How to Reduce CFRP Skin Friction for Improved Aerodynamics

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Aerodynamic Friction Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) has revolutionized aerospace engineering since its commercial introduction in the 1970s. Initially limited to military applications, CFRP has progressively expanded into commercial aviation due to its exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. The evolution of CFRP technology has been marked by continuous improvements in manufacturing processes, from manual layup methods to automated fiber placement systems, enabling more complex and precise structures.

Despite these advancements, the aerodynamic performance of CFRP surfaces remains a significant challenge. The inherent surface characteristics of CFRP components, including micro-roughness from fiber patterns and resin distribution, create increased skin friction compared to traditional metallic surfaces. This friction generates additional drag that compromises the aerodynamic efficiency of aircraft, ultimately affecting fuel consumption and operational costs.

The aerospace industry has established that even minor reductions in skin friction can yield substantial improvements in fuel efficiency. Research indicates that a 1% reduction in total aircraft drag can translate to approximately 0.2% fuel savings, which accumulates to significant operational cost reductions over an aircraft's lifecycle. With global aviation fuel costs exceeding $180 billion annually, the economic incentive for optimizing CFRP aerodynamics is compelling.

Current technical objectives in this field focus on developing surface treatments and coatings that can minimize the micro-roughness of CFRP without compromising its structural integrity or adding significant weight. These include nano-engineered coatings, biomimetic surface designs inspired by natural low-drag surfaces like shark skin, and advanced manufacturing techniques that control fiber orientation and resin distribution to optimize surface smoothness.

Another emerging objective is the development of smart surfaces that can adapt to changing flight conditions, potentially incorporating shape-memory polymers or electro-active materials that modify surface characteristics in response to airflow patterns. These adaptive surfaces represent a paradigm shift from static to dynamic drag reduction strategies.

The environmental impact of aviation has intensified the urgency of these research objectives. With increasing regulatory pressure to reduce carbon emissions, improving aerodynamic efficiency through reduced skin friction has become not just an economic consideration but an environmental imperative. The International Civil Aviation Organization (ICAO) has set ambitious targets for carbon-neutral growth from 2020 onward, making drag reduction technologies critical components of sustainability strategies.

This technical exploration aims to comprehensively assess current approaches to CFRP skin friction reduction, identify promising research directions, and evaluate their potential impact on next-generation aircraft design and performance.

Despite these advancements, the aerodynamic performance of CFRP surfaces remains a significant challenge. The inherent surface characteristics of CFRP components, including micro-roughness from fiber patterns and resin distribution, create increased skin friction compared to traditional metallic surfaces. This friction generates additional drag that compromises the aerodynamic efficiency of aircraft, ultimately affecting fuel consumption and operational costs.

The aerospace industry has established that even minor reductions in skin friction can yield substantial improvements in fuel efficiency. Research indicates that a 1% reduction in total aircraft drag can translate to approximately 0.2% fuel savings, which accumulates to significant operational cost reductions over an aircraft's lifecycle. With global aviation fuel costs exceeding $180 billion annually, the economic incentive for optimizing CFRP aerodynamics is compelling.

Current technical objectives in this field focus on developing surface treatments and coatings that can minimize the micro-roughness of CFRP without compromising its structural integrity or adding significant weight. These include nano-engineered coatings, biomimetic surface designs inspired by natural low-drag surfaces like shark skin, and advanced manufacturing techniques that control fiber orientation and resin distribution to optimize surface smoothness.

Another emerging objective is the development of smart surfaces that can adapt to changing flight conditions, potentially incorporating shape-memory polymers or electro-active materials that modify surface characteristics in response to airflow patterns. These adaptive surfaces represent a paradigm shift from static to dynamic drag reduction strategies.

The environmental impact of aviation has intensified the urgency of these research objectives. With increasing regulatory pressure to reduce carbon emissions, improving aerodynamic efficiency through reduced skin friction has become not just an economic consideration but an environmental imperative. The International Civil Aviation Organization (ICAO) has set ambitious targets for carbon-neutral growth from 2020 onward, making drag reduction technologies critical components of sustainability strategies.

This technical exploration aims to comprehensively assess current approaches to CFRP skin friction reduction, identify promising research directions, and evaluate their potential impact on next-generation aircraft design and performance.

