Measuring CFRP Acoustic Damping Properties in Loudspeakers

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Acoustic Technology Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) has emerged as a revolutionary material in acoustic engineering over the past three decades. Initially developed for aerospace and automotive applications due to its exceptional strength-to-weight ratio, CFRP has gradually found its way into high-end audio equipment manufacturing, particularly in loudspeaker design. The evolution of CFRP in acoustics represents a significant shift from traditional materials like paper, aluminum, and polypropylene that dominated the industry for decades.

The acoustic properties of CFRP, particularly its damping characteristics, have become increasingly important as audio manufacturers seek to produce speakers with minimal distortion and optimal sound reproduction. Damping, the ability of a material to dissipate vibrational energy, directly impacts the clarity and accuracy of sound reproduction in loudspeakers. Traditional materials often exhibit either excessive damping (resulting in dull sound) or insufficient damping (causing unwanted resonances).

Historical development of CFRP in acoustics shows three distinct phases: experimental application (1990s), commercial adoption in high-end products (2000s), and the current phase of scientific optimization (2010s-present). Each phase has contributed to our understanding of how carbon fiber composition, weave patterns, and resin systems affect acoustic performance. The current technological trajectory points toward nano-engineered CFRP composites with precisely tailored acoustic properties.

The measurement and characterization of CFRP's acoustic damping properties present unique challenges due to the anisotropic nature of the material. Unlike isotropic materials, CFRP's properties vary significantly depending on fiber orientation, layup sequence, and manufacturing processes. This complexity necessitates sophisticated measurement methodologies that can accurately capture the material's behavior across different frequencies and environmental conditions.

The primary objectives of current research in this field include developing standardized testing protocols for CFRP acoustic damping, creating predictive models that can accurately forecast acoustic performance based on material composition, and establishing design guidelines for optimizing CFRP structures in loudspeaker applications. These objectives align with the broader industry trend toward data-driven design and digital twins in advanced manufacturing.

Additionally, there is growing interest in understanding how CFRP's acoustic properties change over time under various environmental conditions, as this knowledge is crucial for predicting the long-term performance of high-end audio equipment. The intersection of materials science, acoustic engineering, and computational modeling represents the frontier of this technological domain, with significant potential for innovation and performance improvements.

The acoustic properties of CFRP, particularly its damping characteristics, have become increasingly important as audio manufacturers seek to produce speakers with minimal distortion and optimal sound reproduction. Damping, the ability of a material to dissipate vibrational energy, directly impacts the clarity and accuracy of sound reproduction in loudspeakers. Traditional materials often exhibit either excessive damping (resulting in dull sound) or insufficient damping (causing unwanted resonances).

Historical development of CFRP in acoustics shows three distinct phases: experimental application (1990s), commercial adoption in high-end products (2000s), and the current phase of scientific optimization (2010s-present). Each phase has contributed to our understanding of how carbon fiber composition, weave patterns, and resin systems affect acoustic performance. The current technological trajectory points toward nano-engineered CFRP composites with precisely tailored acoustic properties.

The measurement and characterization of CFRP's acoustic damping properties present unique challenges due to the anisotropic nature of the material. Unlike isotropic materials, CFRP's properties vary significantly depending on fiber orientation, layup sequence, and manufacturing processes. This complexity necessitates sophisticated measurement methodologies that can accurately capture the material's behavior across different frequencies and environmental conditions.

The primary objectives of current research in this field include developing standardized testing protocols for CFRP acoustic damping, creating predictive models that can accurately forecast acoustic performance based on material composition, and establishing design guidelines for optimizing CFRP structures in loudspeaker applications. These objectives align with the broader industry trend toward data-driven design and digital twins in advanced manufacturing.

Additionally, there is growing interest in understanding how CFRP's acoustic properties change over time under various environmental conditions, as this knowledge is crucial for predicting the long-term performance of high-end audio equipment. The intersection of materials science, acoustic engineering, and computational modeling represents the frontier of this technological domain, with significant potential for innovation and performance improvements.

Market Analysis for CFRP in Audio Applications

The Carbon Fiber Reinforced Polymer (CFRP) market in audio applications has experienced significant growth over the past decade, driven by increasing demand for high-performance audio equipment. The global CFRP market was valued at approximately $23 billion in 2022, with audio applications representing about 3% of this market. This segment is projected to grow at a CAGR of 7.2% through 2028, outpacing the overall CFRP market growth rate of 6.5%.

