysis reveals distinct consumer groups: professional athletes focused primarily on performance metrics, enthusiastic amateurs balancing performance with durability, and environmentally conscious consumers seeking sustainable materials. Each segment presents unique opportunities for different composite formulations and marketing approaches. The growing e-bike sector, with 40% annual growth, represents a particularly promising application area for advanced composites that can address the specific structural requirements of these heavier, more powerful bicycles.

Current State and Challenges in Composite Materials

The composite materials landscape has evolved significantly over the past decade, with Carbon Fiber Reinforced Polymers (CFRP) maintaining dominance in high-performance cycling applications. Current market analysis indicates that approximately 85% of professional-grade bicycles utilize some form of CFRP in their construction, highlighting its widespread adoption. However, this mature technology now faces several critical challenges that limit further advancement in cycling applications.

Material cost remains a significant barrier, with raw carbon fiber materials typically costing $20-30 per kilogram for industrial grade and up to $100-200 per kilogram for aerospace-grade fibers. This high cost structure continues to restrict mass-market adoption despite increasing production volumes. Manufacturing complexity presents another substantial challenge, as CFRP production requires specialized equipment, controlled environments, and skilled labor, resulting in high production costs and limited scalability.

Environmental concerns have emerged as a growing challenge for traditional CFRP materials. The carbon fiber production process is energy-intensive, consuming approximately 25-30 kWh per kilogram of fiber produced, and the thermoset resins commonly used are difficult to recycle. This has prompted regulatory pressure in Europe and North America, where end-of-life product management is becoming increasingly stringent.

Advanced Polymer Matrix Composites (APMCs) represent the emerging competitive technology, offering potential solutions to CFRP limitations. These materials incorporate novel matrix systems such as thermoplastic composites, which demonstrate improved impact resistance and recyclability compared to traditional thermoset-based CFRPs. Recent testing shows that some APMCs can achieve up to 40% better impact resistance while maintaining comparable stiffness-to-weight ratios.

Geographically, CFRP technology development remains concentrated in Japan, Germany, and the United States, which collectively control approximately 70% of global carbon fiber production capacity. However, China has rapidly expanded its manufacturing capabilities, increasing its global market share from 10% to nearly 25% over the past five years, primarily in lower-cost industrial-grade materials.

The integration of nanomaterials represents another frontier in composite development, with graphene and carbon nanotubes being incorporated into matrix systems to enhance mechanical properties. Laboratory tests demonstrate potential strength improvements of 15-30%, though commercial-scale production remains limited by processing challenges and high costs.

Addressing these challenges requires interdisciplinary approaches combining materials science, manufacturing engineering, and sustainability considerations. The industry faces a critical inflection point where traditional CFRP technology must evolve to meet emerging performance, cost, and environmental requirements in cycling applications.

Material cost remains a significant barrier, with raw carbon fiber materials typically costing $20-30 per kilogram for industrial grade and up to $100-200 per kilogram for aerospace-grade fibers. This high cost structure continues to restrict mass-market adoption despite increasing production volumes. Manufacturing complexity presents another substantial challenge, as CFRP production requires specialized equipment, controlled environments, and skilled labor, resulting in high production costs and limited scalability.

Environmental concerns have emerged as a growing challenge for traditional CFRP materials. The carbon fiber production process is energy-intensive, consuming approximately 25-30 kWh per kilogram of fiber produced, and the thermoset resins commonly used are difficult to recycle. This has prompted regulatory pressure in Europe and North America, where end-of-life product management is becoming increasingly stringent.

Advanced Polymer Matrix Composites (APMCs) represent the emerging competitive technology, offering potential solutions to CFRP limitations. These materials incorporate novel matrix systems such as thermoplastic composites, which demonstrate improved impact resistance and recyclability compared to traditional thermoset-based CFRPs. Recent testing shows that some APMCs can achieve up to 40% better impact resistance while maintaining comparable stiffness-to-weight ratios.

Geographically, CFRP technology development remains concentrated in Japan, Germany, and the United States, which collectively control approximately 70% of global carbon fiber production capacity. However, China has rapidly expanded its manufacturing capabilities, increasing its global market share from 10% to nearly 25% over the past five years, primarily in lower-cost industrial-grade materials.

The integration of nanomaterials represents another frontier in composite development, with graphene and carbon nanotubes being incorporated into matrix systems to enhance mechanical properties. Laboratory tests demonstrate potential strength improvements of 15-30%, though commercial-scale production remains limited by processing challenges and high costs.