Market Analysis for Low-Drag CFRP Applications

The global market for low-drag Carbon Fiber Reinforced Polymer (CFRP) applications is experiencing significant growth, driven by increasing demands for fuel efficiency and reduced emissions across multiple industries. The aerospace sector currently represents the largest market segment, with commercial aviation leading the adoption of CFRP materials to improve aerodynamic performance and reduce operational costs.

Market research indicates that the automotive industry is rapidly emerging as the second-largest consumer of low-drag CFRP solutions, particularly in high-performance and electric vehicle segments where range extension is critical. This market is projected to grow at a compound annual rate exceeding that of traditional materials as manufacturers seek to meet stringent emissions regulations while maintaining or improving vehicle performance.

The marine industry represents another substantial market opportunity, with racing yachts and commercial vessels increasingly utilizing low-drag CFRP components to reduce hydrodynamic resistance and fuel consumption. Similarly, the wind energy sector has begun incorporating aerodynamically optimized CFRP in turbine blade design to increase energy capture efficiency.

Regional analysis reveals that North America and Europe currently dominate the market for low-drag CFRP applications, largely due to the concentration of aerospace and automotive manufacturing in these regions. However, the Asia-Pacific market is demonstrating the fastest growth rate, driven by expanding aerospace and automotive manufacturing capabilities in China and Japan.

Consumer demand patterns indicate a growing willingness to pay premium prices for products offering demonstrable efficiency improvements. This trend is particularly evident in commercial aviation, where fuel costs represent a significant portion of operational expenses, creating strong economic incentives for technologies that reduce aerodynamic drag.

Market barriers include the relatively high production costs of specialized low-drag CFRP compared to conventional materials, and technical challenges related to manufacturing consistency at scale. Despite these challenges, the market is expected to continue expanding as production technologies mature and economies of scale improve cost structures.

Industry forecasts suggest that technologies specifically focused on reducing skin friction in CFRP applications will see accelerated adoption as manufacturers seek to extract maximum aerodynamic performance from composite structures. This specialized segment is attracting significant investment in research and development, particularly for applications where even marginal improvements in drag reduction translate to substantial operational benefits.

Market research indicates that the automotive industry is rapidly emerging as the second-largest consumer of low-drag CFRP solutions, particularly in high-performance and electric vehicle segments where range extension is critical. This market is projected to grow at a compound annual rate exceeding that of traditional materials as manufacturers seek to meet stringent emissions regulations while maintaining or improving vehicle performance.

The marine industry represents another substantial market opportunity, with racing yachts and commercial vessels increasingly utilizing low-drag CFRP components to reduce hydrodynamic resistance and fuel consumption. Similarly, the wind energy sector has begun incorporating aerodynamically optimized CFRP in turbine blade design to increase energy capture efficiency.

Regional analysis reveals that North America and Europe currently dominate the market for low-drag CFRP applications, largely due to the concentration of aerospace and automotive manufacturing in these regions. However, the Asia-Pacific market is demonstrating the fastest growth rate, driven by expanding aerospace and automotive manufacturing capabilities in China and Japan.

Consumer demand patterns indicate a growing willingness to pay premium prices for products offering demonstrable efficiency improvements. This trend is particularly evident in commercial aviation, where fuel costs represent a significant portion of operational expenses, creating strong economic incentives for technologies that reduce aerodynamic drag.

Market barriers include the relatively high production costs of specialized low-drag CFRP compared to conventional materials, and technical challenges related to manufacturing consistency at scale. Despite these challenges, the market is expected to continue expanding as production technologies mature and economies of scale improve cost structures.

Industry forecasts suggest that technologies specifically focused on reducing skin friction in CFRP applications will see accelerated adoption as manufacturers seek to extract maximum aerodynamic performance from composite structures. This specialized segment is attracting significant investment in research and development, particularly for applications where even marginal improvements in drag reduction translate to substantial operational benefits.

Current Challenges in CFRP Surface Friction Reduction

Despite significant advancements in carbon fiber reinforced polymer (CFRP) manufacturing, the reduction of skin friction for aerodynamic applications remains a persistent challenge. The inherent surface characteristics of CFRP composites often result in higher drag coefficients compared to traditional metallic materials, limiting their aerodynamic efficiency. Current manufacturing processes struggle to consistently produce CFRP surfaces with the ultra-smooth finish required for optimal aerodynamic performance, particularly at high speeds.