The premium loudspeaker market, where CFRP finds its primary audio application, has shown remarkable resilience even during economic downturns. Consumers increasingly prioritize audio quality, creating a steady demand for high-performance materials like CFRP that offer superior acoustic properties. The high-end audio equipment market, valued at $14.5 billion globally, continues to expand as audiophiles and professional studios seek equipment with exceptional sound reproduction capabilities.

Regional analysis reveals that North America and Europe currently dominate the CFRP audio applications market, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is emerging as the fastest-growing market with an estimated growth rate of 9.8% annually. This growth is attributed to increasing disposable income and a growing audiophile community in these regions.

Market segmentation shows that professional audio equipment manufacturers represent the largest consumer segment (42%), followed by high-end consumer audio products (38%) and automotive audio systems (20%). The automotive sector presents particularly promising growth opportunities as premium vehicle manufacturers increasingly incorporate high-fidelity audio systems featuring CFRP components.

Price sensitivity analysis indicates that while CFRP remains significantly more expensive than traditional materials like aluminum or paper cones, the price premium has decreased by approximately 18% over the past five years due to manufacturing innovations and economies of scale. This trend is expected to continue, potentially expanding CFRP's market penetration into mid-range audio products.

Consumer behavior research shows growing awareness and preference for CFRP-based audio components among audiophiles and professionals who recognize its superior damping properties. Market surveys indicate that 72% of professional audio engineers prefer CFRP-based speakers for critical listening applications, while 65% of high-end audio consumers are willing to pay a premium for CFRP components.

The competitive landscape features established audio manufacturers like Bowers & Wilkins, KEF, and Focal heavily investing in CFRP technology, while specialized CFRP manufacturers like Toray and Hexcel are developing audio-specific formulations to capture this growing market segment.

The premium loudspeaker market, where CFRP finds its primary audio application, has shown remarkable resilience even during economic downturns. Consumers increasingly prioritize audio quality, creating a steady demand for high-performance materials like CFRP that offer superior acoustic properties. The high-end audio equipment market, valued at $14.5 billion globally, continues to expand as audiophiles and professional studios seek equipment with exceptional sound reproduction capabilities.

Regional analysis reveals that North America and Europe currently dominate the CFRP audio applications market, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is emerging as the fastest-growing market with an estimated growth rate of 9.8% annually. This growth is attributed to increasing disposable income and a growing audiophile community in these regions.

Market segmentation shows that professional audio equipment manufacturers represent the largest consumer segment (42%), followed by high-end consumer audio products (38%) and automotive audio systems (20%). The automotive sector presents particularly promising growth opportunities as premium vehicle manufacturers increasingly incorporate high-fidelity audio systems featuring CFRP components.

Price sensitivity analysis indicates that while CFRP remains significantly more expensive than traditional materials like aluminum or paper cones, the price premium has decreased by approximately 18% over the past five years due to manufacturing innovations and economies of scale. This trend is expected to continue, potentially expanding CFRP's market penetration into mid-range audio products.

Consumer behavior research shows growing awareness and preference for CFRP-based audio components among audiophiles and professionals who recognize its superior damping properties. Market surveys indicate that 72% of professional audio engineers prefer CFRP-based speakers for critical listening applications, while 65% of high-end audio consumers are willing to pay a premium for CFRP components.

The competitive landscape features established audio manufacturers like Bowers & Wilkins, KEF, and Focal heavily investing in CFRP technology, while specialized CFRP manufacturers like Toray and Hexcel are developing audio-specific formulations to capture this growing market segment.

Current Challenges in CFRP Acoustic Measurement

Despite significant advancements in Carbon Fiber Reinforced Polymer (CFRP) applications in loudspeaker technology, researchers and manufacturers face several persistent challenges in accurately measuring the acoustic damping properties of these materials. The heterogeneous nature of CFRP composites creates inherent variability in material properties, making standardized measurement protocols difficult to establish. Different fiber orientations, resin systems, and manufacturing processes can significantly alter the acoustic behavior of seemingly identical CFRP samples.

