Evaluating CFRP Consistency in Large-Scale Mixing Operations

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Mixing Technology Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in advanced manufacturing over the past four decades. Initially developed for aerospace applications in the 1970s, these composite materials have evolved significantly through continuous innovation in material science and processing technologies. The fundamental principle behind CFRP involves embedding carbon fibers within a polymer matrix to create a material that combines exceptional strength-to-weight ratio with remarkable durability and corrosion resistance.

The evolution of CFRP mixing technology has progressed through several distinct phases. Early methods relied on manual layup techniques with limited consistency and scalability. The 1990s saw the introduction of semi-automated processes, while the 2000s brought significant advancements in computer-controlled mixing systems. Current state-of-the-art approaches incorporate real-time monitoring and adaptive control mechanisms to optimize the mixing process.

Large-scale CFRP production presents unique challenges that differentiate it from laboratory or small-batch manufacturing. The primary technical objective in evaluating CFRP consistency in large-scale mixing operations is to achieve homogeneous dispersion of carbon fibers within the polymer matrix while maintaining precise fiber orientation across the entire production volume. This consistency directly impacts the mechanical properties, structural integrity, and overall performance of the final composite components.

Industry data indicates that even minor variations in mixing parameters can lead to significant inconsistencies in the final product. Research by the National Composites Center has demonstrated that a 5% deviation in fiber distribution can result in up to 15% reduction in tensile strength and 20% decrease in fatigue resistance. These findings underscore the critical importance of developing robust evaluation methodologies for large-scale mixing operations.

The technological trajectory points toward increasingly sophisticated monitoring systems that integrate multiple sensor types, including ultrasonic, optical, and rheological measurements. Machine learning algorithms are being developed to analyze this multi-modal data in real-time, enabling predictive quality control rather than post-production inspection. This shift represents a fundamental change in manufacturing philosophy from detection to prevention of inconsistencies.

Current technical objectives focus on developing standardized protocols for evaluating mixing consistency across different production scales and equipment configurations. These protocols aim to establish quantifiable metrics that correlate with final product performance, enabling manufacturers to optimize their processes based on objective data rather than empirical adjustments. Additionally, there is growing interest in developing in-situ correction mechanisms that can detect and address mixing inconsistencies during the production process.

The evolution of CFRP mixing technology has progressed through several distinct phases. Early methods relied on manual layup techniques with limited consistency and scalability. The 1990s saw the introduction of semi-automated processes, while the 2000s brought significant advancements in computer-controlled mixing systems. Current state-of-the-art approaches incorporate real-time monitoring and adaptive control mechanisms to optimize the mixing process.

Large-scale CFRP production presents unique challenges that differentiate it from laboratory or small-batch manufacturing. The primary technical objective in evaluating CFRP consistency in large-scale mixing operations is to achieve homogeneous dispersion of carbon fibers within the polymer matrix while maintaining precise fiber orientation across the entire production volume. This consistency directly impacts the mechanical properties, structural integrity, and overall performance of the final composite components.

Industry data indicates that even minor variations in mixing parameters can lead to significant inconsistencies in the final product. Research by the National Composites Center has demonstrated that a 5% deviation in fiber distribution can result in up to 15% reduction in tensile strength and 20% decrease in fatigue resistance. These findings underscore the critical importance of developing robust evaluation methodologies for large-scale mixing operations.

The technological trajectory points toward increasingly sophisticated monitoring systems that integrate multiple sensor types, including ultrasonic, optical, and rheological measurements. Machine learning algorithms are being developed to analyze this multi-modal data in real-time, enabling predictive quality control rather than post-production inspection. This shift represents a fundamental change in manufacturing philosophy from detection to prevention of inconsistencies.

Current technical objectives focus on developing standardized protocols for evaluating mixing consistency across different production scales and equipment configurations. These protocols aim to establish quantifiable metrics that correlate with final product performance, enabling manufacturers to optimize their processes based on objective data rather than empirical adjustments. Additionally, there is growing interest in developing in-situ correction mechanisms that can detect and address mixing inconsistencies during the production process.

Market Analysis for Large-Scale CFRP Applications

The global Carbon Fiber Reinforced Polymer (CFRP) market has experienced substantial growth in recent years, driven primarily by increasing demand from aerospace, automotive, and wind energy sectors. The market was valued at approximately 23.8 billion USD in 2021 and is projected to reach 38.6 billion USD by 2027, representing a compound annual growth rate (CAGR) of 8.4%. This growth trajectory underscores the expanding applications of CFRP materials across various industries.