Surface roughness presents the most immediate challenge, as CFRP components typically exhibit micro-irregularities resulting from fiber orientation, resin distribution, and tooling marks. These irregularities, though microscopic, create turbulent boundary layers that significantly increase skin friction drag. Even state-of-the-art autoclave curing processes cannot entirely eliminate these surface imperfections without additional finishing operations.

The heterogeneous nature of CFRP materials compounds the difficulty, as carbon fibers and polymer matrix have different thermal expansion coefficients and mechanical properties. This heterogeneity leads to differential shrinkage during curing, creating surface waviness that affects aerodynamic performance. Current manufacturing techniques have not fully resolved this issue, especially for large-scale components used in aerospace applications.

Environmental degradation poses another significant challenge. CFRP surfaces exposed to operational environments experience erosion, UV damage, and moisture absorption, all of which progressively degrade surface quality and increase friction. Existing protective coatings often add weight or alter the aerodynamic profile, creating a difficult engineering trade-off between protection and performance.

Cost-effective surface treatment technologies represent a substantial hurdle. While techniques such as precision machining, polishing, and application of specialized coatings can improve surface quality, they significantly increase production costs and time. The aerospace and automotive industries continue to seek economically viable solutions that can be implemented at scale without compromising structural integrity or adding excessive weight.

Integration challenges exist between friction reduction technologies and other functional requirements. For instance, incorporating riblets or other drag-reducing surface modifications must be balanced with requirements for lightning strike protection, ice resistance, and maintainability. Current solutions often address these requirements separately, resulting in compromised aerodynamic performance.

Measurement and quality control of CFRP surface properties present additional difficulties. Conventional surface roughness parameters may not adequately characterize the complex surface topography of CFRP materials in terms of their aerodynamic impact. More sophisticated metrology approaches are needed to accurately predict and optimize the aerodynamic performance of CFRP components.

Surface roughness presents the most immediate challenge, as CFRP components typically exhibit micro-irregularities resulting from fiber orientation, resin distribution, and tooling marks. These irregularities, though microscopic, create turbulent boundary layers that significantly increase skin friction drag. Even state-of-the-art autoclave curing processes cannot entirely eliminate these surface imperfections without additional finishing operations.

The heterogeneous nature of CFRP materials compounds the difficulty, as carbon fibers and polymer matrix have different thermal expansion coefficients and mechanical properties. This heterogeneity leads to differential shrinkage during curing, creating surface waviness that affects aerodynamic performance. Current manufacturing techniques have not fully resolved this issue, especially for large-scale components used in aerospace applications.

Environmental degradation poses another significant challenge. CFRP surfaces exposed to operational environments experience erosion, UV damage, and moisture absorption, all of which progressively degrade surface quality and increase friction. Existing protective coatings often add weight or alter the aerodynamic profile, creating a difficult engineering trade-off between protection and performance.

Cost-effective surface treatment technologies represent a substantial hurdle. While techniques such as precision machining, polishing, and application of specialized coatings can improve surface quality, they significantly increase production costs and time. The aerospace and automotive industries continue to seek economically viable solutions that can be implemented at scale without compromising structural integrity or adding excessive weight.

Integration challenges exist between friction reduction technologies and other functional requirements. For instance, incorporating riblets or other drag-reducing surface modifications must be balanced with requirements for lightning strike protection, ice resistance, and maintainability. Current solutions often address these requirements separately, resulting in compromised aerodynamic performance.

Measurement and quality control of CFRP surface properties present additional difficulties. Conventional surface roughness parameters may not adequately characterize the complex surface topography of CFRP materials in terms of their aerodynamic impact. More sophisticated metrology approaches are needed to accurately predict and optimize the aerodynamic performance of CFRP components.

Existing CFRP Skin Friction Reduction Solutions

01 Surface treatments for reducing skin friction in CFRP

Various surface treatments can be applied to Carbon Fiber Reinforced Polymer (CFRP) components to reduce skin friction. These treatments include specialized coatings, surface texturing, and chemical modifications that alter the surface properties of the CFRP. By reducing the coefficient of friction, these treatments can improve aerodynamic performance and reduce drag in applications such as aircraft components and high-speed vehicles.- Surface treatments to reduce skin friction in CFRP: Various surface treatments can be applied to Carbon Fiber Reinforced Polymer (CFRP) materials to reduce skin friction. These treatments include coating applications, surface texturing, and chemical modifications that alter the surface properties of the CFRP. By modifying the surface characteristics, the aerodynamic or hydrodynamic performance of CFRP components can be significantly improved, reducing drag and enhancing efficiency in applications such as aircraft components and marine structures.

