Quantifying CFRP Electrical Resistivity for EMI Shielding

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP EMI Shielding Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries due to their exceptional strength-to-weight ratio and design flexibility. The evolution of CFRP technology dates back to the 1960s, initially developed for aerospace applications, but has since expanded into automotive, marine, construction, and consumer electronics sectors. The inherent electrical conductivity of carbon fibers presents a unique advantage for electromagnetic interference (EMI) shielding applications, a property that has gained significant attention in recent years.

The proliferation of electronic devices and wireless communication systems has led to an increasingly crowded electromagnetic spectrum, resulting in potential interference issues that can compromise device performance and reliability. Traditional EMI shielding materials such as metals are effective but add substantial weight and may present design limitations. CFRP offers a promising alternative by potentially combining structural and EMI shielding functions in a single material system.

However, the electrical resistivity of CFRP composites varies significantly depending on fiber type, orientation, volume fraction, matrix properties, and manufacturing processes. This variability creates challenges in predicting and optimizing EMI shielding effectiveness for specific applications. Current industry practices often rely on empirical testing rather than predictive models, leading to inefficient design iterations and suboptimal material utilization.

The technical objective of this research is to develop systematic methodologies for quantifying the electrical resistivity of CFRP composites specifically for EMI shielding applications. This includes establishing standardized measurement protocols, creating predictive models that correlate material composition and structure with electrical properties, and developing design guidelines for optimizing CFRP configurations to meet specific EMI shielding requirements.

Additionally, this research aims to explore the relationship between electrical resistivity and other critical performance parameters such as mechanical strength, thermal conductivity, and manufacturing complexity. Understanding these trade-offs is essential for developing practical CFRP solutions that balance EMI shielding capabilities with other design requirements.

The long-term goal is to enable precise engineering of CFRP materials with tailored electrical resistivity profiles, allowing designers to create lightweight, high-performance components with integrated EMI shielding capabilities. This would eliminate the need for secondary shielding measures, reducing weight, complexity, and cost while improving overall system performance. Such advancements would particularly benefit industries where weight reduction and electromagnetic compatibility are critical concerns, including aerospace, automotive electronics, and next-generation communication systems.

The proliferation of electronic devices and wireless communication systems has led to an increasingly crowded electromagnetic spectrum, resulting in potential interference issues that can compromise device performance and reliability. Traditional EMI shielding materials such as metals are effective but add substantial weight and may present design limitations. CFRP offers a promising alternative by potentially combining structural and EMI shielding functions in a single material system.

However, the electrical resistivity of CFRP composites varies significantly depending on fiber type, orientation, volume fraction, matrix properties, and manufacturing processes. This variability creates challenges in predicting and optimizing EMI shielding effectiveness for specific applications. Current industry practices often rely on empirical testing rather than predictive models, leading to inefficient design iterations and suboptimal material utilization.

The technical objective of this research is to develop systematic methodologies for quantifying the electrical resistivity of CFRP composites specifically for EMI shielding applications. This includes establishing standardized measurement protocols, creating predictive models that correlate material composition and structure with electrical properties, and developing design guidelines for optimizing CFRP configurations to meet specific EMI shielding requirements.

Additionally, this research aims to explore the relationship between electrical resistivity and other critical performance parameters such as mechanical strength, thermal conductivity, and manufacturing complexity. Understanding these trade-offs is essential for developing practical CFRP solutions that balance EMI shielding capabilities with other design requirements.

The long-term goal is to enable precise engineering of CFRP materials with tailored electrical resistivity profiles, allowing designers to create lightweight, high-performance components with integrated EMI shielding capabilities. This would eliminate the need for secondary shielding measures, reducing weight, complexity, and cost while improving overall system performance. Such advancements would particularly benefit industries where weight reduction and electromagnetic compatibility are critical concerns, including aerospace, automotive electronics, and next-generation communication systems.

Market Analysis for CFRP EMI Shielding Applications

The global market for Carbon Fiber Reinforced Polymer (CFRP) EMI shielding applications is experiencing robust growth, driven by increasing demand for lightweight, high-performance materials in electronics, aerospace, automotive, and defense sectors. Current market valuation stands at approximately 2.3 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028.