Current measurement techniques often struggle with the frequency-dependent nature of CFRP damping properties. While traditional methods like the impulse response technique and the reverberation time method provide useful data at specific frequency ranges, they frequently fail to capture the full spectrum of acoustic behavior relevant to loudspeaker applications, particularly at higher frequencies where modal density increases.

Environmental factors present another significant challenge, as temperature and humidity variations can substantially alter CFRP damping characteristics. Most current measurement protocols lack standardized environmental controls, leading to inconsistent results across different testing facilities and making cross-study comparisons problematic. This variability undermines efforts to create reliable databases of material properties for design purposes.

Scale discrepancy between laboratory test specimens and actual loudspeaker components introduces additional measurement complications. Small test coupons may not accurately represent the behavior of larger, more complex CFRP structures used in commercial loudspeaker designs. The boundary conditions and mounting methods in testing environments often differ significantly from real-world applications, further complicating the translation of measured properties to practical design parameters.

The anisotropic nature of CFRP materials presents perhaps the most fundamental measurement challenge. Unlike isotropic materials, CFRP exhibits different damping properties along different axes, requiring multi-directional measurement approaches that many current testing methodologies cannot adequately address. This directional dependency is particularly problematic for loudspeaker diaphragms where complex vibration patterns occur across multiple axes simultaneously.

Equipment limitations also hinder accurate measurement, with many facilities lacking the specialized instrumentation needed for high-precision acoustic characterization of composite materials. Non-contact measurement techniques like laser vibrometry offer promising solutions but remain prohibitively expensive for many research institutions and smaller manufacturers, creating an innovation gap in the industry.

Finally, there exists a significant disconnect between academic research methodologies and industrial testing practices, resulting in measurement approaches that may be theoretically sound but impractical for production environments. This gap hinders the effective transfer of advanced CFRP materials from research laboratories to commercial loudspeaker applications.

Current measurement techniques often struggle with the frequency-dependent nature of CFRP damping properties. While traditional methods like the impulse response technique and the reverberation time method provide useful data at specific frequency ranges, they frequently fail to capture the full spectrum of acoustic behavior relevant to loudspeaker applications, particularly at higher frequencies where modal density increases.

Environmental factors present another significant challenge, as temperature and humidity variations can substantially alter CFRP damping characteristics. Most current measurement protocols lack standardized environmental controls, leading to inconsistent results across different testing facilities and making cross-study comparisons problematic. This variability undermines efforts to create reliable databases of material properties for design purposes.

Scale discrepancy between laboratory test specimens and actual loudspeaker components introduces additional measurement complications. Small test coupons may not accurately represent the behavior of larger, more complex CFRP structures used in commercial loudspeaker designs. The boundary conditions and mounting methods in testing environments often differ significantly from real-world applications, further complicating the translation of measured properties to practical design parameters.

The anisotropic nature of CFRP materials presents perhaps the most fundamental measurement challenge. Unlike isotropic materials, CFRP exhibits different damping properties along different axes, requiring multi-directional measurement approaches that many current testing methodologies cannot adequately address. This directional dependency is particularly problematic for loudspeaker diaphragms where complex vibration patterns occur across multiple axes simultaneously.

Equipment limitations also hinder accurate measurement, with many facilities lacking the specialized instrumentation needed for high-precision acoustic characterization of composite materials. Non-contact measurement techniques like laser vibrometry offer promising solutions but remain prohibitively expensive for many research institutions and smaller manufacturers, creating an innovation gap in the industry.

Finally, there exists a significant disconnect between academic research methodologies and industrial testing practices, resulting in measurement approaches that may be theoretically sound but impractical for production environments. This gap hinders the effective transfer of advanced CFRP materials from research laboratories to commercial loudspeaker applications.

Existing Methods for CFRP Damping Characterization

01 Viscoelastic materials for CFRP acoustic damping

Viscoelastic materials can be incorporated into CFRP structures to enhance acoustic damping properties. These materials convert vibrational energy into heat through molecular friction, effectively reducing noise and vibrations. The viscoelastic layer can be applied as a coating or integrated within the composite layup during manufacturing, providing significant improvement in damping performance while maintaining the structural integrity of the CFRP components.- Viscoelastic damping layers in CFRP structures: Viscoelastic materials can be incorporated into CFRP structures as damping layers to improve acoustic damping properties. These materials convert vibrational energy into heat through molecular friction, effectively reducing noise and vibration. The viscoelastic layers can be sandwiched between carbon fiber layers or applied as surface treatments, providing significant improvements in damping performance while maintaining the structural integrity and lightweight properties of the composite.