Addressing these challenges requires interdisciplinary approaches combining materials science, manufacturing engineering, and sustainability considerations. The industry faces a critical inflection point where traditional CFRP technology must evolve to meet emerging performance, cost, and environmental requirements in cycling applications.

Current Technical Solutions in Cycling Composites

01 Manufacturing methods for CFRP composites

Various manufacturing techniques are employed to produce carbon fiber reinforced polymer composites, including molding processes, layup methods, and curing technologies. These methods focus on optimizing the integration of carbon fibers with polymer matrices to achieve desired mechanical properties. Advanced manufacturing approaches include automated fiber placement, resin transfer molding, and specialized curing cycles that enhance the structural integrity and performance of the resulting composites.- Manufacturing methods for CFRP composites: Various manufacturing techniques are employed to produce carbon fiber reinforced polymer composites with enhanced properties. These methods include pultrusion, resin transfer molding, and automated fiber placement. The manufacturing processes are designed to ensure proper fiber alignment, minimize voids, and achieve optimal fiber-to-resin ratios, resulting in composites with superior mechanical properties and performance characteristics.

- Resin systems for advanced polymer matrix composites: Advanced polymer matrix composites utilize specialized resin systems to enhance performance characteristics. These include thermosetting resins like epoxies and bismaleimides, as well as thermoplastic matrices that offer improved toughness and processing advantages. The resin systems are often modified with additives to improve specific properties such as thermal stability, flame resistance, and impact strength, creating composites tailored for demanding applications.

- Interface optimization between carbon fibers and polymer matrices: The interface between carbon fibers and polymer matrices plays a crucial role in determining the mechanical properties of CFRP composites. Various surface treatments and sizing agents are applied to carbon fibers to improve adhesion with the polymer matrix. These treatments modify the fiber surface chemistry and topography, enhancing the interfacial bonding and stress transfer between the fibers and matrix, which results in improved mechanical properties and durability of the composite.

- Structural applications of CFRP composites: CFRP composites are extensively used in structural applications across various industries due to their high strength-to-weight ratio and excellent mechanical properties. These applications include aerospace components, automotive structures, civil infrastructure, and sporting goods. The composites are designed to meet specific performance requirements such as load-bearing capacity, fatigue resistance, and dimensional stability, often replacing traditional materials like metals in critical structural components.

- Multifunctional and smart CFRP composites: Advanced research in CFRP technology focuses on developing multifunctional and smart composites that offer capabilities beyond mechanical performance. These include self-healing properties, embedded sensors for structural health monitoring, electrical conductivity for electromagnetic shielding, and thermal management features. By integrating additional functionalities into the composite structure, these materials can respond to environmental changes or damage, providing enhanced performance and safety in critical applications.

02 Polymer matrix formulations for advanced composites

Advanced polymer matrices for CFRP composites include specialized formulations designed to enhance mechanical properties, thermal stability, and chemical resistance. These matrices often incorporate modified epoxy resins, thermoplastic polymers, or hybrid systems that provide improved interfacial bonding with carbon fibers. Additives and modifiers are used to tailor specific properties such as toughness, flame retardancy, and processing characteristics, resulting in composites with superior performance for demanding applications.Expand Specific Solutions03 Interface optimization between carbon fibers and polymer matrices

The interface between carbon fibers and polymer matrices plays a critical role in determining the mechanical properties of CFRP composites. Surface treatments and sizing agents are applied to carbon fibers to improve adhesion with the polymer matrix. Advanced techniques include plasma treatment, chemical functionalization, and nanoparticle incorporation at the interface. These methods enhance load transfer between fibers and matrix, resulting in improved interlaminar shear strength, fracture toughness, and overall composite performance.Expand Specific Solutions04 Multifunctional CFRP composites with enhanced properties

Multifunctional CFRP composites incorporate additional functionalities beyond structural performance, such as electrical conductivity, thermal management, self-healing capabilities, and sensing functions. These advanced composites often integrate nanomaterials like carbon nanotubes, graphene, or metal nanoparticles within the polymer matrix or at fiber interfaces. The resulting materials can monitor their own structural health, provide electromagnetic shielding, or exhibit improved damage tolerance while maintaining excellent mechanical properties.Expand Specific Solutions05 Sustainable approaches for CFRP composites