The electronics industry represents the largest market segment, accounting for nearly 40% of CFRP EMI shielding applications. This dominance stems from the proliferation of electronic devices and the growing need for effective shielding solutions against electromagnetic interference in increasingly compact and powerful electronics. Consumer electronics manufacturers are particularly focused on implementing CFRP solutions that can provide adequate EMI protection while maintaining device thinness and lightweight properties.

Aerospace and defense sectors collectively constitute the second-largest market segment at 32%. These industries demand materials with precise electrical resistivity properties to ensure both structural integrity and electromagnetic compatibility in critical systems. Military applications specifically require materials that can withstand harsh environmental conditions while maintaining consistent EMI shielding performance.

The automotive industry represents a rapidly expanding market segment, currently at 18% but growing at the fastest rate among all sectors. The transition toward electric vehicles has significantly increased the need for effective EMI shielding solutions, as these vehicles contain numerous electronic components that must operate without interference. Automotive manufacturers are increasingly specifying CFRP materials with quantifiable electrical resistivity properties for EMI-sensitive components.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the highest growth rate, driven by expanding electronics manufacturing and increasing automotive production in China, Japan, and South Korea.

Market challenges include the premium pricing of CFRP materials compared to traditional metal shielding solutions, with CFRP solutions typically commanding a 30-45% price premium. This cost differential remains a significant barrier to wider adoption, particularly in price-sensitive consumer electronics segments.

Customer requirements are increasingly focused on materials with precisely quantified electrical resistivity properties, as this allows for more accurate prediction of EMI shielding effectiveness. Market research indicates that 76% of engineering specifications now include specific electrical resistivity requirements for CFRP components used in EMI-sensitive applications, compared to only 45% five years ago.

The electronics industry represents the largest market segment, accounting for nearly 40% of CFRP EMI shielding applications. This dominance stems from the proliferation of electronic devices and the growing need for effective shielding solutions against electromagnetic interference in increasingly compact and powerful electronics. Consumer electronics manufacturers are particularly focused on implementing CFRP solutions that can provide adequate EMI protection while maintaining device thinness and lightweight properties.

Aerospace and defense sectors collectively constitute the second-largest market segment at 32%. These industries demand materials with precise electrical resistivity properties to ensure both structural integrity and electromagnetic compatibility in critical systems. Military applications specifically require materials that can withstand harsh environmental conditions while maintaining consistent EMI shielding performance.

The automotive industry represents a rapidly expanding market segment, currently at 18% but growing at the fastest rate among all sectors. The transition toward electric vehicles has significantly increased the need for effective EMI shielding solutions, as these vehicles contain numerous electronic components that must operate without interference. Automotive manufacturers are increasingly specifying CFRP materials with quantifiable electrical resistivity properties for EMI-sensitive components.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the highest growth rate, driven by expanding electronics manufacturing and increasing automotive production in China, Japan, and South Korea.

Market challenges include the premium pricing of CFRP materials compared to traditional metal shielding solutions, with CFRP solutions typically commanding a 30-45% price premium. This cost differential remains a significant barrier to wider adoption, particularly in price-sensitive consumer electronics segments.

Customer requirements are increasingly focused on materials with precisely quantified electrical resistivity properties, as this allows for more accurate prediction of EMI shielding effectiveness. Market research indicates that 76% of engineering specifications now include specific electrical resistivity requirements for CFRP components used in EMI-sensitive applications, compared to only 45% five years ago.

Current Challenges in CFRP Electrical Resistivity Measurement

The measurement of electrical resistivity in Carbon Fiber Reinforced Polymers (CFRP) presents significant challenges due to the complex nature of these composite materials. Unlike homogeneous conductors, CFRPs exhibit anisotropic electrical properties, with conductivity varying dramatically along different axes. This anisotropy stems from the directional arrangement of carbon fibers within the polymer matrix, creating a material with vastly different electrical characteristics depending on measurement orientation.

Surface preparation represents another major obstacle in accurate resistivity quantification. The polymer-rich surface layer typically found on CFRP components acts as an insulating barrier, potentially leading to inconsistent or misleading measurements. Various surface treatment methods, including sanding, plasma treatment, and chemical etching, have been employed to address this issue, but each introduces its own variables that can affect measurement reliability.