The aerospace sector remains the largest consumer of CFRP materials, accounting for roughly 36% of the total market share. Major aircraft manufacturers like Boeing and Airbus have significantly increased the proportion of composite materials in their latest models, with the Boeing 787 Dreamliner and Airbus A350 XWB incorporating approximately 50% CFRP by weight. This trend is expected to continue as manufacturers seek to reduce aircraft weight and improve fuel efficiency.

The automotive industry represents the fastest-growing segment for large-scale CFRP applications, with a projected CAGR of 11.2% through 2027. Premium automotive manufacturers have led this adoption, with BMW's i-Series and various models from McLaren and Ferrari incorporating significant CFRP components. The push toward electric vehicles has further accelerated this trend, as manufacturers seek to offset battery weight through lightweight structural components.

Wind energy applications constitute another significant market segment, particularly for large wind turbine blades exceeding 80 meters in length. The sector accounts for approximately 18% of global CFRP consumption, with growth closely tied to renewable energy investments worldwide. The need for consistent material properties becomes particularly critical in these large-scale applications, where structural integrity directly impacts operational safety and efficiency.

Regional analysis indicates that North America and Europe currently dominate the market with a combined share of 62%, though Asia-Pacific is experiencing the fastest growth rate at 9.7% annually. China has emerged as a particularly important market, with government initiatives supporting domestic CFRP production capacity expansion and applications in aerospace and renewable energy sectors.

Market challenges include persistent high material costs, with carbon fiber still priced at 15-30 USD per kilogram depending on quality grade, significantly higher than traditional materials. Supply chain constraints and production scalability issues also impact market growth, with particular emphasis on ensuring consistent material properties during large-scale manufacturing processes. The industry's ability to address these consistency challenges in mixing operations will be crucial for unlocking further market potential, especially in cost-sensitive applications.

The aerospace sector remains the largest consumer of CFRP materials, accounting for roughly 36% of the total market share. Major aircraft manufacturers like Boeing and Airbus have significantly increased the proportion of composite materials in their latest models, with the Boeing 787 Dreamliner and Airbus A350 XWB incorporating approximately 50% CFRP by weight. This trend is expected to continue as manufacturers seek to reduce aircraft weight and improve fuel efficiency.

The automotive industry represents the fastest-growing segment for large-scale CFRP applications, with a projected CAGR of 11.2% through 2027. Premium automotive manufacturers have led this adoption, with BMW's i-Series and various models from McLaren and Ferrari incorporating significant CFRP components. The push toward electric vehicles has further accelerated this trend, as manufacturers seek to offset battery weight through lightweight structural components.

Wind energy applications constitute another significant market segment, particularly for large wind turbine blades exceeding 80 meters in length. The sector accounts for approximately 18% of global CFRP consumption, with growth closely tied to renewable energy investments worldwide. The need for consistent material properties becomes particularly critical in these large-scale applications, where structural integrity directly impacts operational safety and efficiency.

Regional analysis indicates that North America and Europe currently dominate the market with a combined share of 62%, though Asia-Pacific is experiencing the fastest growth rate at 9.7% annually. China has emerged as a particularly important market, with government initiatives supporting domestic CFRP production capacity expansion and applications in aerospace and renewable energy sectors.

Market challenges include persistent high material costs, with carbon fiber still priced at 15-30 USD per kilogram depending on quality grade, significantly higher than traditional materials. Supply chain constraints and production scalability issues also impact market growth, with particular emphasis on ensuring consistent material properties during large-scale manufacturing processes. The industry's ability to address these consistency challenges in mixing operations will be crucial for unlocking further market potential, especially in cost-sensitive applications.

Current Challenges in CFRP Consistency Control

The manufacturing of Carbon Fiber Reinforced Polymers (CFRP) at industrial scale presents significant challenges in maintaining consistency throughout the mixing process. Current large-scale operations struggle with several critical issues that impact the final product quality and performance characteristics. These challenges stem from both the inherent properties of carbon fiber materials and the limitations of existing manufacturing technologies.