Sustainable approaches to CFRP composites focus on reducing environmental impact through bio-based polymer matrices, recyclable composite systems, and energy-efficient manufacturing processes. Bio-derived resins from plant sources can replace petroleum-based polymers, while specialized recycling technologies enable recovery of carbon fibers from end-of-life composites. Advanced design strategies optimize material usage and extend service life, contributing to more environmentally friendly composite solutions without compromising performance requirements.Expand Specific Solutions

Key Manufacturers and Competition Landscape

The cycling industry is witnessing a technological evolution in composite materials, with competition between Carbon Fiber Reinforced Polymers (CFRP) and Advanced Polymer Matrix Composites intensifying. Currently in the growth phase, this market is expanding as manufacturers seek lighter, stronger materials for high-performance bicycles. Leading academic institutions (Shanghai Jiao Tong University, University of Tokyo) are collaborating with established manufacturers (Honda, Mercedes-Benz) to advance material science applications. Innovative startups like Papershell AB are disrupting the space with sustainable alternatives. Companies including QinetiQ, Samsung Electronics, and Mizuno are investing in proprietary composite technologies, while specialized firms such as Sugino Machine focus on manufacturing processes. The technology is approaching maturity but continues to evolve through cross-industry partnerships and sustainability-driven innovation.

Donghua University

Technical Solution: Donghua University has pioneered research comparing CFRP with advanced polymer matrix composites specifically optimized for cycling applications. Their approach focuses on nano-modified polymer matrices that enhance the interface between carbon fibers and the surrounding polymer. By incorporating graphene and carbon nanotubes into conventional epoxy systems, their research demonstrates significant improvements in interlaminar shear strength and impact resistance compared to traditional CFRP. Their most innovative development involves a gradient-property polymer matrix where the mechanical characteristics transition from rigid to more compliant across the thickness of the composite, creating structures with direction-specific stiffness. This technology allows bicycle components to be stiff in the primary load direction while providing controlled flexibility in other directions. Their manufacturing approach utilizes vacuum-assisted resin transfer molding with precise temperature and pressure control to optimize fiber-matrix adhesion.

Strengths: Superior interlaminar properties compared to conventional CFRP; excellent vibration damping characteristics; potential for reduced manufacturing costs through optimized resin consumption. Weaknesses: Technology still primarily in research phase; scalability challenges for mass production; requires precise process control for consistent results.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed a comprehensive materials solution for cycling applications that systematically compares and integrates CFRP with advanced polymer matrix composites. Their approach centers on a proprietary "Composite Integration Platform" that strategically employs different composite systems within a single bicycle frame. High-modulus carbon fiber/epoxy systems are utilized in areas requiring maximum stiffness (bottom bracket, head tube), while advanced polymer matrices with discontinuous carbon fiber reinforcement are employed in areas where vibration damping is critical. ITW's manufacturing technology involves a hybrid molding process that combines filament winding, compression molding, and selective reinforcement to create structures with tailored mechanical properties. Their latest innovation incorporates thermoplastic-modified epoxy systems that maintain the high performance of traditional CFRP while improving impact resistance and potential recyclability.

Strengths: Highly customizable mechanical properties; excellent fatigue resistance; balanced weight-to-performance ratio; potential for modular design and manufacturing. Weaknesses: Complex quality control requirements; higher initial tooling costs; requires specialized bonding techniques between different composite systems.

Core Innovations in Advanced Composite Materials

“a method of fabricating carbon fiber reinforced polymer composite”

PatentActiveIN202321066950A

Innovation

- A method combining hand layup (HL) with vacuum-assisted resin transfer molding (VARTM) to ensure proper resin impregnation and minimize voids, using a resin mixture of epoxy resin and hardener, applied to carbon fiber fabrics, which are then subjected to VARTM for enhanced interfacial adhesion and mechanical properties.

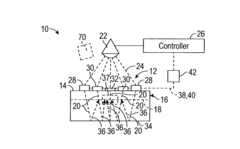

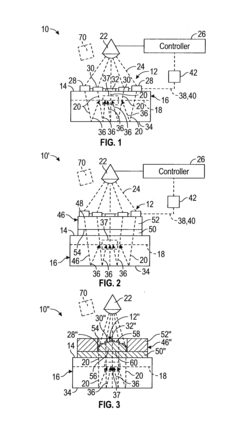

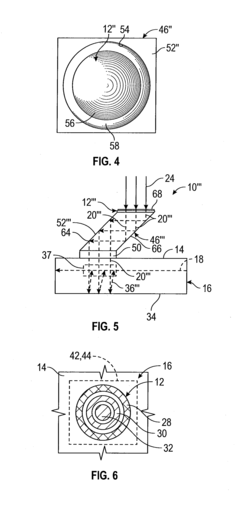

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

Sustainability and Lifecycle Assessment

The sustainability profile of cycling components has become increasingly important as manufacturers and consumers alike focus on environmental impact. When comparing Carbon Fiber Reinforced Polymers (CFRP) with Advanced Polymer Matrix Composites in cycling applications, lifecycle assessment reveals significant differences in environmental footprint.