Contact resistance at the electrode-CFRP interface further complicates measurement accuracy. Traditional two-probe methods often incorporate contact resistance into the overall measurement, resulting in artificially elevated resistivity values. While four-probe methods can theoretically eliminate this effect, their implementation on complex CFRP geometries remains problematic, particularly for thin laminates or curved surfaces.

The inherent heterogeneity of CFRP materials creates additional measurement challenges. Fiber volume fraction, void content, and fiber-matrix interface quality all influence electrical conductivity but vary throughout a single component. This spatial variation necessitates multiple measurement points to characterize a component adequately, yet standardized protocols for such multi-point assessments are lacking in the industry.

Environmental factors also significantly impact CFRP resistivity measurements. Temperature and humidity fluctuations can alter both the polymer matrix properties and the fiber-matrix interface characteristics, leading to substantial measurement variations. Most current testing protocols fail to adequately control or account for these environmental variables.

Scale-dependent effects present yet another challenge. Laboratory measurements on small samples often fail to translate to full-scale components due to manufacturing variations and geometric complexities. The industry lacks robust scaling relationships between coupon-level measurements and full-component electromagnetic interference (EMI) shielding performance.

Standardization remains perhaps the most critical challenge. Despite the growing importance of CFRP electrical properties for EMI shielding applications, universally accepted measurement standards specific to these materials are notably absent. Current practices often adapt methods designed for homogeneous conductors, leading to inconsistent results across different laboratories and testing facilities.

Surface preparation represents another major obstacle in accurate resistivity quantification. The polymer-rich surface layer typically found on CFRP components acts as an insulating barrier, potentially leading to inconsistent or misleading measurements. Various surface treatment methods, including sanding, plasma treatment, and chemical etching, have been employed to address this issue, but each introduces its own variables that can affect measurement reliability.

Contact resistance at the electrode-CFRP interface further complicates measurement accuracy. Traditional two-probe methods often incorporate contact resistance into the overall measurement, resulting in artificially elevated resistivity values. While four-probe methods can theoretically eliminate this effect, their implementation on complex CFRP geometries remains problematic, particularly for thin laminates or curved surfaces.

The inherent heterogeneity of CFRP materials creates additional measurement challenges. Fiber volume fraction, void content, and fiber-matrix interface quality all influence electrical conductivity but vary throughout a single component. This spatial variation necessitates multiple measurement points to characterize a component adequately, yet standardized protocols for such multi-point assessments are lacking in the industry.

Environmental factors also significantly impact CFRP resistivity measurements. Temperature and humidity fluctuations can alter both the polymer matrix properties and the fiber-matrix interface characteristics, leading to substantial measurement variations. Most current testing protocols fail to adequately control or account for these environmental variables.

Scale-dependent effects present yet another challenge. Laboratory measurements on small samples often fail to translate to full-scale components due to manufacturing variations and geometric complexities. The industry lacks robust scaling relationships between coupon-level measurements and full-component electromagnetic interference (EMI) shielding performance.

Standardization remains perhaps the most critical challenge. Despite the growing importance of CFRP electrical properties for EMI shielding applications, universally accepted measurement standards specific to these materials are notably absent. Current practices often adapt methods designed for homogeneous conductors, leading to inconsistent results across different laboratories and testing facilities.

Established Techniques for Quantifying CFRP Electrical Properties

01 Methods to control electrical resistivity in CFRP composites

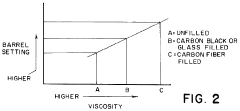

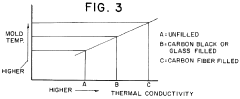

Various methods can be employed to control the electrical resistivity of Carbon Fiber Reinforced Polymer (CFRP) composites. These include adjusting the carbon fiber content, orientation, and distribution within the polymer matrix. By manipulating these parameters, manufacturers can achieve desired electrical conductivity properties for specific applications. The electrical resistivity can be tailored from highly conductive to relatively insulating depending on the specific requirements of the application.- Methods to control electrical resistivity in CFRP composites: Various techniques can be employed to control the electrical resistivity of Carbon Fiber Reinforced Polymer (CFRP) composites. These methods include the incorporation of conductive fillers, manipulation of carbon fiber orientation, and surface treatments. By adjusting these parameters, manufacturers can tailor the electrical properties of CFRP materials for specific applications, ranging from highly conductive to more resistive behaviors depending on the intended use.