One of the primary challenges is achieving uniform fiber distribution within the polymer matrix during large batch mixing. As production volumes increase, maintaining homogeneous dispersion becomes exponentially more difficult. Studies indicate that fiber agglomeration and clustering occur more frequently in large-scale operations, creating weak points in the final composite structure and reducing overall mechanical performance by up to 30% compared to laboratory samples.

Temperature control presents another significant hurdle in large-scale CFRP production. The exothermic nature of polymer curing reactions can create thermal gradients across large mixing vessels, leading to inconsistent cure rates and varying degrees of cross-linking. These variations directly impact the glass transition temperature and mechanical properties of the final composite, creating unpredictable performance characteristics across a single production batch.

Viscosity management during mixing operations remains problematic as well. The addition of carbon fibers significantly increases the viscosity of the polymer matrix, making thorough mixing increasingly difficult as batch sizes grow. Current industrial mixers often fail to generate sufficient shear forces throughout the entire volume, resulting in inconsistent fiber wetting and regions of poor interfacial bonding between fibers and the matrix.

Quality control methodologies for large-scale operations present additional challenges. Traditional sampling techniques may not adequately represent the entire batch, as inconsistencies can be localized within specific regions of the mixing vessel. Non-destructive testing methods like ultrasonic inspection and thermography have limited penetration depth in carbon fiber composites, making it difficult to detect internal inconsistencies in thick sections.

Environmental factors such as ambient humidity and temperature fluctuations further complicate consistency control in industrial settings. Carbon fibers can absorb moisture from the environment, affecting their surface chemistry and bonding characteristics with the polymer matrix. Current moisture control systems struggle to maintain optimal conditions throughout extended mixing operations, particularly in facilities located in regions with variable climate conditions.

One of the primary challenges is achieving uniform fiber distribution within the polymer matrix during large batch mixing. As production volumes increase, maintaining homogeneous dispersion becomes exponentially more difficult. Studies indicate that fiber agglomeration and clustering occur more frequently in large-scale operations, creating weak points in the final composite structure and reducing overall mechanical performance by up to 30% compared to laboratory samples.

Temperature control presents another significant hurdle in large-scale CFRP production. The exothermic nature of polymer curing reactions can create thermal gradients across large mixing vessels, leading to inconsistent cure rates and varying degrees of cross-linking. These variations directly impact the glass transition temperature and mechanical properties of the final composite, creating unpredictable performance characteristics across a single production batch.

Viscosity management during mixing operations remains problematic as well. The addition of carbon fibers significantly increases the viscosity of the polymer matrix, making thorough mixing increasingly difficult as batch sizes grow. Current industrial mixers often fail to generate sufficient shear forces throughout the entire volume, resulting in inconsistent fiber wetting and regions of poor interfacial bonding between fibers and the matrix.

Quality control methodologies for large-scale operations present additional challenges. Traditional sampling techniques may not adequately represent the entire batch, as inconsistencies can be localized within specific regions of the mixing vessel. Non-destructive testing methods like ultrasonic inspection and thermography have limited penetration depth in carbon fiber composites, making it difficult to detect internal inconsistencies in thick sections.

Environmental factors such as ambient humidity and temperature fluctuations further complicate consistency control in industrial settings. Carbon fibers can absorb moisture from the environment, affecting their surface chemistry and bonding characteristics with the polymer matrix. Current moisture control systems struggle to maintain optimal conditions throughout extended mixing operations, particularly in facilities located in regions with variable climate conditions.

Existing Quality Control Methods for CFRP Mixing

01 Manufacturing processes for consistent CFRP production

Various manufacturing processes are employed to ensure consistency in CFRP production. These include automated layup techniques, controlled curing processes, and precision molding methods. These processes help maintain uniform fiber distribution, orientation, and resin content throughout the composite material, resulting in consistent mechanical properties and performance characteristics.- Manufacturing processes for consistent CFRP production: Various manufacturing processes are employed to ensure consistency in CFRP production. These include automated layup techniques, controlled curing processes, and precision molding methods that maintain uniform fiber distribution and orientation. Advanced manufacturing technologies help minimize variations in material properties, ensuring consistent mechanical performance across different production batches.

- Quality control methods for CFRP consistency: Quality control methods are essential for maintaining CFRP consistency. These include non-destructive testing techniques, real-time monitoring systems during manufacturing, and standardized inspection protocols. These methods help identify inconsistencies in fiber alignment, resin distribution, and detect potential defects that could affect the structural integrity and performance of the final CFRP components.