- CFRP composite structures with optimized friction properties: Specialized CFRP composite structures can be engineered with optimized friction properties. These structures incorporate specific fiber orientations, resin systems, and layup configurations designed to achieve desired friction characteristics. By controlling the composition and architecture of the composite, manufacturers can create CFRP components with tailored friction properties suitable for specific applications, such as aerospace components, automotive parts, and industrial equipment where controlled friction is critical for performance.

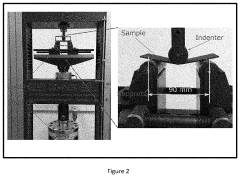

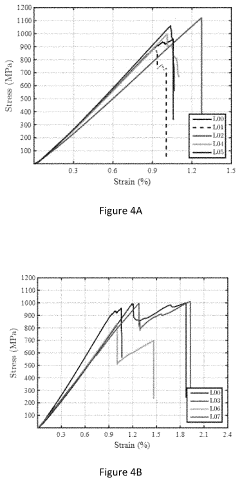

- Friction testing methods for CFRP materials: Various testing methodologies have been developed to accurately measure and characterize the skin friction properties of CFRP materials. These methods include tribological testing, wind tunnel testing, and specialized friction coefficient measurement techniques. Advanced sensors and measurement systems are employed to gather precise data on how CFRP surfaces interact with different media under various conditions, providing essential information for design optimization and performance prediction in applications where friction characteristics are critical.

- CFRP friction components for braking systems: CFRP materials are increasingly used in friction components for high-performance braking systems. The unique properties of carbon fiber reinforced polymers, including high temperature resistance, lightweight characteristics, and controllable friction coefficients, make them ideal for brake discs, pads, and other friction elements. These components offer advantages such as reduced weight, improved heat dissipation, and consistent friction performance under extreme conditions, particularly valuable in aerospace, automotive racing, and other demanding applications.

- Nano-modified CFRP surfaces for friction control: Nanotechnology applications in CFRP surface modification offer advanced approaches to friction control. By incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the surface layers of CFRP components, significant improvements in friction properties can be achieved. These nano-modified surfaces provide enhanced wear resistance, self-lubricating properties, and precisely controlled friction coefficients, enabling CFRP components to perform optimally in applications where surface interaction characteristics are critical to overall system performance.

02 Structural design modifications for CFRP friction reduction

Specific structural design modifications can be implemented in CFRP components to reduce skin friction. These include optimized fiber orientation, layering techniques, and geometric configurations that minimize surface roughness. By carefully designing the structure of CFRP components, manufacturers can achieve smoother surfaces with lower friction coefficients, which is particularly important in aerospace and automotive applications where drag reduction is critical.Expand Specific Solutions03 Composite material formulations for improved friction properties

Advanced formulations of CFRP materials can be developed with specific additives and matrix modifications to improve friction characteristics. These formulations may include specialized resins, nanomaterials, and friction-modifying agents that are incorporated during the manufacturing process. The resulting composite materials exhibit enhanced surface properties with reduced friction coefficients while maintaining the high strength-to-weight ratio that makes CFRP desirable for various applications.Expand Specific Solutions04 Testing and measurement methods for CFRP skin friction

Specialized testing and measurement techniques have been developed to accurately assess the skin friction properties of CFRP materials. These methods include advanced surface profilometry, friction coefficient testing under various conditions, and computational fluid dynamics simulations. By employing these testing methodologies, engineers can quantify the friction characteristics of CFRP components and validate the effectiveness of friction reduction strategies in real-world applications.Expand Specific Solutions05 Manufacturing processes to control CFRP surface friction

Innovative manufacturing processes have been developed to control and optimize the surface friction properties of CFRP components. These processes include specialized molding techniques, precision machining methods, and post-production treatments that result in smoother surfaces with controlled friction characteristics. By implementing these manufacturing approaches, producers can create CFRP components with consistent and predictable friction properties for applications where precise control of skin friction is essential.Expand Specific Solutions