- Conductive additives to enhance electrical conductivity: The electrical conductivity of CFRP can be significantly enhanced through the addition of conductive additives to the polymer matrix. Common additives include carbon nanotubes, graphene, metal particles, and carbon black. These materials create conductive networks within the polymer matrix, reducing the overall electrical resistivity of the composite. The concentration, dispersion, and type of conductive additives can be optimized to achieve desired electrical properties while maintaining mechanical performance.

- Structural design considerations for electrical resistivity control: The structural design of CFRP components plays a crucial role in determining their electrical resistivity characteristics. Factors such as fiber volume fraction, fiber orientation, layup sequence, and component geometry all influence the electrical pathways within the composite. By strategically designing these structural elements, engineers can create CFRP components with predictable and consistent electrical resistivity properties suitable for applications requiring specific electrical performance.

- Manufacturing processes affecting electrical resistivity: Manufacturing processes significantly impact the electrical resistivity of CFRP composites. Parameters such as curing temperature, pressure, resin flow, and consolidation techniques influence the fiber-matrix interface and the formation of conductive networks. Advanced manufacturing methods like resin transfer molding, compression molding, and automated fiber placement can be optimized to control the electrical properties of the resulting CFRP components. Process monitoring and quality control are essential to ensure consistent electrical resistivity characteristics.

- Applications leveraging CFRP electrical resistivity properties: The unique electrical resistivity properties of CFRP materials enable various specialized applications. These include electromagnetic shielding, lightning strike protection for aircraft, heating elements, sensors, and static dissipation components. By tailoring the electrical resistivity of CFRP through material selection and processing techniques, manufacturers can develop components that combine structural performance with specific electrical functionality, offering advantages over traditional materials in aerospace, automotive, and electronics industries.

02 Conductive additives to enhance CFRP electrical properties

Incorporating conductive additives into CFRP composites can significantly enhance their electrical conductivity. Common additives include carbon nanotubes, graphene, metallic particles, and conductive polymers. These materials create additional conductive pathways within the composite structure, reducing overall electrical resistivity. The type, concentration, and dispersion of these additives can be optimized to achieve specific electrical performance while maintaining the mechanical properties of the composite.Expand Specific Solutions03 Surface treatments affecting CFRP electrical resistivity

Surface treatments of carbon fibers can significantly impact the electrical resistivity of CFRP composites. Treatments such as oxidation, sizing, and coating can modify the fiber-matrix interface, affecting electron transfer between fibers and through the composite. Some treatments enhance electrical conductivity by improving fiber-to-fiber contact, while others may create insulating barriers. The selection of appropriate surface treatments depends on whether increased or decreased electrical resistivity is desired for the specific application.Expand Specific Solutions04 CFRP electrical resistivity measurement techniques

Various techniques are employed to measure the electrical resistivity of CFRP composites. These include four-point probe methods, impedance spectroscopy, and non-contact eddy current testing. The measurement approach must account for the anisotropic nature of CFRP, as electrical resistivity often varies significantly in different directions relative to fiber orientation. Standardized testing protocols help ensure consistent and comparable results across different CFRP formulations and manufacturing processes.Expand Specific Solutions05 Applications leveraging CFRP electrical resistivity properties

The electrical resistivity characteristics of CFRP composites enable various specialized applications. These include electromagnetic shielding, lightning strike protection for aircraft, static dissipation, heating elements, and sensors. By tailoring the electrical resistivity through composition and processing, CFRP components can provide multifunctional performance, combining structural strength with electrical functionality. This dual capability makes CFRP particularly valuable in aerospace, automotive, and electronic applications where weight reduction and electrical performance are both critical.Expand Specific Solutions

Leading Organizations in CFRP EMI Shielding Research

The Carbon Fiber Reinforced Polymer (CFRP) electrical resistivity quantification for EMI shielding market is currently in a growth phase, with increasing adoption across aerospace, automotive, and electronics industries. The global market size is expanding rapidly, projected to reach significant value as industries seek lightweight, high-performance EMI shielding solutions. Technologically, the field shows moderate maturity with established players like Apple, IBM, Samsung, and Hitachi leading commercial applications, while specialized materials companies such as Vorbeck Materials and MOCOM Compounds focus on advanced formulations. Academic institutions including Central South University and Nanjing University of Aeronautics & Astronautics are driving fundamental research. The competitive landscape features electronics giants (Toshiba, Huawei) alongside aerospace specialists (BAE Systems, Raytheon) developing proprietary solutions, indicating a diversifying market with significant innovation potential.