- Resin formulation for consistent CFRP properties: The formulation of polymer resins plays a crucial role in achieving consistent CFRP properties. Specialized additives, curing agents, and stabilizers are incorporated to control viscosity, flow behavior, and curing kinetics. These formulations ensure uniform resin distribution throughout the carbon fiber reinforcement, resulting in consistent mechanical, thermal, and chemical properties in the final composite material.

- Fiber alignment and distribution techniques: Techniques for controlling carbon fiber alignment and distribution are critical for CFRP consistency. These include automated fiber placement, specialized weaving methods, and prepreg preparation processes that ensure uniform fiber orientation and spacing. Consistent fiber architecture leads to predictable mechanical properties, reducing variability in strength, stiffness, and impact resistance across the composite structure.

- Environmental conditioning for CFRP stability: Environmental conditioning methods are employed to maintain CFRP consistency throughout its service life. These include moisture control during storage and processing, temperature stabilization techniques, and protective coatings that prevent environmental degradation. These approaches help minimize dimensional changes, maintain mechanical properties, and ensure long-term performance consistency of CFRP components under various operating conditions.

02 Quality control methods for CFRP consistency

Quality control methods are essential for maintaining CFRP consistency. These include non-destructive testing techniques, real-time monitoring systems, and standardized inspection protocols. These methods help identify variations in fiber alignment, resin distribution, void content, and other parameters that could affect the consistency and performance of CFRP components.Expand Specific Solutions03 Resin formulation and fiber treatment for improved consistency

Specific resin formulations and fiber treatments are developed to enhance CFRP consistency. These include modified epoxy systems, sizing agents for carbon fibers, and additives that improve fiber-matrix adhesion. These formulations and treatments help achieve uniform wetting of fibers, consistent curing behavior, and reliable mechanical properties across different production batches.Expand Specific Solutions04 Structural design considerations for consistent CFRP performance

Structural design approaches are implemented to ensure consistent CFRP performance. These include optimized fiber orientation patterns, balanced laminate designs, and strategic reinforcement placement. These design considerations help minimize variations in load distribution, stress concentration, and deformation behavior, resulting in more predictable and consistent performance of CFRP structures.Expand Specific Solutions05 Environmental factors affecting CFRP consistency

Environmental factors significantly impact CFRP consistency during manufacturing and in-service conditions. These include temperature and humidity control during processing, exposure to UV radiation, moisture absorption, and thermal cycling. Understanding and managing these environmental factors is crucial for maintaining consistent physical and mechanical properties of CFRP components throughout their lifecycle.Expand Specific Solutions

Leading CFRP Material Manufacturers and Equipment Providers

The CFRP consistency evaluation market in large-scale mixing operations is currently in a growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The market is projected to reach approximately $3.5 billion by 2025, driven by demand for lightweight, high-strength materials. Leading aerospace companies like Airbus Operations GmbH are pioneering advanced mixing technologies, while academic institutions including Xi'an Jiaotong University and Beihang University are developing innovative evaluation methodologies. The technology landscape shows varying maturity levels, with established players such as Illinois Tool Works and Schlumberger offering commercial solutions, while emerging companies like Precision Combustion are introducing disruptive technologies. Research collaboration between industry leaders and academic institutions is accelerating standardization efforts and improving quality control processes for large-scale CFRP production.

Airbus Operations GmbH

Technical Solution: Airbus has developed an advanced CFRP (Carbon Fiber Reinforced Polymer) consistency evaluation system for large-scale mixing operations that combines real-time monitoring with predictive analytics. Their approach utilizes distributed sensor networks throughout mixing vessels to continuously monitor critical parameters including viscosity, temperature gradients, fiber orientation, and resin distribution. The system employs ultrasonic testing and rheological analysis during the mixing process to detect inconsistencies before composite layup. Airbus has implemented machine learning algorithms that analyze historical mixing data to predict potential quality issues and automatically adjust mixing parameters. Their manufacturing facilities utilize automated mixing systems with precise control over mixing speed, temperature, and duration to ensure batch-to-batch consistency. Additionally, Airbus has developed specialized non-destructive testing methods for final verification of CFRP consistency that can detect microscopic variations in material properties.