CFRP production is notably energy-intensive, requiring approximately 183-286 MJ/kg of energy, significantly higher than many traditional materials. The carbon fiber manufacturing process involves high-temperature treatment (up to 1500°C) of polyacrylonitrile precursors, resulting in substantial CO2 emissions—estimated at 20-30 kg CO2 per kg of carbon fiber produced. These environmental costs present challenges to CFRP's sustainability credentials despite its performance advantages.

Advanced Polymer Matrix Composites, particularly those incorporating bio-based resins or recycled materials, demonstrate improved sustainability metrics. Recent innovations include composites utilizing flax, hemp, or recycled carbon fibers that reduce embodied energy by 30-50% compared to traditional CFRP. These materials achieve a smaller carbon footprint while maintaining acceptable mechanical properties for many cycling applications.

End-of-life considerations further differentiate these materials. Traditional CFRP presents significant recycling challenges due to the thermoset nature of epoxy matrices, often resulting in landfill disposal. Emerging pyrolysis and solvolysis techniques can recover carbon fibers, but typically with 10-40% degradation in mechanical properties. In contrast, some advanced composites incorporate thermoplastic matrices that enable more straightforward recycling pathways.

Water consumption and chemical usage during manufacturing also merit consideration. CFRP production typically requires 120-200 liters of water per kilogram of finished product, with additional environmental concerns stemming from sizing agents and resin systems. Advanced composites utilizing water-based resins or solvent-free manufacturing processes can reduce these impacts by up to 60%.

Economic sustainability analysis indicates that while CFRP components typically command premium pricing, advanced composites may offer better lifecycle value when accounting for environmental externalities. Carbon taxation scenarios project potential cost increases of 5-15% for traditional CFRP manufacturing by 2030, potentially shifting market dynamics toward more sustainable alternatives.

The cycling industry has begun implementing sustainability certifications and standards that may influence material selection. The Environmental Product Declaration (EPD) framework and emerging Circular Economy metrics are increasingly being applied to cycling components, creating market incentives for materials with superior lifecycle performance.

CFRP production is notably energy-intensive, requiring approximately 183-286 MJ/kg of energy, significantly higher than many traditional materials. The carbon fiber manufacturing process involves high-temperature treatment (up to 1500°C) of polyacrylonitrile precursors, resulting in substantial CO2 emissions—estimated at 20-30 kg CO2 per kg of carbon fiber produced. These environmental costs present challenges to CFRP's sustainability credentials despite its performance advantages.

Advanced Polymer Matrix Composites, particularly those incorporating bio-based resins or recycled materials, demonstrate improved sustainability metrics. Recent innovations include composites utilizing flax, hemp, or recycled carbon fibers that reduce embodied energy by 30-50% compared to traditional CFRP. These materials achieve a smaller carbon footprint while maintaining acceptable mechanical properties for many cycling applications.

End-of-life considerations further differentiate these materials. Traditional CFRP presents significant recycling challenges due to the thermoset nature of epoxy matrices, often resulting in landfill disposal. Emerging pyrolysis and solvolysis techniques can recover carbon fibers, but typically with 10-40% degradation in mechanical properties. In contrast, some advanced composites incorporate thermoplastic matrices that enable more straightforward recycling pathways.

Water consumption and chemical usage during manufacturing also merit consideration. CFRP production typically requires 120-200 liters of water per kilogram of finished product, with additional environmental concerns stemming from sizing agents and resin systems. Advanced composites utilizing water-based resins or solvent-free manufacturing processes can reduce these impacts by up to 60%.

Economic sustainability analysis indicates that while CFRP components typically command premium pricing, advanced composites may offer better lifecycle value when accounting for environmental externalities. Carbon taxation scenarios project potential cost increases of 5-15% for traditional CFRP manufacturing by 2030, potentially shifting market dynamics toward more sustainable alternatives.