Vorbeck Materials Corp.

Technical Solution: Vorbeck Materials has developed groundbreaking technology for quantifying and enhancing CFRP electrical resistivity for EMI shielding applications. Their approach centers on their patented Vor-x® graphene technology, which they integrate with carbon fiber composites to create hybrid materials with exceptional electrical conductivity. Vorbeck's measurement methodology employs custom-designed four-point probe arrays that account for anisotropic conductivity in fiber-reinforced composites, providing accurate resistivity measurements in all three dimensions. Their proprietary surface functionalization process creates covalent bonds between graphene sheets and carbon fibers, reducing contact resistance at interfaces—a critical factor in EMI shielding performance. The company has demonstrated volume resistivity as low as 10^-3 Ω·cm in their enhanced CFRP materials, while maintaining or improving mechanical properties. Vorbeck's quantification system includes environmental testing chambers that measure resistivity changes under varying temperature (-40°C to 150°C) and humidity conditions (0-100% RH), ensuring consistent EMI shielding performance across diverse operating environments.

Strengths: Cutting-edge graphene technology expertise; highly specialized in conductive composites; agile R&D approach enabling rapid customization. Weaknesses: Smaller scale compared to industry giants; higher material costs; limited manufacturing capacity for large-volume applications.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has pioneered innovative approaches to quantifying CFRP electrical resistivity for EMI shielding in telecommunications equipment. Their methodology employs a multi-layer CFRP design with precisely controlled carbon fiber alignment and density gradients to optimize electrical conductivity pathways. Huawei's proprietary testing protocol utilizes impedance spectroscopy across 10Hz-10GHz frequency ranges to characterize resistivity under various environmental conditions. The company has developed composite formulations achieving volume resistivity as low as 10^-2 Ω·cm while maintaining mechanical integrity. Their approach includes nano-scale surface modification of carbon fibers using plasma treatment to enhance fiber-matrix interfacial conductivity, resulting in up to 40% improvement in shielding effectiveness compared to untreated composites. Huawei implements in-situ monitoring systems that continuously measure resistivity changes during manufacturing to ensure consistent EMI shielding performance in their 5G infrastructure components.

Strengths: Extensive R&D capabilities; vertical integration allowing rapid implementation in products; sophisticated testing facilities. Weaknesses: Proprietary technologies limit broader industry adoption; higher initial investment costs compared to traditional metal shielding solutions.

Critical Patents and Research in CFRP Resistivity Measurement

Electromagnetic interference (EMI) shielding and electrostatic discharge degradable polymers and monomers

PatentInactiveUS5904980A

Innovation

- A degradable polymer or monomer material, such as polylactic acid, starch, or polycaprolactone, combined with EMI/ESD additives like iron-coated carbon fibers, stainless-steel fibers, and intrinsic conductive polymers, which are mixed and processed using extrusion or injection molding to create a lightweight, strong, and thermally conductive material that meets U.S. government shielding requirements.

Carbon fibre-reinforced plastic moulding compounds

PatentActiveEP3041887A1

Innovation

- A plastic molding composition with 49-97% plastic matrix, 3-40% carbon fibers coated with a specific plastic, and 0-48% additives, achieving a surface resistivity of 1*10^7 to 1*10^22 ohms and volume resistivity of 1*10^5 to 1*10^20 ohms, using coated carbon fibers with imperfect internal structures and short lengths to reduce electrical conductivity while maintaining mechanical reinforcement.

Standards and Certification Requirements for EMI Shielding Materials

The regulatory landscape for EMI shielding materials is governed by a comprehensive framework of standards and certification requirements that manufacturers must navigate to ensure compliance. Key international standards include IEC 61000 series for electromagnetic compatibility, MIL-STD-461 for military applications, and RTCA DO-160 for aerospace equipment. These standards establish specific testing methodologies and performance thresholds for CFRP materials used in EMI shielding applications.