Strengths: Superior integration with aircraft manufacturing processes, extensive historical data for machine learning models, and comprehensive quality control systems. Their approach reduces waste by identifying inconsistencies early in production. Weaknesses: High implementation costs, system complexity requiring specialized training, and potential challenges in adapting the technology to non-aerospace applications with different material requirements.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed a multi-faceted approach to evaluating CFRP consistency in large-scale mixing operations through their "TotalMix" quality assurance system. This comprehensive solution combines mechanical, optical, and chemical analysis techniques to ensure uniform fiber distribution and resin properties. ITW's system employs proprietary mixing equipment with integrated torque monitoring that continuously measures resistance changes during the mixing process, providing real-time feedback on material consistency. Their approach includes automated sampling systems that extract material at predetermined intervals for immediate rheological testing and fiber orientation analysis. The company has pioneered the use of high-resolution optical scanning technology that creates detailed 3D maps of fiber distribution within test samples, allowing for quantitative assessment of mixing uniformity. ITW's system also incorporates thermal analysis techniques that evaluate cure behavior consistency across batches, ensuring predictable performance in final applications. Additionally, they've developed specialized software that tracks mixing parameters across production runs to identify trends and optimize processes for maximum consistency.

Strengths: Extensive experience across multiple industries provides versatile application knowledge, robust mechanical engineering approach to mixing equipment design, and strong focus on practical implementation in manufacturing environments. Their systems are designed for high-volume production with minimal operator intervention. Weaknesses: Less specialized in aerospace-grade materials compared to dedicated aerospace manufacturers, and potentially less advanced in predictive analytics compared to companies with larger data science teams.

Key Innovations in CFRP Consistency Evaluation

Thermoplastic impregnation of large tow textile grade carbon fiber

PatentPendingUS20250091254A1

Innovation

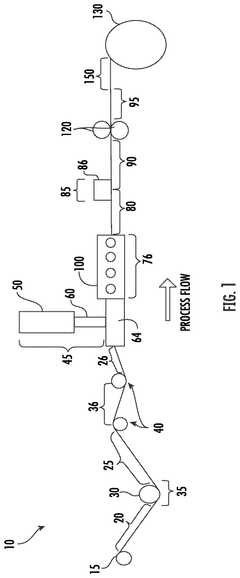

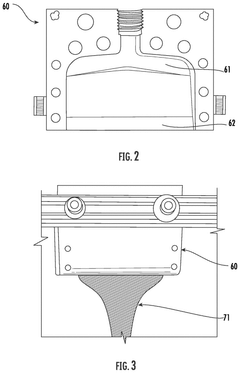

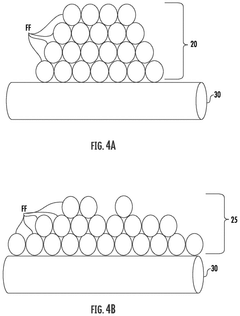

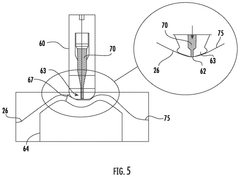

- A process and system for impregnating large carbon fiber tows with polymers, involving spreading, heating, extruding molten polymer resin through a die, and mechanically contacting the fibers to achieve full impregnation, resulting in a cost-effective CFRP intermediate product with a 30-70% fiber weight fraction, suitable for various manufacturing processes.

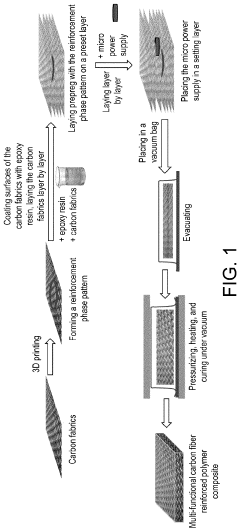

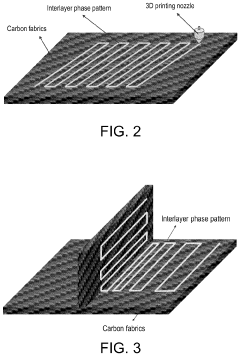

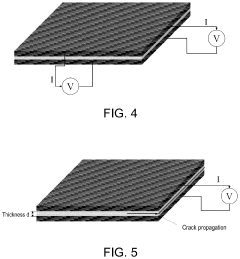

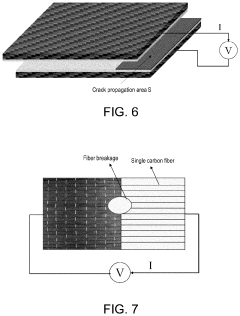

Preparation method and product of carbon fiber reinforced polymer composite with designable characteristic structure