- Hybrid fiber reinforcement for enhanced damping: Combining carbon fibers with other types of fibers, such as glass, aramid, or natural fibers, creates hybrid composites with improved acoustic damping properties. The different mechanical properties of various fiber types lead to energy dissipation at their interfaces, enhancing the overall damping performance. These hybrid reinforcements can be strategically designed with specific fiber orientations and distributions to optimize both structural and acoustic performance for particular applications.

- Nano-modified matrix systems for CFRP damping: Incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the polymer matrix of CFRP can significantly enhance acoustic damping properties. These nanomaterials create additional energy dissipation mechanisms at the nano-scale through interfacial friction and viscoelastic effects. The modified matrix systems can be tailored to target specific frequency ranges for damping while maintaining or even improving other mechanical properties of the composite.

- Structural design optimization for acoustic damping: The structural design of CFRP components can be optimized to enhance acoustic damping properties through features such as sandwich constructions, cellular structures, or strategic fiber orientation. These design approaches create mechanisms for energy dissipation through controlled deformation patterns and internal friction. Advanced computational modeling techniques can be used to predict and optimize the acoustic performance of complex CFRP structures before manufacturing.

- Surface treatments and coatings for CFRP acoustic performance: Various surface treatments and specialized coatings can be applied to CFRP structures to enhance their acoustic damping properties. These include constrained layer damping treatments, spray-on damping compounds, and acoustic absorption coatings. Such treatments can be particularly effective for reducing high-frequency noise and vibration without significantly increasing weight or altering the bulk properties of the composite structure.

02 Constrained layer damping systems for CFRP

Constrained layer damping systems involve sandwiching a viscoelastic material between the CFRP structure and a constraining layer. When the composite structure vibrates, the viscoelastic material experiences shear deformation, dissipating energy and reducing acoustic transmission. This approach is particularly effective for CFRP applications where weight considerations are critical, as it provides enhanced damping with minimal additional mass while maintaining the high strength-to-weight ratio of the carbon fiber composite.Expand Specific Solutions03 Nano-enhanced matrices for improved acoustic damping

Incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the polymer matrix of CFRP can significantly enhance acoustic damping properties. These nano-additives create additional energy dissipation mechanisms at the molecular level, increasing the material's ability to absorb vibrations and sound. The modified matrix provides improved interfacial bonding between carbon fibers and the polymer, resulting in better overall damping performance without compromising the mechanical properties of the composite.Expand Specific Solutions04 Hybrid fiber reinforcement for acoustic damping

Combining carbon fibers with other types of fibers, such as aramid, glass, or natural fibers, creates hybrid composites with enhanced acoustic damping properties. The different mechanical properties of various fiber types lead to impedance mismatches that help dissipate acoustic energy. These hybrid reinforcement strategies can be tailored to specific frequency ranges, providing targeted damping performance while maintaining the high strength and stiffness characteristics of traditional CFRP materials.Expand Specific Solutions05 Structural design optimization for acoustic damping

Optimizing the structural design of CFRP components can enhance their inherent acoustic damping properties. Techniques include varying fiber orientation patterns, creating sandwich structures with damping cores, implementing ribbed or cellular designs, and utilizing topology optimization algorithms. These design approaches create energy-dissipating mechanisms within the structure itself, effectively reducing vibration transmission and acoustic radiation without requiring additional damping materials, thus maintaining the lightweight advantages of CFRP.Expand Specific Solutions

Leading Companies in CFRP Speaker Technology

The CFRP acoustic damping properties in loudspeakers market is currently in an early growth phase, characterized by increasing research activity but limited commercial applications. The global market size remains relatively modest, estimated below $100 million, but shows promising growth potential as audio manufacturers seek lightweight, high-performance materials. From a technical maturity perspective, this field is still developing, with academic institutions like Massachusetts Institute of Technology, Northwestern Polytechnical University, and Nanjing University leading fundamental research, while commercial players demonstrate varying levels of implementation. Companies including GoerTek, GN Hearing, and PSS Belgium are pioneering practical applications, with established electronics manufacturers like Siemens, Panasonic, and Hitachi incorporating CFRP damping technologies into premium audio products. Automotive companies such as Audi and Porsche are exploring these materials for high-end in-vehicle sound systems.