Leading Companies in Aerospace CFRP Innovation

The CFRP skin friction reduction market is in its growth phase, with increasing demand for aerodynamic efficiency in aerospace applications. The global market is estimated to reach $2-3 billion by 2025, driven by fuel efficiency requirements and carbon emission regulations. Leading aerospace manufacturers Airbus and Boeing are at the forefront of this technology, with significant R&D investments in surface modification techniques. Academic institutions like Northwestern Polytechnical University and University of Tokyo are advancing fundamental research, while specialized materials companies such as SGL Carbon and Integran Technologies are developing innovative surface treatments. Japanese entities including JAXA and Nippon Steel are making notable contributions in nano-coating technologies, positioning themselves as key players in this emerging field.

Airbus Operations GmbH

Technical Solution: Airbus has developed a multi-faceted approach to reduce CFRP skin friction for improved aerodynamics. Their primary technology involves applying specialized surface coatings with nano-structured materials that create a hydrophobic effect on carbon fiber surfaces. This "riblet film" technology creates microscopic grooves on the aircraft surface that can reduce turbulent skin friction by up to 8%. Airbus has also pioneered laser surface texturing techniques that modify CFRP surfaces at the microscale level, creating patterns that disrupt boundary layer formation. Their BLADE (Breakthrough Laminar Aircraft Demonstrator in Europe) program specifically tests these technologies on A340 test aircraft, demonstrating drag reduction of approximately 10% compared to conventional designs. Additionally, Airbus employs computational fluid dynamics (CFD) modeling to optimize surface treatments before physical implementation, reducing development cycles significantly.

Strengths: Airbus's solutions are already flight-tested and proven to deliver measurable drag reduction in real-world conditions. Their integrated approach combining surface treatments with aerodynamic design offers comprehensive benefits. Weaknesses: The technologies require precise manufacturing tolerances and may add maintenance complexity over the aircraft lifecycle. Some surface treatments may degrade over time requiring periodic renewal.

The Boeing Co.

Technical Solution: Boeing has developed an innovative approach to CFRP skin friction reduction through their proprietary micro-vortex generator (MVG) technology. This system employs precisely engineered surface modifications to the carbon fiber composite skin that create controlled micro-vortices in the boundary layer. These vortices effectively reduce skin friction by altering the air flow characteristics across the surface. Boeing's technology includes a specialized manufacturing process that integrates these features directly during the CFRP layup process, eliminating the need for secondary operations. Their ecoDemonstrator program has tested these surfaces extensively, showing drag reductions of 1-2% across the aircraft, which translates to significant fuel savings. Boeing has also developed specialized surface sealants with embedded lubricating particles that gradually migrate to the surface during flight, maintaining low-friction properties throughout extended service periods.

Strengths: Boeing's approach integrates friction reduction features directly into the manufacturing process, avoiding add-on solutions that might deteriorate. Their technology has been validated through extensive flight testing on commercial aircraft. Weaknesses: The manufacturing complexity increases production costs initially, and the technology requires precise quality control to ensure consistent performance across large surface areas.

Key Patents in CFRP Surface Modification

Bio-inspired composite laminate design with high out-of-plane strength and ductility

PatentActiveUS11207867B1

Innovation

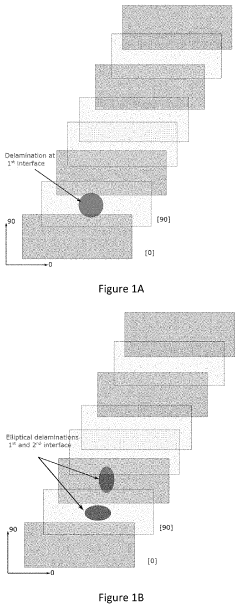

- Bio-inspired CFRP composite laminates are designed with intentionally introduced delaminations at specific positions and sizes during the lamination process to control crack propagation and enhance ductility, featuring a pseudo-ductile response with increased failure strain and energy absorption.

Polybutadiyne coated carbon fiber reinforced polymer composites

PatentInactiveUS4918117A

Innovation

- The use of vapor-deposited polybutadiyne as a coating for carbon fibers, which is formed by simultaneously depositing and polymerizing butadiyne monomers, creating a closely adherent film that promotes adhesion between the fibers and the matrix resin, with mild reaction temperatures and exceptional thermal stability, suitable for use in organic polymer matrix composites.