PatentActiveUS11952472B2

Innovation

- A CFRP preparation method with a designable characteristic structure incorporating multiple layers of carbon fabric and a micro power supply for in-situ damage detection, using conductive carbon fibers to monitor resistance changes and embed sensors for precise, accurate, and intelligent real-time feedback, eliminating the need for external power sources and enhancing repairability.

Environmental Impact of CFRP Manufacturing Processes

The manufacturing of Carbon Fiber Reinforced Polymers (CFRP) presents significant environmental challenges that must be addressed as production scales increase. The carbon fiber production process is notably energy-intensive, consuming between 200-400 MJ/kg of energy, primarily from electricity and natural gas. This high energy demand translates to substantial greenhouse gas emissions, with estimates suggesting that carbon fiber production generates 20-30 kg CO2 equivalent per kilogram of material produced.

Large-scale mixing operations in CFRP manufacturing introduce additional environmental concerns. The resins commonly used, such as epoxies and polyesters, contain volatile organic compounds (VOCs) that are released during mixing and curing processes. These emissions contribute to air pollution and can pose health risks to workers and surrounding communities. Measurements from industrial facilities indicate VOC emissions ranging from 2-5% of total resin weight during processing.

Water usage represents another critical environmental factor in CFRP production. The manufacturing process requires significant quantities of water for cooling and washing operations, with estimates of 10-15 liters per kilogram of finished CFRP. Wastewater from these processes often contains chemical contaminants including sizing agents, catalysts, and resin residues that require specialized treatment before discharge.

Chemical waste management presents ongoing challenges in CFRP manufacturing. The hardeners, accelerators, and other additives used in large-scale mixing operations can generate hazardous waste streams. Industry data indicates that approximately 5-8% of raw materials become waste during production. These materials require proper disposal protocols to prevent environmental contamination.

The end-of-life considerations for CFRP components remain problematic. Unlike traditional materials, CFRP products are difficult to recycle due to the heterogeneous nature of the composite. Current recycling technologies recover only 30-40% of the original material value, with the remainder typically directed to landfills or incineration, both of which carry additional environmental impacts.

Recent innovations in CFRP manufacturing are beginning to address these environmental concerns. Bio-based resins derived from renewable resources can reduce the carbon footprint by 15-25% compared to petroleum-based alternatives. Closed-loop water systems have demonstrated water usage reductions of up to 60% in pilot implementations. Additionally, solvent-free mixing technologies are emerging that can eliminate VOC emissions almost entirely while maintaining product consistency.

Large-scale mixing operations in CFRP manufacturing introduce additional environmental concerns. The resins commonly used, such as epoxies and polyesters, contain volatile organic compounds (VOCs) that are released during mixing and curing processes. These emissions contribute to air pollution and can pose health risks to workers and surrounding communities. Measurements from industrial facilities indicate VOC emissions ranging from 2-5% of total resin weight during processing.

Water usage represents another critical environmental factor in CFRP production. The manufacturing process requires significant quantities of water for cooling and washing operations, with estimates of 10-15 liters per kilogram of finished CFRP. Wastewater from these processes often contains chemical contaminants including sizing agents, catalysts, and resin residues that require specialized treatment before discharge.

Chemical waste management presents ongoing challenges in CFRP manufacturing. The hardeners, accelerators, and other additives used in large-scale mixing operations can generate hazardous waste streams. Industry data indicates that approximately 5-8% of raw materials become waste during production. These materials require proper disposal protocols to prevent environmental contamination.

The end-of-life considerations for CFRP components remain problematic. Unlike traditional materials, CFRP products are difficult to recycle due to the heterogeneous nature of the composite. Current recycling technologies recover only 30-40% of the original material value, with the remainder typically directed to landfills or incineration, both of which carry additional environmental impacts.