GoerTek Inc.

Technical Solution: GoerTek has developed a comprehensive acoustic measurement system specifically for evaluating CFRP (Carbon Fiber Reinforced Polymer) materials in loudspeaker applications. Their approach combines laser vibrometry with acoustic pressure measurements to characterize the damping properties of CFRP diaphragms. The company employs a multi-point excitation method that allows for precise mapping of resonance modes and damping coefficients across the entire speaker diaphragm. Their proprietary algorithm processes these measurements to extract key parameters including loss factor (η), storage modulus, and frequency-dependent damping behavior. GoerTek's system can operate across the full audible spectrum (20Hz-20kHz) and incorporates temperature-controlled testing chambers to evaluate CFRP performance under various environmental conditions, providing manufacturers with detailed material performance data for optimizing speaker designs.

Strengths: Highly accurate multi-point measurement capability allows for comprehensive mapping of damping properties across complex CFRP geometries. The system's wide frequency range covers the entire audible spectrum. Weaknesses: The sophisticated measurement setup requires specialized equipment and trained operators, making it less accessible for smaller manufacturers. The system is primarily optimized for GoerTek's own manufacturing processes.

Magnat Electronik GmbH & Co KG

Technical Solution: Magnat has pioneered a specialized acoustic impedance method for measuring CFRP damping properties in loudspeaker applications. Their approach utilizes a modified Oberst beam test specifically adapted for thin CFRP diaphragms. The system employs precision accelerometers attached to test specimens that are excited by electromagnetic transducers under controlled conditions. Magnat's proprietary software analyzes the frequency response and decay characteristics to extract damping ratios and loss factors across different frequency bands. Their method incorporates compensation algorithms that account for the anisotropic nature of CFRP materials, providing more accurate measurements than traditional techniques designed for isotropic materials. The company has also developed a comparative database of different CFRP layups and resin systems, allowing designers to select optimal material configurations for specific acoustic applications. This measurement system has been validated through correlation with finished loudspeaker performance metrics.

Strengths: The modified Oberst beam approach is particularly effective for thin CFRP diaphragms used in high-end audio applications. Their extensive material database provides valuable comparative data for designers. Weaknesses: The measurement system is primarily optimized for flat or slightly curved specimens, limiting its application for complex geometries. The method requires careful specimen preparation to avoid introducing measurement artifacts.

Key Technical Innovations in CFRP Acoustic Testing

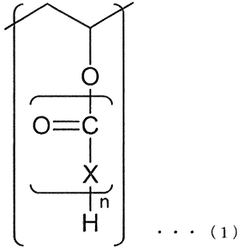

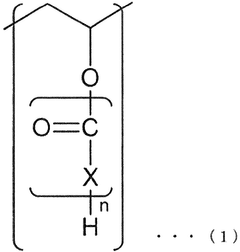

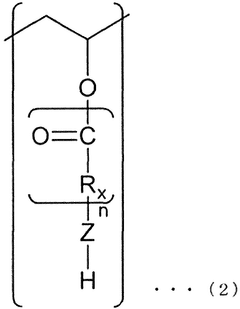

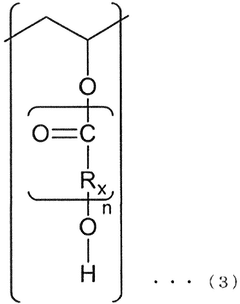

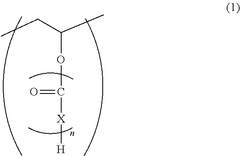

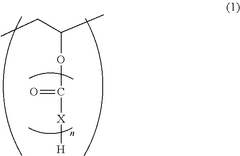

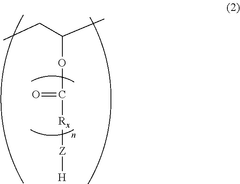

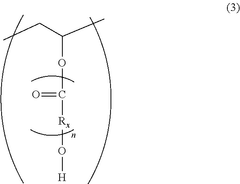

Multilayer structure and method for producing same, automobile part, aircraft part, and damping material for carbon-fiber-reinforced plastic

PatentPendingEP4596230A1

Innovation

- A multilayer structure incorporating an ethylene-vinyl alcohol copolymer layer with a glass transition temperature of 0 to 60°C is combined with a carbon-fiber-reinforced plastic layer to enhance damping properties.