Environmental Impact of CFRP Surface Treatments

The environmental implications of Carbon Fiber Reinforced Polymer (CFRP) surface treatments for aerodynamic improvement warrant careful consideration as aerospace industries increasingly adopt these advanced materials. Traditional surface treatments often involve chemical processes that release volatile organic compounds (VOCs) and hazardous air pollutants, contributing to air quality degradation and potential health risks for workers in manufacturing facilities.

Chemical polishing and etching methods commonly used to reduce skin friction typically employ strong acids, solvents, and other environmentally problematic substances. These processes generate significant hazardous waste streams that require specialized disposal procedures, increasing both environmental burden and operational costs. For instance, chromic acid treatments, while effective for surface preparation, pose serious environmental and health concerns due to hexavalent chromium content.

Water consumption represents another critical environmental factor, as many surface finishing techniques require substantial amounts of water for processing and rinsing. This becomes particularly problematic in regions facing water scarcity issues. Additionally, the energy intensity of certain treatments, especially thermal processes used for surface modification, contributes to the carbon footprint of CFRP components, potentially offsetting some of the environmental benefits gained through improved aerodynamics.

Newer, more environmentally friendly approaches are emerging in response to these challenges. Plasma treatments offer a lower-impact alternative by modifying surface properties without chemical waste generation. Similarly, laser texturing techniques provide precise surface modification with minimal environmental impact, though their energy requirements must be considered in overall assessment.

Nanocoating technologies present promising solutions with potentially reduced environmental impacts. These ultra-thin coatings require minimal material input while delivering significant friction reduction benefits. However, the environmental fate and potential toxicity of nanoparticles remain subjects of ongoing research and regulatory scrutiny.

Life cycle assessment (LCA) studies indicate that despite initial environmental costs, optimized CFRP surfaces can yield net environmental benefits through operational fuel savings over aircraft lifespans. A comprehensive analysis suggests that a 1% reduction in drag can translate to approximately 0.75% fuel savings, potentially justifying more resource-intensive surface treatments from a full life-cycle perspective.

Regulatory frameworks worldwide are increasingly restricting traditional surface treatment chemicals, driving innovation toward greener alternatives. The aerospace industry's shift toward more sustainable manufacturing practices has accelerated research into bio-based surface treatments and environmentally benign processing methods that maintain performance while reducing ecological impact.

Chemical polishing and etching methods commonly used to reduce skin friction typically employ strong acids, solvents, and other environmentally problematic substances. These processes generate significant hazardous waste streams that require specialized disposal procedures, increasing both environmental burden and operational costs. For instance, chromic acid treatments, while effective for surface preparation, pose serious environmental and health concerns due to hexavalent chromium content.

Water consumption represents another critical environmental factor, as many surface finishing techniques require substantial amounts of water for processing and rinsing. This becomes particularly problematic in regions facing water scarcity issues. Additionally, the energy intensity of certain treatments, especially thermal processes used for surface modification, contributes to the carbon footprint of CFRP components, potentially offsetting some of the environmental benefits gained through improved aerodynamics.

Newer, more environmentally friendly approaches are emerging in response to these challenges. Plasma treatments offer a lower-impact alternative by modifying surface properties without chemical waste generation. Similarly, laser texturing techniques provide precise surface modification with minimal environmental impact, though their energy requirements must be considered in overall assessment.

Nanocoating technologies present promising solutions with potentially reduced environmental impacts. These ultra-thin coatings require minimal material input while delivering significant friction reduction benefits. However, the environmental fate and potential toxicity of nanoparticles remain subjects of ongoing research and regulatory scrutiny.

Life cycle assessment (LCA) studies indicate that despite initial environmental costs, optimized CFRP surfaces can yield net environmental benefits through operational fuel savings over aircraft lifespans. A comprehensive analysis suggests that a 1% reduction in drag can translate to approximately 0.75% fuel savings, potentially justifying more resource-intensive surface treatments from a full life-cycle perspective.

Regulatory frameworks worldwide are increasingly restricting traditional surface treatment chemicals, driving innovation toward greener alternatives. The aerospace industry's shift toward more sustainable manufacturing practices has accelerated research into bio-based surface treatments and environmentally benign processing methods that maintain performance while reducing ecological impact.