Recent innovations in CFRP manufacturing are beginning to address these environmental concerns. Bio-based resins derived from renewable resources can reduce the carbon footprint by 15-25% compared to petroleum-based alternatives. Closed-loop water systems have demonstrated water usage reductions of up to 60% in pilot implementations. Additionally, solvent-free mixing technologies are emerging that can eliminate VOC emissions almost entirely while maintaining product consistency.

Standardization and Certification Requirements for CFRP Production

The standardization and certification landscape for Carbon Fiber Reinforced Polymer (CFRP) production has evolved significantly in response to growing industry demands for consistency and quality assurance, particularly in large-scale mixing operations. Current international standards such as ISO 11357 for thermal analysis and ASTM D3171 for fiber content determination provide foundational frameworks, but remain insufficient for comprehensive quality control in advanced manufacturing environments.

Industry-specific certifications have emerged to address these gaps, with aerospace standards like AS9100 and NADCAP imposing rigorous requirements for CFRP production processes. These certifications mandate detailed documentation of mixing parameters, environmental controls, and material traceability—critical factors for ensuring batch-to-batch consistency in large-scale operations.

Material qualification protocols represent another crucial aspect of the certification framework. These typically require manufacturers to demonstrate statistical process control capabilities through extensive testing regimes that validate mixing homogeneity across production scales. The aerospace industry, for instance, often requires a minimum of 30 consecutive production runs with consistent results before granting material qualification status.

Testing methodologies for certification purposes have become increasingly sophisticated, incorporating rheological analysis, differential scanning calorimetry (DSC), and dynamic mechanical analysis (DMA) to characterize resin behavior during mixing operations. These advanced techniques enable manufacturers to establish quantifiable metrics for consistency evaluation, moving beyond traditional qualitative assessments.

Regulatory compliance adds another layer of complexity, with regional variations in environmental and safety standards affecting CFRP production certification. The European Union's REACH regulations impose strict documentation requirements for chemical constituents, while North American standards focus more heavily on process validation and statistical quality control methodologies.

Emerging certification trends point toward increased emphasis on digital verification systems, with blockchain-based traceability and real-time monitoring becoming integral components of next-generation certification frameworks. These technologies enable continuous validation of mixing parameters against established standards, facilitating more responsive quality control systems.

For manufacturers seeking to optimize large-scale CFRP mixing operations, a strategic approach to certification involves early engagement with certification bodies, implementation of robust statistical process control methodologies, and investment in advanced monitoring technologies that align with evolving industry standards. This proactive stance not only ensures regulatory compliance but also positions organizations to adapt to increasingly stringent certification requirements in high-performance CFRP applications.

Industry-specific certifications have emerged to address these gaps, with aerospace standards like AS9100 and NADCAP imposing rigorous requirements for CFRP production processes. These certifications mandate detailed documentation of mixing parameters, environmental controls, and material traceability—critical factors for ensuring batch-to-batch consistency in large-scale operations.

Material qualification protocols represent another crucial aspect of the certification framework. These typically require manufacturers to demonstrate statistical process control capabilities through extensive testing regimes that validate mixing homogeneity across production scales. The aerospace industry, for instance, often requires a minimum of 30 consecutive production runs with consistent results before granting material qualification status.

Testing methodologies for certification purposes have become increasingly sophisticated, incorporating rheological analysis, differential scanning calorimetry (DSC), and dynamic mechanical analysis (DMA) to characterize resin behavior during mixing operations. These advanced techniques enable manufacturers to establish quantifiable metrics for consistency evaluation, moving beyond traditional qualitative assessments.

Regulatory compliance adds another layer of complexity, with regional variations in environmental and safety standards affecting CFRP production certification. The European Union's REACH regulations impose strict documentation requirements for chemical constituents, while North American standards focus more heavily on process validation and statistical quality control methodologies.

Emerging certification trends point toward increased emphasis on digital verification systems, with blockchain-based traceability and real-time monitoring becoming integral components of next-generation certification frameworks. These technologies enable continuous validation of mixing parameters against established standards, facilitating more responsive quality control systems.

For manufacturers seeking to optimize large-scale CFRP mixing operations, a strategic approach to certification involves early engagement with certification bodies, implementation of robust statistical process control methodologies, and investment in advanced monitoring technologies that align with evolving industry standards. This proactive stance not only ensures regulatory compliance but also positions organizations to adapt to increasingly stringent certification requirements in high-performance CFRP applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!