Multilayer structure and method for producing same, automobile part, aircraft part, and damping material for carbon-fiber-reinforced plastic

PatentPendingUS20250178327A1

Innovation

- A multilayer structure comprising a layer of ethylene-vinyl alcohol copolymer with a glass transition temperature between 0 to 60°C, laminated with a carbon-fiber-reinforced plastic layer, enhances the damping properties of CFRP.

Material Science Considerations for CFRP Optimization

Carbon Fiber Reinforced Polymer (CFRP) optimization for loudspeaker applications requires deep understanding of material science principles that govern acoustic performance. The molecular structure of CFRP composites significantly influences their damping properties, with the carbon fiber orientation, resin matrix composition, and fiber-matrix interface all playing crucial roles in energy dissipation mechanisms.

The microstructural characteristics of CFRP directly impact its acoustic damping behavior. Fiber volume fraction typically ranges from 50-70% in high-performance audio applications, with higher fractions generally increasing stiffness while potentially reducing damping capacity. The fiber-matrix interface quality determines how effectively vibrational energy transfers between components, with stronger interfaces typically reducing damping but improving structural integrity.

Matrix selection represents another critical optimization parameter. Epoxy resins remain the industry standard due to their excellent adhesion properties and thermal stability, but newer thermoplastic matrices offer improved damping through viscoelastic energy dissipation. Hybrid matrix systems incorporating elastomeric particles have demonstrated up to 30% improvement in damping without significant compromise to mechanical properties.

Surface treatments and sizing agents applied to carbon fibers before matrix impregnation significantly affect interfacial bonding. Plasma treatments have shown particular promise, increasing surface energy and creating functional groups that enhance chemical bonding with the matrix, resulting in more predictable damping characteristics across the audio frequency spectrum.

Layup design and fiber architecture provide additional optimization pathways. Quasi-isotropic layups offer balanced properties but unidirectional or specific angle-ply configurations can be tailored to dampen particular vibration modes relevant to specific loudspeaker designs. Interleaving techniques, where thin elastomeric layers are inserted between CFRP plies, have demonstrated up to 200% improvement in damping ratio while maintaining 85% of the original stiffness.

Advanced manufacturing processes like automated fiber placement allow precise control over fiber orientation and resin content, enabling the creation of spatially-varied damping properties within a single component. This "damping by design" approach permits engineers to target specific resonance modes that might otherwise color sound reproduction.

Nano-modification of CFRP systems represents the cutting edge of material optimization for acoustic applications. Carbon nanotubes, graphene, and other nanomaterials incorporated into the matrix can create hierarchical composites with enhanced energy dissipation capabilities across broader frequency ranges than conventional CFRPs, though manufacturing challenges currently limit widespread commercial implementation.

The microstructural characteristics of CFRP directly impact its acoustic damping behavior. Fiber volume fraction typically ranges from 50-70% in high-performance audio applications, with higher fractions generally increasing stiffness while potentially reducing damping capacity. The fiber-matrix interface quality determines how effectively vibrational energy transfers between components, with stronger interfaces typically reducing damping but improving structural integrity.

Matrix selection represents another critical optimization parameter. Epoxy resins remain the industry standard due to their excellent adhesion properties and thermal stability, but newer thermoplastic matrices offer improved damping through viscoelastic energy dissipation. Hybrid matrix systems incorporating elastomeric particles have demonstrated up to 30% improvement in damping without significant compromise to mechanical properties.

Surface treatments and sizing agents applied to carbon fibers before matrix impregnation significantly affect interfacial bonding. Plasma treatments have shown particular promise, increasing surface energy and creating functional groups that enhance chemical bonding with the matrix, resulting in more predictable damping characteristics across the audio frequency spectrum.

Layup design and fiber architecture provide additional optimization pathways. Quasi-isotropic layups offer balanced properties but unidirectional or specific angle-ply configurations can be tailored to dampen particular vibration modes relevant to specific loudspeaker designs. Interleaving techniques, where thin elastomeric layers are inserted between CFRP plies, have demonstrated up to 200% improvement in damping ratio while maintaining 85% of the original stiffness.