The cycling industry has begun implementing sustainability certifications and standards that may influence material selection. The Environmental Product Declaration (EPD) framework and emerging Circular Economy metrics are increasingly being applied to cycling components, creating market incentives for materials with superior lifecycle performance.

Performance Testing Methodologies

Performance testing methodologies for comparing CFRP (Carbon Fiber Reinforced Polymer) with advanced polymer matrix composites in cycling applications require rigorous standardization to ensure reliable and reproducible results. The testing protocols typically encompass mechanical property assessment, fatigue resistance evaluation, environmental durability testing, and real-world performance simulation.

Mechanical property testing forms the foundation of comparative analysis, utilizing standardized methods such as ASTM D3039 for tensile properties, ASTM D790 for flexural characteristics, and ASTM D7264 for composite laminate properties. These tests quantify fundamental parameters including tensile strength, modulus of elasticity, and strain-to-failure ratios that directly influence cycling component performance. For cycling-specific applications, modified test fixtures are often employed to better simulate the unique loading conditions experienced during riding.

Fatigue resistance testing represents a critical dimension in cycling component evaluation, as these parts undergo millions of loading cycles during their service life. Testing methodologies include ASTM D3479 for tension-tension fatigue and modified protocols for compression-compression and flexural fatigue. Advanced testing incorporates variable amplitude loading patterns that replicate actual riding conditions, including sprint accelerations, climbing forces, and impact events from road irregularities.

Environmental durability assessment evaluates how composites perform under varying conditions encountered in cycling applications. Standardized protocols include ASTM D5229 for moisture absorption characteristics and ASTM G154 for UV exposure effects. Cycling-specific methodologies often incorporate thermal cycling (-20°C to 70°C) to simulate extreme usage scenarios and salt spray exposure tests to evaluate corrosion resistance in components exposed to rider perspiration or road treatments.

Impact resistance testing utilizes modified drop-weight impact tests (ASTM D7136) and instrumented impact testing to evaluate the energy absorption capabilities of different composite systems. For cycling applications, specialized test fixtures simulate impacts from road debris, crashes, and transportation incidents. High-speed imaging and acoustic emission monitoring provide additional insights into failure mechanisms during impact events.

Field testing methodologies complement laboratory evaluations by assessing real-world performance. These include instrumented road testing with strain gauges and accelerometers to measure actual loading conditions, controlled track testing for comparative performance evaluation, and professional rider feedback protocols. Advanced methodologies incorporate digital twin modeling that correlates laboratory test data with field performance to develop predictive models for long-term component behavior.

Mechanical property testing forms the foundation of comparative analysis, utilizing standardized methods such as ASTM D3039 for tensile properties, ASTM D790 for flexural characteristics, and ASTM D7264 for composite laminate properties. These tests quantify fundamental parameters including tensile strength, modulus of elasticity, and strain-to-failure ratios that directly influence cycling component performance. For cycling-specific applications, modified test fixtures are often employed to better simulate the unique loading conditions experienced during riding.

Fatigue resistance testing represents a critical dimension in cycling component evaluation, as these parts undergo millions of loading cycles during their service life. Testing methodologies include ASTM D3479 for tension-tension fatigue and modified protocols for compression-compression and flexural fatigue. Advanced testing incorporates variable amplitude loading patterns that replicate actual riding conditions, including sprint accelerations, climbing forces, and impact events from road irregularities.

Environmental durability assessment evaluates how composites perform under varying conditions encountered in cycling applications. Standardized protocols include ASTM D5229 for moisture absorption characteristics and ASTM G154 for UV exposure effects. Cycling-specific methodologies often incorporate thermal cycling (-20°C to 70°C) to simulate extreme usage scenarios and salt spray exposure tests to evaluate corrosion resistance in components exposed to rider perspiration or road treatments.

Impact resistance testing utilizes modified drop-weight impact tests (ASTM D7136) and instrumented impact testing to evaluate the energy absorption capabilities of different composite systems. For cycling applications, specialized test fixtures simulate impacts from road debris, crashes, and transportation incidents. High-speed imaging and acoustic emission monitoring provide additional insights into failure mechanisms during impact events.

Field testing methodologies complement laboratory evaluations by assessing real-world performance. These include instrumented road testing with strain gauges and accelerometers to measure actual loading conditions, controlled track testing for comparative performance evaluation, and professional rider feedback protocols. Advanced methodologies incorporate digital twin modeling that correlates laboratory test data with field performance to develop predictive models for long-term component behavior.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!