Cost-Benefit Analysis of Advanced CFRP Solutions

When evaluating advanced CFRP (Carbon Fiber Reinforced Polymer) solutions for reducing skin friction and improving aerodynamics, a comprehensive cost-benefit analysis is essential to determine economic viability alongside technical performance.

Initial implementation costs for advanced CFRP surface treatments represent a significant investment. Manufacturing processes such as micro-texturing, nano-coating applications, and precision molding techniques require specialized equipment and expertise. Current estimates indicate that implementing these advanced solutions can increase production costs by 15-30% compared to standard CFRP manufacturing processes, depending on the complexity of the aerodynamic requirements.

Operational benefits must be quantified against these increased costs. Reduced skin friction from optimized CFRP surfaces translates directly into fuel efficiency improvements. Industry testing shows that aircraft utilizing advanced CFRP solutions with optimized surface characteristics can achieve 2-5% reduction in drag, potentially resulting in 1-3% fuel savings. For commercial aviation, this represents millions of dollars in operational cost reduction over an aircraft's lifetime.

Maintenance considerations also factor significantly into the cost-benefit equation. While traditional surface treatments may require more frequent renewal, advanced CFRP solutions often demonstrate superior durability. Self-cleaning hydrophobic coatings, for instance, maintain performance characteristics longer than conventional treatments, reducing maintenance frequency by up to 40% according to recent field tests.

Lifecycle analysis reveals that the break-even point for most advanced CFRP solutions occurs between 3-5 years of operation, depending on usage intensity and fuel costs. For high-utilization applications such as commercial aircraft or high-performance racing vehicles, ROI acceleration is notable, sometimes achieving break-even in under 2 years.

Environmental benefits, while harder to quantify directly, contribute to the overall value proposition. Reduced fuel consumption translates to lower emissions, potentially offering regulatory advantages and supporting corporate sustainability goals. Carbon offset credits and compliance with increasingly stringent environmental regulations represent tangible financial benefits that should be factored into comprehensive analysis.

Market differentiation value must also be considered. Manufacturers implementing cutting-edge CFRP solutions can command premium pricing and gain competitive advantages through performance differentiation. This market positioning benefit, while variable across industries, typically adds 5-10% to product value perception according to consumer willingness-to-pay studies.

Initial implementation costs for advanced CFRP surface treatments represent a significant investment. Manufacturing processes such as micro-texturing, nano-coating applications, and precision molding techniques require specialized equipment and expertise. Current estimates indicate that implementing these advanced solutions can increase production costs by 15-30% compared to standard CFRP manufacturing processes, depending on the complexity of the aerodynamic requirements.

Operational benefits must be quantified against these increased costs. Reduced skin friction from optimized CFRP surfaces translates directly into fuel efficiency improvements. Industry testing shows that aircraft utilizing advanced CFRP solutions with optimized surface characteristics can achieve 2-5% reduction in drag, potentially resulting in 1-3% fuel savings. For commercial aviation, this represents millions of dollars in operational cost reduction over an aircraft's lifetime.

Maintenance considerations also factor significantly into the cost-benefit equation. While traditional surface treatments may require more frequent renewal, advanced CFRP solutions often demonstrate superior durability. Self-cleaning hydrophobic coatings, for instance, maintain performance characteristics longer than conventional treatments, reducing maintenance frequency by up to 40% according to recent field tests.

Lifecycle analysis reveals that the break-even point for most advanced CFRP solutions occurs between 3-5 years of operation, depending on usage intensity and fuel costs. For high-utilization applications such as commercial aircraft or high-performance racing vehicles, ROI acceleration is notable, sometimes achieving break-even in under 2 years.

Environmental benefits, while harder to quantify directly, contribute to the overall value proposition. Reduced fuel consumption translates to lower emissions, potentially offering regulatory advantages and supporting corporate sustainability goals. Carbon offset credits and compliance with increasingly stringent environmental regulations represent tangible financial benefits that should be factored into comprehensive analysis.

Market differentiation value must also be considered. Manufacturers implementing cutting-edge CFRP solutions can command premium pricing and gain competitive advantages through performance differentiation. This market positioning benefit, while variable across industries, typically adds 5-10% to product value perception according to consumer willingness-to-pay studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!