Advanced manufacturing processes like automated fiber placement allow precise control over fiber orientation and resin content, enabling the creation of spatially-varied damping properties within a single component. This "damping by design" approach permits engineers to target specific resonance modes that might otherwise color sound reproduction.

Nano-modification of CFRP systems represents the cutting edge of material optimization for acoustic applications. Carbon nanotubes, graphene, and other nanomaterials incorporated into the matrix can create hierarchical composites with enhanced energy dissipation capabilities across broader frequency ranges than conventional CFRPs, though manufacturing challenges currently limit widespread commercial implementation.

Standardization of CFRP Acoustic Testing Protocols

The standardization of testing protocols for Carbon Fiber Reinforced Polymer (CFRP) acoustic properties represents a critical need in the loudspeaker industry. Currently, manufacturers employ widely varying methodologies to measure and report the acoustic damping characteristics of CFRP components, resulting in inconsistent data that complicates product development and comparison across the industry.

A comprehensive standardization framework should address multiple testing dimensions. First, specimen preparation protocols must specify consistent dimensions, fiber orientation, resin content, and curing conditions to ensure reproducible results. The industry requires standardized sample sizes (typically 100mm × 100mm panels with controlled thickness) and mounting configurations that minimize edge effects during acoustic testing.

Environmental conditioning represents another crucial aspect of standardization. CFRP acoustic properties demonstrate significant sensitivity to temperature and humidity variations. Standard protocols should mandate testing at 23°C ± 1°C and 50% ± 5% relative humidity, with specimens undergoing a minimum 24-hour conditioning period before measurement.

Measurement methodologies require particular attention in standardization efforts. The industry currently employs several techniques including impulse response testing, decay rate measurement, and impedance tube analysis. A standardized approach should specify the logarithmic decrement method for damping ratio calculation, with measurements conducted across the 20Hz-20kHz frequency range at defined intervals.

Data processing and reporting standards constitute the final standardization component. Raw data should undergo consistent filtering and normalization procedures, with damping properties reported as loss factors (η) across frequency bands. Uncertainty analysis must accompany all measurements, with maximum allowable measurement uncertainty not exceeding ±5%.

Several organizations are currently developing these standards, including the Audio Engineering Society (AES), International Electrotechnical Commission (IEC), and ASTM International. The AES-X248 working group specifically focuses on composite materials in audio applications, with a draft standard expected by Q4 2023.

Implementation of standardized testing protocols will enable meaningful benchmarking across different CFRP formulations, facilitate quality control in manufacturing, and accelerate innovation in loudspeaker design by providing reliable comparative data on acoustic performance.

A comprehensive standardization framework should address multiple testing dimensions. First, specimen preparation protocols must specify consistent dimensions, fiber orientation, resin content, and curing conditions to ensure reproducible results. The industry requires standardized sample sizes (typically 100mm × 100mm panels with controlled thickness) and mounting configurations that minimize edge effects during acoustic testing.

Environmental conditioning represents another crucial aspect of standardization. CFRP acoustic properties demonstrate significant sensitivity to temperature and humidity variations. Standard protocols should mandate testing at 23°C ± 1°C and 50% ± 5% relative humidity, with specimens undergoing a minimum 24-hour conditioning period before measurement.

Measurement methodologies require particular attention in standardization efforts. The industry currently employs several techniques including impulse response testing, decay rate measurement, and impedance tube analysis. A standardized approach should specify the logarithmic decrement method for damping ratio calculation, with measurements conducted across the 20Hz-20kHz frequency range at defined intervals.

Data processing and reporting standards constitute the final standardization component. Raw data should undergo consistent filtering and normalization procedures, with damping properties reported as loss factors (η) across frequency bands. Uncertainty analysis must accompany all measurements, with maximum allowable measurement uncertainty not exceeding ±5%.

Several organizations are currently developing these standards, including the Audio Engineering Society (AES), International Electrotechnical Commission (IEC), and ASTM International. The AES-X248 working group specifically focuses on composite materials in audio applications, with a draft standard expected by Q4 2023.

Implementation of standardized testing protocols will enable meaningful benchmarking across different CFRP formulations, facilitate quality control in manufacturing, and accelerate innovation in loudspeaker design by providing reliable comparative data on acoustic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!