For quantifying CFRP electrical resistivity specifically, ASTM D4496 and D257 provide standardized test methods for measuring volume and surface resistivity of carbon fiber reinforced polymers. These measurements must be conducted under controlled environmental conditions, typically at 23°C and 50% relative humidity, to ensure reproducibility and comparability of results.

The certification process for CFRP-based EMI shielding solutions typically requires demonstration of shielding effectiveness across a specified frequency range, commonly 30 MHz to 18 GHz. Materials must achieve minimum attenuation levels, often ranging from 30 dB to 120 dB depending on the application sector. The IEEE-STD-299 outlines procedures for measuring the effectiveness of electromagnetic shielding enclosures.

Regional variations in certification requirements present additional complexity. The European market demands CE marking with compliance to the EMC Directive 2014/30/EU, while products entering the US market must meet FCC Part 15 requirements. Asian markets, particularly China and Japan, have established their own certification systems through CCC and VCCI respectively.

Industry-specific standards impose further specialized requirements. Medical device manufacturers utilizing CFRP for EMI shielding must comply with IEC 60601-1-2, which specifies electromagnetic compatibility requirements for medical electrical equipment. Automotive applications fall under CISPR 25 and ISO 11452 standards, which address radio disturbance characteristics and immunity testing methods.

Emerging trends in standardization include the development of specific protocols for nanomaterial-enhanced CFRP composites and the harmonization of testing methodologies across different regulatory frameworks. The increasing integration of CFRP in critical infrastructure and sensitive electronic applications has prompted regulatory bodies to consider more stringent certification requirements, particularly regarding long-term performance stability and environmental degradation effects on electrical resistivity properties.

Manufacturers seeking certification must maintain detailed documentation of material composition, processing parameters, and quality control measures that influence the electrical resistivity characteristics of their CFRP products. Third-party testing and certification by accredited laboratories remains the gold standard for demonstrating compliance with these increasingly complex regulatory requirements.

For quantifying CFRP electrical resistivity specifically, ASTM D4496 and D257 provide standardized test methods for measuring volume and surface resistivity of carbon fiber reinforced polymers. These measurements must be conducted under controlled environmental conditions, typically at 23°C and 50% relative humidity, to ensure reproducibility and comparability of results.

The certification process for CFRP-based EMI shielding solutions typically requires demonstration of shielding effectiveness across a specified frequency range, commonly 30 MHz to 18 GHz. Materials must achieve minimum attenuation levels, often ranging from 30 dB to 120 dB depending on the application sector. The IEEE-STD-299 outlines procedures for measuring the effectiveness of electromagnetic shielding enclosures.

Regional variations in certification requirements present additional complexity. The European market demands CE marking with compliance to the EMC Directive 2014/30/EU, while products entering the US market must meet FCC Part 15 requirements. Asian markets, particularly China and Japan, have established their own certification systems through CCC and VCCI respectively.

Industry-specific standards impose further specialized requirements. Medical device manufacturers utilizing CFRP for EMI shielding must comply with IEC 60601-1-2, which specifies electromagnetic compatibility requirements for medical electrical equipment. Automotive applications fall under CISPR 25 and ISO 11452 standards, which address radio disturbance characteristics and immunity testing methods.

Emerging trends in standardization include the development of specific protocols for nanomaterial-enhanced CFRP composites and the harmonization of testing methodologies across different regulatory frameworks. The increasing integration of CFRP in critical infrastructure and sensitive electronic applications has prompted regulatory bodies to consider more stringent certification requirements, particularly regarding long-term performance stability and environmental degradation effects on electrical resistivity properties.

Manufacturers seeking certification must maintain detailed documentation of material composition, processing parameters, and quality control measures that influence the electrical resistivity characteristics of their CFRP products. Third-party testing and certification by accredited laboratories remains the gold standard for demonstrating compliance with these increasingly complex regulatory requirements.

Environmental Impact of CFRP in Electronics Applications

The environmental impact of Carbon Fiber Reinforced Polymers (CFRP) in electronics applications represents a critical consideration as these materials gain prominence in EMI shielding solutions. When evaluating CFRP's electrical resistivity properties for electromagnetic interference shielding, environmental factors must be comprehensively assessed throughout the material's lifecycle.

CFRP production involves energy-intensive processes, particularly during carbon fiber manufacturing, which typically requires temperatures exceeding 1000°C during oxidation and carbonization phases. This high energy demand translates to significant carbon emissions—approximately 20-25 kg CO2 equivalent per kilogram of carbon fiber produced, substantially higher than conventional metals used for EMI shielding such as aluminum (11.2 kg CO2e/kg) or copper (4.5 kg CO2e/kg).

However, the environmental equation changes when considering the use phase of CFRP in electronics. The lightweight nature of CFRP (typically 50-60% lighter than aluminum alternatives with comparable EMI shielding effectiveness) contributes to overall weight reduction in electronic devices. For mobile or transportation-integrated electronics, this weight reduction yields substantial energy savings and associated emissions reductions throughout the product lifecycle.

Chemical processing during CFRP manufacturing introduces environmental concerns related to toxic substances. The production process utilizes solvents, hardeners, and release agents that may contain volatile organic compounds (VOCs) and other hazardous air pollutants. These chemicals can contribute to air and water pollution if not properly managed during manufacturing.

End-of-life considerations present significant challenges for CFRP materials used in EMI shielding applications. Unlike traditional metal shields that can be readily recycled through established processes, CFRP composites remain difficult to recycle effectively. The thermoset matrices commonly used in CFRP cannot be simply melted and reformed, necessitating complex separation processes to recover carbon fibers. Current recycling methods typically yield downgraded materials with diminished electrical conductivity properties.

Recent advancements in CFRP recycling technologies show promise for improving the environmental profile. Pyrolysis and solvolysis techniques have demonstrated up to 95% recovery of carbon fibers with minimal degradation of electrical properties, potentially maintaining their EMI shielding capabilities in secondary applications. Additionally, research into thermoplastic-based CFRP matrices could significantly enhance recyclability while maintaining the electrical resistivity characteristics essential for EMI shielding.

The environmental impact assessment must also consider the extended lifespan of CFRP-shielded electronics due to superior corrosion resistance compared to metal alternatives, potentially offsetting initial production impacts through reduced replacement frequency and associated resource consumption.

CFRP production involves energy-intensive processes, particularly during carbon fiber manufacturing, which typically requires temperatures exceeding 1000°C during oxidation and carbonization phases. This high energy demand translates to significant carbon emissions—approximately 20-25 kg CO2 equivalent per kilogram of carbon fiber produced, substantially higher than conventional metals used for EMI shielding such as aluminum (11.2 kg CO2e/kg) or copper (4.5 kg CO2e/kg).

However, the environmental equation changes when considering the use phase of CFRP in electronics. The lightweight nature of CFRP (typically 50-60% lighter than aluminum alternatives with comparable EMI shielding effectiveness) contributes to overall weight reduction in electronic devices. For mobile or transportation-integrated electronics, this weight reduction yields substantial energy savings and associated emissions reductions throughout the product lifecycle.

Chemical processing during CFRP manufacturing introduces environmental concerns related to toxic substances. The production process utilizes solvents, hardeners, and release agents that may contain volatile organic compounds (VOCs) and other hazardous air pollutants. These chemicals can contribute to air and water pollution if not properly managed during manufacturing.

End-of-life considerations present significant challenges for CFRP materials used in EMI shielding applications. Unlike traditional metal shields that can be readily recycled through established processes, CFRP composites remain difficult to recycle effectively. The thermoset matrices commonly used in CFRP cannot be simply melted and reformed, necessitating complex separation processes to recover carbon fibers. Current recycling methods typically yield downgraded materials with diminished electrical conductivity properties.

Recent advancements in CFRP recycling technologies show promise for improving the environmental profile. Pyrolysis and solvolysis techniques have demonstrated up to 95% recovery of carbon fibers with minimal degradation of electrical properties, potentially maintaining their EMI shielding capabilities in secondary applications. Additionally, research into thermoplastic-based CFRP matrices could significantly enhance recyclability while maintaining the electrical resistivity characteristics essential for EMI shielding.

The environmental impact assessment must also consider the extended lifespan of CFRP-shielded electronics due to superior corrosion resistance compared to metal alternatives, potentially offsetting initial production impacts through reduced replacement frequency and associated resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!